Method of knitting fabric

A clothing and knitting technology, which is applied in the field of knitting clothing, can solve the problems of broken thread, the inability to fully increase the number of stitches of the opening for the neckline, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

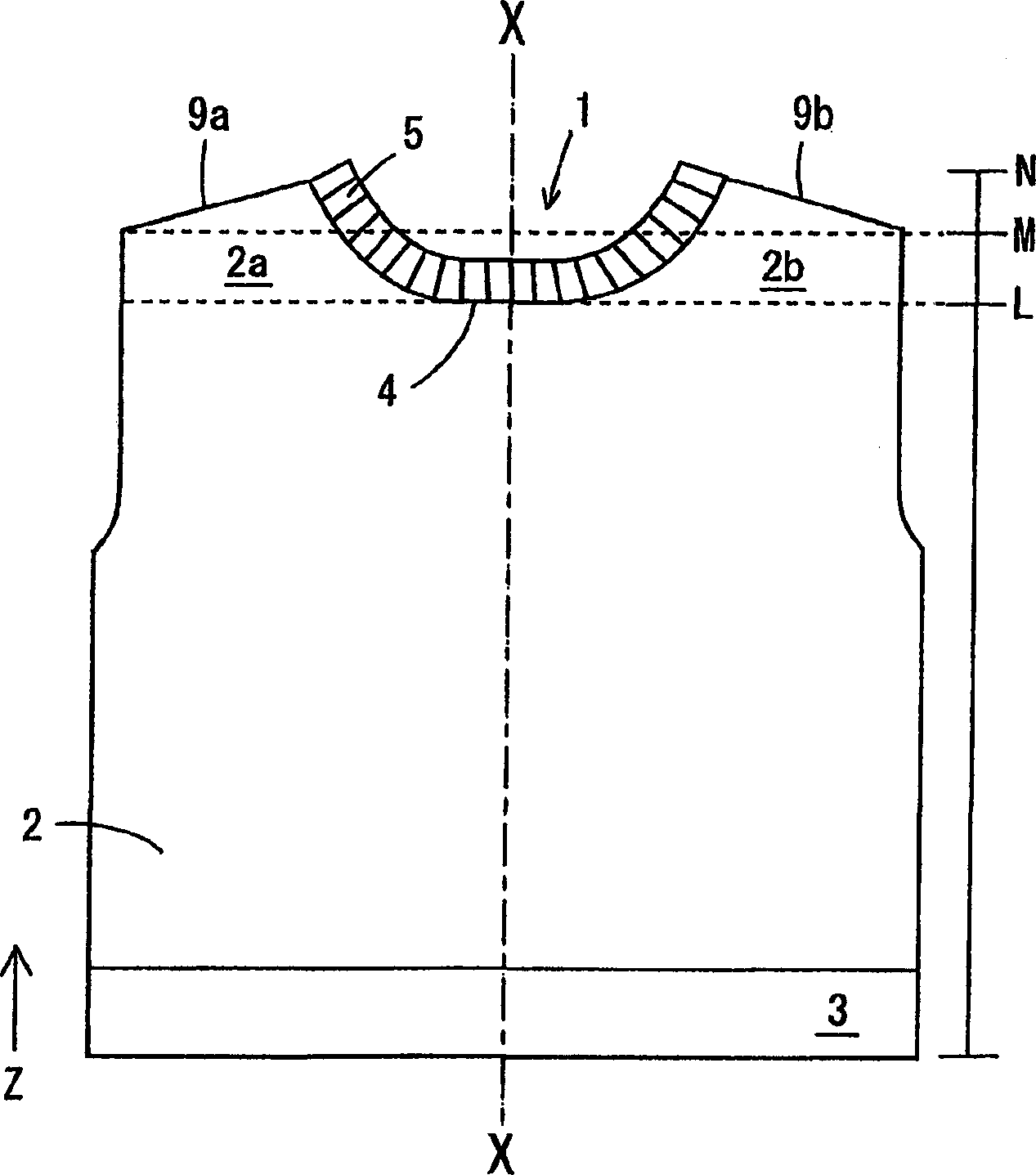

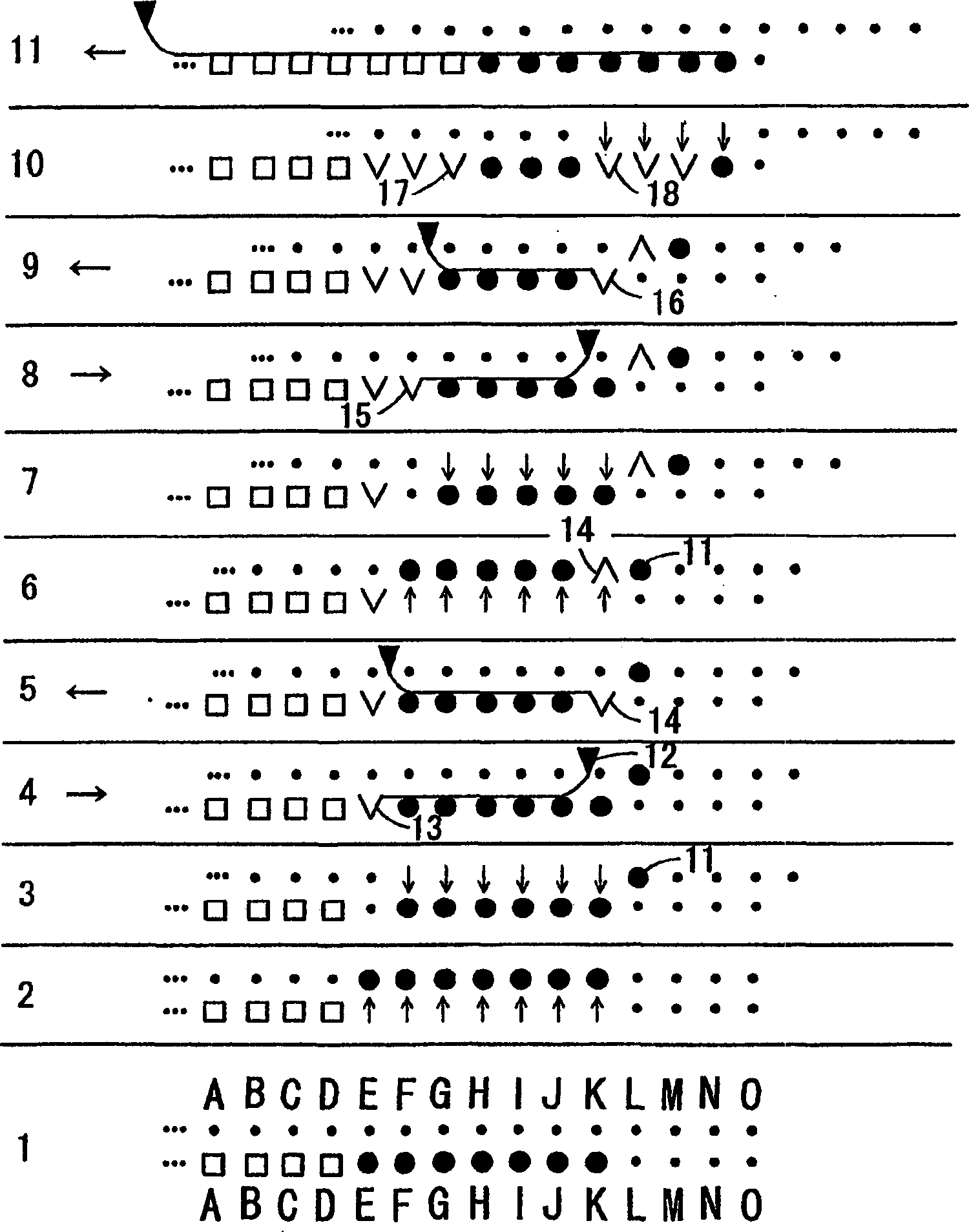

[0029] The first embodiment of the present invention is based on figure 1 and figure 2 Forming the shoulders while increasing the number of wales around the opening 1 for the neckline figure 1 The weaving condition of the vest's predecessor large piece 2 will be described as an example. figure 1 showing the vest's predecessor blockbuster 2, figure 2 It is a knitting course diagram which shows the knitting after the start of formation of the shoulder part 9a, 9b.

[0030] The front body piece 2 of the vest is woven from the hem rib 3 to the neckline opening 1 along the arrow Z direction, and after the line L that forms the neckline opening 1 starts, the right front body piece 2a and the left front body piece on the right side of the neckline opening 1 are knitted. A large piece of 2b branch braiding. The right front body piece 2a and the left front body piece 2b use the peripheral edge 4 of the opening 1 for the neckline and the side ends of the body part 2 as places f...

no. 2 example

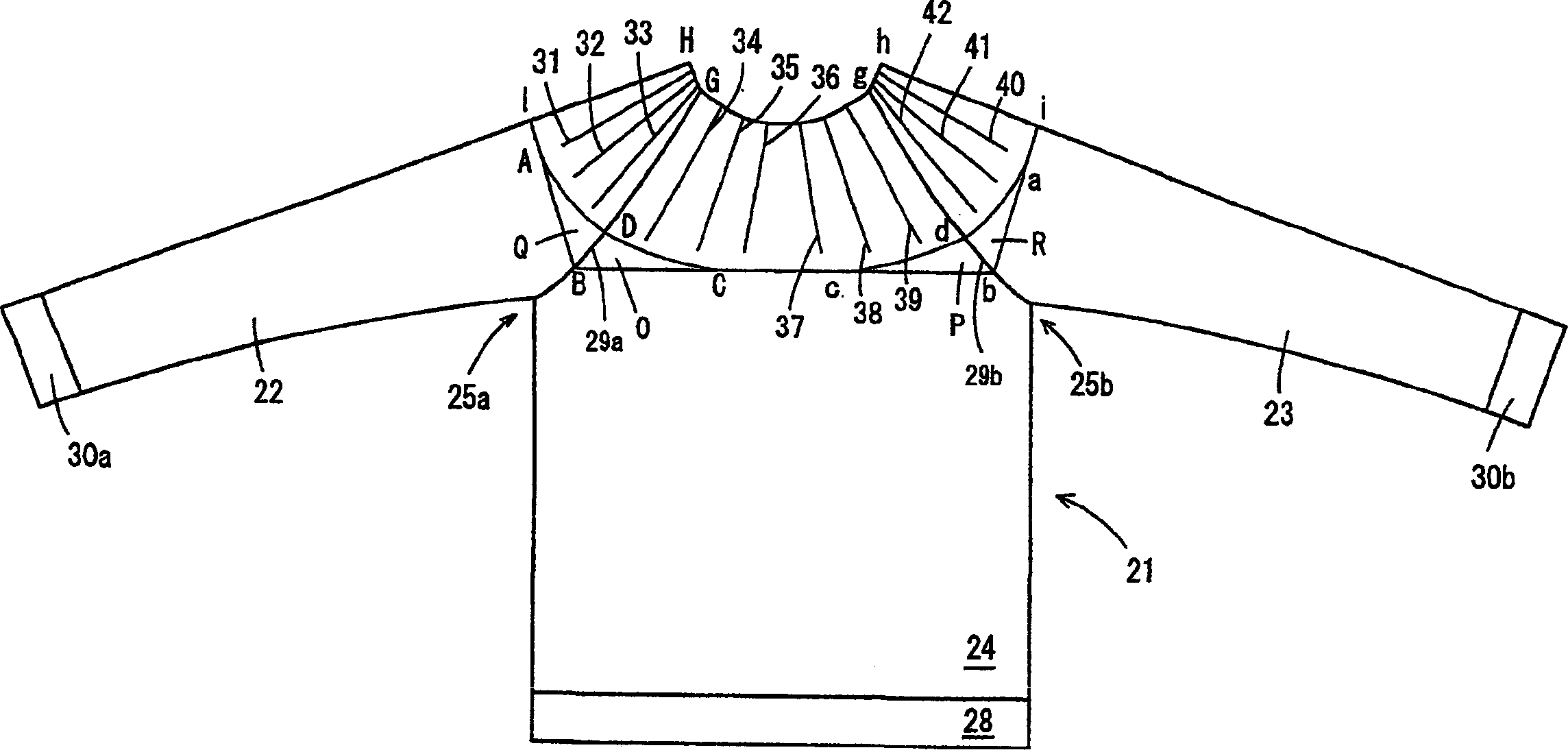

[0036] Below, use Figure 3 ~ Figure 5 A second embodiment of the present invention will be described. The second embodiment is, from image 3 An embodiment of knitting a knitted pullover around the shoulders of the knitted garments for a knitted pullover 21 that will be the front part of the knitted pullover, wherein the knitted pullover has a joint line that overlaps adjacent stitches and an opening for neckline. It is a pattern commonly known as an umbrella pattern that expands radially in the center. In the second embodiment, the joining of the body part and the left and right sleeves of the knitted pullover 21 knitted in different regions starts from the armpit. Before the umbrella pattern is formed, at the joining place of the sleeves 22, 23 and the body piece 24, the reversed course knitting regions O, P, Q, R spanning the sleeves and the body are formed by reverse course knitting, and then, By forming an umbrella pattern, an umbrella pattern expanding radially with ...

no. 3 example

[0044] Below, refer to Figure 6 A third embodiment of the present invention will be described. The third embodiment is an embodiment of knitted garments in which the woven umbrella pattern expands radially with the same diameter. Figure 6 -a is the front view of the knitted garment 61 knitted by the third embodiment, Figure 6 -b is a top view of the knitted garment 61, Figure 6 -c is a view of the knitted garment 61 being knitted on a flat knitting machine. Knitted garments 61 are knitted in a cylindrical shape along the direction of arrow Z from the needle-starting place 62, and the front side knitted garments part 61a and the rear side knitted garments are placed in the state where the transverse direction of the knitted garments 61 becomes the longitudinal direction of the needle bed. The fabric part 61b is knitted as a tubular knitted garment continuous at both ends. When weaving to the line J, in the right reversed course knitting regions 63a, 63b and the left rev...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com