Torsional cable for robot arm

A robot arm and cable technology, applied in the direction of power cables, insulated cables, bendable cables, etc., can solve the problems of inapplicability, super softness, poor high strength, etc., and achieve increased bending resistance, increased breaking force, Effect of preventing external low-frequency electromagnetic interference

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1~4

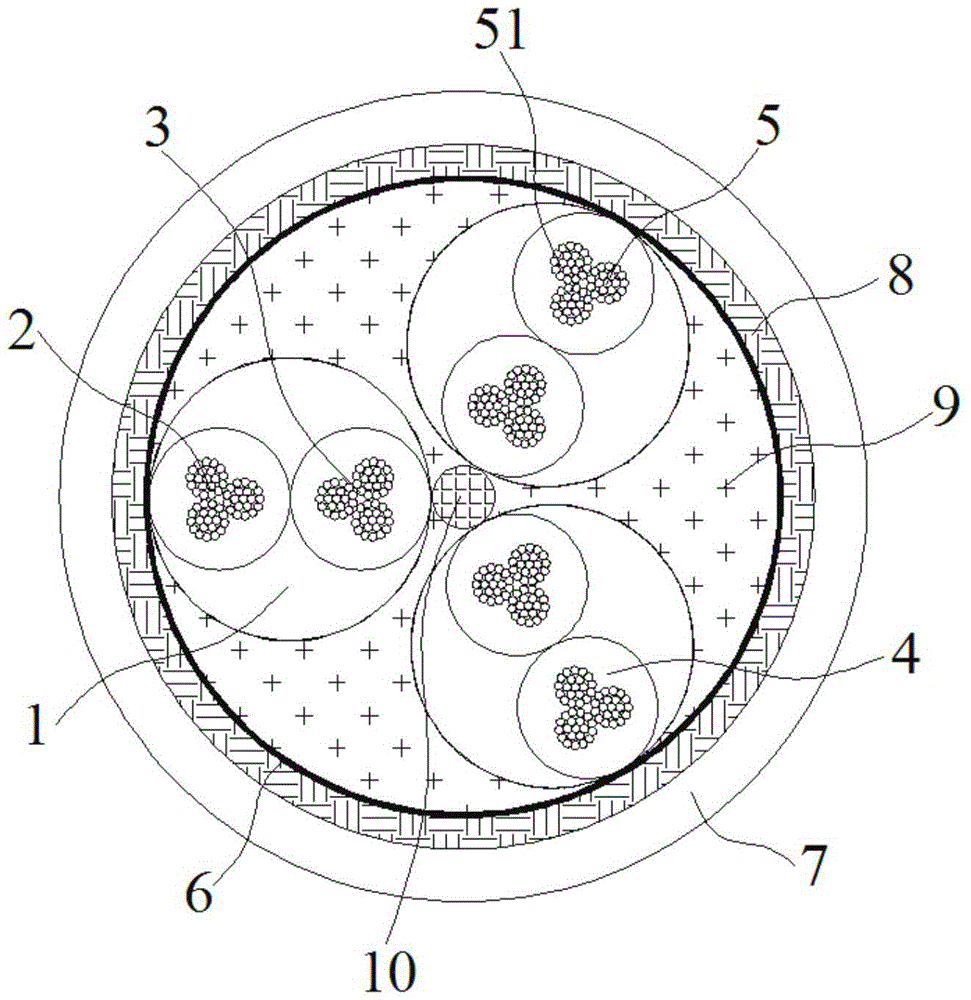

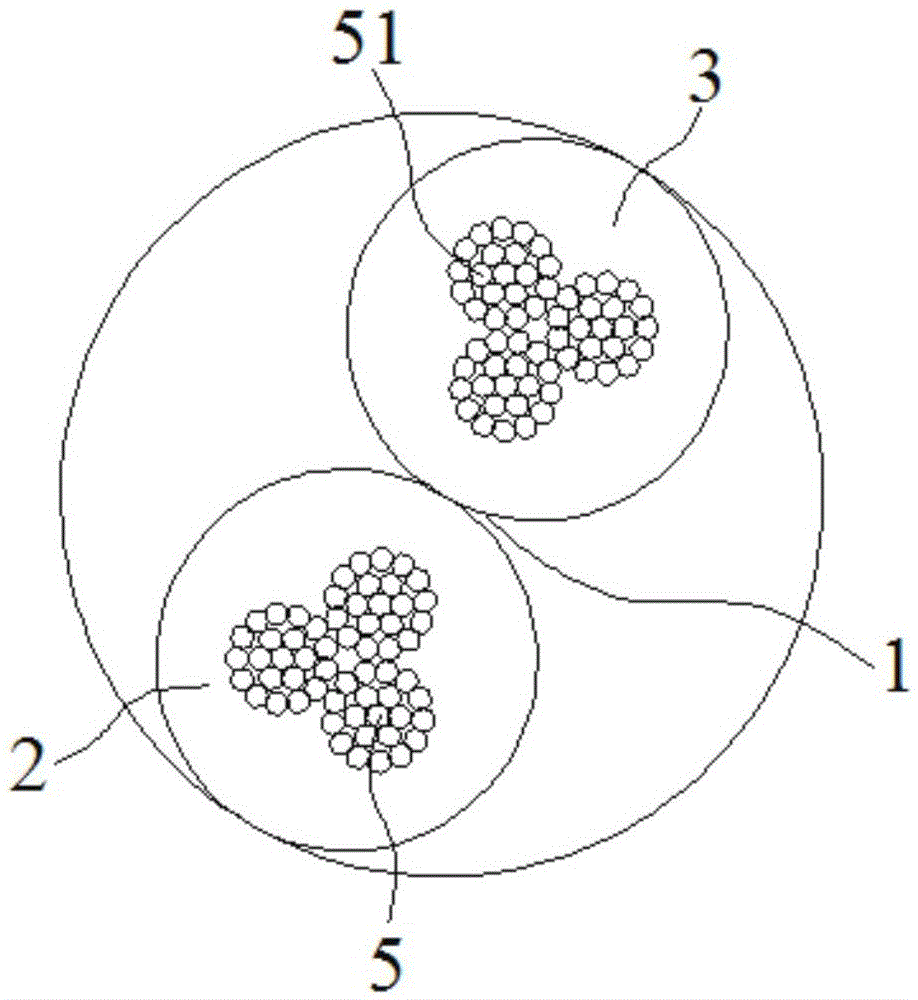

[0042] Embodiments 1 to 4: A twisted cable for a robot arm, including a cable core twisted by three twisted wire pairs 1, each of which is composed of a first composite twisted conductor 2 and a second composite twisted conductor 3 The outer surfaces of the first composite stranded conductor 2 and the second composite stranded conductor 3 are covered with an insulating layer 4, and the first composite stranded conductor 2 and the second composite stranded conductor 3 are made of 3 copper wires 5 stranded combined;

[0043] A tissue paper 6 is wrapped around the outer surface of the three twisted wire pairs 1, an outer sheath layer 7 is wrapped on the outer surface of the tissue paper 6, and a metal shield is arranged between the outer sheath layer 7 and the tissue paper 6 Layer 8, the gap between the tissue paper 6 and the three twisted wire pairs 1 is filled with several cotton yarns 9; an aramid yarn 10 is located in the gap at the center of the three twisted wire pairs 1. ...

Embodiment 2

[0045] Embodiment 2: A twisted cable for a robot arm, including a cable core formed by twisting three twisted wire pairs 1, and the twisted wire pairs 1 are all twisted by a first composite twisted conductor 2 and a second composite twisted conductor 3 Formed, the outer surfaces of the first composite stranded conductor 2 and the second composite stranded conductor 3 are coated with an insulating layer 4, and the first composite stranded conductor 2 and the second composite stranded conductor 3 are all formed by twisting three copper wires 5. become;

[0046]A tissue paper 6 is wrapped around the outer surface of the three twisted wire pairs 1, an outer sheath layer 7 is wrapped on the outer surface of the tissue paper 6, and a metal shield is arranged between the outer sheath layer 7 and the tissue paper 6 Layer 8, the gap between the tissue paper 6 and the three twisted wire pairs 1 is filled with several cotton yarns 9; an aramid yarn 10 is located in the gap at the center ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| degree of grafting | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com