Light emitting device and backlight device

一种发光装置、发光元件的技术,应用在照明装置、照明装置的零部件、照明装置的防损措施等方向,能够解决壳体部件104裂纹、碰撞等问题,达到降低断线不良、降低发生概率、光效率良好的效果

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 Embodiment approach

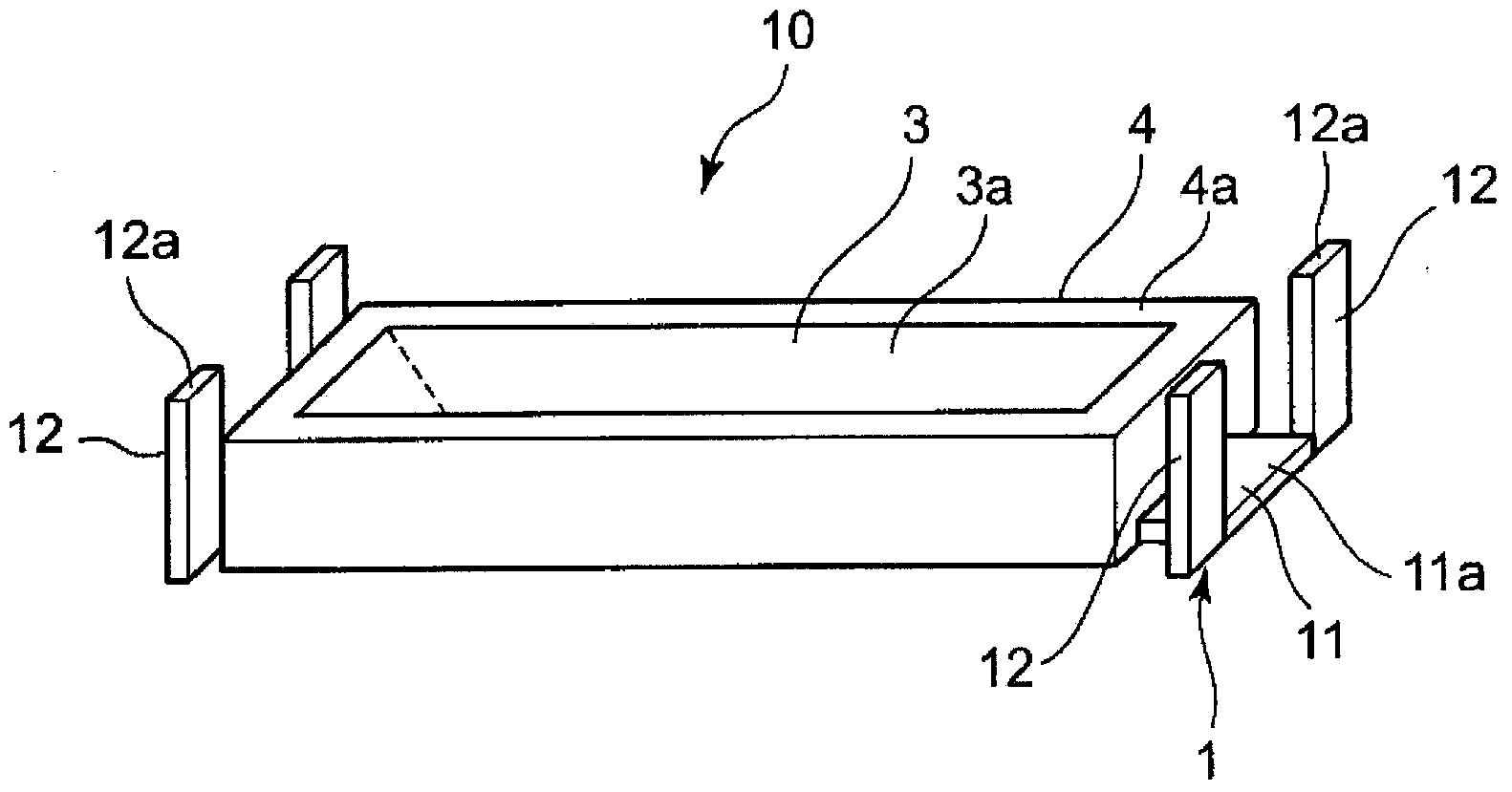

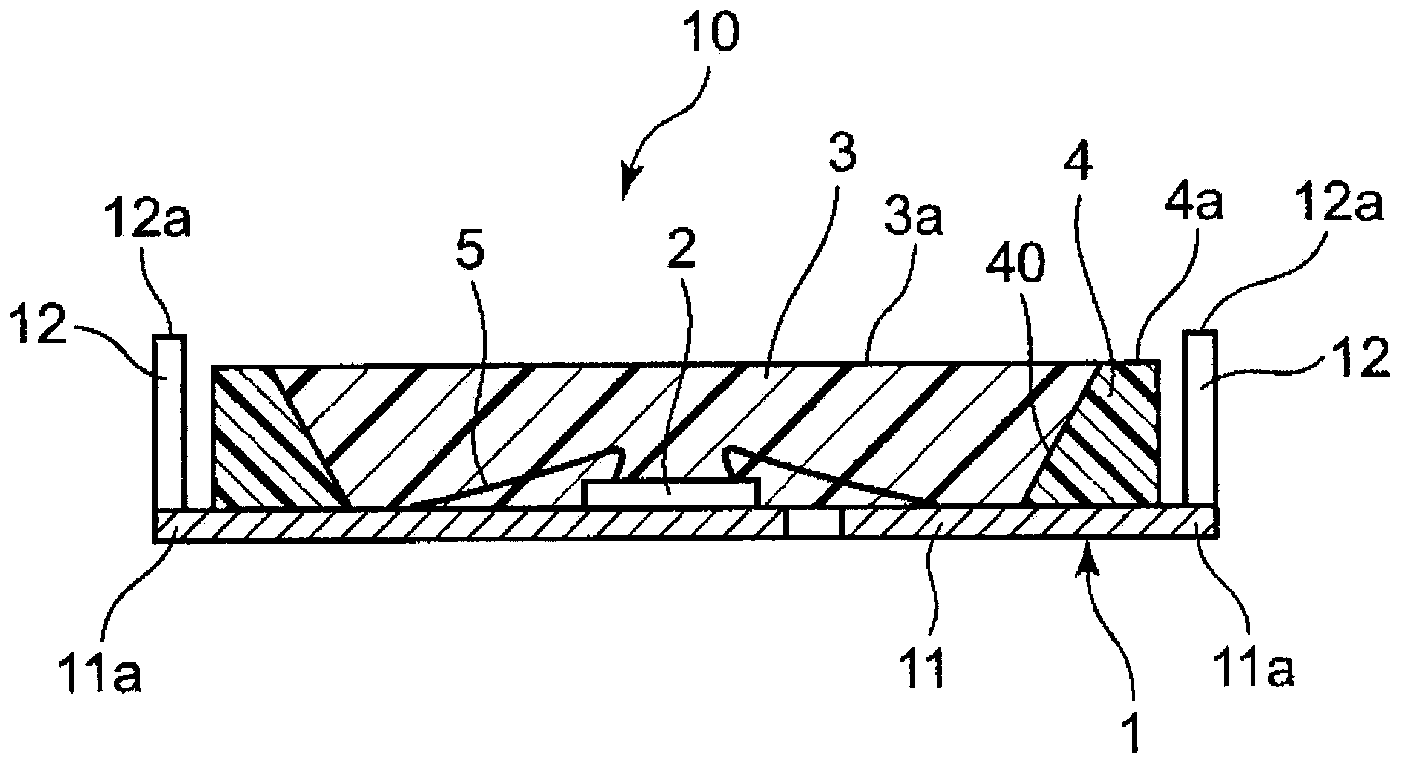

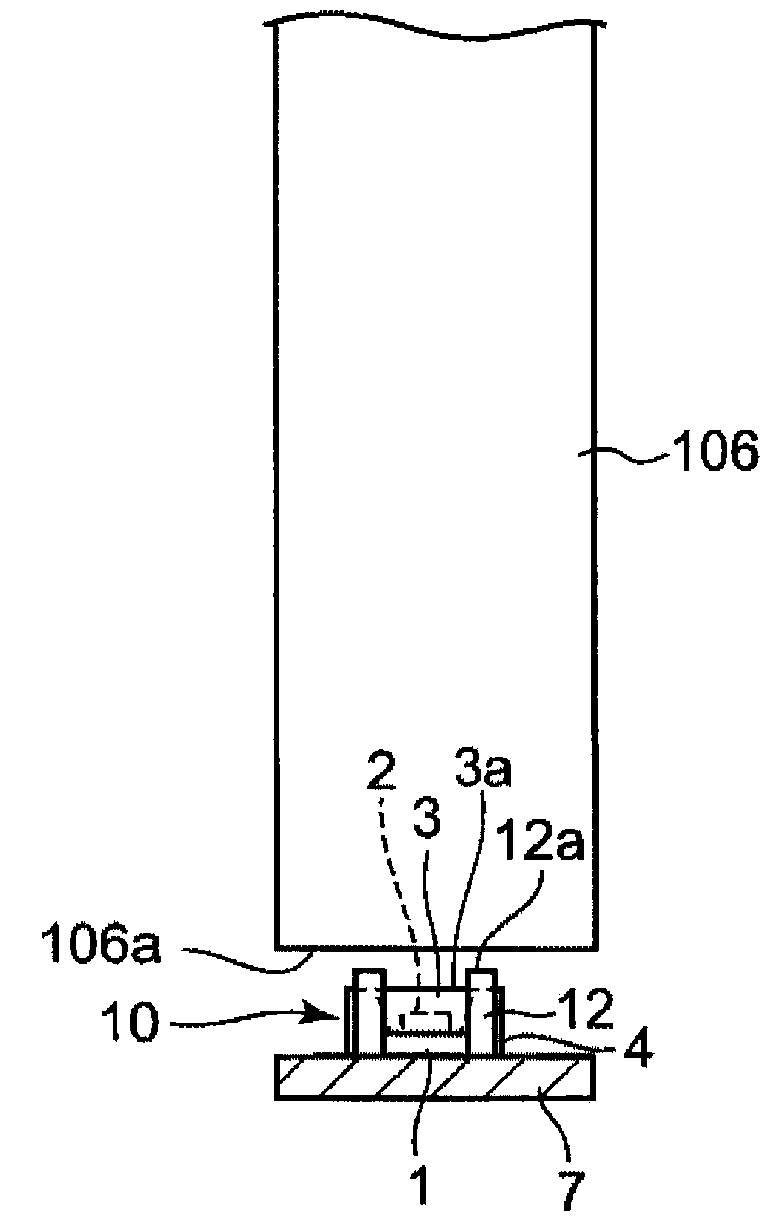

[0060] Figure 1A It is a perspective view showing the light emitting device of the first embodiment of the present invention. Figure 1B It is a cross-sectional view of the light-emitting device. Such as Figure 1A with Figure 1B As shown, the light-emitting device 10 has a lead frame 1, a housing member 4, a light-emitting element 2, and a sealing resin 3.

[0061] The above-mentioned lead frame 1 is made of metal, and has a lead frame main body 11 and a bumper portion 12 standing up from the lead frame main body 11.

[0062] The case member 4 is made of resin, and the bottom surface of the case member 4 is attached to the lead frame main body 11. For example, the case member 4 is formed together with the lead frame 1 by insert molding.

[0063] The housing member 4 has a hole 40. The light-emitting element 2 is arranged in the hole 40. The inner surface of the hole portion 40 is formed as an inclined surface such that the opening side of the hole portion 40 is widened, and the...

no. 2 Embodiment approach

[0083] Figure 4A It is a perspective view showing a light emitting device according to the second embodiment of the present invention. Figure 4B It is a cross-sectional view of the light-emitting device. The difference from the first embodiment described above is described. In the second embodiment, the position where the buffer portion of the lead frame is provided is different.

[0084] In addition, in this second embodiment, the same reference numerals as those of the first embodiment described above are the same configurations as those of the first embodiment described above, and therefore the description thereof is omitted.

[0085] Such as Figure 4A with Figure 4B As shown, in the lead frame 1A of the light-emitting device 10A of the second embodiment, the lead frame main body 11A has a terminal portion 11 a that protrudes from the end in the plane direction and is exposed from the housing member 4. The lead frame main body 11A is formed in a rectangular shape. Terminal ...

no. 3 Embodiment approach

[0093] Figure 5A It is a perspective view showing a light emitting device according to a third embodiment of the present invention. Figure 5B It is a cross-sectional view of the light-emitting device. The difference from the first embodiment described above is described. In the third embodiment, the position where the buffer portion of the lead frame is provided is different.

[0094] In addition, in this third embodiment, since the same reference numerals as in the above-mentioned first embodiment are the same structures as those in the above-mentioned first embodiment, the description thereof is omitted.

[0095] Such as Figure 5A with Figure 5B As shown, in the lead frame 1B of the light-emitting device 10B of the third embodiment, the lead frame main body 11B has a terminal portion 11 a that protrudes from the end in the plane direction and is exposed from the housing member 4. The lead frame main body 11B is formed in a rectangular shape. A pair of opposing sides of the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com