Equal-distance molding press

A molding press, isometric technology, applied in printing presses, rotary presses, printing and other directions, can solve the problem of difficult isometric printing of molding presses

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

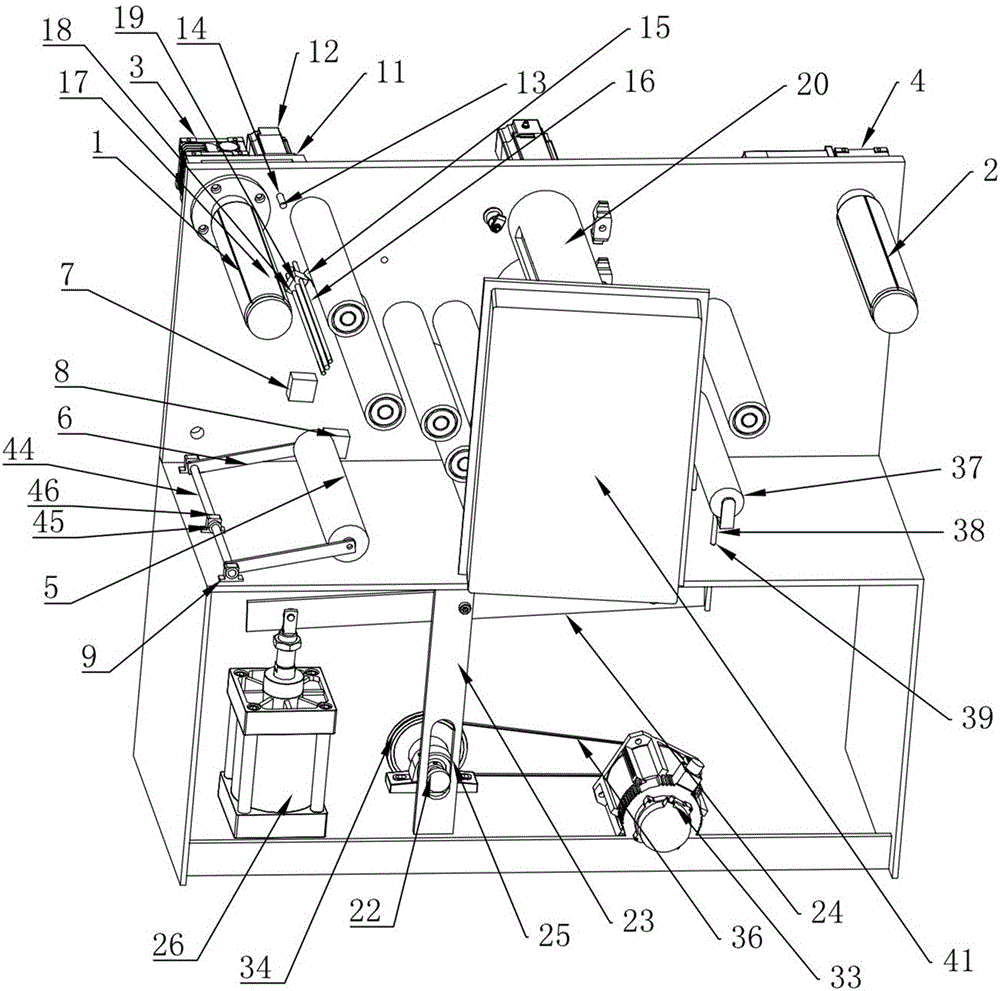

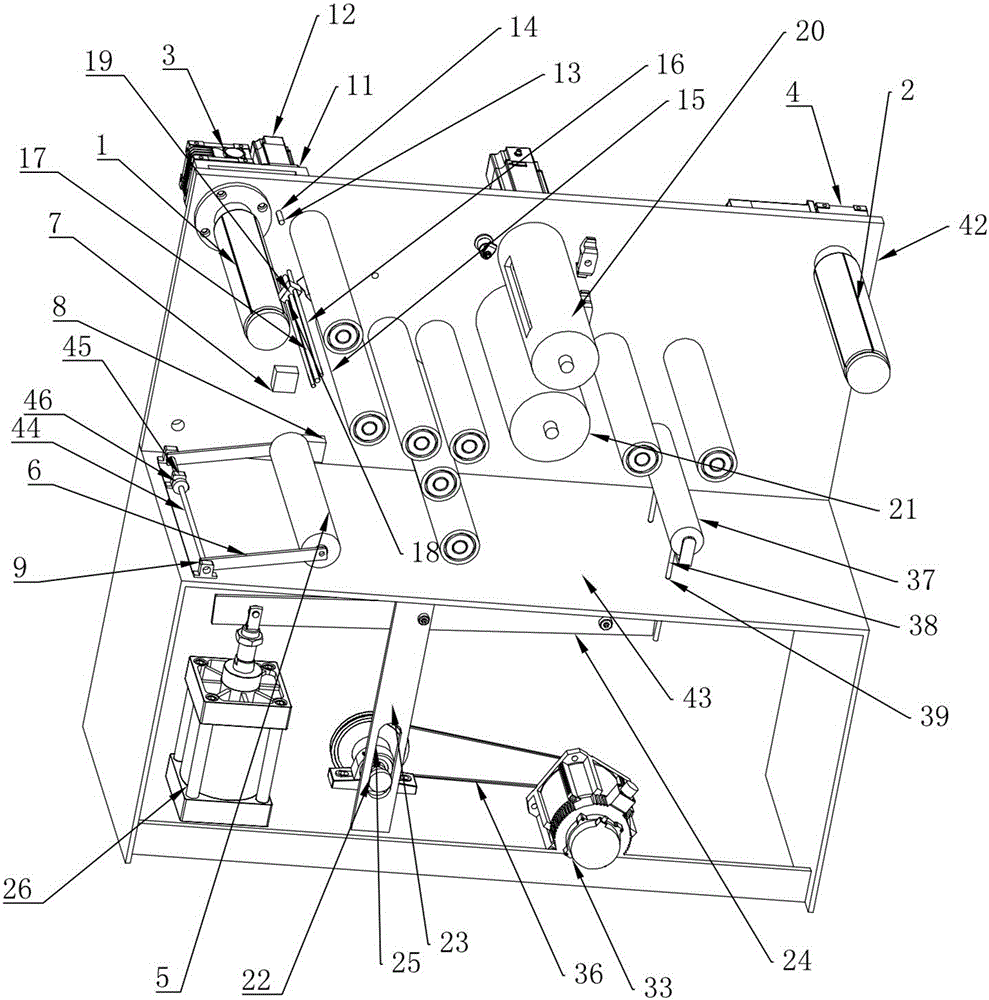

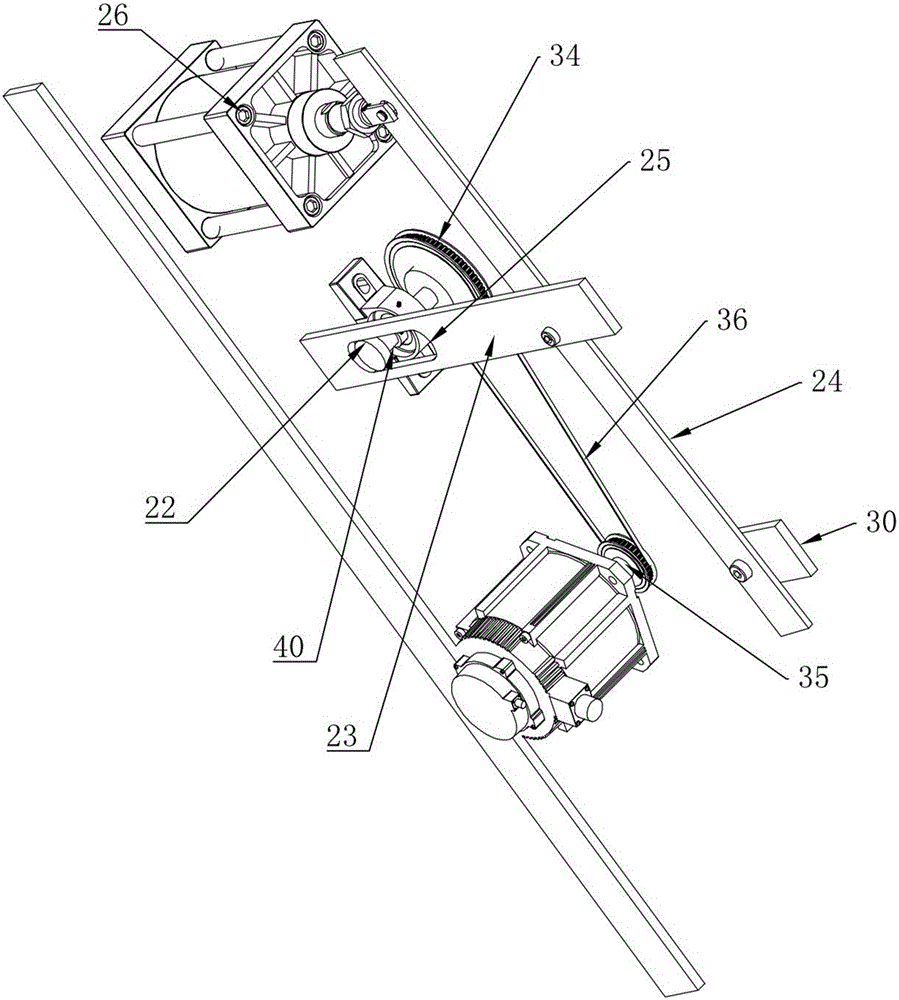

[0032]As an improved specific embodiment: the installation plate 42 is provided with an adjustment plate 11 on one side of the unwinding roller 1, the first driving structure is arranged on the adjustment plate 11, and the adjustment plate 11 is also provided with Rotating motor 12, the output end of described rotating motor 12 is provided with first screw rod 13, and described mounting plate 42 is provided with first screw hole 14, and described first screw rod 13 is threadedly connected on the first screw hole 14 and forms Threaded screw construction.

[0033] Through the above-mentioned technical scheme, in the process of use, after the deflection of the lower roll film, the first screw 13 on the rotating motor 12 can be driven by driving the rotating motor 12. Since the first screw 13 and the first screw hole 14 form a The structure of a threaded screw can adjust the position of the adjusting plate 11 relative to the mounting plate 42, and the first driving mechanism 3 is ...

Embodiment approach

[0036] As an improved specific embodiment: the mounting plate 42 is provided with a mounting rod 16 and a second screw rod 17, and the sensor 15 is provided with a mounting hole 18 for the mounting rod 16 to pass through and a screw thread for the second screw rod 17. connected to the second screw hole 19 , the second screw rod 17 is rotatably connected to the mounting plate 42 .

[0037] By installing the sensor 15 on the installation rod 16, the sensor 15 can be installed at any position of the installation rod 16, so that it can be adjusted as required. When adjusting the position of the sensor 15, the second screw rod can be rotated directly, so that the position of the sensor 15 can be adjusted. This adjustment structure is simple in structure and easy to operate. As an improved specific embodiment: it also includes an upper pressing roller 20 and a lower pressing roller 21 for applying patterns, the upper pressing roller 20 is arranged between the unwinding roller 1 and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com