Take-up device for electric power

A wire take-up device and electric power technology, applied in the field of electric power, can solve problems such as easy knotting of wires, inconvenient use, and inability to adjust the tightness of wires

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

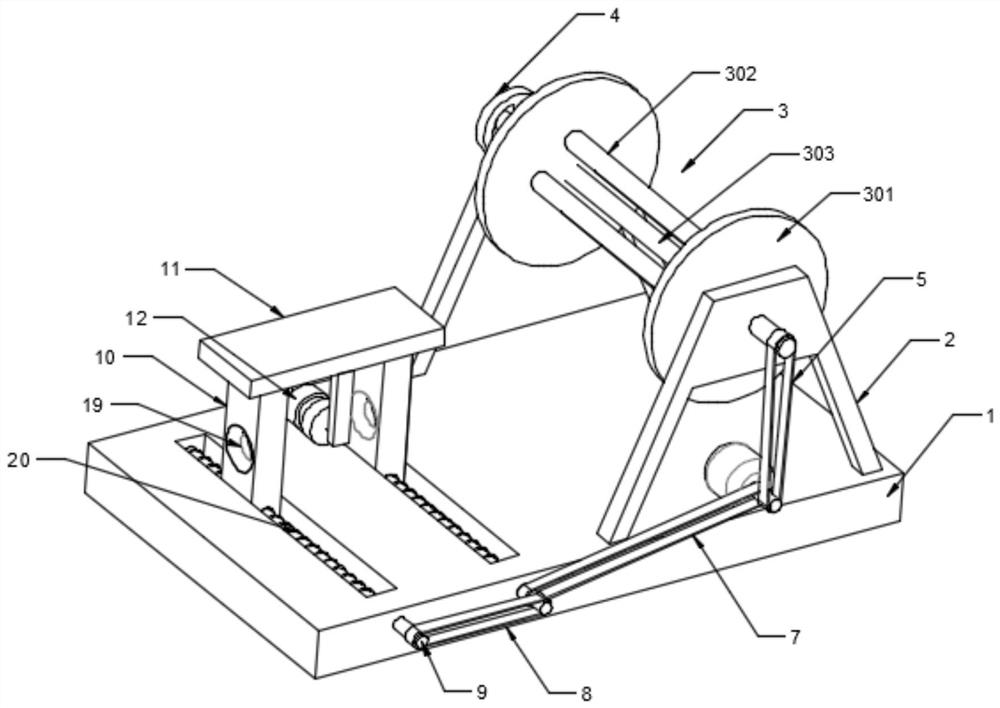

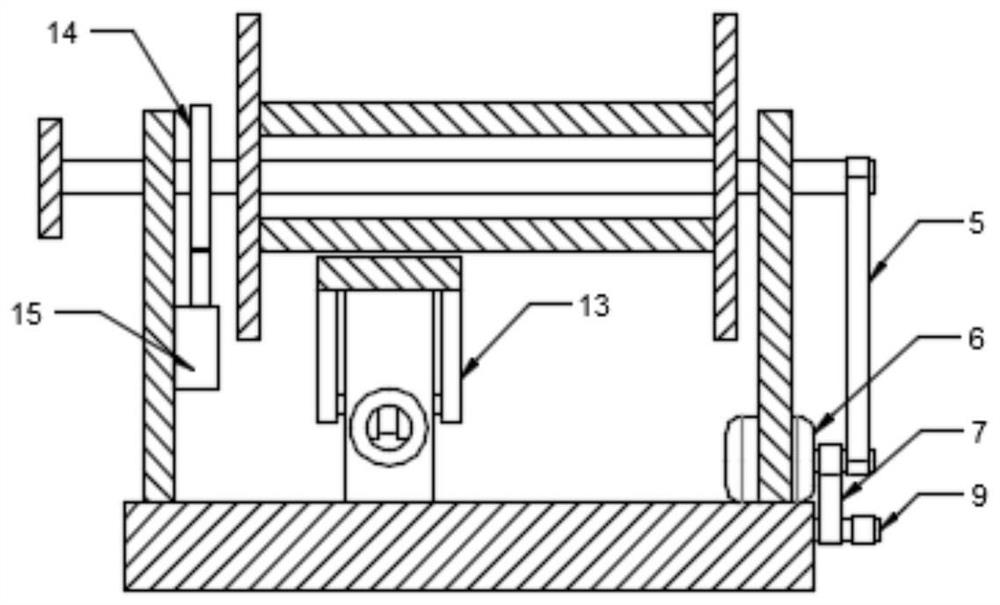

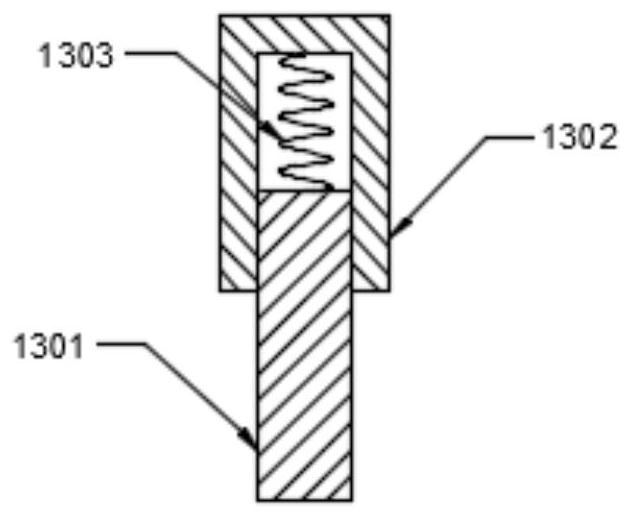

[0026] see Figure 1-4 , a wire take-up device for electric power, comprising a base 1, a support frame 2 is fixedly installed on both sides of the base 1, a wire roller assembly 3 is arranged between the two support frames 2, and a wire take-up adjustment assembly is arranged on the base 1, so The specific type of the wire-receiving adjustment assembly is not limited. In this embodiment, preferably, the wire-receiving adjustment assembly includes a slider 10, a mounting plate 11, a drum 12 and a fixing plate 13. The two sliders 10 are arranged on the base 1 and Both are provided with wire holes 19, and the mounting plate 11 is fixedly installed above the slider 10, and the two mounting plates 13 are symmetrically arranged at the lower end of the mounting plate 11, and the specific type of the mounting plate 13 is not limited. In this embodiment, the preferred , the fixed plate 13 includes a sleeve rod 1301, a sleeve 1302 and a connecting spring 1303, the sleeve 1302 is fixedl...

Embodiment 2

[0035] In order to improve the neatness of wire winding, this embodiment is further improved on the basis of Embodiment 1. The improvement is that: the base 1 is provided with a reciprocating assembly that drives two sliders 10 to reciprocate, and the reciprocating assembly The specific type is not limited. In this embodiment, preferably, the reciprocating assembly includes a second belt 7, a third belt 8, a reciprocating screw rod 9 and a chute 20. Two chute 20 are provided in the base 1 in parallel, and two The reciprocating screw mandrel 9 is rotatably installed in the two chutes 20 and one end extends to the outside of the base 1 and is driven and connected by the third belt 8. The second belt 7 is driven to connect the output end of the drive motor 6 with one of the reciprocating screw mandrels 9, and the two The sliders 10 are respectively slidably installed in the two slide grooves 20 and are threadedly connected with the reciprocating screw mandrel 9 .

[0036]In order...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com