A mine hoist tail rope monitoring device

A monitoring device and technology for mines, which are applied to lifting equipment, elevators, transportation and packaging in mines, can solve the problems of high failure rate of tail rope switches, difficulty in debugging and difficulty in tightening, etc., and achieve rapid judgment and emergency conversion processing. , The effect of avoiding the aggravation of tail rope damage and reducing the failure rate of the tail rope

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

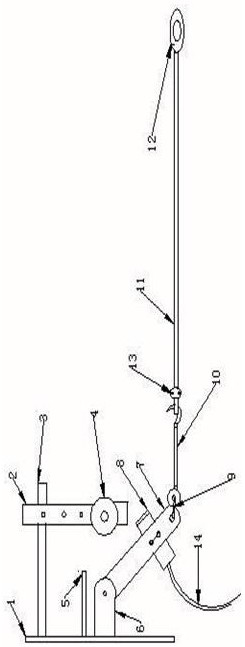

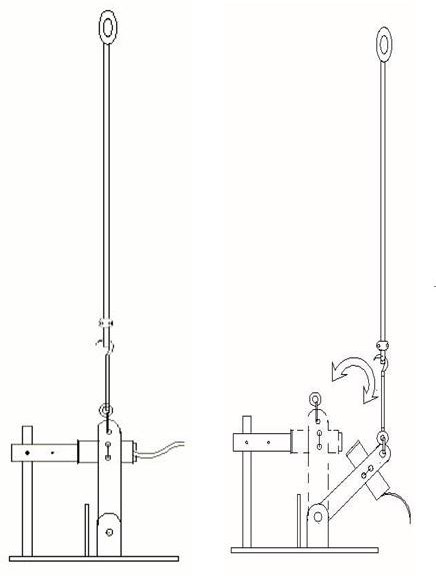

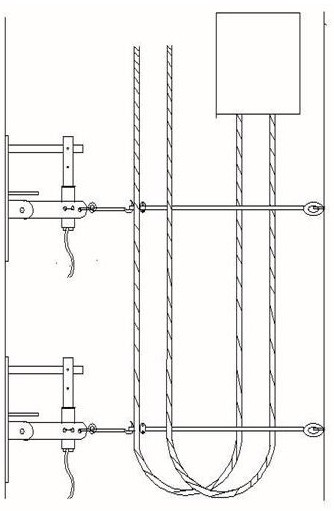

[0055] Embodiment 1: see Figure 1-Figure 7, a mine hoist tail rope monitoring device, the monitoring device includes a detection switch bracket, a magnetic switch 8, a steel wire rope assembly and a double switch series switchable control circuit, the magnetic control switch 8, the steel wire rope assembly and the double switch series switchable The conversion control circuits are all arranged on the detection switch bracket, and the detection switch bracket includes a bottom plate 1, a magnet fixing plate 2, an angle iron front extension frame 3, an induction source magnet 4, a baffle plate 5, a splint 6, a rocker arm 7 and a mounting hole , the base plate 1 is fixed to the derrick on one side through the installation hole, the upper right side of the base plate 1 is vertically welded with an angle iron front extension frame 3, and the outer end of the angle iron front extension frame 3 is vertically installed with a magnet fixing plate 2, and the magnet fixing plate 2 is ext...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com