Transition method and transition joint between polar plate and copper conducting beam

A transition joint, conductive beam technology, applied in the electrolysis process, electrodes, electrolysis components, etc., can solve the problems of poor anode plate adsorption rate, large current energy consumption, and high product cost, and achieve increased output, improved production efficiency, and resistance value. small effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

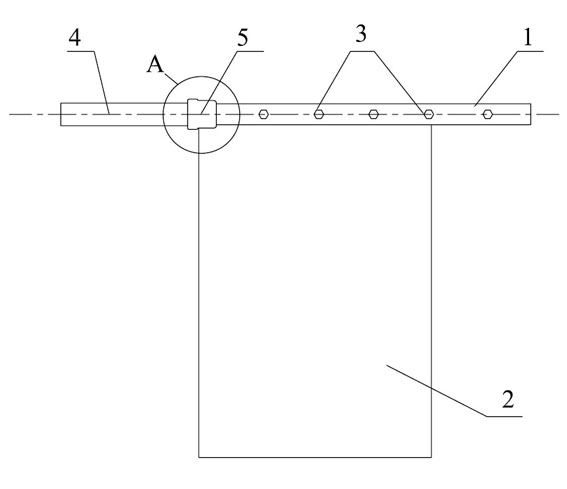

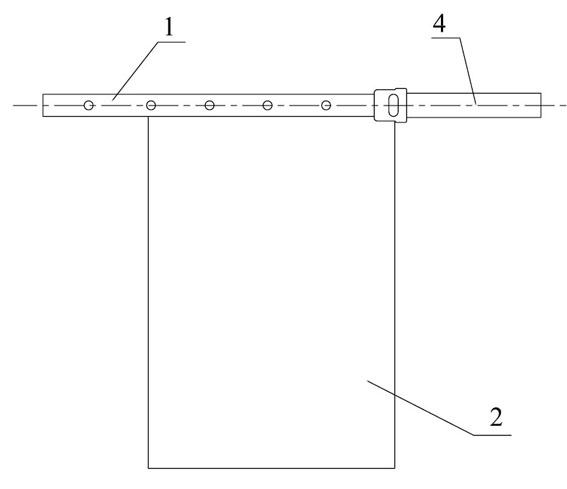

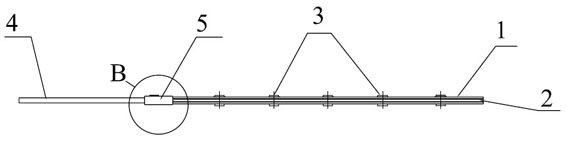

[0019] Refer to attached Figure 1-5 . The transition method between the polar plate and the copper conductive beam of the present invention is provided with a conductive beam 1, and the upper ends of the conductive beam 1 and the pole plate 2 are fixed with bolts 3, and the transition method is also provided with a mold, which is close to a section of the conductive beam 4, A section of the conductive beam 1 close to the copper conductive beam, the part of the pole plate 2 connected to the section of the conductive beam close to the copper conductive beam, and the area of the pole plate close to this part are placed flat into the exothermic welded aluminum in the mold In the thermal reaction chamber, it is welded together by exothermic welding, the flux of the exothermic welding contains copper oxide, and the height of the reaction chamber is greater than the thickness of the copper conductive beam and the sum of the conductive beam and the pole plate. Thickness, the width...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com