Method and device for detecting pre-shrinking rate of preshrunk woven fabric

A detection device and a pre-shrinking machine technology, applied in the direction of measuring device, textile testing, using optical devices, etc., can solve the problems of inability to guide and adjust the parameters of the pre-shrinking process, low accuracy of the pre-shrinking rate, etc., and achieve accurate fabric shrinkage. , to ensure the effect of tension

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

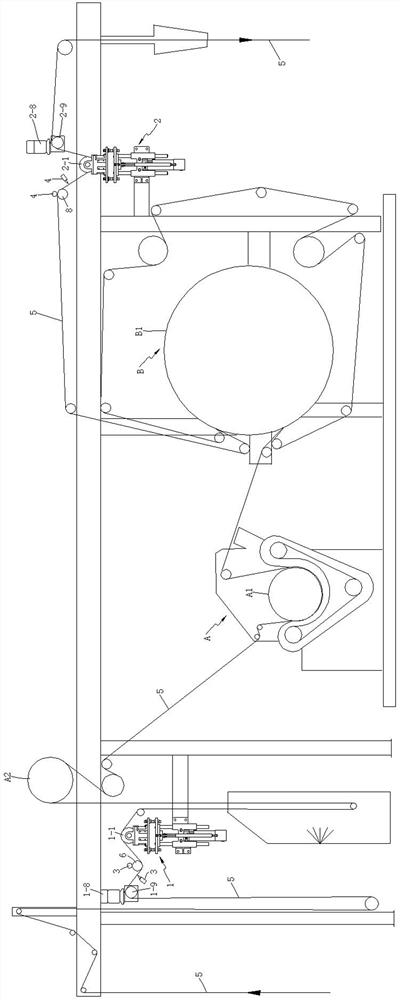

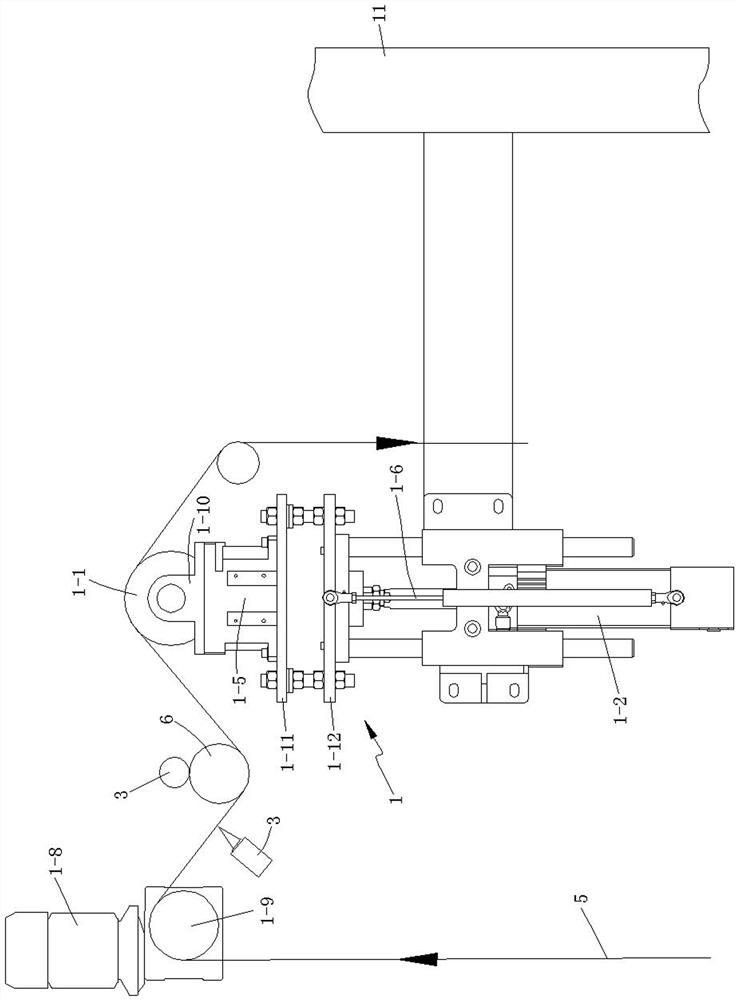

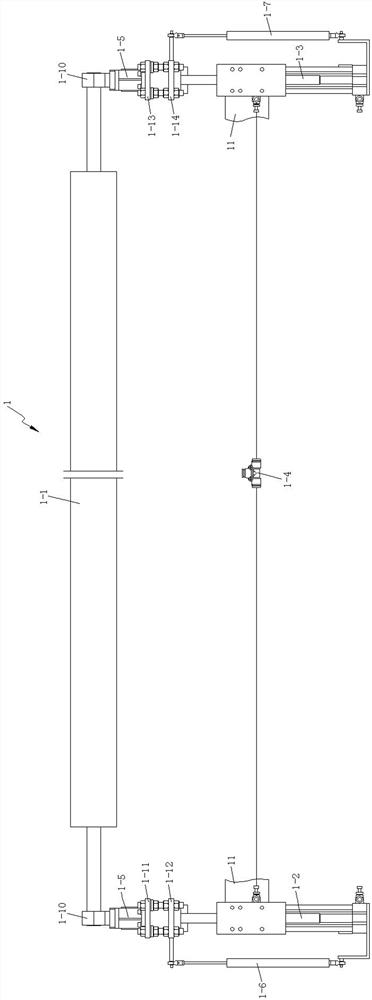

[0031] As a preferred embodiment of the present invention, the first fabric tension adjustment mechanism includes a first fabric guide roller 1-1 for adjusting the fabric tension on the cloth inlet side of the rubber blanket shrinkage unit, and the second fabric tension adjustment mechanism It includes the second fabric guide roller 2-1 for adjusting the fabric tension on the outlet side of the woolen blanket drying unit. By detecting the positions of the first and second fabric guide rollers, when the fabric passes through the first fabric tension adjustment mechanism, it is preferably the same as The electrical control master unit of the rubber blanket shrinkage unit A—the heating and pressure roller A1 or the fabric on the wet drying cylinder A2 keeps running synchronously, and the fabric passes through the second fabric tension adjustment mechanism and the woolen drying unit B, preferably the woolen drying cylinder The fabric on B1 keeps running synchronously.

[0032] As ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com