Yarn winding system and control method

A control method and yarn technology, which is applied in the direction of conveying filamentous materials, thin material processing, transportation and packaging, etc., can solve the problems that the yarn tension is difficult to control, and the yarn is not moving at a uniform speed, so as to overcome the yarn tension Inconstant, evenly wound effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0042] The technical solutions in the embodiments of the present invention will be clearly and completely described below in conjunction with the accompanying drawings in the embodiments of the present invention. Obviously, the described embodiments are only a part of the embodiments of the present invention, rather than all the embodiments.

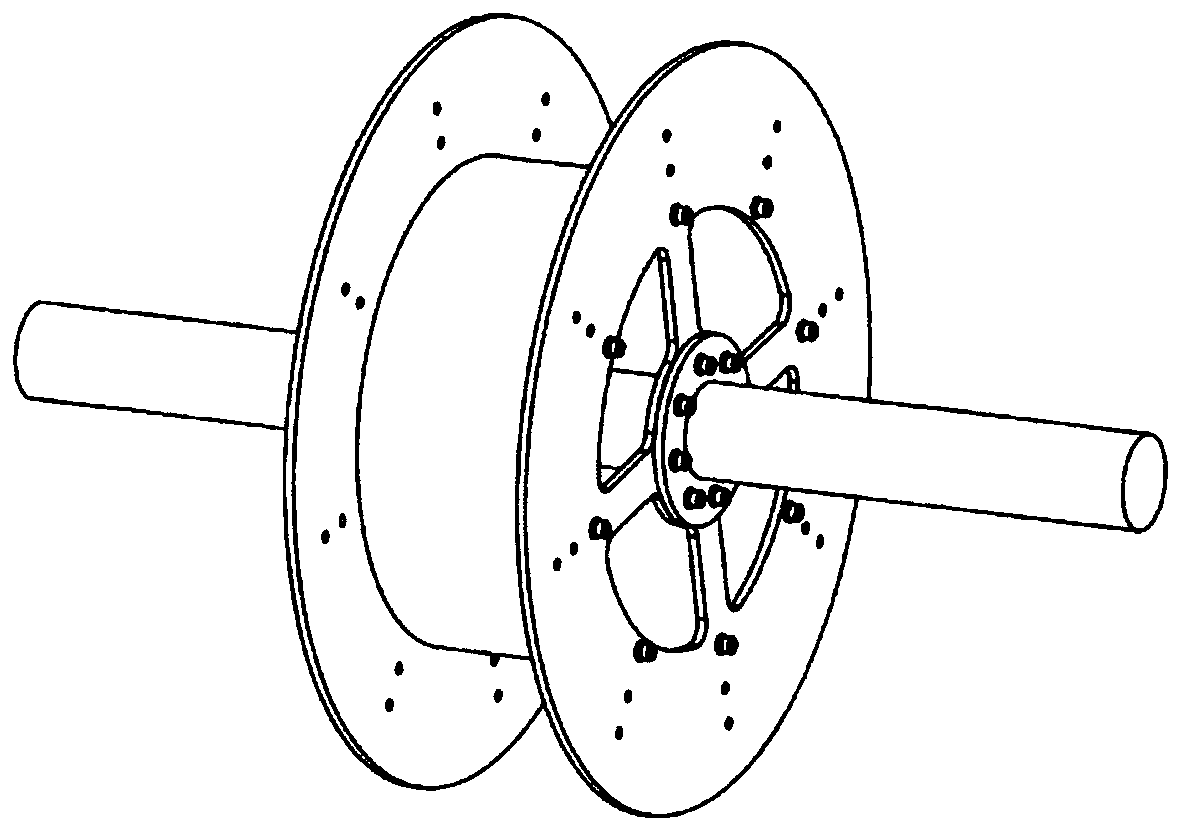

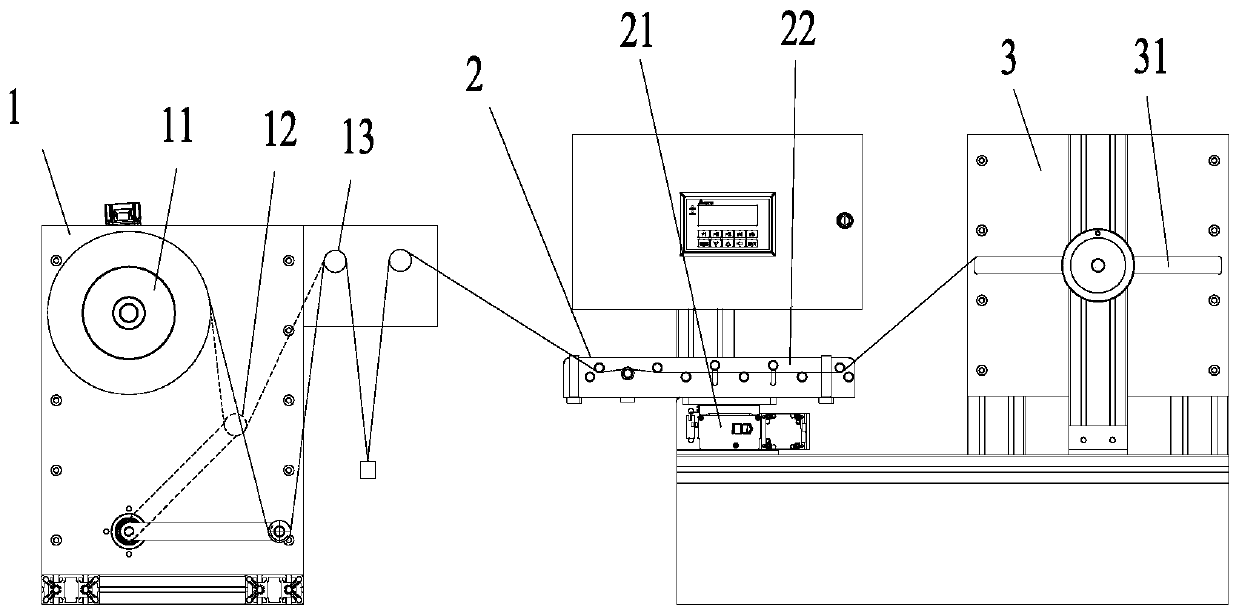

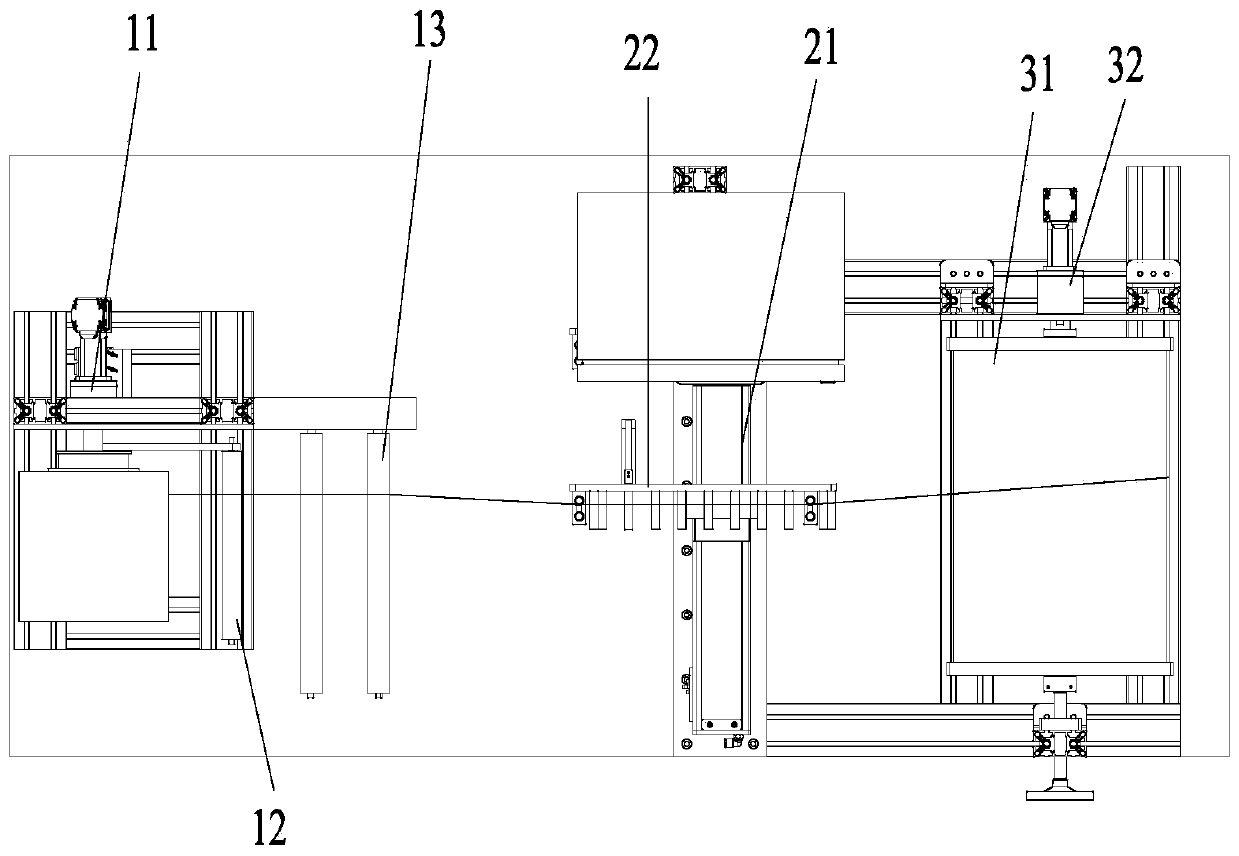

[0043] Such as Figure 2-3 The yarn winding system shown includes:

[0044] The unwinding device 1 is used to unwind the yarn on the bobbin under constant tension. The unwinding device 1 further includes a bobbin driving member 11, a swing rod 12 and a yarn storage rod 13. The bobbin driving member 11 fixes the yarn bobbin to It drives the yarn drum to rotate at a uniform speed; one end of the swing arm of the swing rod 12 is set to rotate, and the other end of the swing arm is provided with a rotating shaft along the axial direction of the yarn drum, and the yarn package released from the yarn drum is set around the rotating shaft; At least...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com