Tension equipment of continuous mill system

A tension device and tension technology, applied in the direction of braking/tightening device, tension/pressure control, etc., can solve the problems of large fluctuation of tension control, affecting production output and product quality, and complex control system.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

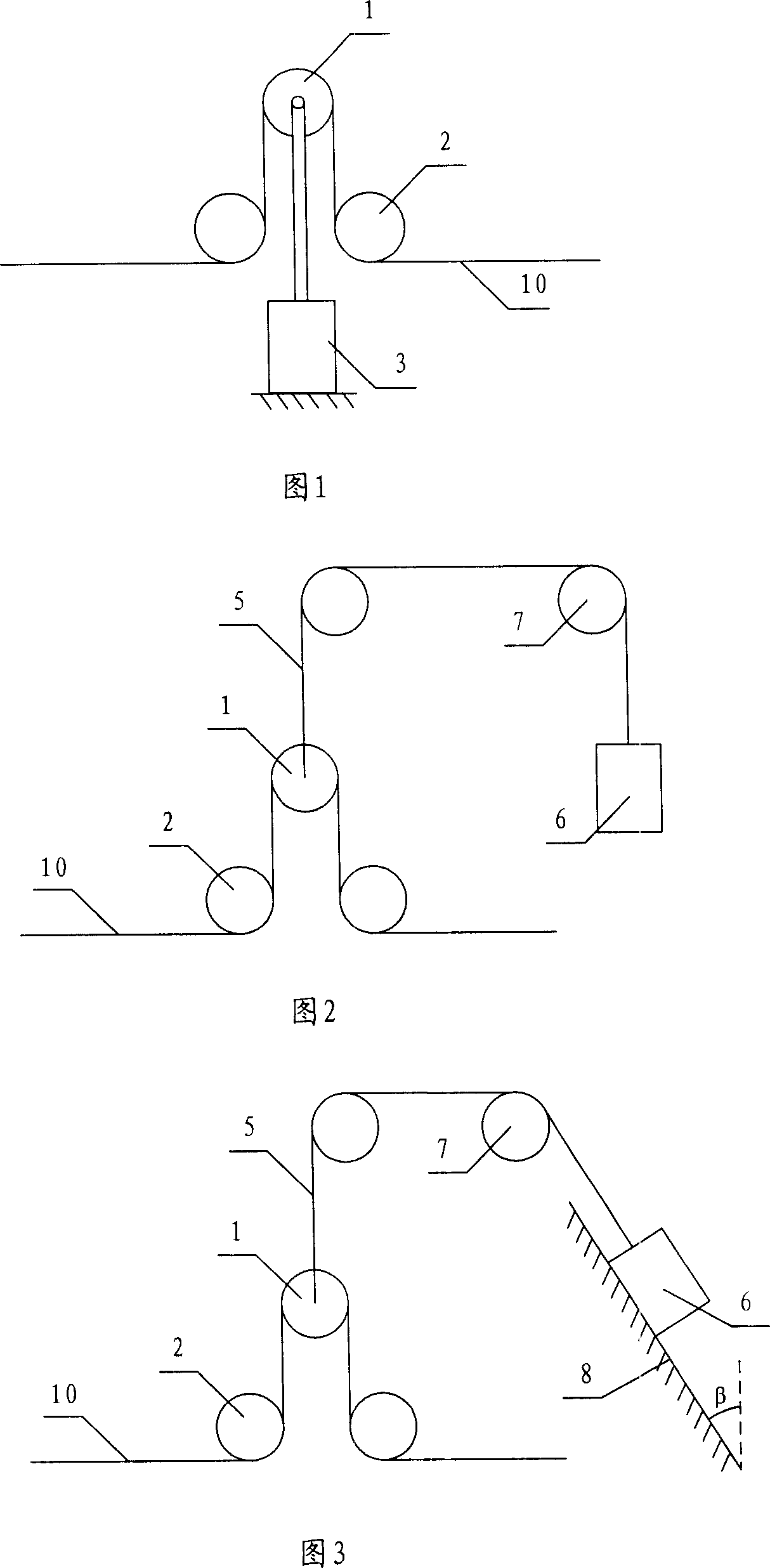

[0028] Fig. 1 is a schematic structural diagram of the first embodiment of the present invention. As shown in Figure 1, the tension device in the continuous rolling system of this embodiment includes a floating roller 1 and two guide rollers 2 located on both sides of the floating roller 1, and the two guide rollers 2 are responsible for guiding the rolling piece 10 to move from left to right , the floating roll 1 is used to support the rolled piece 10, and the rolled piece between the floating roll 1 and the two guide rolls 2 is vertical. The floating roller 1 is connected with the hydraulic device 3 with constant support force output, so that the floating roller 1 can move up and down according to the change of the tension of the rolled piece, and the tension of the rolled piece can be kept constant by changing the length of the rolled piece between the floating roller and the two guide rollers .

[0029] When the tension of the rolling piece 10 between the two rolling mill...

no. 2 example

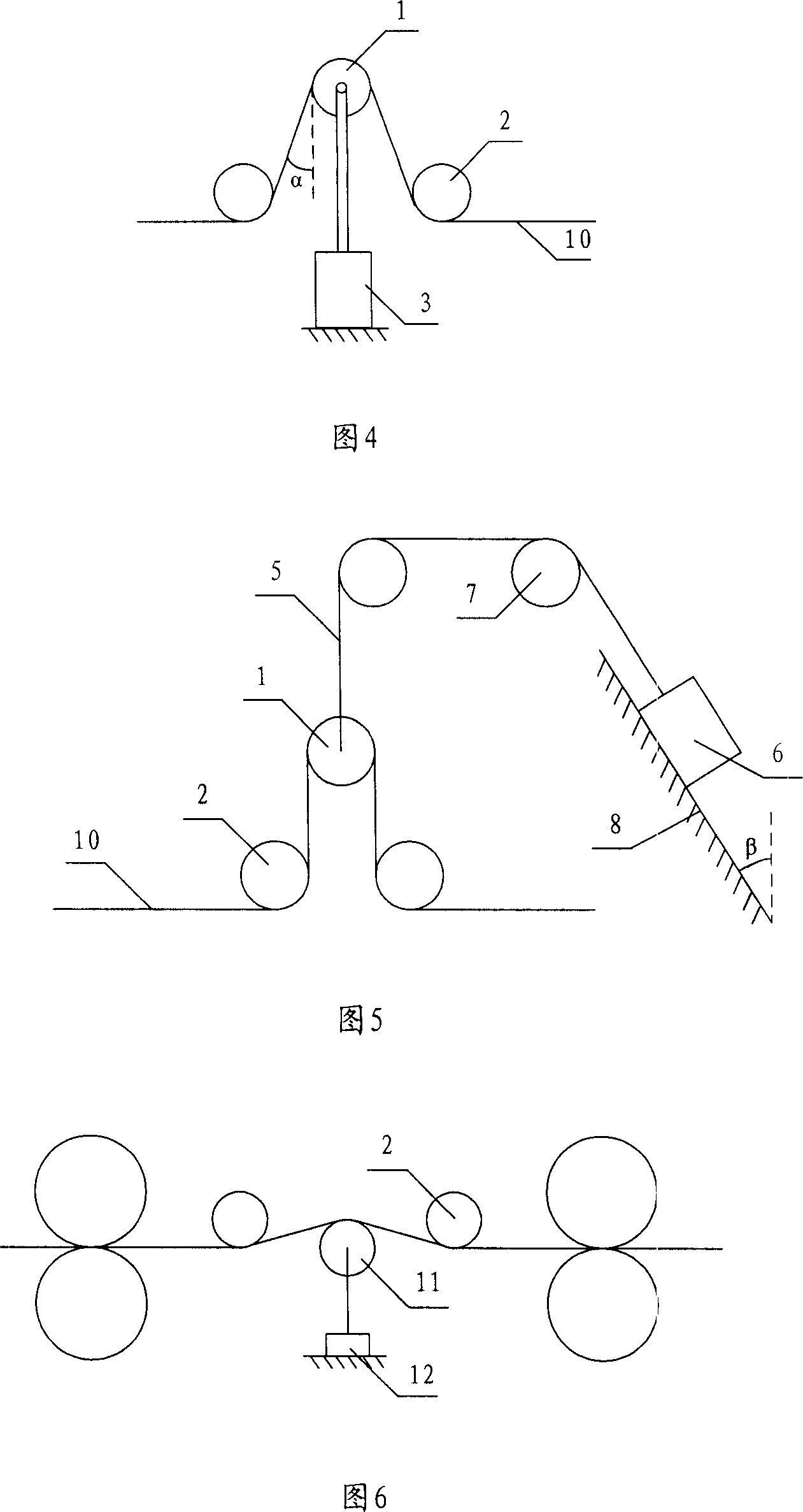

[0031] Fig. 2 is a schematic structural diagram of a second embodiment of the present invention. As shown in Figure 2, the tension device in the continuous rolling system of this embodiment includes a floating roll 1 and two guide rolls 2 positioned on both sides of the floating roll 1, and the two guide rolls 2 are responsible for guiding the rolling piece 10 to move from left to right , the floating roll 1 is used to support the rolled piece 10, and the rolled piece between the floating roll 1 and the two guide rolls 2 is vertical. The floating roller 1 is connected to a counterweight 6 through the suspension cable 5 and the fixed pulley block 7. The counterweight 6 has a constant weight and produces a constant tension on the suspension cable 5 and the floating roller 1, so that the floating roller 1 moves up and down according to the tension change of the rolled piece , by changing the length of the rolled piece between the floating roller and the two guide rollers to keep ...

no. 3 example

[0034] Fig. 3 is a schematic structural diagram of a third embodiment of the present invention. As shown in FIG. 3 , this embodiment is a structural improvement of the second embodiment shown in FIG. 2 . The difference is that the weight body is arranged on an inclined plane 8 , and the included angle between the inclined plane 8 and the vertical direction is β. In this embodiment, by setting the slope, the tension of the counterweight body 6 acting on the suspension cable 5 can be changed according to the change of the β angle. When the set constant tension needs to be changed, the β angle can be adjusted to change the 5 pairs of floating rollers of the suspension cable. 1, but no matter how the slope β angle is adjusted, the tension of the counterweight 6 acting on the suspension cable 5 is constant during the operation of the continuous rolling system.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com