Marking machine

A marking machine and frame technology, applied in the field of marking machines, can solve the problems of reduced work efficiency, waste of manpower and material resources, inconvenient use, etc., and achieve the effects of improving production efficiency, firm pattern, and convenient use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] In order to enable those skilled in the art to better understand the technical solution of the present invention, the technical solution of the present invention will be further described below in conjunction with the accompanying drawings.

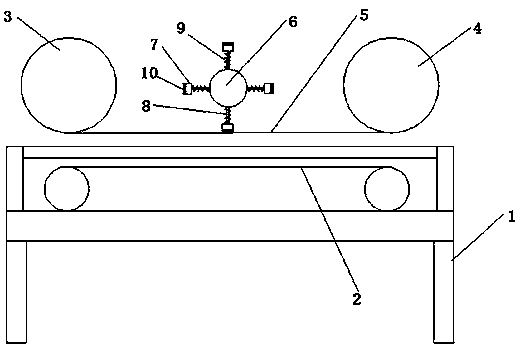

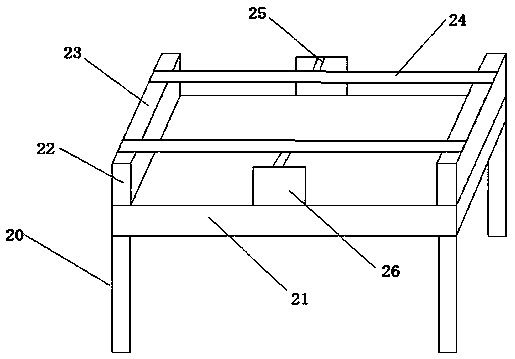

[0016] Such as figure 1 A marking machine shown includes a frame 1, wherein the frame 1 is composed of a vertical rod 20 and a top plate 21, and a support plate 22 is installed at the four corners of the top plate 21, and a third slide is installed in the radial direction of the support plate 22. rail 23, the third slide rail 23 is slidably provided with a crossbar 24, and the crossbar 24 is installed on the two support plates 22 arranged horizontally above the top plate 21, and the outer sidewall of the crossbar 24 is connected with a cylinder 26 through a push rod 25, through which Cylinder 26 drives push rod 25, promotes cross bar 24 to move on the third slide rail 23, can adjust the distance between two cross bars 24, so that i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com