Tension adjusting mechanism for multi-wire cutting machine

A tension adjustment mechanism, multi-wire cutting machine technology, applied in fine working devices, stone processing equipment, manufacturing tools, etc., can solve the problems of easy wire breakage, unstable tension adjustment, low sensitivity, etc., to achieve low cost and tension. Consistent, highly accurate results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] In order to further illustrate the principle of the present invention, the present invention will be described in detail in conjunction with the accompanying drawings.

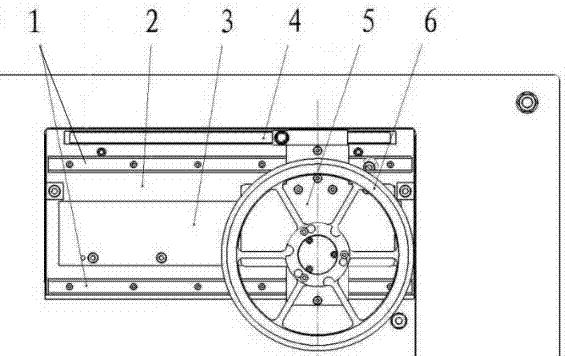

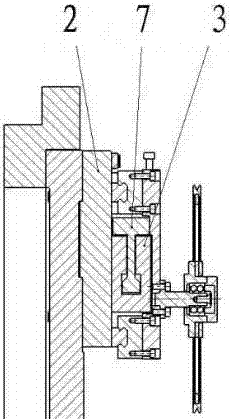

[0017] Such as figure 1 and 2 As shown, the tension adjustment mechanism of the multi-wire cutting machine includes a linear guide rail 1, a frame 2, a stator assembly 3, a magnetic scale 4, a mover assembly 5, a pulley assembly 6 and a mover 7, and the linear guide rail 1 is fixed on the machine on the frame 2; the stator assembly 3 is fixed on the frame 2, and is located in the middle of the two linear guide rails 2; the magnetic scale 4 is fixed on the frame 2, and is set along the direction of the linear guide rail 1 on one side; the moving subassembly 5 slides It is arranged on the linear guide rail 1; the pulley assembly 6 is connected with the mover assembly 5; the mover 7 is connected to and drives the mover assembly 5.

[0018] Such as figure 1 As shown, the linear guide rail 1 is fixed on t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com