A double-swing arm type tension control device and a double-swing arm type lamination machine

A tension control, double swing arm technology, applied in final product manufacturing, sustainable manufacturing/processing, electrochemical generators, etc., can solve the problems of long time lamination, tearing, loose diaphragm, etc., to eliminate the length of the diaphragm Mutation, increase lamination speed, avoid the effect of diaphragm loosening

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

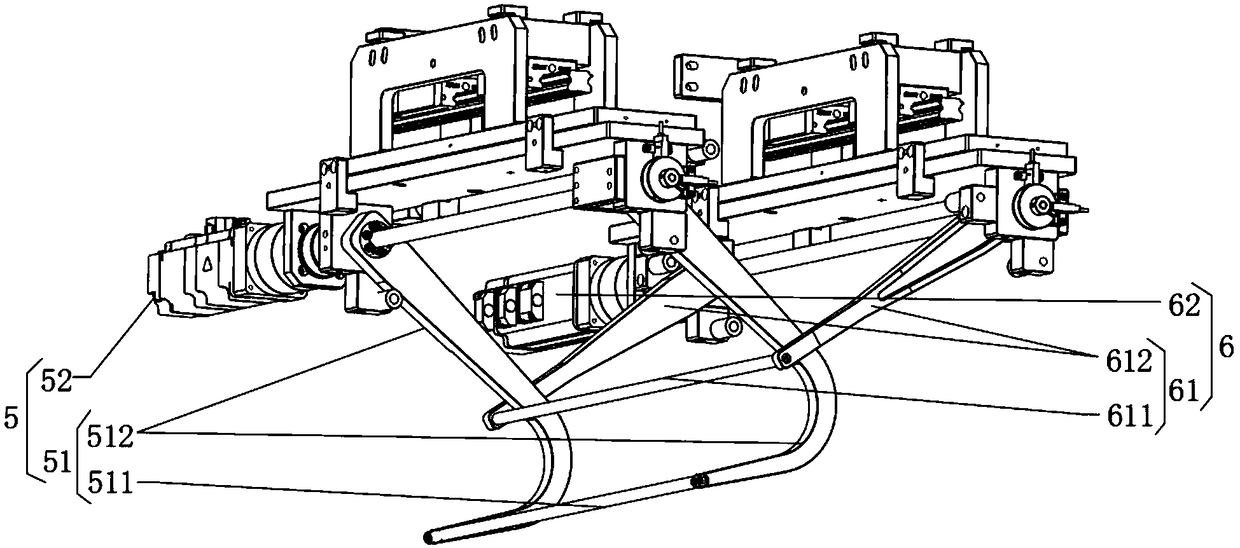

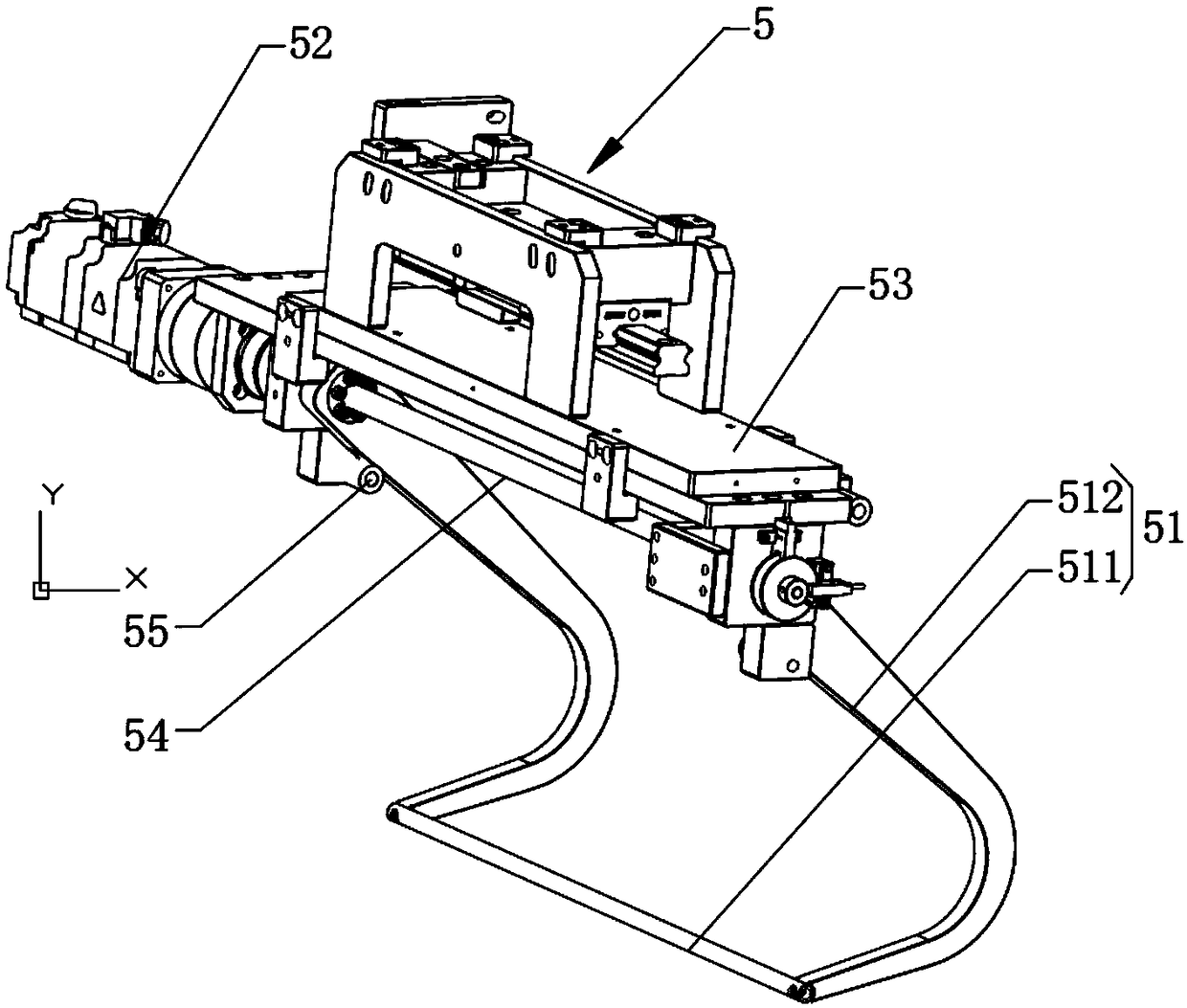

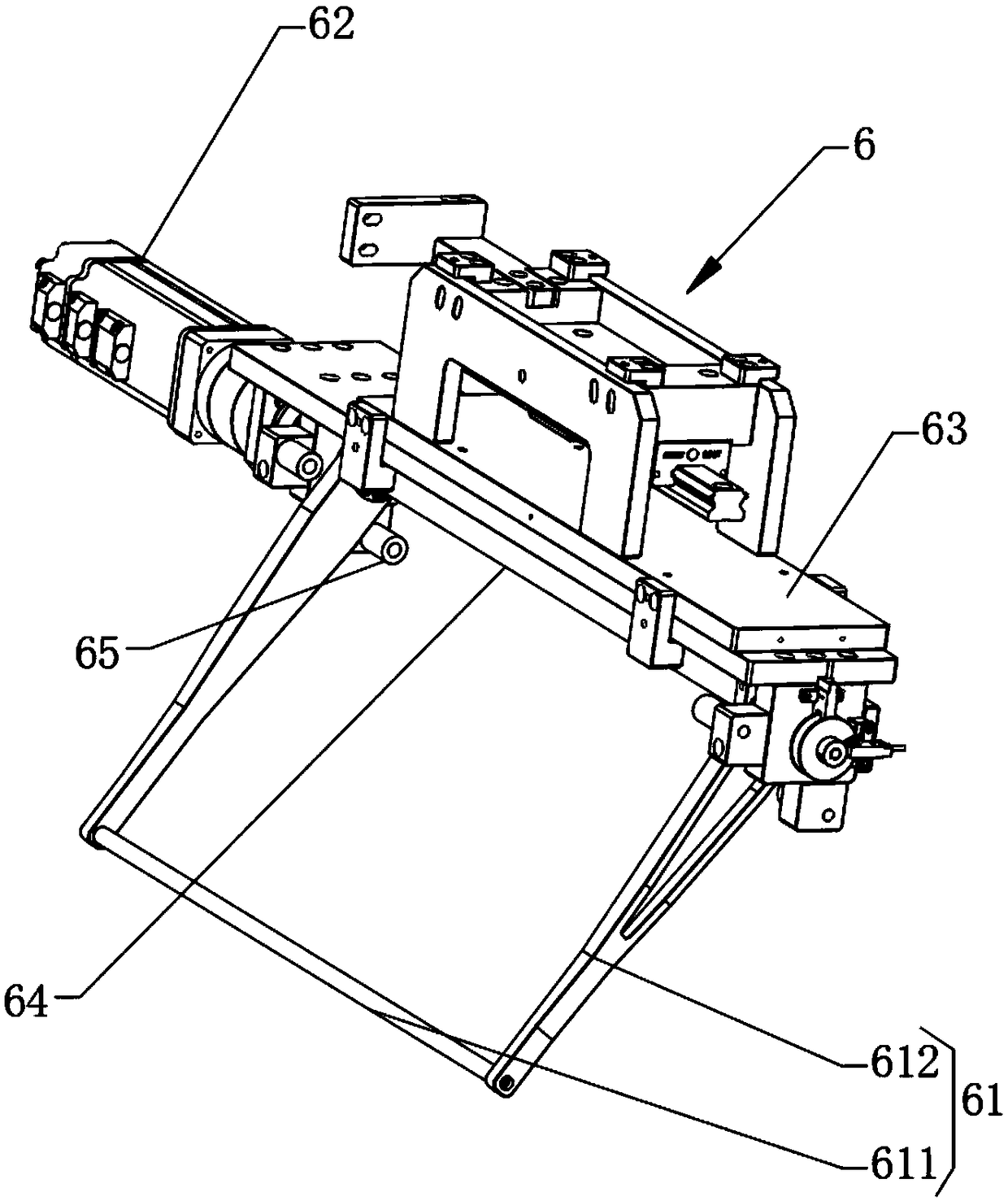

[0024] A double swing arm type tension control device for folding the diaphragm 7, including a first swing arm mechanism 5 and a second swing arm mechanism 6, through which the first swing arm mechanism 5 and the second swing arm mechanism 6 swing to move the The diaphragm 7 is Z-guided and folded. When the first swing arm mechanism 5 guides the diaphragm 7 to one side, the second swing arm mechanism 6 tensions the diaphragm 7. When the second swing arm mechanism 6, when the diaphragm 7 is guided to the other side, the first swing arm mechanism 5 tensions the diaphragm 7.

[0025] The double-swing arm type tension control device of the present invention uses the first swing arm mechanism 5 and the second swing arm mechanism 6 to swing according to a certain logical relationship to carry out Z-shaped guiding and folding of the diaphragm 7. Specifically, when the first swing arm mechanism 5 When the diaphragm 7 is guided to one side, the second swing arm mechanism 6 tensions the...

Embodiment 2

[0036] A double-swing arm type lamination machine, comprising: a lamination table mechanism 1 for lamination, a diaphragm discharge mechanism 2 arranged above the lamination table mechanism 1, a diaphragm discharge mechanism arranged on the lamination table mechanism 1 and a diaphragm discharge mechanism 2, a double-swing arm tension control device, a first feeding device 3 provided on one side of the stacking table mechanism 1 for transporting the positive electrode sheet to the stacking table mechanism 1, and a part of the stacking table mechanism 1 The other side is used to convey the negative electrode sheet to the second feeding device 4 of the stacking platform mechanism 1; it includes a first swing arm mechanism 5 and a second swing arm mechanism 6, through which the first swing arm mechanism 5 and the second swing arm mechanism The second swing arm mechanism 6 swings to guide and fold the diaphragm 7 in a Z shape. When the first swing arm mechanism 5 guides the diaphrag...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com