Steel wire rope clamping device based on air pressure transmission

A clamping device and pneumatic transmission technology, applied in the direction of the hoisting device, the spring mechanism, etc., can solve the problems of wire rope damage, disorder, insufficient pre-tightening force, etc., and achieve the effect of avoiding damage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

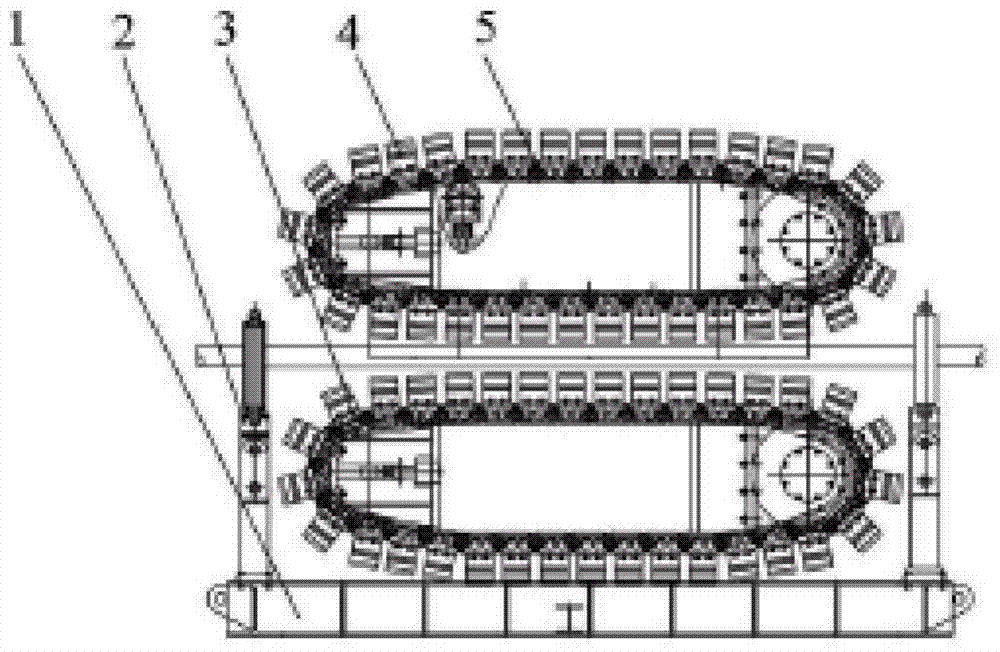

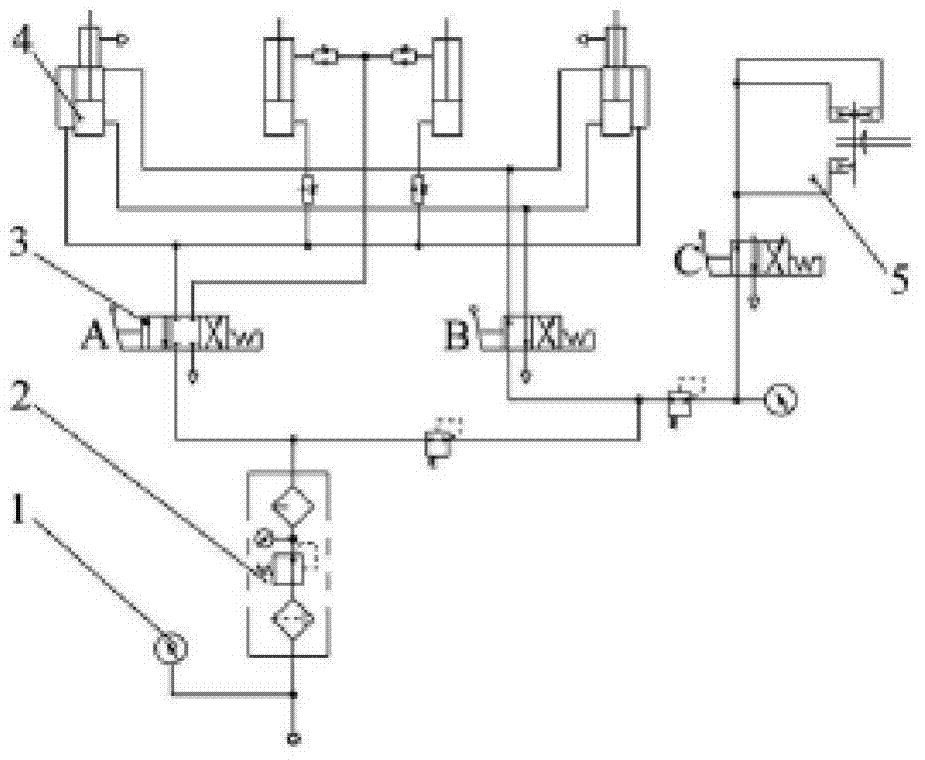

[0026] Refer to attached figure 1 , 2 Make the wire rope clamping device of the present invention.

[0027] The main technical parameters of the wire rope clamping device are shown in Table 1.

[0028] Table 1. Main technical parameters of wire rope clamping device

[0029] Maximum tension (kN)

98

Maximum speed (m / min)

30

Applicable wire rope diameter (mm)

40~76

Working air pressure (kg / cm 2 )

7~9.9

Brake rated torque (Nm)

8870

Track positive pressure (kN)

179

Working condition friction coefficient ζ

0.55

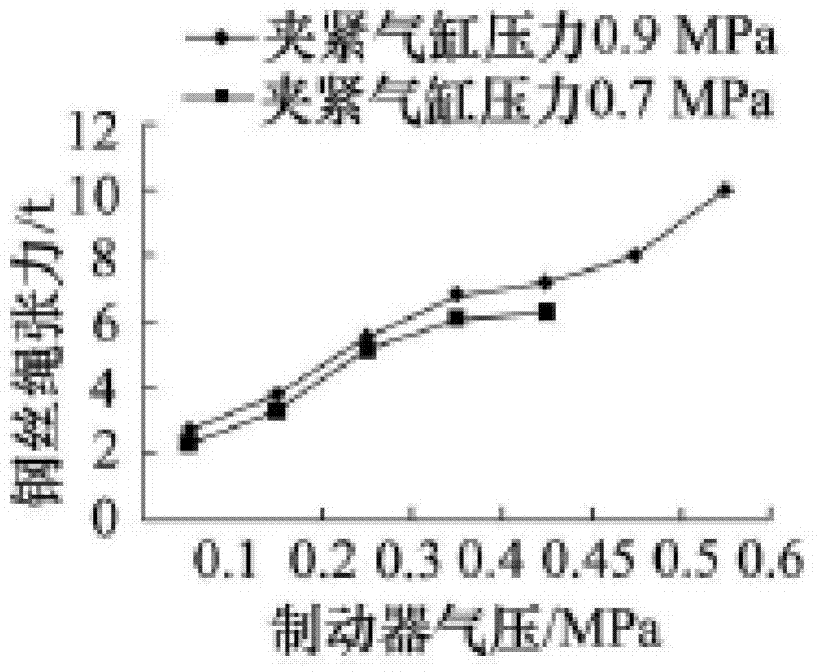

[0030] The steel wire rope clamping device can generate a constant damping force on the steel wire rope, and the steel wire rope will not produce rope disorder. The tension of the wire rope can be changed by adjusting the intake pressure of the brake. The tension of the wire rope is measured by the GGD-331 peak force gauge, and the graph of the tension of the wire rope and the adjustm...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com