Synchronous belt forming device

A molding equipment and synchronous belt technology, applied in the field of CNC machine tools, can solve the problems of occupying space, low production efficiency and poor stability of the synchronous belt molding machine, and achieve the effects of good stability, high yield and high production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] The present invention will be further explained below in conjunction with the accompanying drawings and embodiments.

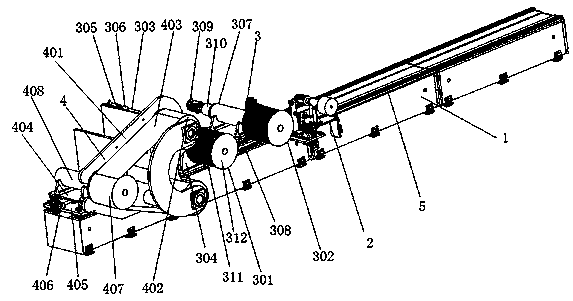

[0017] Such as Figure 1-Figure 2 As shown, a synchronous belt forming equipment includes a frame 1, a steel wire winding mechanism 2, a steel wire output mechanism 3 and a steel belt extrusion forming mechanism 4, and the frame 1 is provided with a linear guide rail 5, and the steel wire is wound The wire device 2, the steel wire output mechanism 3 and the steel strip extrusion forming mechanism 4 are sequentially arranged on the linear guide rail 5;

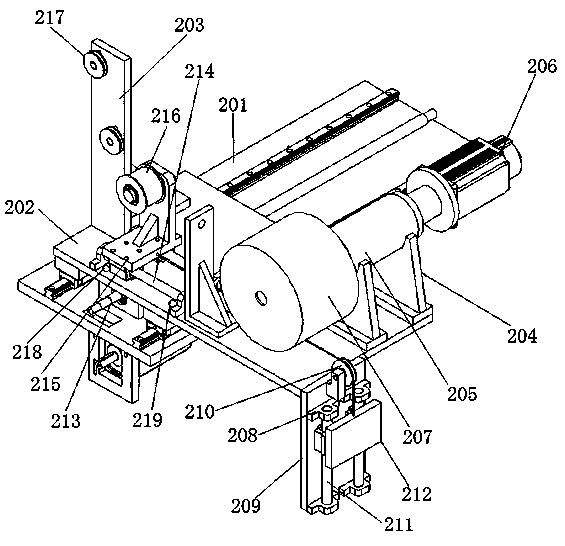

[0018] The wire winding mechanism 2 includes a first base plate 201, a second base plate 202, a reversing wheel mounting plate 203, a first headstock base 204, a first headstock 205, a first servo motor 206, a steel wire cylinder 207 and a A counterweight mechanism 208 with steel wire tightened, the counterweight mechanism 208 includes a support vertical plate 209, a reversing pulley 210, a first light ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com