Tension adjustment device for high-strength fiber laid fabric

A technology of tension adjustment device and high-strength fiber, which is applied in the directions of transportation and packaging, winding strips, and thin material processing, etc., which can solve the problems of uneven gaps between fibers, production quality decline, and uneven fiber gaps, etc., and achieve simple device structure , Guarantee the production quality, and the effect of stable polyethylene fiber tension

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] Below in conjunction with accompanying drawing and specific embodiment the present invention is described in further detail:

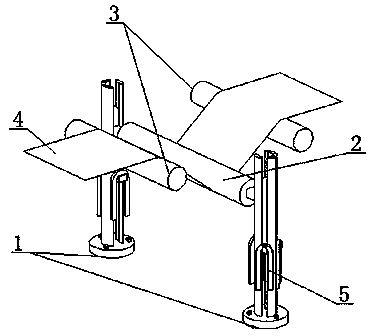

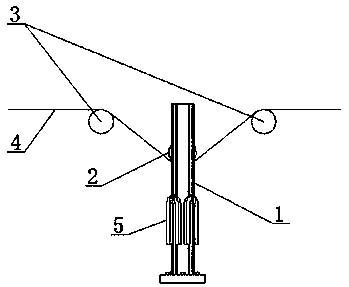

[0023] Such as figure 1 and 2 A high-strength fiber non-weft fabric tension adjustment device shown includes a support 1 and a lower pressure roller 2 that is movably arranged on the support 1. The entire device is arranged between two rollers 201 in the production line, and the support 1 is fixed on the ground. The non-weft fabric fiber 4 passes under the lower pressing roller 2 .

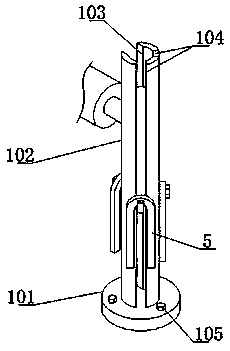

[0024] Such as image 3 and 4 The shown bracket 1 is used to support the whole device. The bracket 1 includes two bases, and the vertical guide tubes 102 are all arranged on the two bases. The guide tubes 102 are hollow round tubes with an open top. The opposite part of the side is provided with a vertical main guide groove 103, and the side of the guide pipe 102 is also provided with two auxiliary guide grooves 104. And open at the top of the guide tube 102 . ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com