Tension adjusting mechanism for copper foil surface treating machine

A technology of surface treatment machine and tension adjustment, which is applied in the direction of thin material processing, coiling, transportation and packaging, etc., which can solve the problem of not being able to meet constant tension at any time, smooth winding and unstable winding tension, which affect the collection of copper foil. Roll quality and other issues, to achieve the effect of simple installation, flexible movement, and easy use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

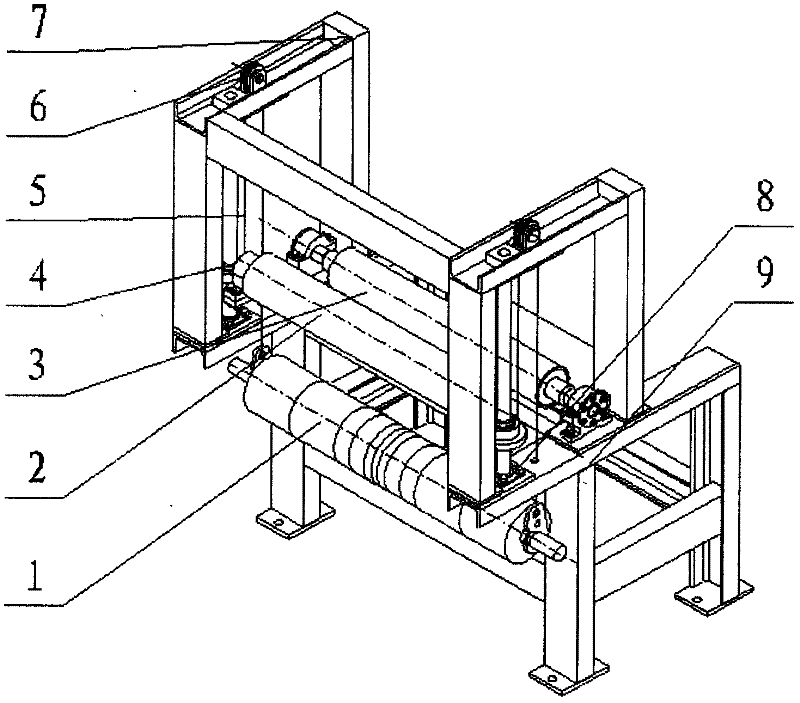

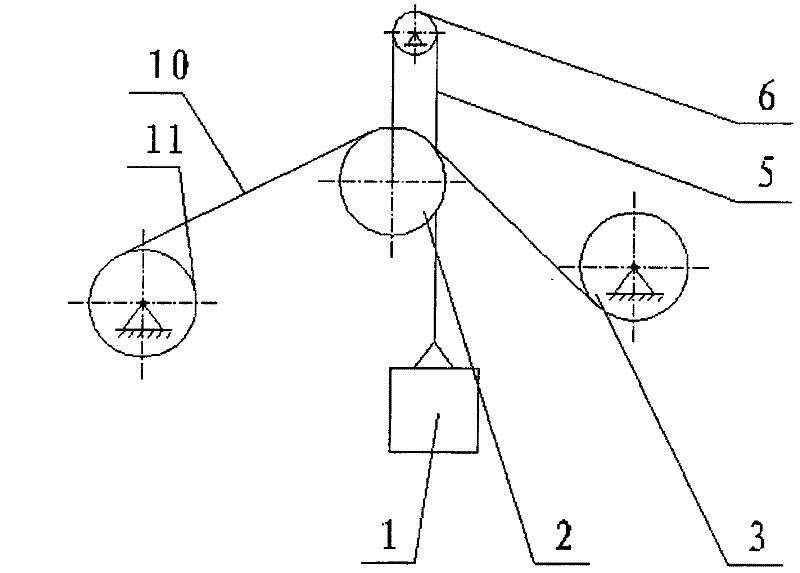

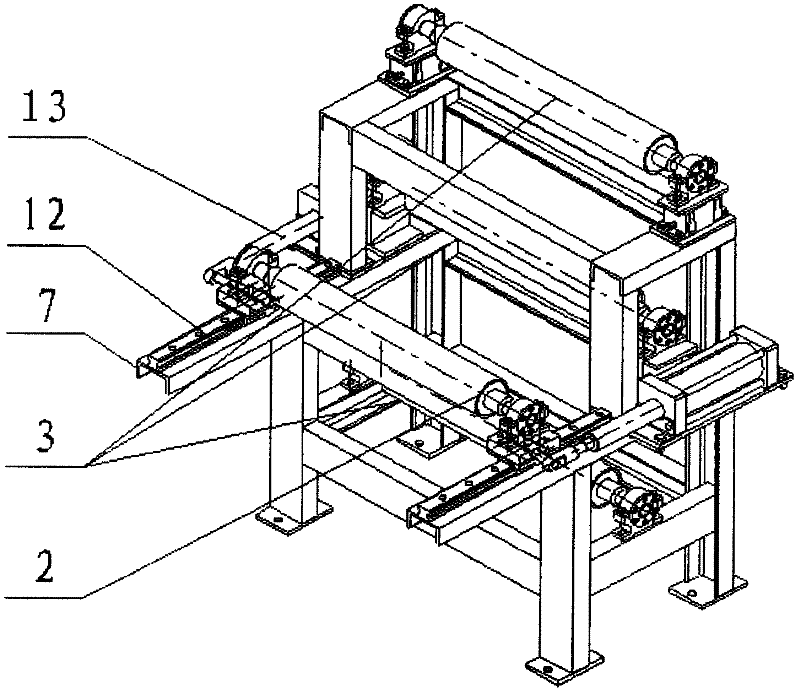

[0047] This embodiment includes a counterweight roller 1, a tension adjustment roller 2, a guide roller 3, a linear bearing pair 4, a steel wire rope 5, a pair of fixed pulleys 6, an upper bracket 7, two pairs of guide rod fixing seats 8 and a lower bracket 9. Both the upper bracket 7 and the lower bracket 9 are frame structures, and the upper bracket 7 is fixed on the upper surface of the lower bracket 9 . The guide roller 3 is installed in the middle of the upper surface of the lower bracket 9; the counterweight roller 1 is located on one side of the tension adjustment roller 2, below the longitudinal beam of the lower bracket 9, and is hung on one end of the steel wire rope 5 through the fixed pulley 6; The other side of heavy roller 1, the top of lower bracket 9 longitudinal beams, is contained on the guide rod holder 8 that is positioned at lower bracket 9 upper surfaces. A pair of fixed pulleys 6 are installed on the fixed pulley fixed plate 27 respectively, and the fixe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com