Portal frame type compound wood processing center

A compound processing center and wood technology, applied in the field of wood processing, can solve the problems of high cost and affecting processing efficiency, and achieve the effects of reducing production costs, improving product manufacturing efficiency, and convenient tool change

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

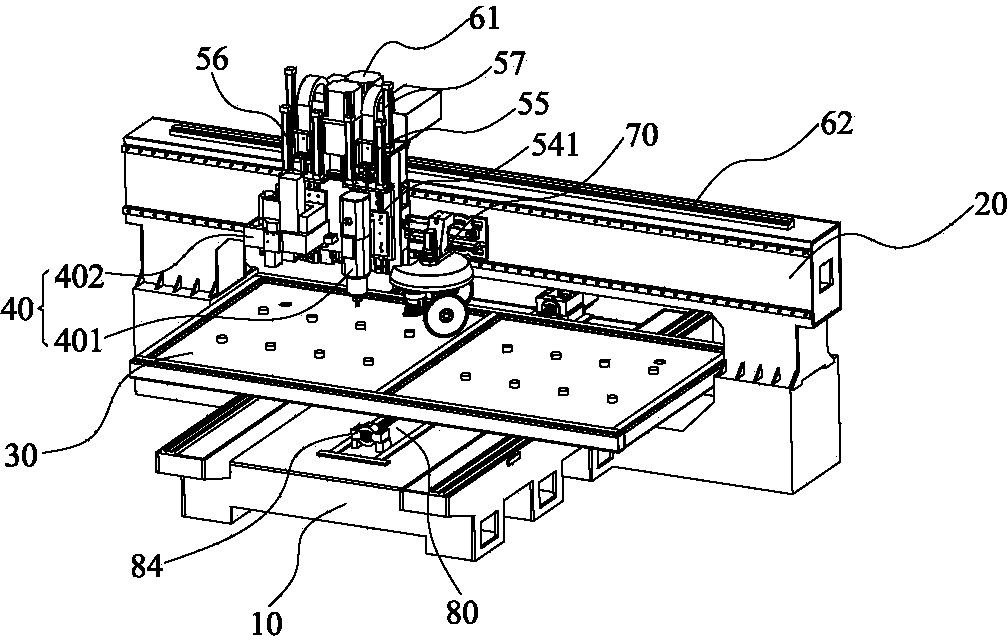

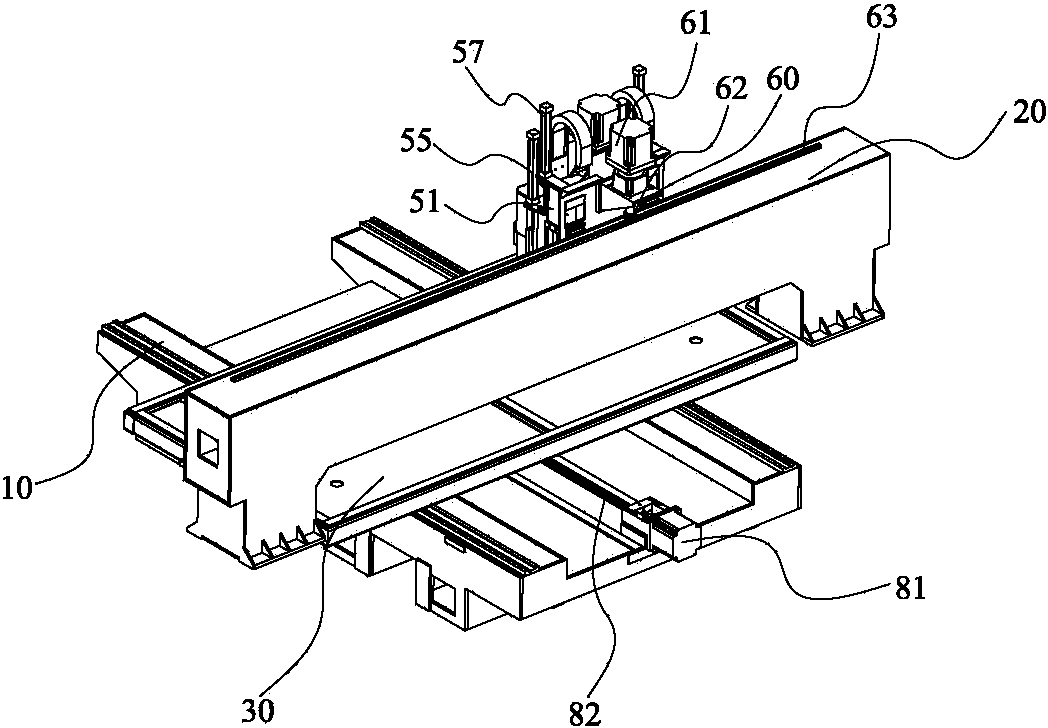

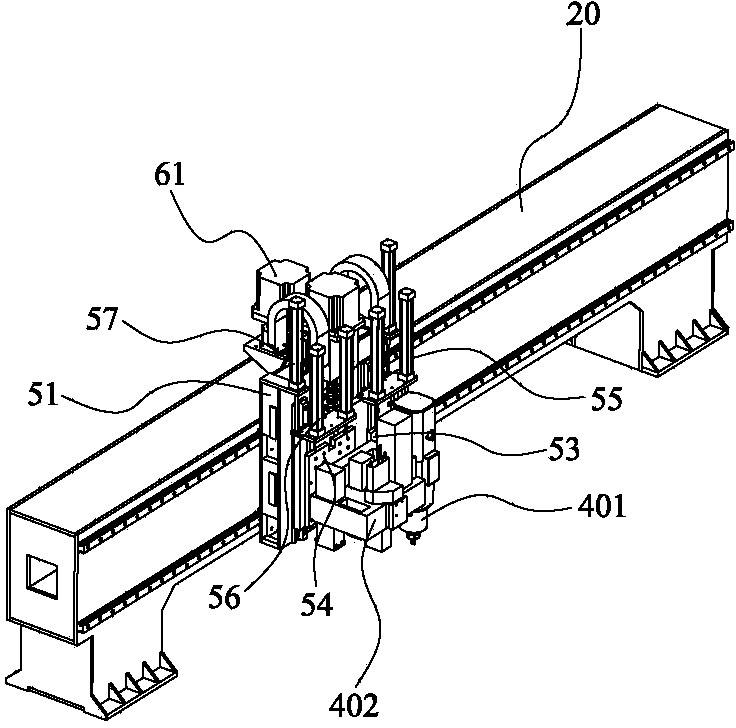

[0066] The present invention as Figure 1 to Figure 12 As shown, a gantry-type wood composite processing center includes a base 10, a beam 20, a workbench 30, a wood processing device 40 installed on the beam 20, a vertical moving device 50 that drives the wood processing device 40 to move up and down, and drives The lateral moving device 60 for the lateral movement of the wood processing device 40 and the tool magazine 70 for changing the tool of the wood processing device 40, wherein,

[0067] The crossbeam 20 is installed across the top of the base 10, and the two ends of the crossbeam 20 are provided with supporting beams extending downward. The internal reinforcement module 23, the reinforcement module 23 includes a second rectangular tube 231 smaller than the first rectangular tube 22 and a support plate 232 extending outward from the walls of the second rectangular tube 231, the top ends of the support plate 232 are respectively welded to The inner wall of the first re...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com