Tensioning and rectifying system of steel belt of plastic film casting machine set

A technology of plastic film and steel belt, applied in the field of tensioning and deviation correction system of steel belt of plastic film casting unit, can solve the problems of high cost, complex system, many detection sensors, etc., to improve consistency, high detection accuracy, Responsive effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

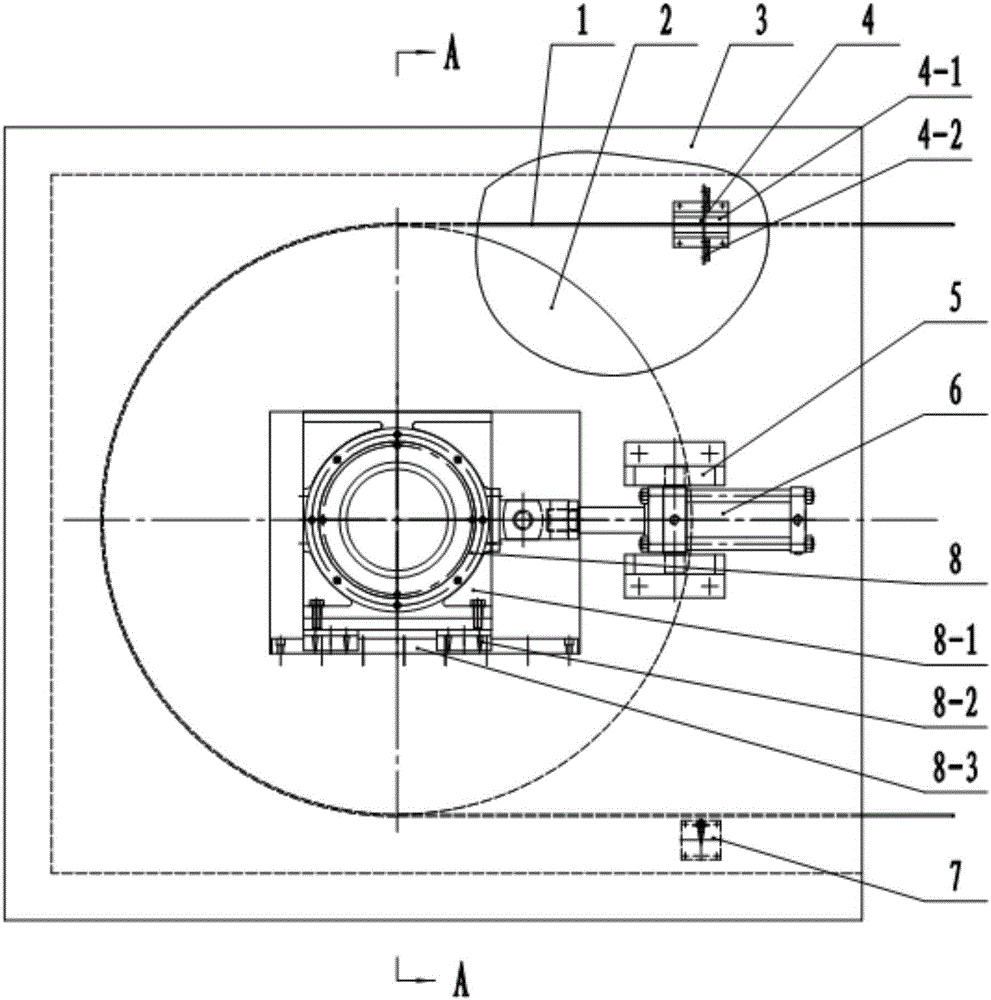

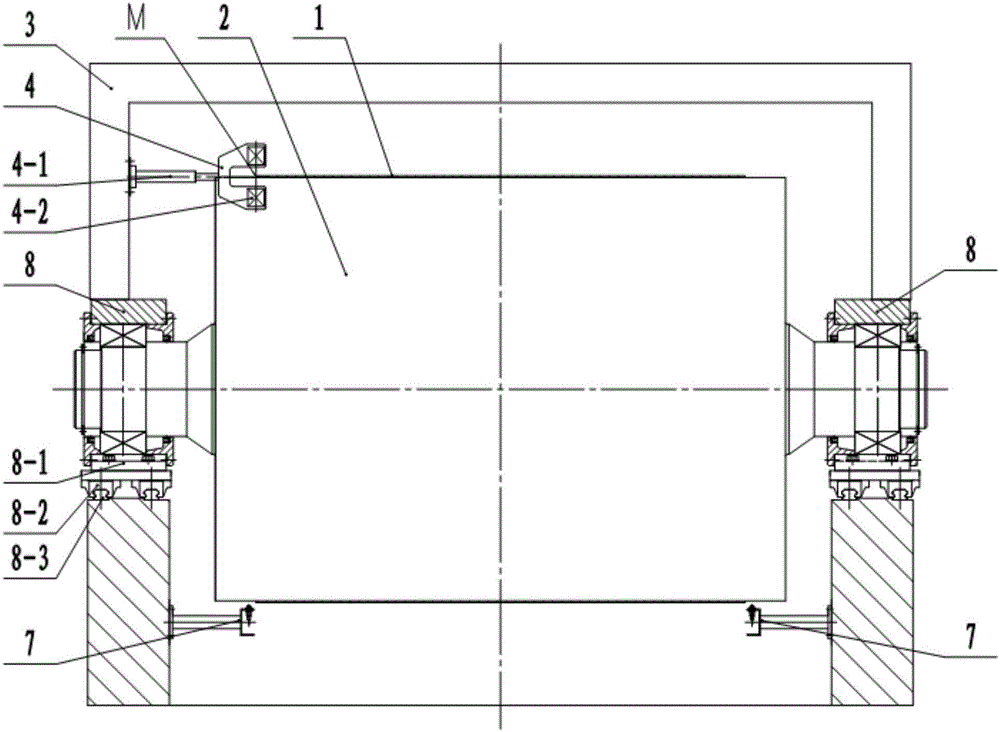

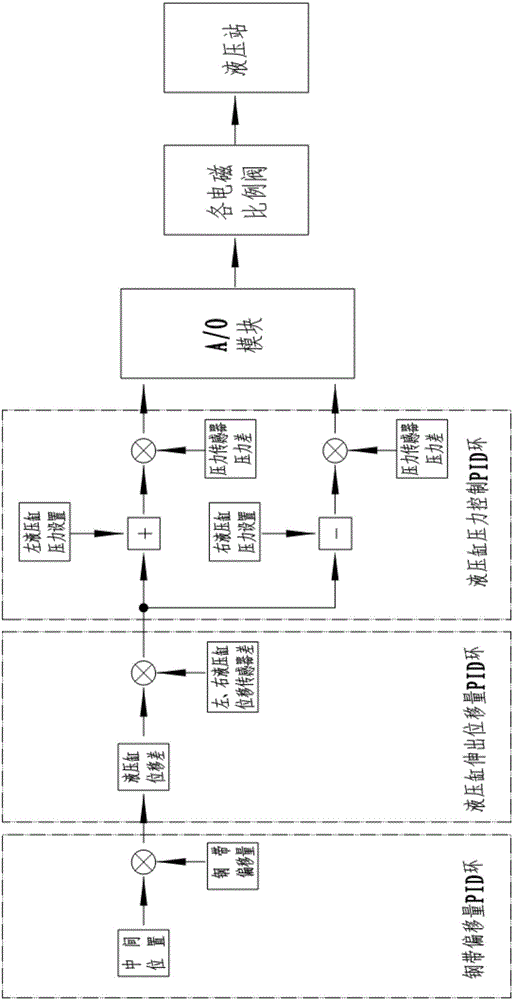

[0026] Example of the correction device for the steel belt of the plastic film casting unit figure 1 , figure 2As shown, it includes steel belt 1, drive roll, tension chill roll 2, machine base 3, hydraulic system and PLC control system; The axial centerlines of the tight cooling rollers 2 are parallel to each other, and the driving rollers are installed on the supporting and fixing seats on the left and right sides, and the supporting and fixing seats are fixed on the machine base 3 . The two shaft ends of the tensioning cold roller 2 are installed on the supporting sliding seats 8 on the left and right sides, and the supporting sliding seats 8 on each side include a bearing seat 8-1, a slider 8-2 and a linear guide rail 8-3, and the supporting sliding seats 8 Above the seat 8 is the bearing seat 8-1, the two shaft ends of the tensioning cold roller 2 are installed in the bearing seat 8-1 through bearings, the linear guide rail 8-3 is installed on the frame 3 of the tape ca...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com