Internally meshed double-screw pump

A twin-screw pump and internal meshing technology, applied in the direction of pumps, pump components, rotary piston pumps, etc., can solve the problems of centrifugal force generated by the rotor, reduce noise and vibration, and expand the scope of application

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

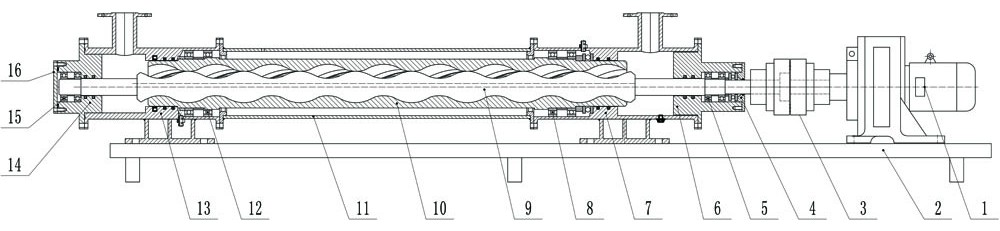

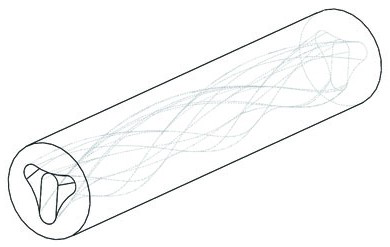

[0024] The present invention is not limited by the following implementation examples, and specific implementation manners can be determined according to the technical solutions of the present invention and actual conditions. Combine below Figure 1-5 The present invention is described below. The positional relationship of up, down, left, right, etc. is based on the attached figure 1 determined by the layout direction.

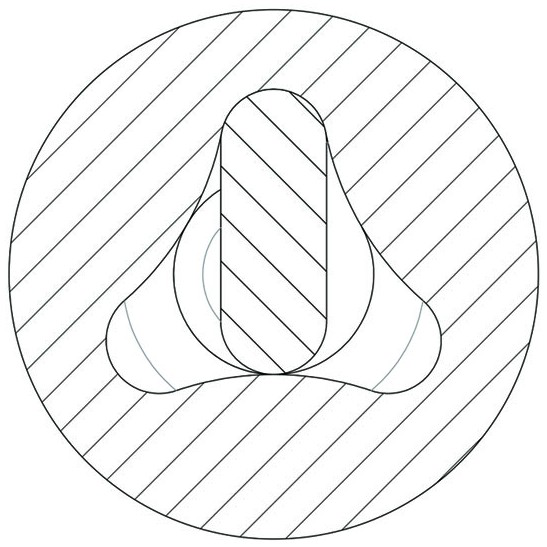

[0025] Such as Figure 1 to Figure 5As shown, an internal meshing twin-screw pump includes a motor 1, a base 2, a coupling 3, a bearing cover I4, an inner bearing group I5, a bearing seat I6, an inlet cavity 7, an outer bearing group I8, an inner rotor 9, Outer rotor 10, outer connecting cylinder 11, outer bearing group II12, outlet cavity 13, bearing housing II14, inner bearing group II15, bearing end cover II16, characterized in that the outer rotor 10 is a rotating body structure, and the inner part is a spiral surface structure The left and right ends o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com