Belt deviation sensor

A sensor and deviation technology, applied in the conveyor control device, conveyor objects, transportation and packaging, etc., can solve the problems of belt deviation wear, inability to obtain deviation data, complex belt deviation, etc., to reduce losses. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

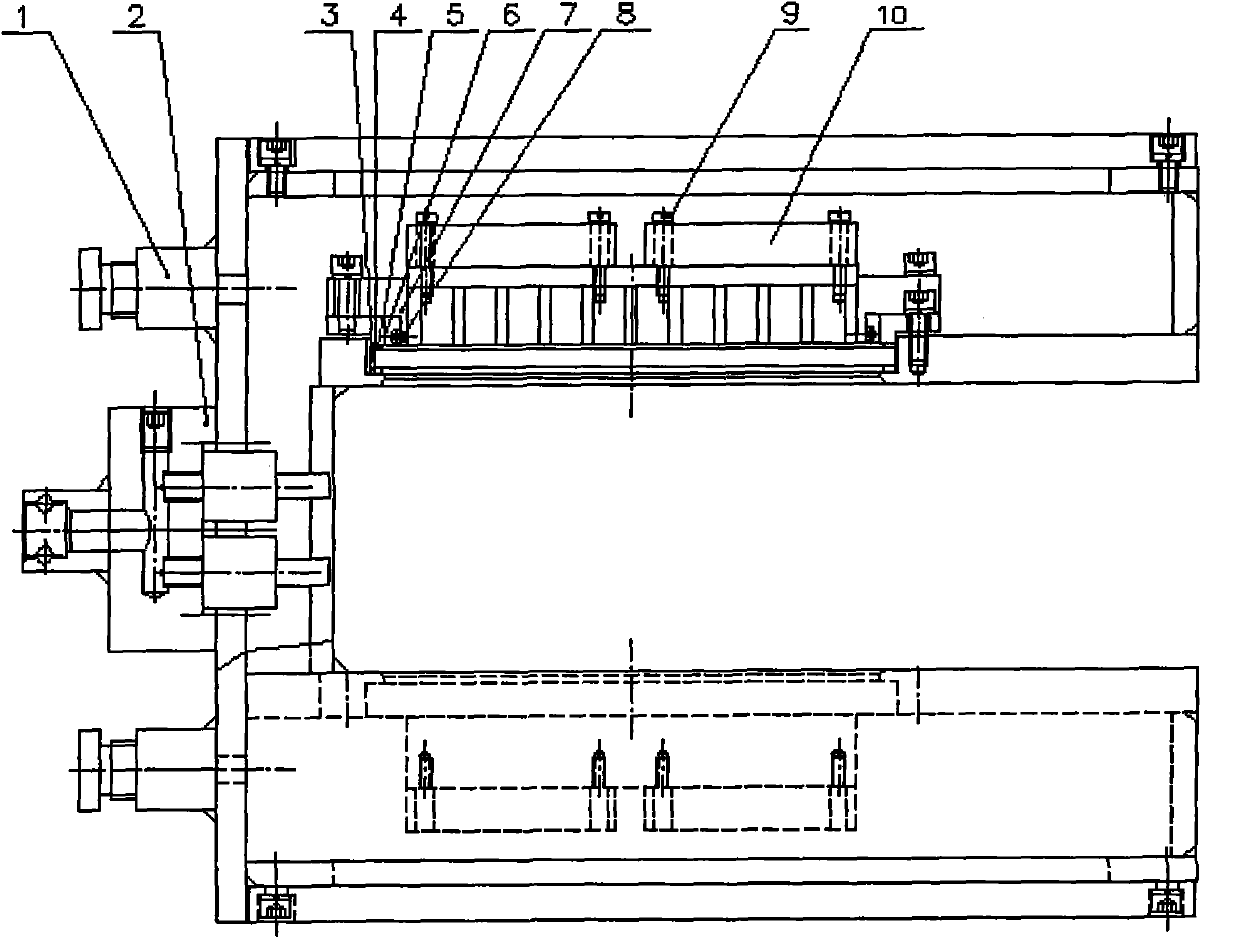

[0012] The following embodiments will further describe the present invention in conjunction with the accompanying drawings.

[0013] Such as figure 1 As shown, a belt deviation sensor includes a box body 1 and a through-beam photoelectric switch 9. The box body 1 is U-shaped, and two sets of photoelectric through-beam switches 9 are installed inside. There is a cleaning component 2 on one side of the box body 1. The cleaning component 2 includes a joint seat and a water nozzle. It is connected to the deviation sensor box through 4 M10*40 screws of GB / T70.1-2000. Two fuel injection nozzles The included angle is 60 °, and the water spray direction is aligned with the upper and lower two windows 3, and the windows 3 adopt a plexiglass plate. The through-beam photoelectric switch 9 is fixed in series with the clamp block 7 through the stud 8, 4 pieces of GB / T70.1-2000M6*20 will install the fixed through-beam photoelectric switch 9 on the gland 6, and then 10 pieces of GB / T70. 1-...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com