Packaging strip

A technology for sealing and wrapping strips, which is applied in the field of packaging and packaging tools after sorting goods in the express delivery industry. It can solve the problems of high risk of pulling back, strong sealing force, troublesome use, etc., to simplify the production process, prevent the seal from pulling back, Use strong and durable effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

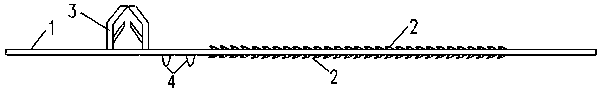

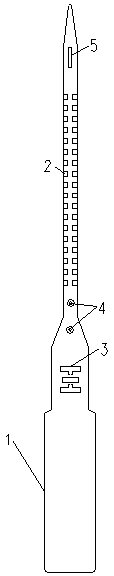

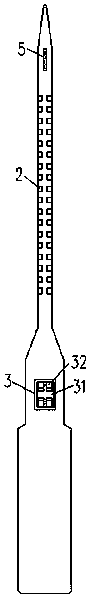

[0014] Such as figure 1 , figure 2 , image 3 and Figure 4 As shown, a package strip includes a plastic lock bar 1, a plurality of rows of anti-return locking teeth 2 are respectively arranged on the upper and lower sides of the plastic locking bar 1, each row is composed of two anti-return locking teeth 2, and one end of the plastic locking bar 1 is provided Lock core 3, two lock tongues 32 are respectively arranged at the front and rear ends of the lock hole 31 of the lock core 3. The lock tongue 32 has a one-way insertion and reverse stuck structure, and there is a plastic lock rod insertion space between the front and rear rows of lock tongues 32 , friction teeth 5 are set on the plastic lock bar 1 at the front part of the lock core 3, and a hanging hole 5 is set at the front end of the plastic lock bar 1.

[0015] The plastic lock rod and lock cylinder of the present invention are injection molded at one time, which simplifies the production process and improves the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com