Method for opening a drafting system

A traction device and roller technology, applied in drafting equipment, textiles, papermaking, spinning machines, etc., can solve the problems of fragile fiber belts and machine stoppages, and achieve the effect of preventing thin spots

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

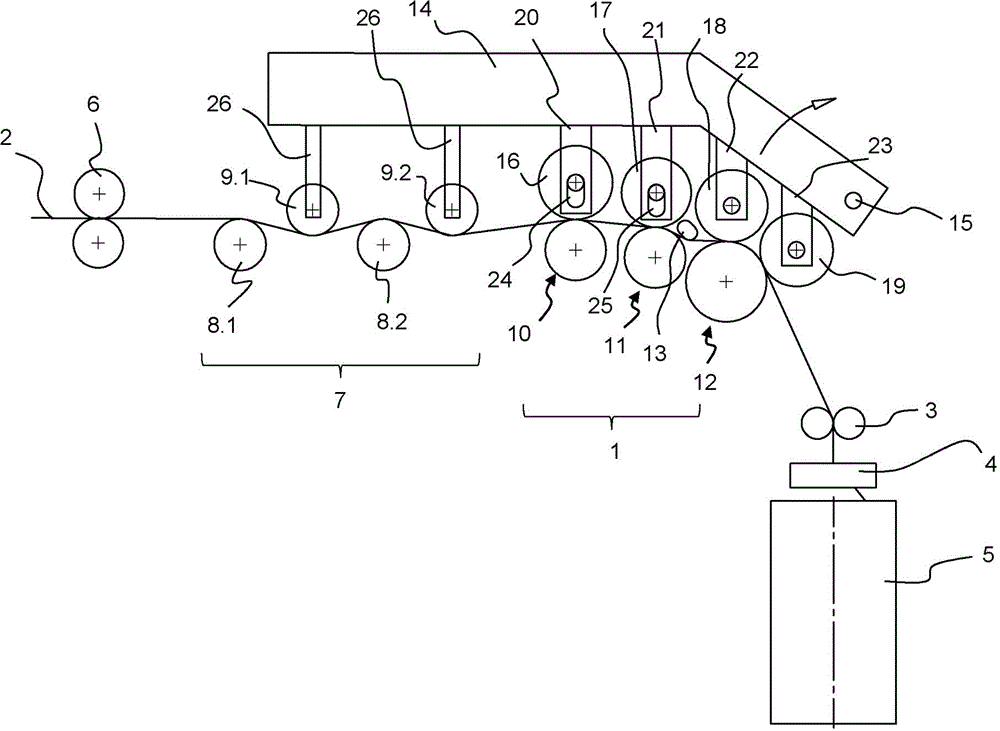

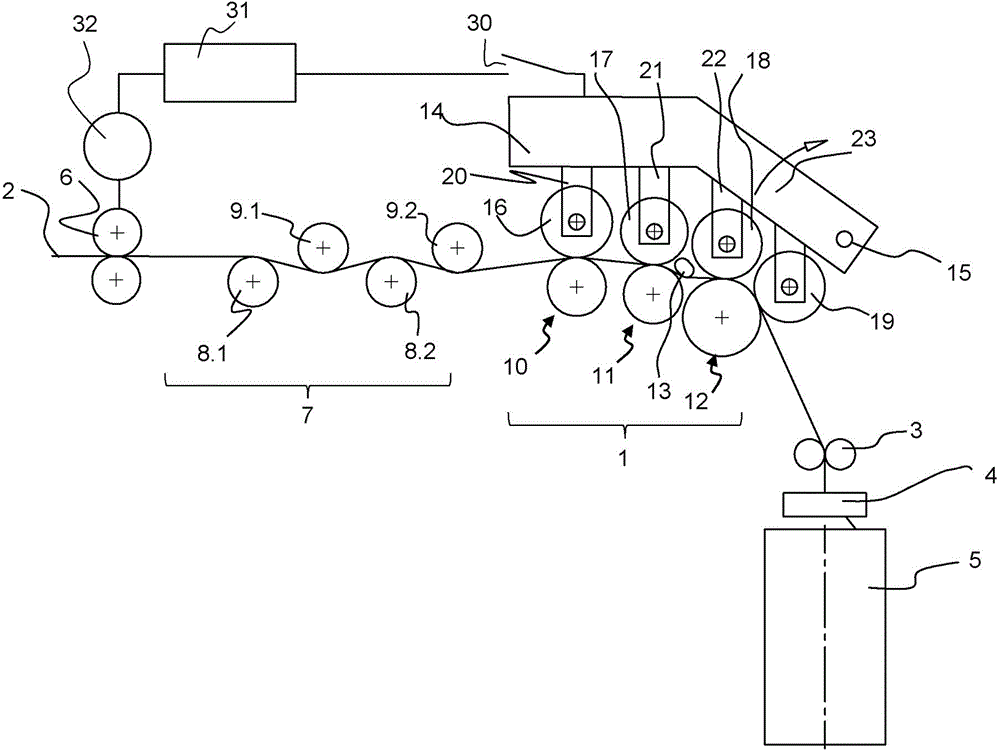

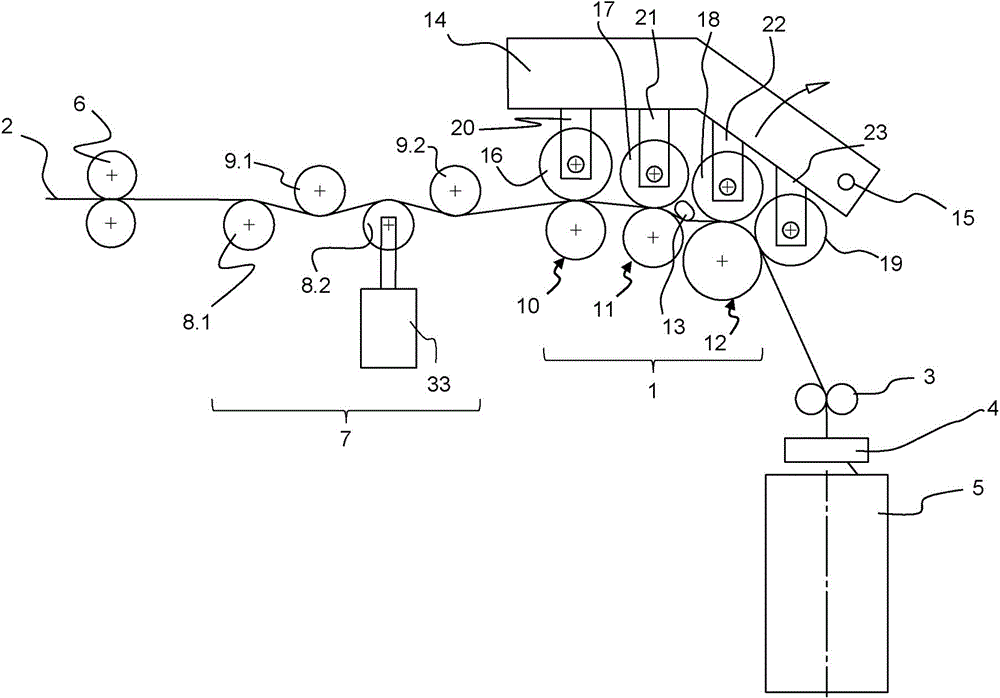

[0030] figure 1 The drawing device 1 is shown diagrammatically, on which there is a stretched fiber belt 2, followed by a pair of calender rollers 3 and a rotating disc 4 placed next to a pot-like device 5. The pair of drive rollers 6 leads the fiber strip 2 to the drawing device 1 . A deflection position 7 is installed between the drive roller pair 6 and the traction device. At the deflection point 7, the fiber strip 2 is deflected wave-like toward the lower deflection points 8.1 and 8.2 and the upper deflection points 9.1 and 9.2. The fiber band 2 is clamped by the drive roller pair 6 and the input roller pair 10 of the traction device 1 respectively. Between the pair of input rollers 10 and the pair of intermediate rollers 11 and between the pair of intermediate rollers 11 and the pair of output rollers 12, the fiber ribbon 2 is stretched in a predetermined form. Between the pair of intermediate rollers 11 and the pair of output rollers 12 is installed a pressure bar 13 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com