Patents

Literature

146results about How to "Solve the clamping problem" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

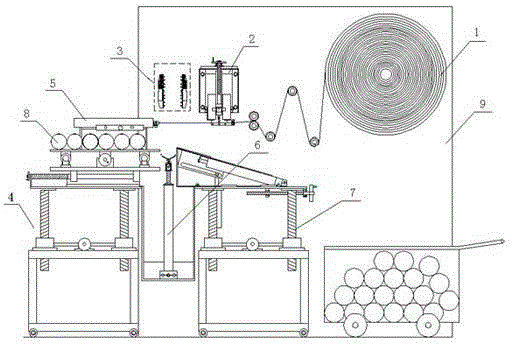

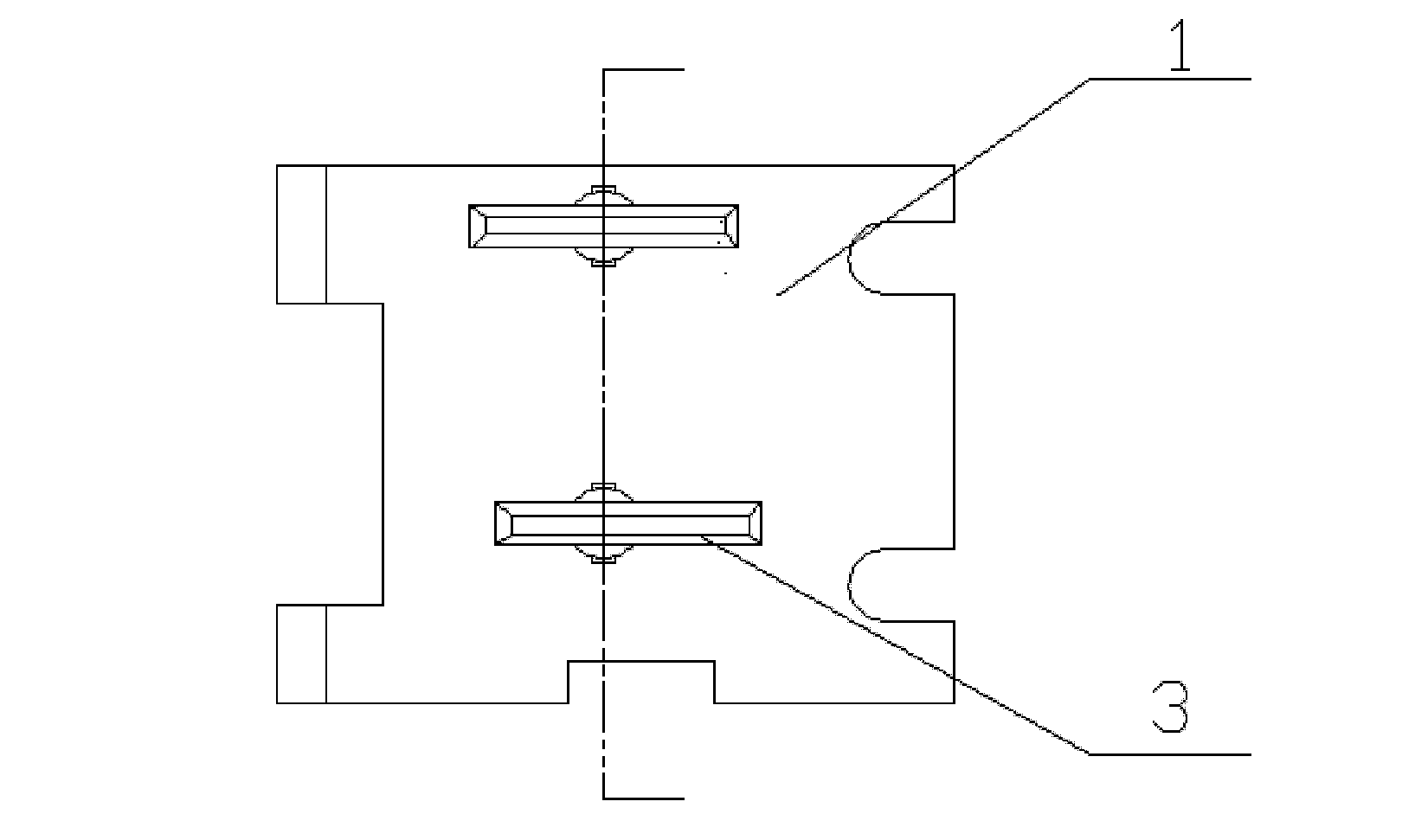

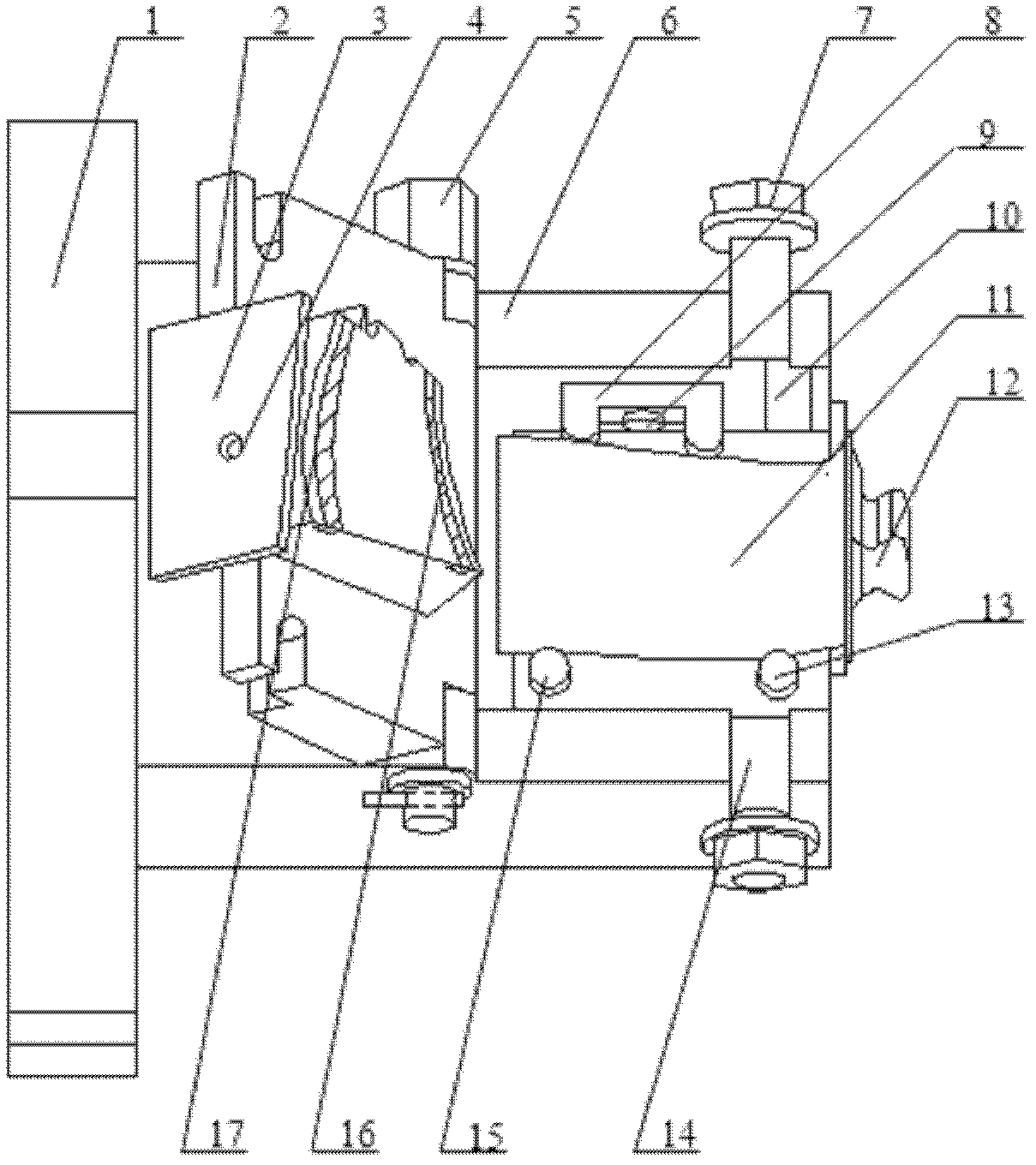

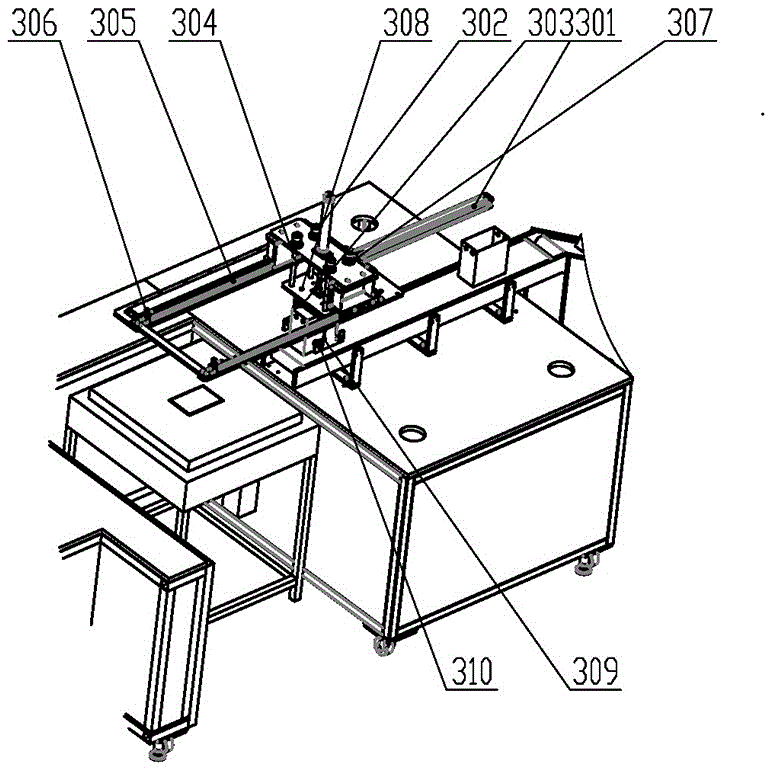

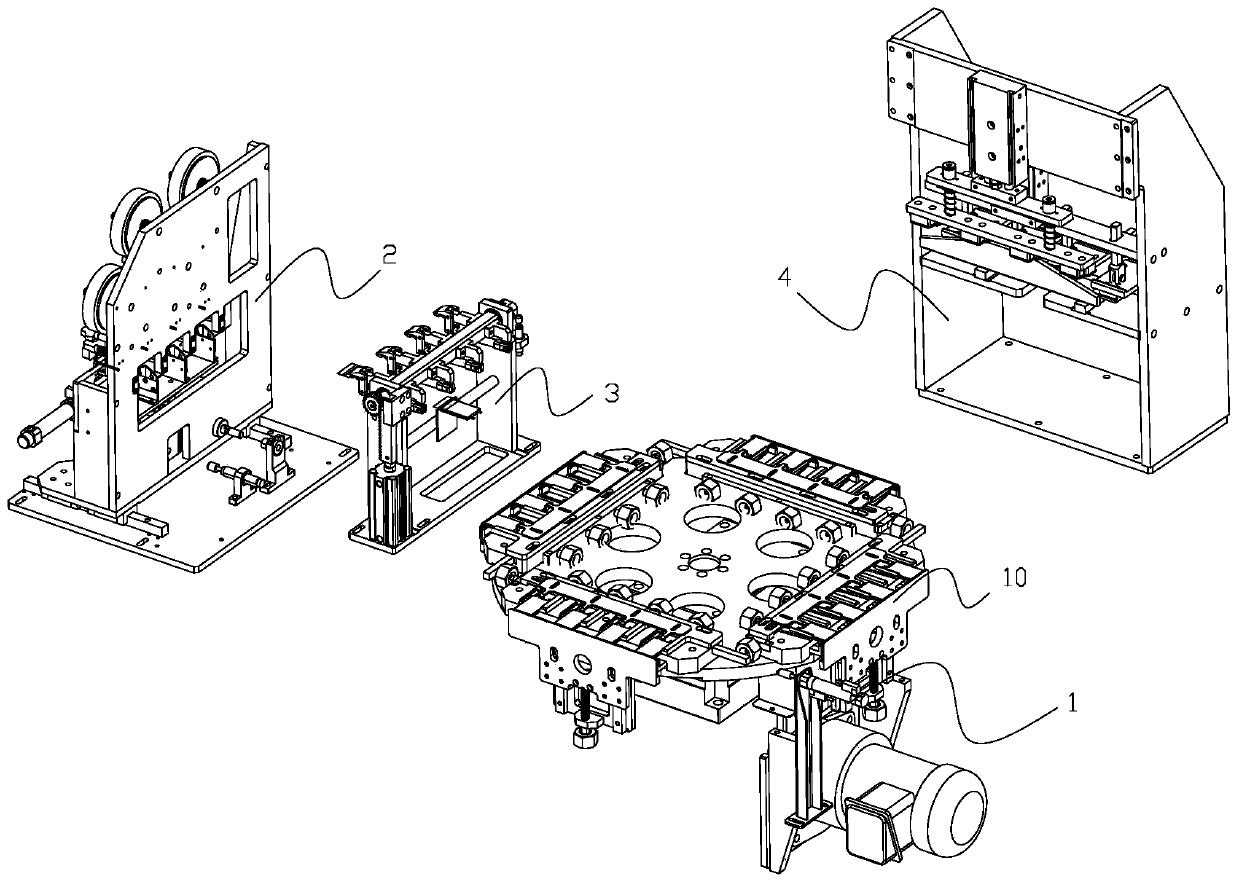

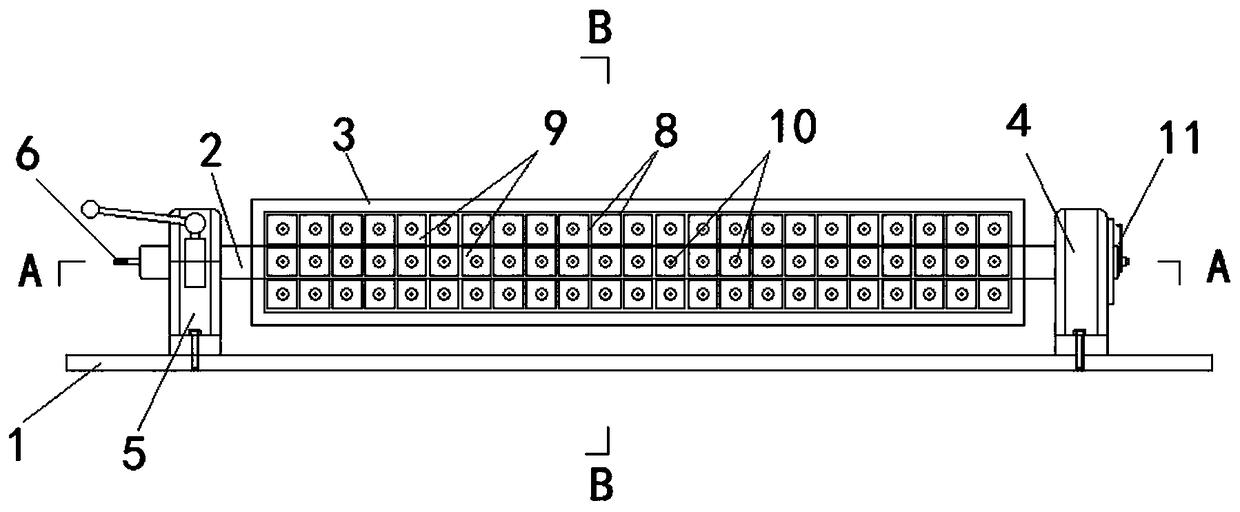

Full-automatic filter element winding machine

ActiveCN104925558AAchieve clampingSolve the thickness of the wallWebs handlingWinding machineAdhesive

The invention relates to a full-automatic filter element winding machine which comprises a filter element paper unreeling mechanism, an adhesive-dispensing cutting mechanism, a clamping drive mechanism, a three-dimensional lifting platform, a filter screen jacking mechanism, an oblique jacking and discharging mechanism and a central control cabinet. A filter paper clamping traction device adjusts the filter element paper position corresponding to the inlet point adhesive-dispensing cutting mechanism and performs filter element paper traction. An adhesive-dispensing of the adhesive-dispensing cutting mechanism performs adhesive dispensing on filter element paper, and the filter element paper is cut off through the cutting device after winding is completed. The filter screen jacking mechanism lifts a filter element screen to the clamping drive mechanism. The clamping drive mechanism is used for clamping the filter element screen and drives the filter element screen to rotate and to be wounded with the filter element paper. The filter element screen completing winding through the clamping drive mechanism drops to the oblique jacking and discharging mechanism and is moved out of a winding machine through the oblique jacking and discharging mechanism. The full-automatic filter element winding machine has a full-automatic multi-azimuth adjusting function, completely replaces manual operation to wind the filter paper on the filter element screen, production efficiency and product quality are improved, and production cost is reduced.

Owner:珠海圣菲玛滤清器有限公司

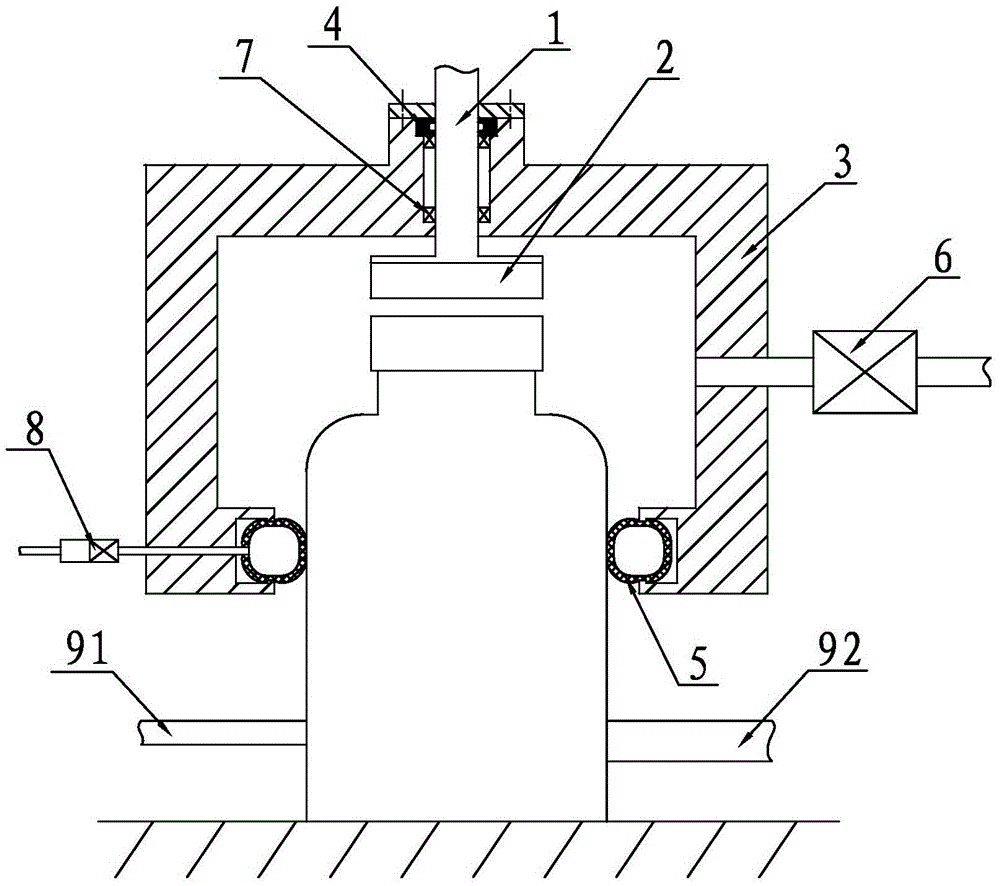

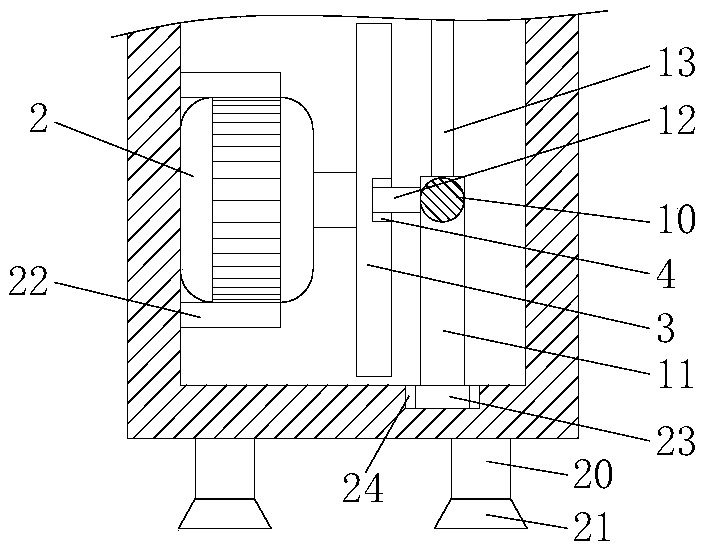

Vacuumizing lid rotating device of hard bottle

PendingCN105564703AAchieve positioningAchieve clampingPackaging under vacuum/special atmosphereEngineeringBottle

The invention discloses a vacuumizing lid rotating device of a hard bottle. The device comprises a lid rotating shaft, a lid rotating head, a vacuum cover, a main shaft sealing ring and an inflation clamping sealing ring; the lid rotating shaft is mounted on the vacuum cover through the main shaft sealing ring; the lid rotating head is fixedly mounted at the lower end of the lid rotating shaft, and is arranged in an inner cavity of the vacuum cover; the inflation clamping sealing ring is peripherally arranged on the side wall of the lower section of the inner cavity of the vacuum cover; the lid rotating head is positioned above the inflation clamping sealing ring; the inflation clamping sealing ring is communicated with a pressure gas source through a pressure gas access control device; and a vacuumizing joint is formed in the vacuum cover above the inflation clamping sealing ring, and is connected with the inner cavity of the vacuum cover and a vacuumizing device. The vacuumizing lid rotating device greatly improves the tightness of the inner cavity of the vacuum cover, largely reduces the vacuumizing energy consumption, shortens the vacuumizing time, is high in production efficiency, is more reliable in clamping of the bottle, and prevents the conditions of fracturing damage of the bottle caused by overhigh inflation pressure and incomplete sealing of a vacuum chamber caused by overlow pressure.

Owner:CHANGZHOU YONGYI PACKAGING TECH

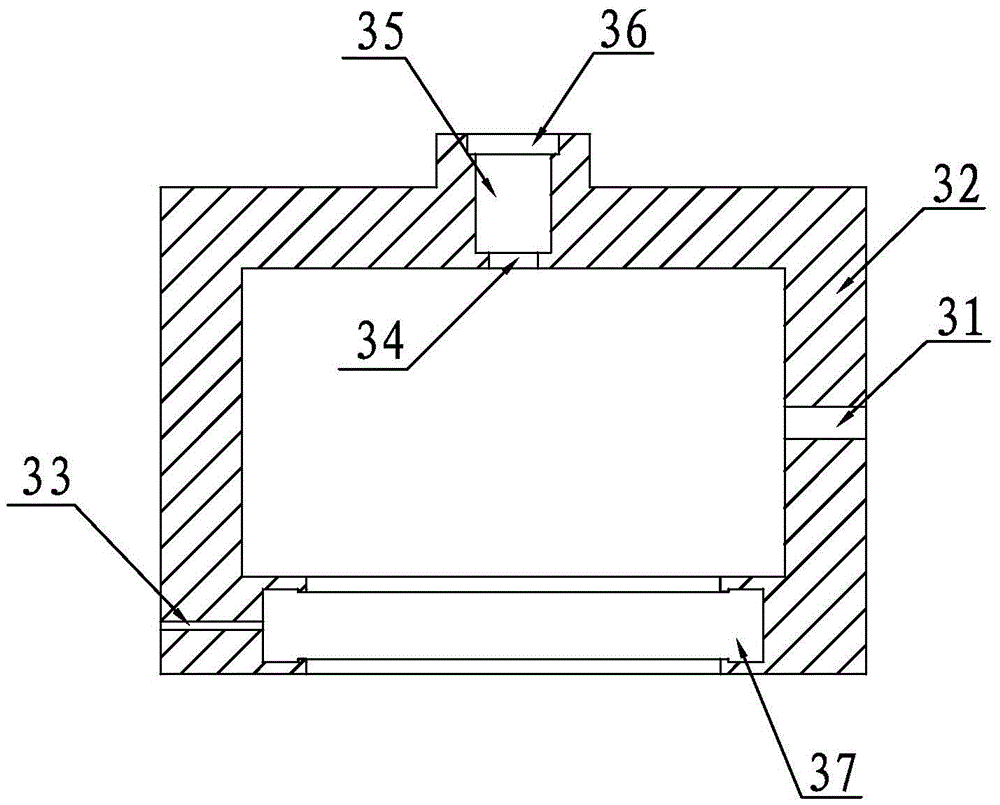

Hydraulic fixture used for machining precision forging blade tenon root

InactiveCN102615534AUniform clamping forceStable clamping forcePositioning apparatusMetal-working holdersAviationEngineering

The invention discloses a hydraulic fixture used for machining a precision forging blade tenon root. The fixture consists of a fixture box cover part in contact with a blade back and a fixture box body part in contact with a blade basin; by transferring pressure of liquid in a hydraulic cavity of the fixture to other parts, a blade is clamped, so that the clamping force applied on the blade is more uniform and stable; when the hydraulic fixture is used for clamping, the blade can be clamped and loosened only by screwing a pressing regulation rod in and out, the operation control is convenient, and the damage to the blade is reduced. According to the hydraulic fixture used for machining the precision forging blade tenon root, the machining efficiency of the blade of an aviation engine can be improved, the machining precision of the blade of the aviation engine is also improved, and the clamping problem brought about when the precision forging blade tenon root is machined is solved; the fixture is simple in structure, convenient to install and high in positioning precision; the positioning precision is not affected even when the hydraulic fixture is dismounted for a plurality of times; and the hydraulic fixture is also applicable to the machining and application of the other types of blades.

Owner:NORTHWESTERN POLYTECHNICAL UNIV

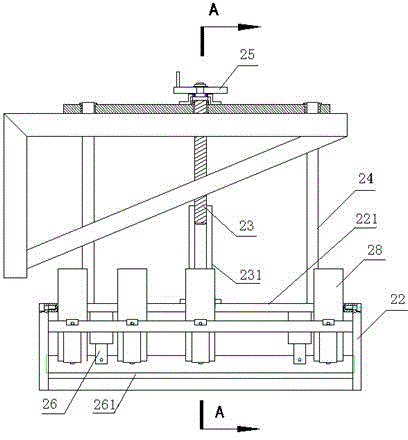

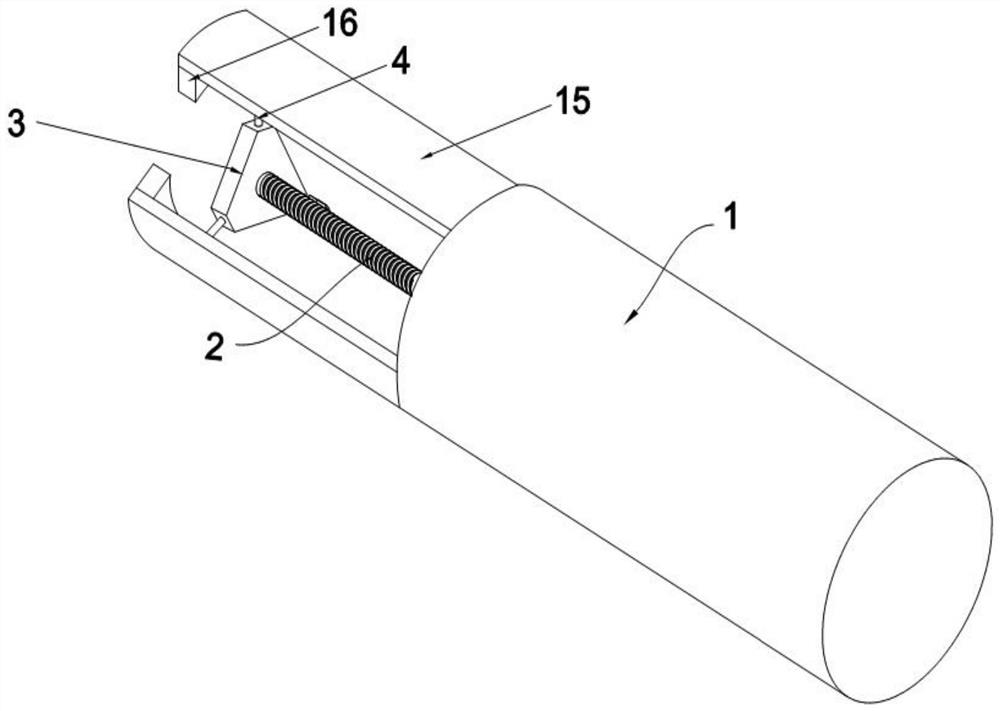

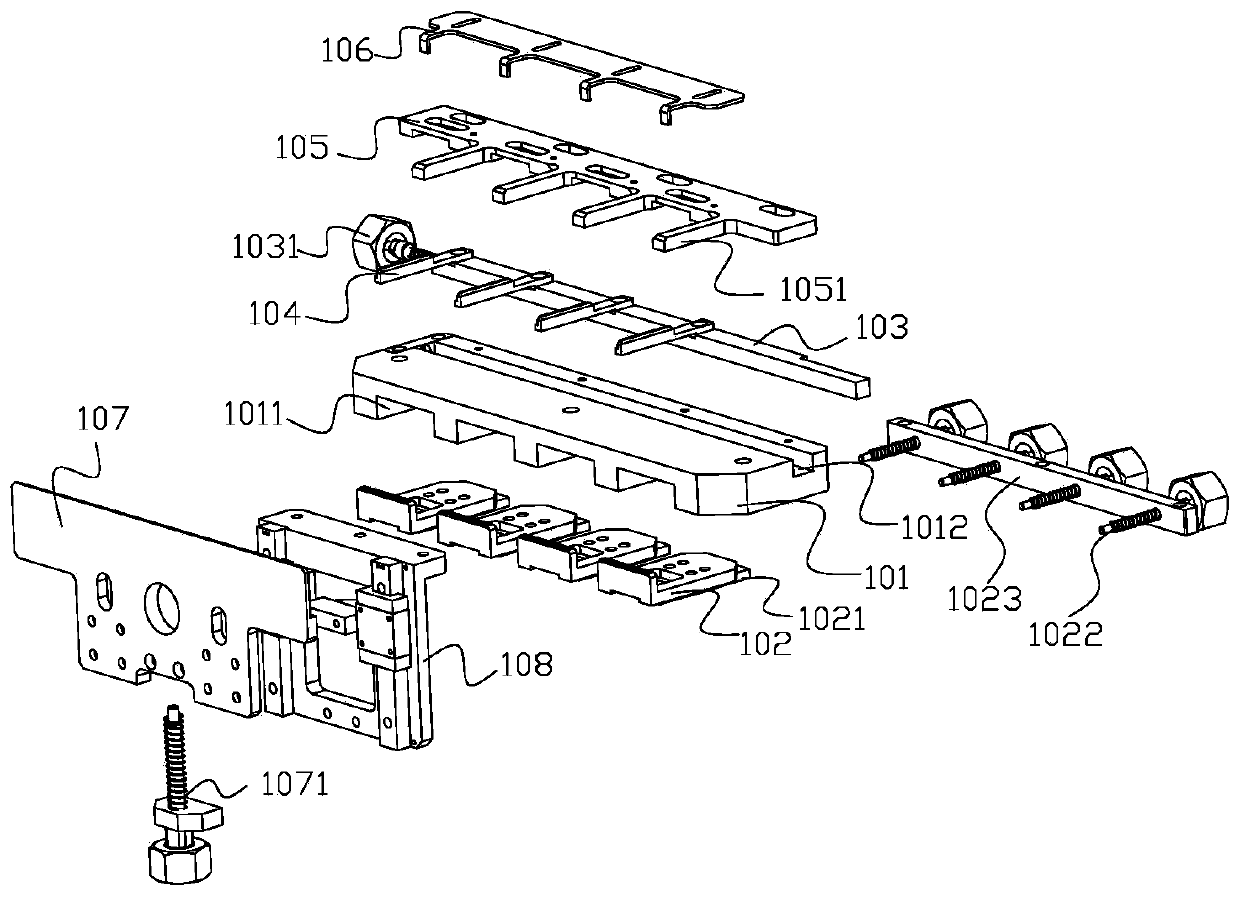

Clamp for shaft parts and clamping device

InactiveCN102049693ASolve the clamping problemIncrease productivityPositioning apparatusMetal-working holdersEngineeringMachining

The invention relates to a clamp for shaft parts, which is characterized by comprising a positioning plate, a sliding block arranged in a sliding groove of the positioning plate, a locking block I matched with the sliding block, a restoring spring for allowing the sliding block to generate restoring force and a workpiece arranged on the positioning plate by a positioning needle, wherein the locking block I allows the sliding block to slide towards both edges to clamp the workpiece on the positioning plate in the locking state; and in the loosening state of the locking block I, the sliding block restores inwards to loosen the workpiece by the restoring force generated by the restoring spring, so that the workpiece is disassembled and replaced. A plurality of sets of clamps are fixedly arranged on a positioning base of the clamping device, so that the problems of the positioning and clamping of the shaft parts with the diameters of between 1.5 and 10 millimeters are solved effectively; and the machining, assembly or disassembly can be performed simultaneously on the clamp, and the clamp has high production efficiency, accurate positioning, firm clamping and a simple and practical structure, and is suitable for batch production.

Owner:福昌精密制品(深圳)有限公司

Resin pressing curved surface numerical control machining clamp for performing precision forging on blade tenon root

InactiveCN102632410AAvoid deformationHigh positioning accuracyPositioning apparatusMetal-working holdersNumerical controlEngineering

The invention discloses a resin pressing curved surface numerical control machining clamp for performing precision forging on a blade tenon root. A clamp box cover is connected with a clamp box body through an eccentric pin shaft; parts of the clamp box body and the clamp box cover, which are contacted with a blade back, a blade basin and the tenon root, are made of resin materials, so that a blade can bear impact and vibration which are caused by a cutting force of a cutter during machining, and the blade can be machined stably and is deformed difficultly; and the positioning precision is improved. According to the clamp, the efficiency of machining an aircraft engine blade is improved, and the machining precision of the clamp can be improved, so that the problem about clamping during blade tenon root precision forging is solved. The clamp has a simple structure and is convenient to mount and high in positioning precision; and the clamp can be assembled and disassembled frequently without influencing the positioning precision. The clamp is used for machining the tenon root of the aircraft engine blade and tenon roots of similar thin wall blades, such as a working blade of a gas turbine, a guide blade and the like.

Owner:NORTHWESTERN POLYTECHNICAL UNIV

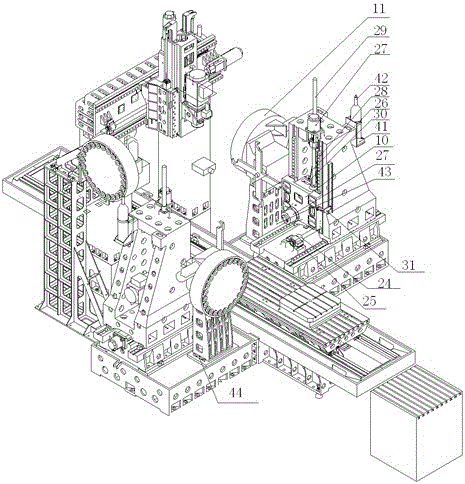

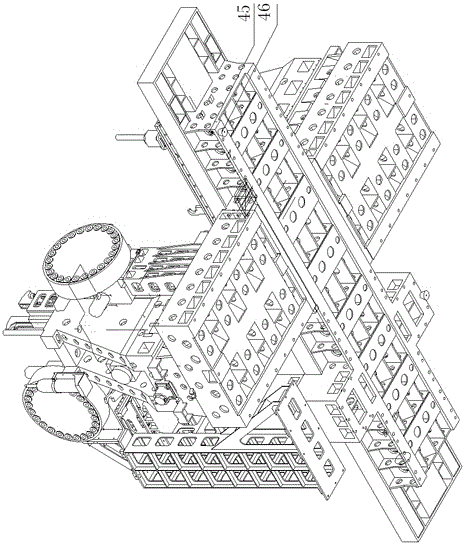

Composite flexible manufacturing unit

ActiveCN106625030ACompact structureSmall footprintFeeding apparatusLarge fixed membersNumerical controlCommon base

The invention relates to numerically-controlled machine tools, in particular to a composite flexible manufacturing unit, and mainly aims to solve the technical problems that an existing flexible manufacturing unit is large in floor space and high in investment, large and medium key part machining is large in error due to multiple clamping and multiple positioning, low in machining precision and small in application range, and the like in the prior art. The composite flexible manufacturing unit comprises a flexible manufacturing unit base and is characterized in that at least one gantry machining center, at least one horizontal machining center, at least one vertical machining center base, at least one machine tool body, at least one saddle, at least one standing column and at least one spindle box are connected to the flexible manufacturing unit base. The flexible manufacturing unit is provided with a common base and a common working table which formed by the machining centers, a common flexible clamp and a common central control device, a conveying device is arranged outside the flexible manufacturing unit, the base is connected with the gantry machining centers and the horizontal machining centers composited to the same machine tool, and all of or part of the vertical machining centers are provided with tool magazines.

Owner:HANGZHOU DATIAN CNC MACHINE TOOL

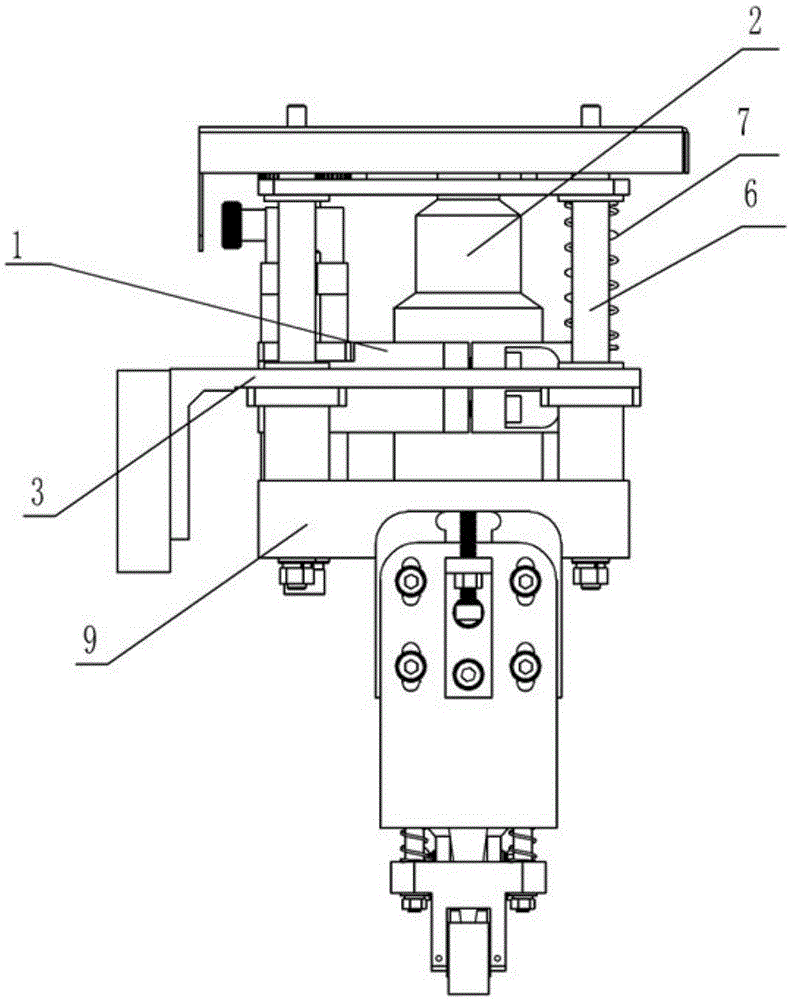

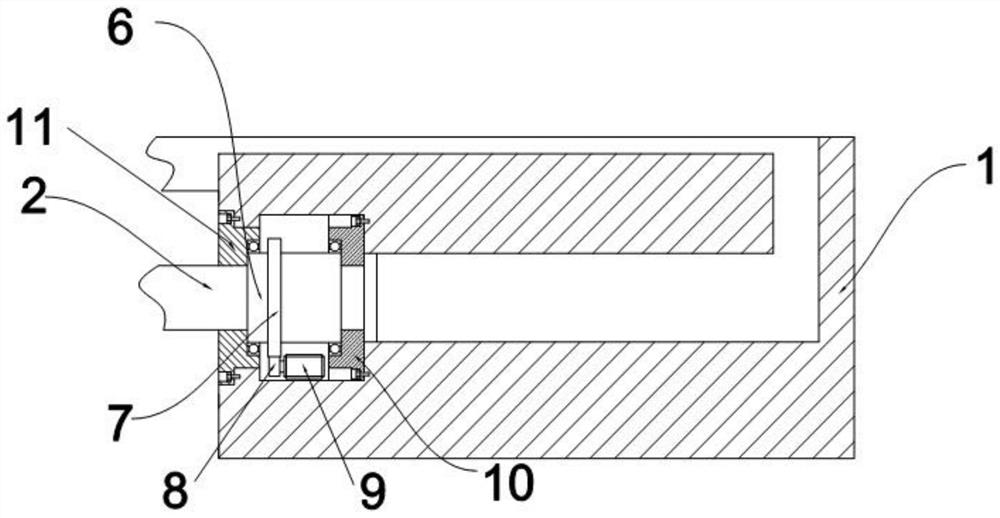

Novel multifunctional fixed defocusing amount laser welding head

InactiveCN105537767ASolve the clamping problemSimple structureLaser beam welding apparatusSurface mountingLaser

The invention discloses a novel multifunctional fixed defocusing amount laser welding head which comprises a follow-up mechanism, a welding lens and a base. A connection plate is mounted below the base, the two sides of the connection plate are symmetrically and fixedly provided with two guide rods, the guide rods penetrate through mounting holes in the base to be connected with the connection plate, the portions, above the base, of the guide rods are sleeved with elastic elements, the upper surface of the connection plate is fixedly provided with a height adjusting mechanism for adjusting the welding lens, the welding lens is mounted on the height adjusting mechanism, and the lower surface of the connection plate is provided with a contact support and a contact. According to the novel multifunctional fixed defocusing amount laser welding head, the contact tightly presses upper parts to be welded on lower parts at the welding position point by point, the problem of clamping the parts is solved conveniently, welding quality is guaranteed, the structure of a clamp is simplified, operation is simple, flattening, pressing and welding of the parts on the upper surface of the contact are completed in the moving process, and welding efficiency is improved.

Owner:武汉市楚源光电有限公司

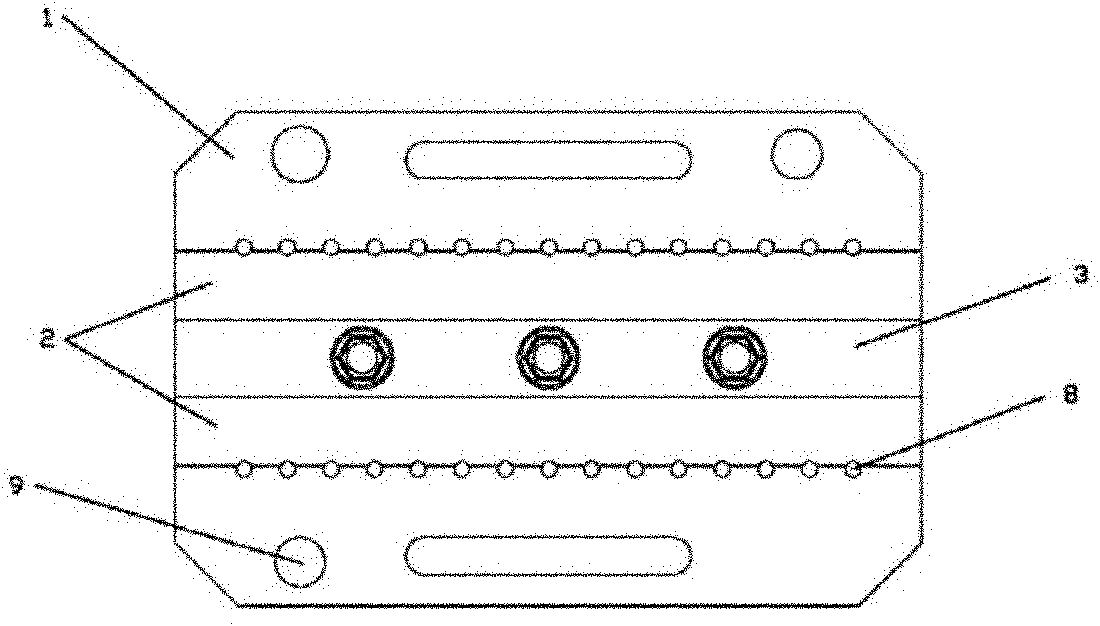

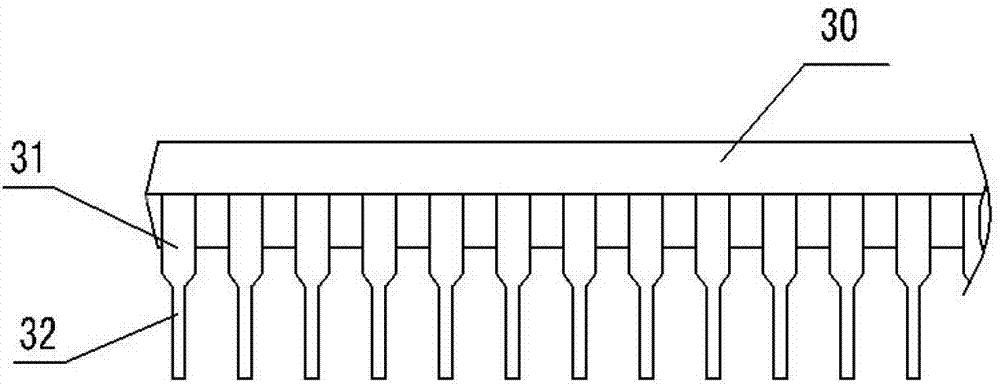

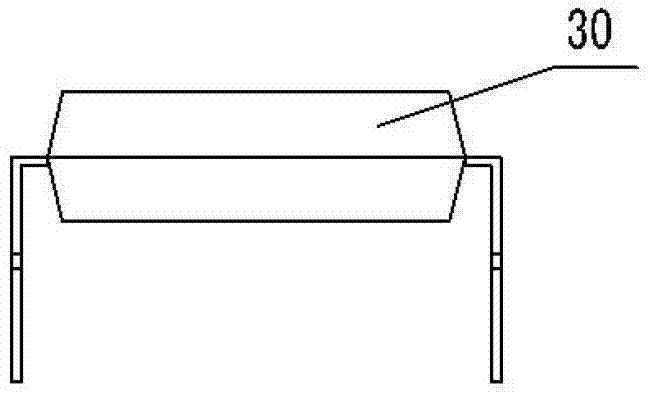

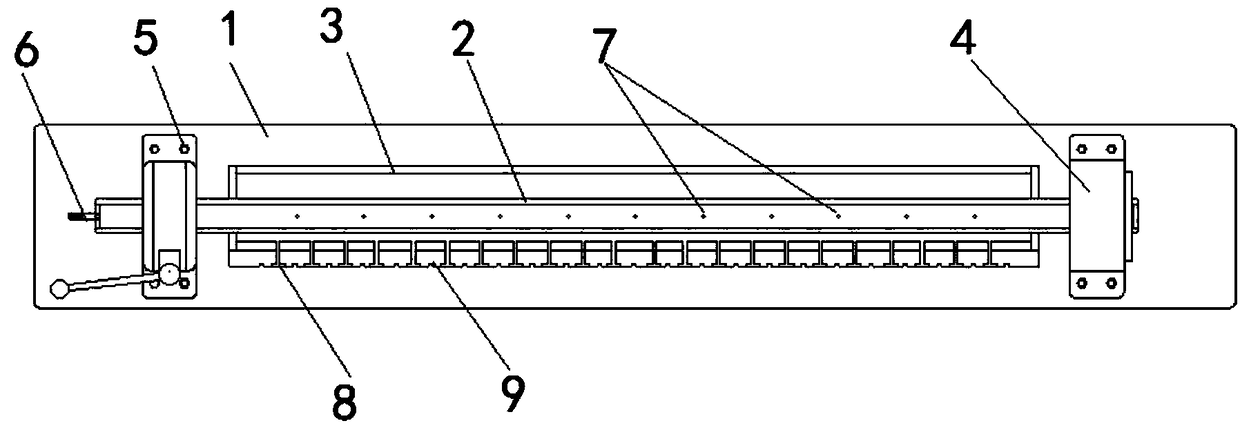

Pin trimming device based on recycled DIP (dual in-line package) type IC (integrated circuit) chip

InactiveCN102856237ASolving Pin Coplanar Trim IssuesSolve the bendSemiconductor/solid-state device manufacturingIntegrated circuit layoutPhotonic integrated circuit

The invention discloses a pin trimming device based on recycled DIP (dual in-line package) type IC (integrated circuit) chip. The pin trimming device is characterized by comprising a pin coplane trimming unit, a pin tooth root trimming unit, a pin prong trimming unit and a pin finishing unit. Based on the device disclosed by the invention, the DIP type IC chip can be efficiently, accurately, economically and practically recycled through the pin coplane trimming, the pin tooth root trimming, the pin prong trimming and the pin finishing in sequence.

Owner:HEFEI UNIV OF TECH

Machining technology for rotary blade type hydraulic steering gear

InactiveCN101537569AImprove consistencyReduce manufacturing costOther manufacturing equipments/toolsEngineeringCopper

The invention relates to the machining technology for a steering gear, in particular to the machining technology for a rotary blade type hydraulic steering gear, comprising a machining procedure for an inside hole of a cylinder body and a sealing surface at the lower end of the cylinder body, a machining procedure for a sealing groove on the sealing surface at the lower end of the cylinder body, a machining procedure for appearance of a stationary blade and a machining procedure for the stationary blade and a connecting hole of the cylinder body, a combination machining procedure for the cylinder body, the stationary blade and a copper sleeve, a machining procedure for an inside conical hole of a rotor and a machining procedure for an incomplete arc surface of the rotor. The machining procedures of the invention can greatly improve the machining accuracy and efficiency of each main part of the rotary blade type hydraulic steering gear, lower the production cost, as well as improve the working efficiency and the product quality.

Owner:CSSC NANJING LUZHOU MACHINE

Filter screen cutting machine for sewage treatment

InactiveCN108858373ASolve the problem that the filter screens of different sizes cannot be clampedSolve the clamping problemMetal working apparatusArchitectural engineeringSewage treatment

The invention discloses a filter screen cutting machine for sewage treatment. The filter screen cutting machine comprises a workbench, wherein the left side of the workbench is fixedly connected withan equipment box, the left side of an inner cavity of the equipment box is fixedly connected with a motor, the right end of an output end of the motor is fixedly connected with a first rotating rod, and the right side of the first rotating rod penetrates through the equipment box and the workbench in sequence and extends to an inner cavity of the workbench and is sleeved with a driving wheel. Thefilter screen cutting machine for the sewage treatment solves the problem that an existing filter screen cutting machine cannot clamp filter screens with different sizes through the arrangement and cooperative use of the workbench, a belt, the first rotating rod, the motor, the equipment box, the driving wheel, a threaded sleeve, supporting rods, a mounting plate, a cutting device, supporting legs, a forward threaded rod, an inverse threaded rod, a second rotating rod, a driven wheel, an opening, fixing rods, grips, a pull rod, a limiting box, a spring, a limiting plate, a telescopic rod, a fixing plate, a placement plate and a connecting block.

Owner:宋胜利

Machining and positioning method for anti-deformation thin-wall pipe fitting

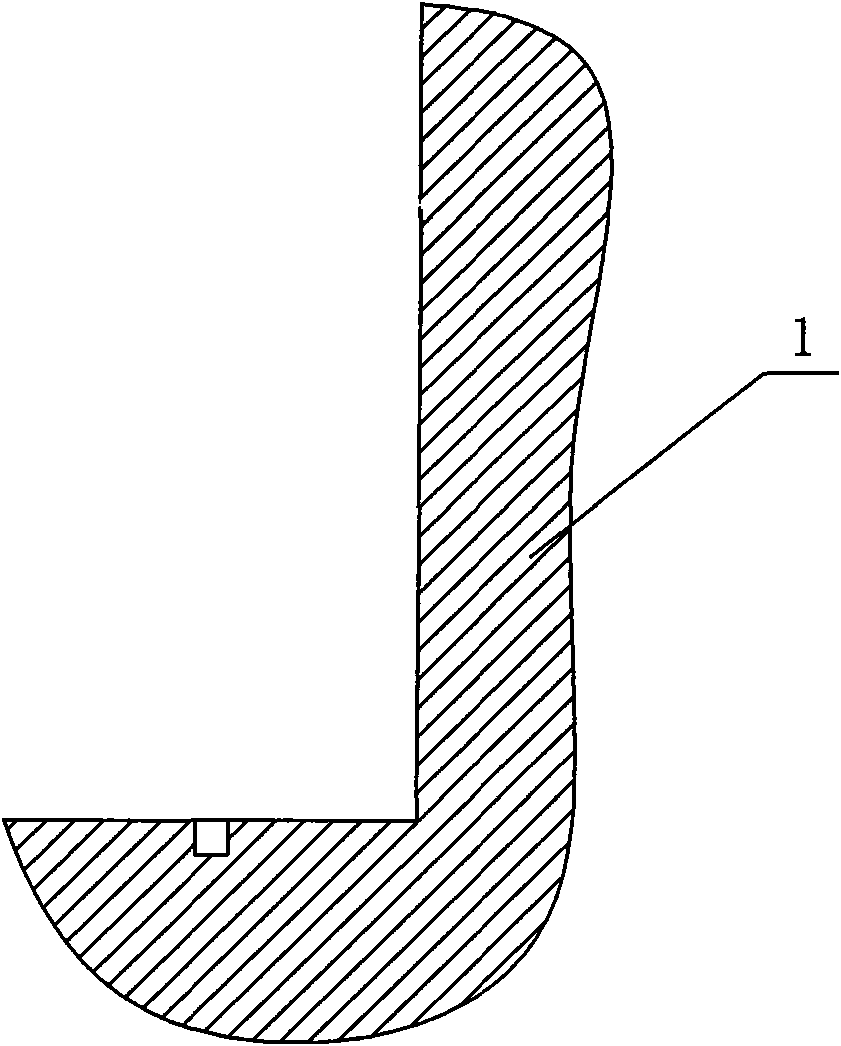

ActiveCN112846851ASolve the clamping problemPracticalPositioning apparatusMetal-working holdersPipe fittingClassical mechanics

The invention discloses a machining and positioning method for an anti-deformation thin-wall pipe fitting. The inner part and the outer part of the thin-wall pipe fitting are supported when the thin-wall pipe fitting is machined, the clamping force is guaranteed through the magnetic connection of an electromagnet and a permanent magnet so that the supporting force of the permanent magnet to the inner part of the thin-wall pipe fitting is counteracted with the supporting force of an electric telescopic rod to the outer part of the thin-wall pipe fitting, coaxial clamping of the device and the thin-wall pipe fitting is achieved, deformation of the pipe fitting during machining is avoided, and the product precision and the qualified rate after machining are guaranteed.

Owner:山东华舜重工集团有限公司

Cam clamping device

InactiveCN103111859ASolve the clamping problemPositioning apparatusMetal-working holdersEngineeringCam

The invention discloses a cam clamping device which comprises a clamping device, a force applying device and a reset device. The clamping device comprises an elastic clamping sleeve and a clamping jaw, wherein the elastic clamping sleeve clamps workpieces from the inner portion, and the clamping jaw clamps the workpieces from the outer portion. An extruding sleeve is arranged at the outer portion of the elastic clamping sleeve. The force applying device comprises a force applying handle which is fixedly connected with a cam. The elastic clamping sleeve is connected with the inner side of the cam in a threaded mode. The outer side of the cam contacts with a drive end of the clamping jaw. The clamping jaw is fixed on a support through a hinge joint point. A driven end of the clamping jaw is a clamping head of a clamping workpiece. A reset spring of the clamping jaw is arranged on the support. The force applying handle is rotated to enable the ram to rotate. The elastic clamping sleeve is connected with the inner side of the cam in the threaded mode to drive the elastic clamping sleeve to move down. Due to the fact that the extruding sleeve is arranged at the outer portion of the elastic clamping sleeve, the elastic clamping sleeve clamps the workpieces from the inner portion. Meanwhile, the outer side of the cam contacts with the drive end of the clamping jaw to drive the clamping jaw to clamp the workpieces from the outer portion, and thereby the workpieces are achieved to be clamped from the inner portion and the outer portion through the cam.

Owner:CHONGQING MING SHIELD ELECTROMAGNETIC VALVE

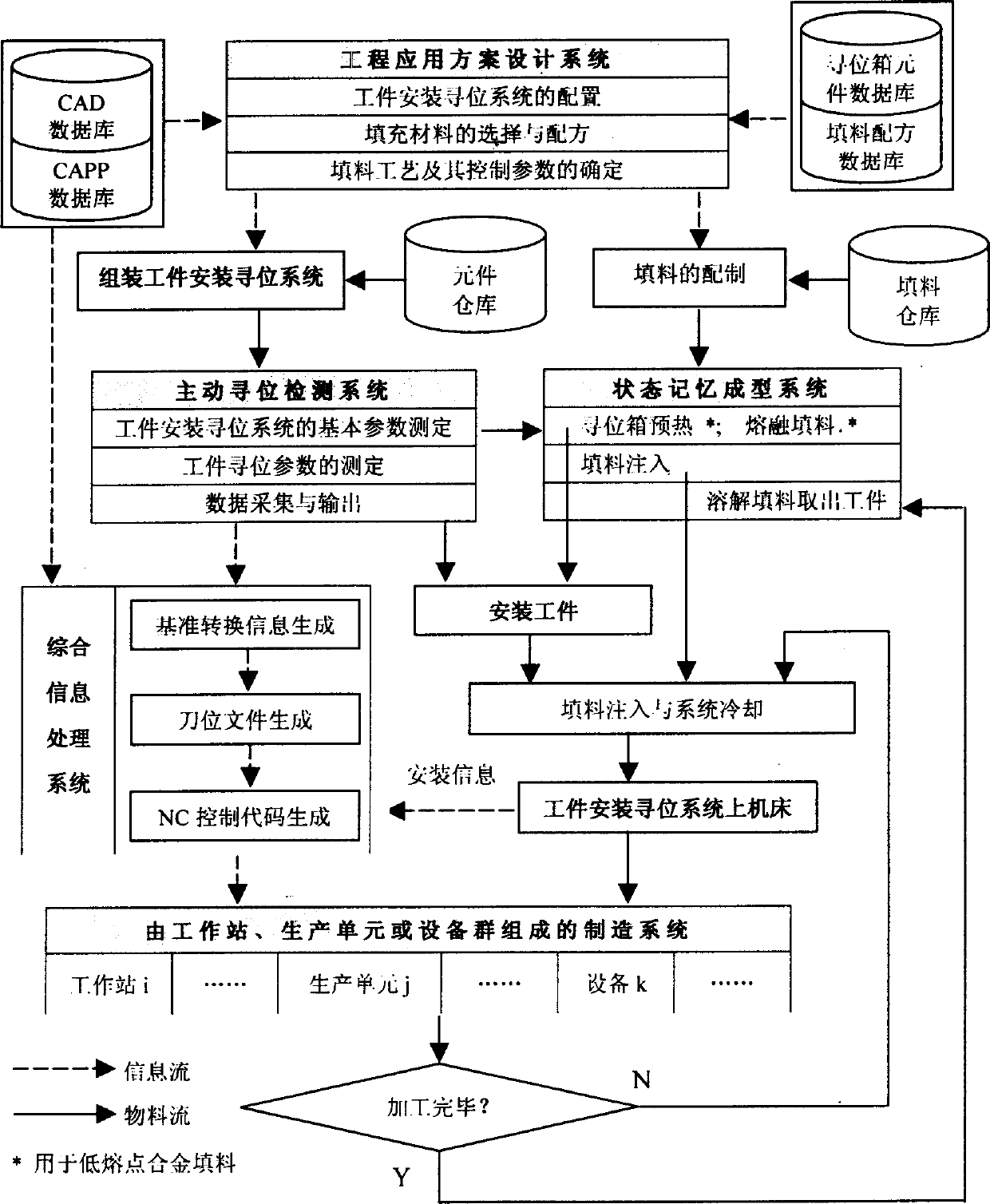

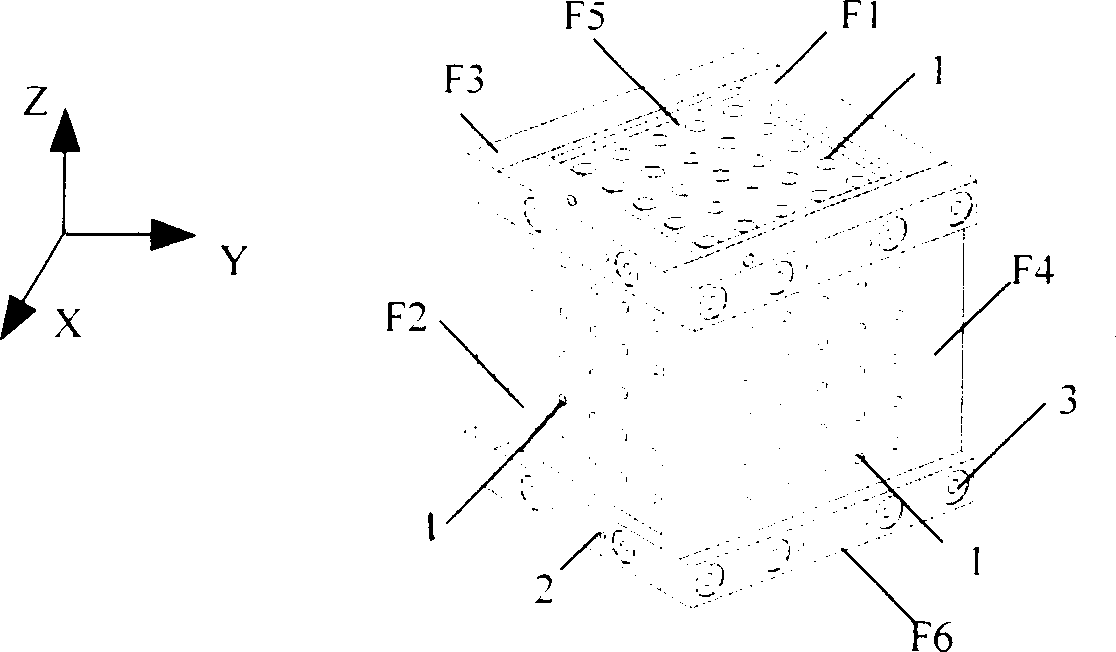

Method for processing mounting system based on active addressing and position memory

InactiveCN1394714AAvoid the influence of machining accuracySolve the clamping problemAssembly machinesNumerical controlDefined ProcedureEngineering

The machining method based on active location and position memory mounting system is mainly characterized by that said method includes the following steps: adopting standard location box to blank to be machined and make the blank face with arbitrary shape; adopting filler state of restore memory position so as to make the original mounting position of workpiece in the arbitrarily-changed procedure conversion do not produce change; based on the original mounting reference of workpiece and coordinate conversion method calculating procedure coordinate parameter and making digital control machining program. The workpiece blank is placed into location box, accurately positioned by using location element and fastening element, the filler is injected and the original mounting position of the workpiece can be defined, then can be machined according to the defined procedure.

Owner:DONGHUA UNIV

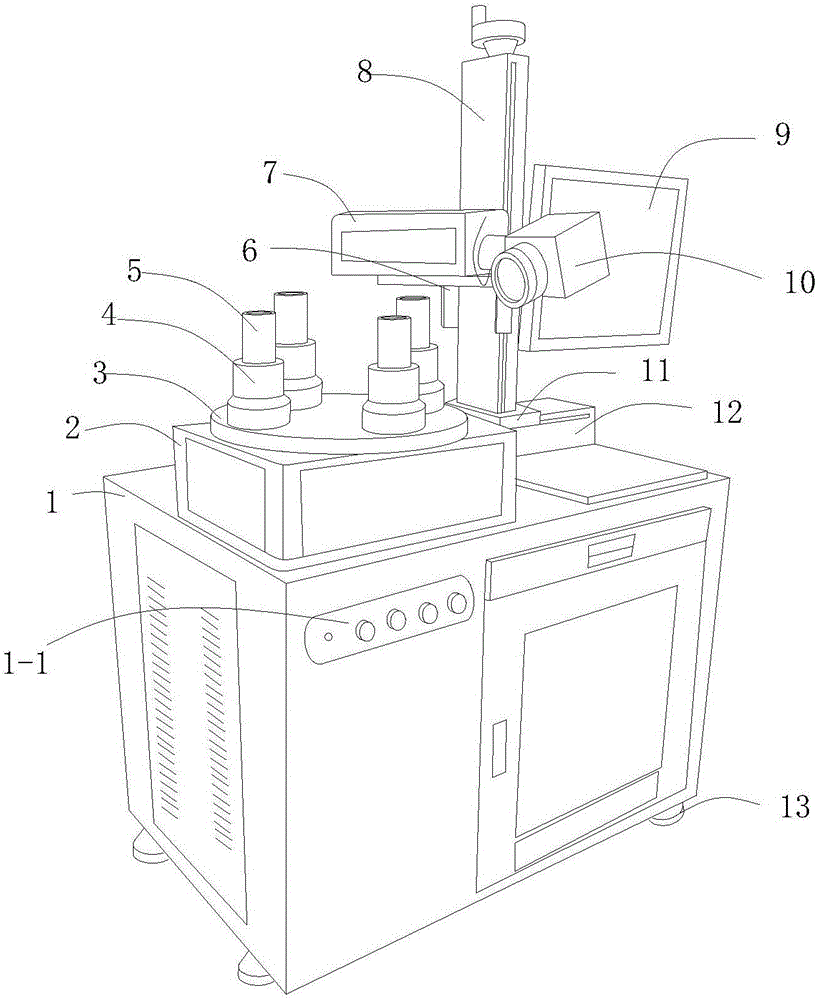

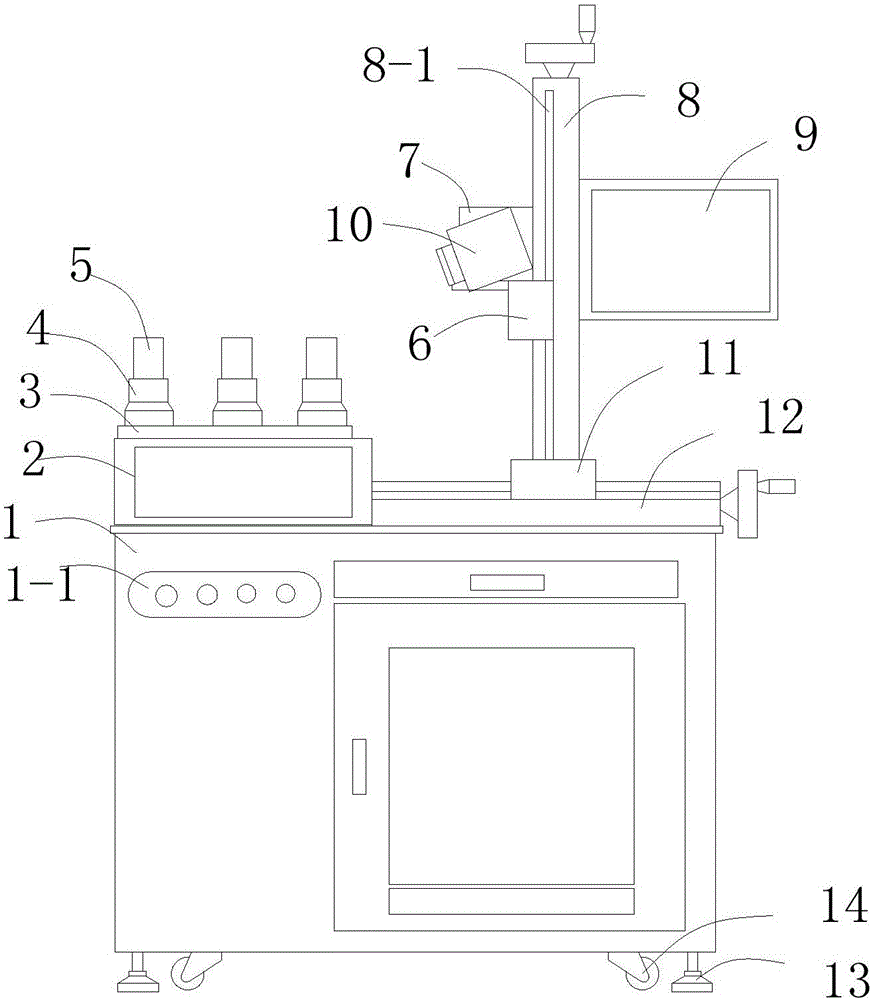

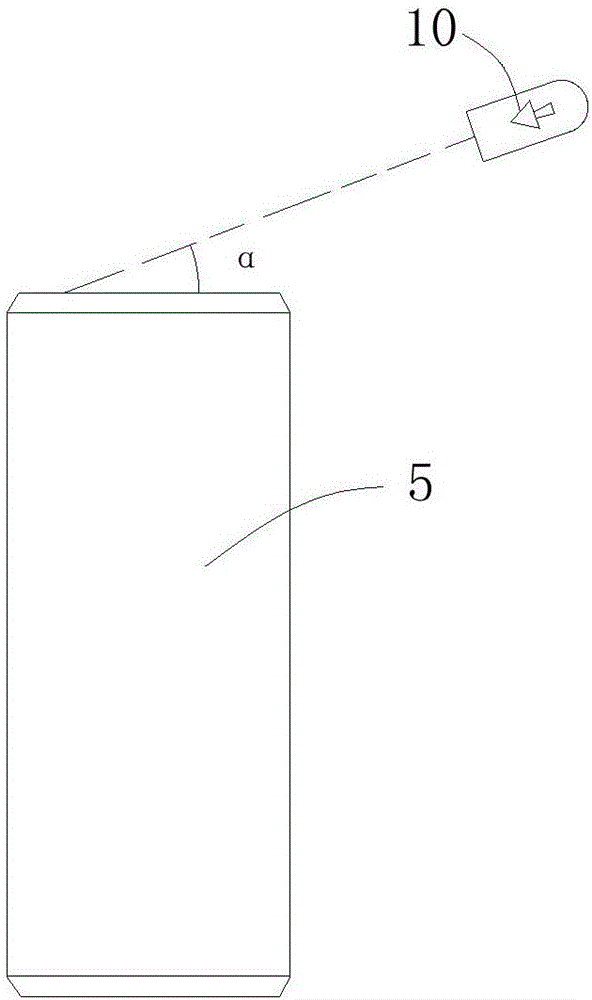

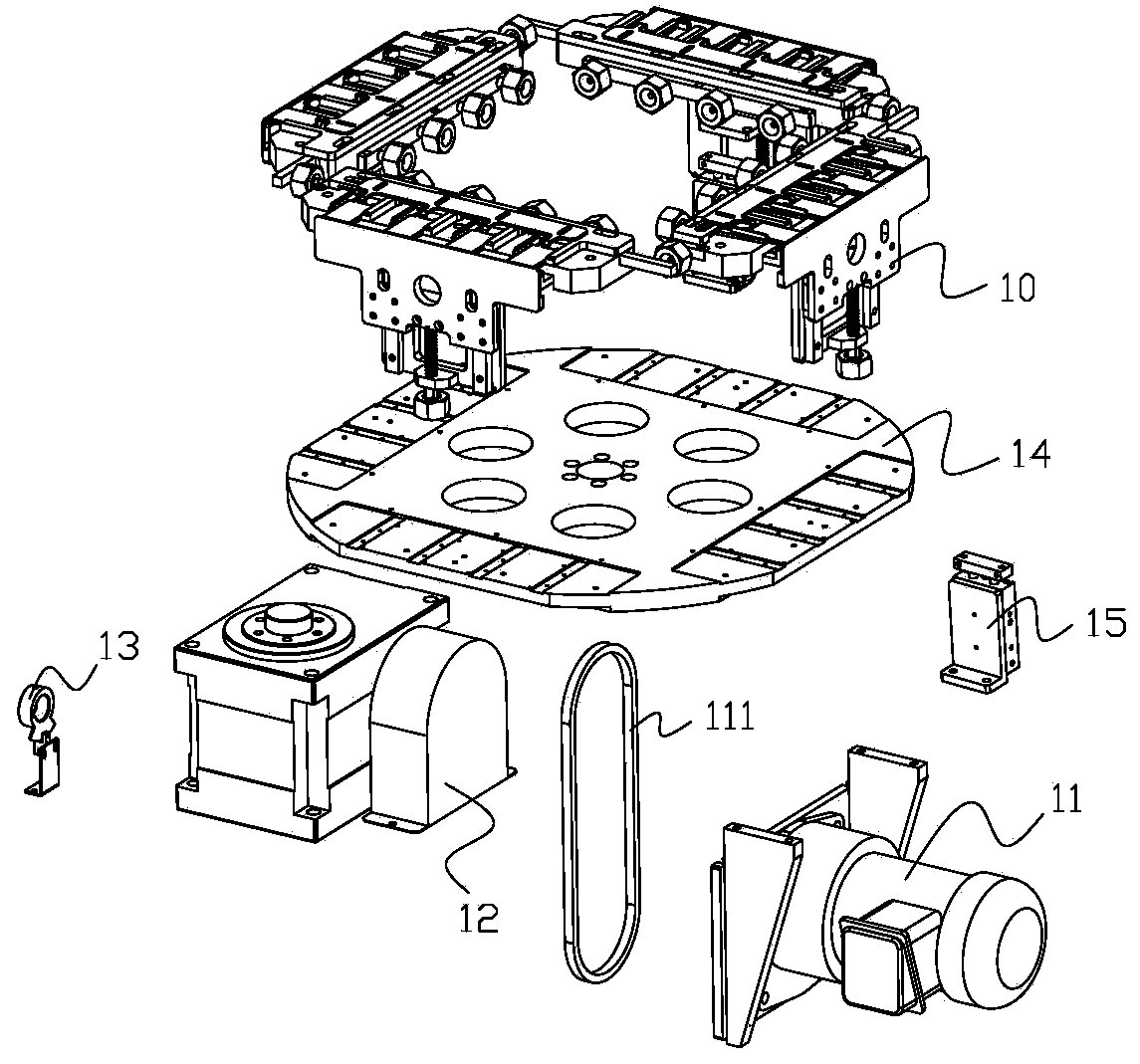

Inner hole laser marking equipment used for sucker rod coupling and marking method thereof

The invention discloses inner hole laser marking equipment used for a sucker rod coupling and a marking method thereof, and relates to the technical field of laser marking. The inner hole laser marking equipment comprises an electric control cabinet and a laser. An indexing separator is arranged on the electric control cabinet. A rotary plate is connected to the indexing separator. A plurality of adapting sleeves used for mounting the marking coupling are evenly distributed on the rotary plate. A rotary laser head is movably connected to the laser. The inner hole laser marking equipment has the advantages that the structure is simple, the working efficiency is high, the labor intensity is low, inner hole marking of the to-be-marked coupling is facilitated, and marking characters are not liable to be abraded; during operation, the to-be-marked coupling is mounted on the adapting sleeves of the rotary plate, the position of the laser is adjusted, required marking parameters are input into a computer, the focal distance of the laser beamon the inner wall of the coupling is adjusted, then marking is started, the focal distance of the laser beams is adjusted, deep marking and carbonizing marking can be achieved, after marking of a product is completed, the rotary plate rotates automatically to another product for marking, and thus uninterrupted marking operation can be achieved.

Owner:重庆亮科激光科技有限公司 +1

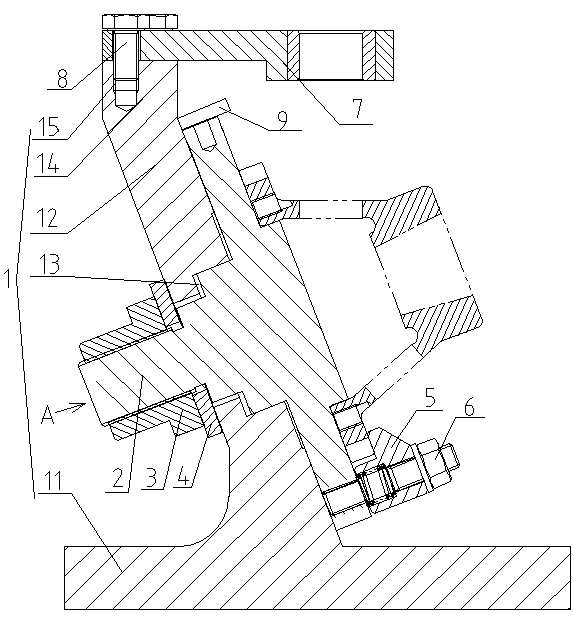

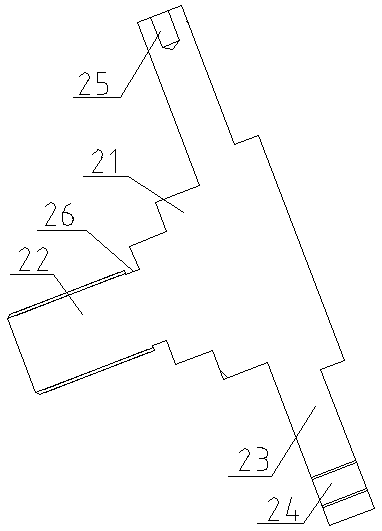

Forming tool device for oblique holes

ActiveCN109454269AImprove machining efficiency and precisionEasy to replaceDrill jigsEngineeringMachining

The invention discloses a forming tool device for oblique holes. The forming tool device comprises a profiling apparatus which is used for shifting the oblique holes to be in a vertical machining state, and a pressing claw apparatus which is disposed on the profiling apparatus and used for clamping an oblique hole carrier. By means of the profiling apparatus, the oblique holes on the oblique holecarrier are vertically distributed, through the pressing claw apparatus, the oblique hole carrier is clamped onto the profiling apparatus, and thus the machining efficiency and accuracy of the side oblique holes are improved.

Owner:泰安泰山福神齿轮箱有限责任公司

Polishing device of injection molding product

InactiveCN108608300ASolve the clamping problemImprove practicalityPolishing machinesGrinding work supportsEngineeringRotating disc

The invention discloses a polishing device of an injection molding product. The polishing device comprises a shell, a first motor is fixedly connected to the rear side of the inner wall of the shell,the output end of the first motor is fixedly connected with a rotating disc, and a sliding groove is formed in the surface of the rotating disc; and the two sides of the inner wall of the shell are correspondingly and fixedly connected with telescopic boxes. According to the device, the shell, the first motor, the rotating disc, the sliding and moving groove, the telescopic boxes, a limiting plate, a sliding block, a sliding groove, a reset spring, a telescopic rod, a supporting plate, a sliding column, a connecting plate, a clamping plate, an air cylinder, a fixed plate, a motor box, a secondmotor and a polished piece are used in a cooperation mode, so that the problem that an existing polishing device cannot automatically tight clamp the injection molding product can be solved; the polishing device for the injection molding product has the advantage of automatic tight clamping, the labor force of workers is reduced, a lot of time of a user is reduced, so that the practicability of the polishing device is improved, and the use of the user is facilitated.

Owner:湖州新元素金属制品有限公司

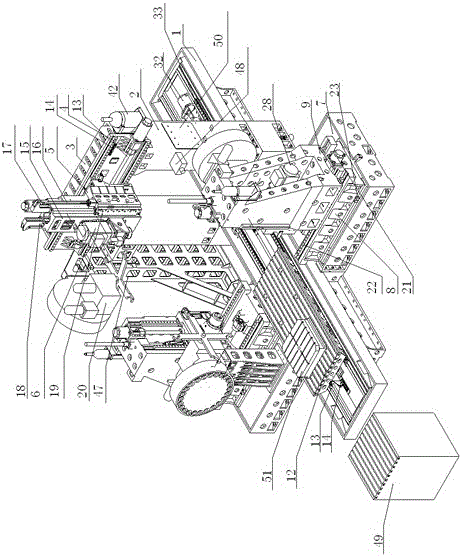

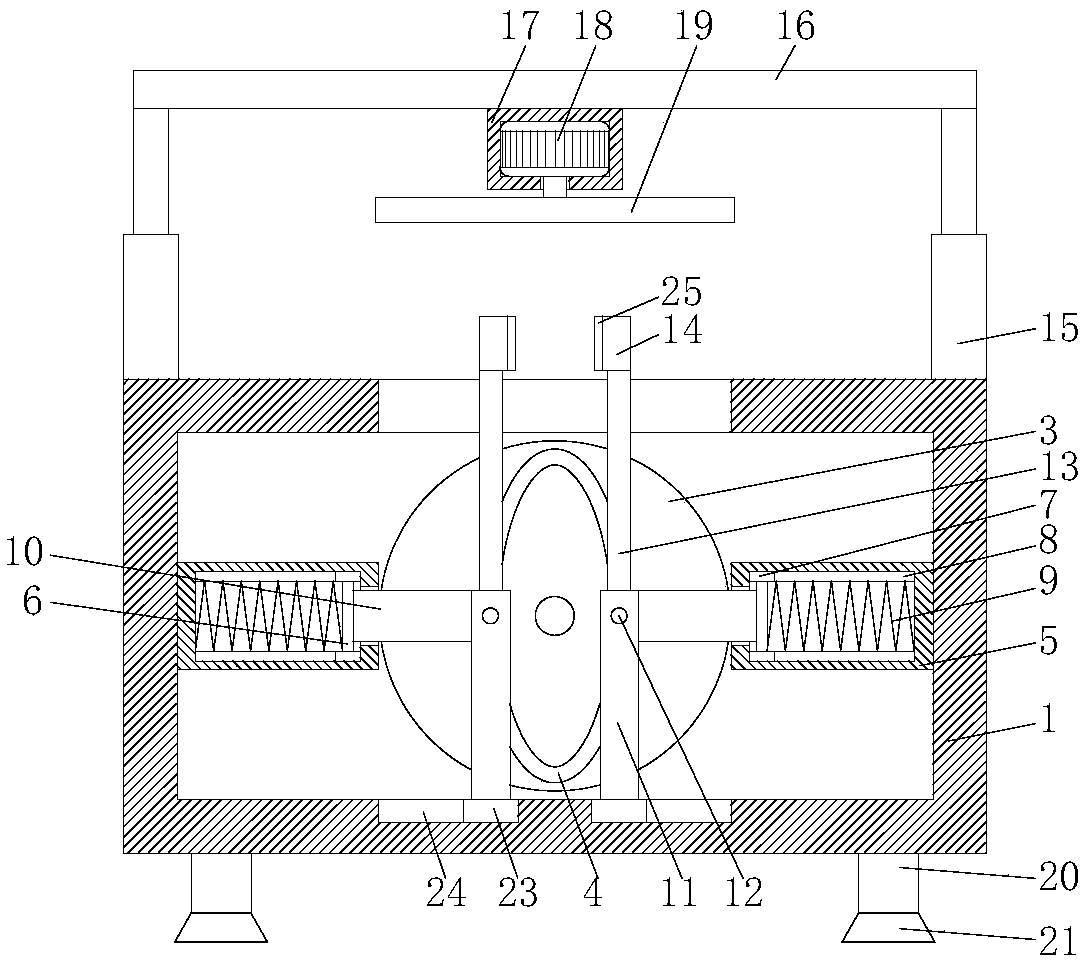

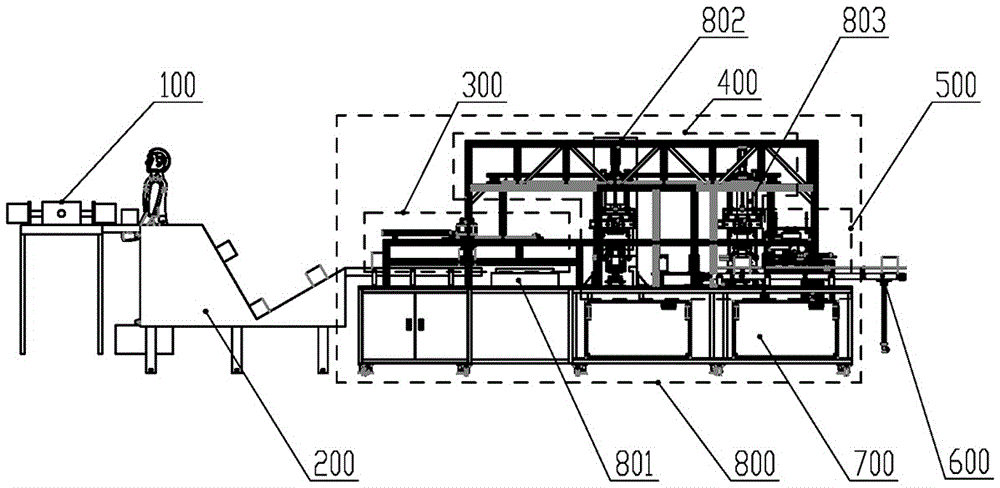

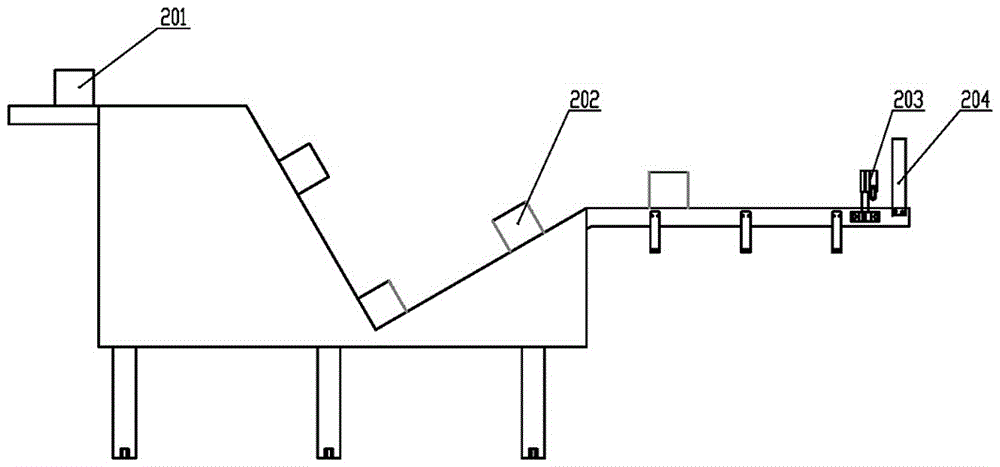

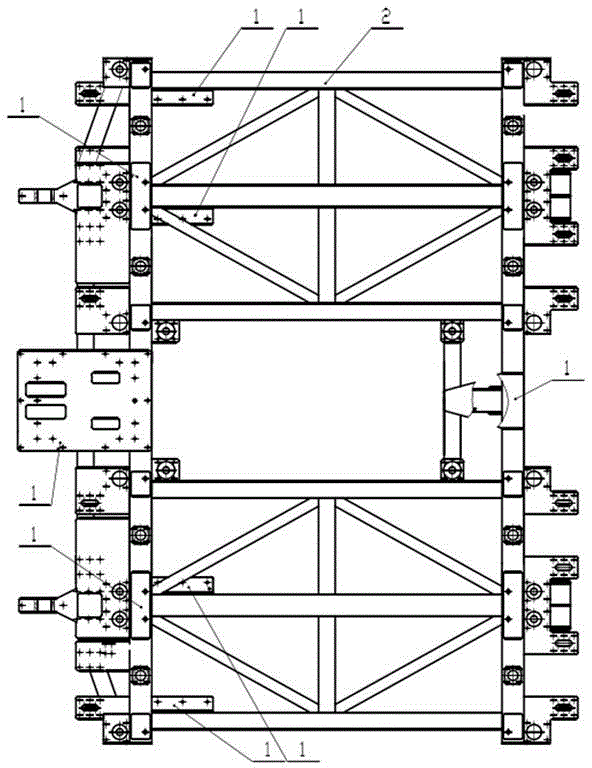

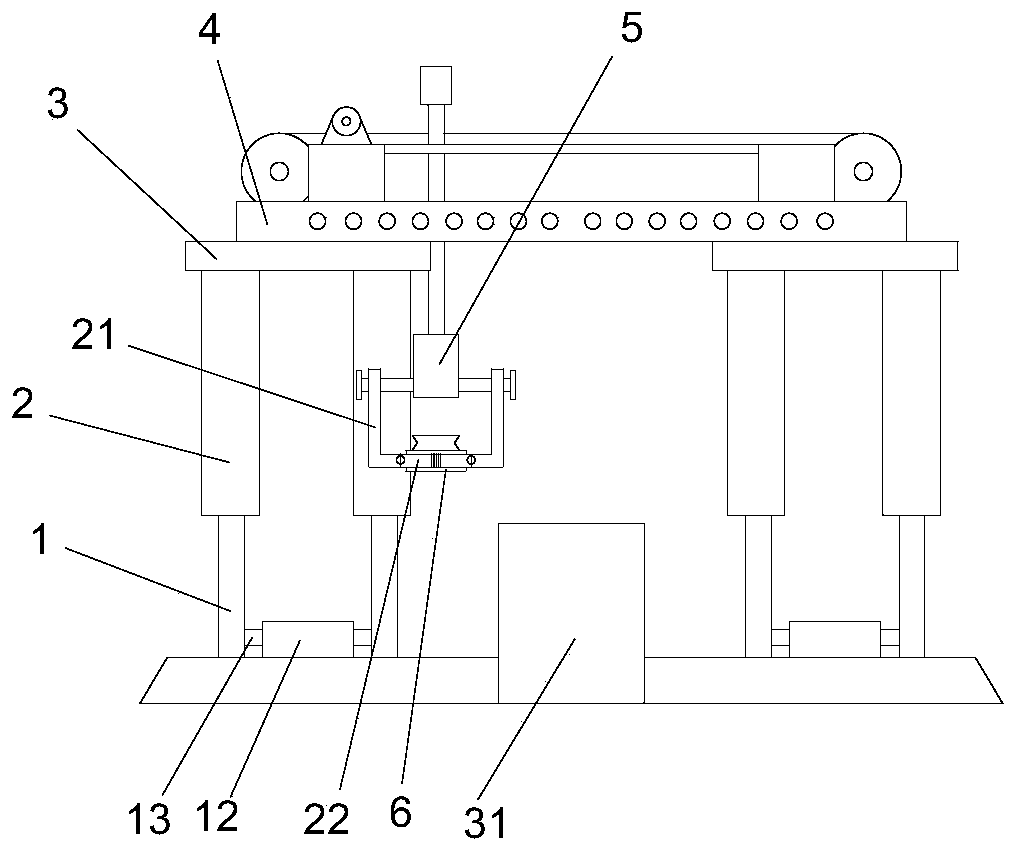

High-efficiency automatic square tank production line

ActiveCN105562546AAutomate operationSolve the clamping problemMetal-working feeding devicesStripping-off devicesProduction lineEngineering

The invention discloses a high-efficiency automatic square tank production line. The high-efficiency automatic square tank production line comprises a forming device, a loading device, a conveying device module I, a conveying device module II, a conveying device module III, a machining device, an unloading device and a control box. The loading device and the unloading device are arranged on the front and back sides of a conveying device in parallel to realize automatic loading and unloading of square tanks. The conveying device module I, the conveying device module II and the conveying device module III are positioned between left and right stand columns of the machining device to realize conveying of the square tanks; and the machining device clamps the square tanks. The machining device is positioned in the middle of the production line; a main shaft part of the machining device can realize high-efficiency machining of the tanks; and the control box is positioned in a production line welding box to control operation of the production line. The high-efficiency automatic square tank production line realizes forming, loading / unloading, conveying, clamping and machining automation of the square tanks based on a mechanical-electrical integration principle, simplifies the machining process, improves the production efficiency, can reduce the worker number, and reduces the potential safety hazard in the production process.

Owner:TAIZHOU LANYI INTELLIGENT EQUIP TECH CO LTD

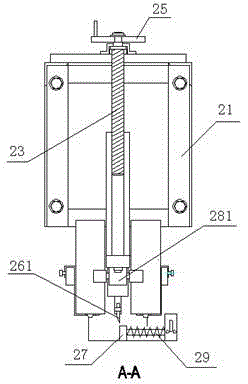

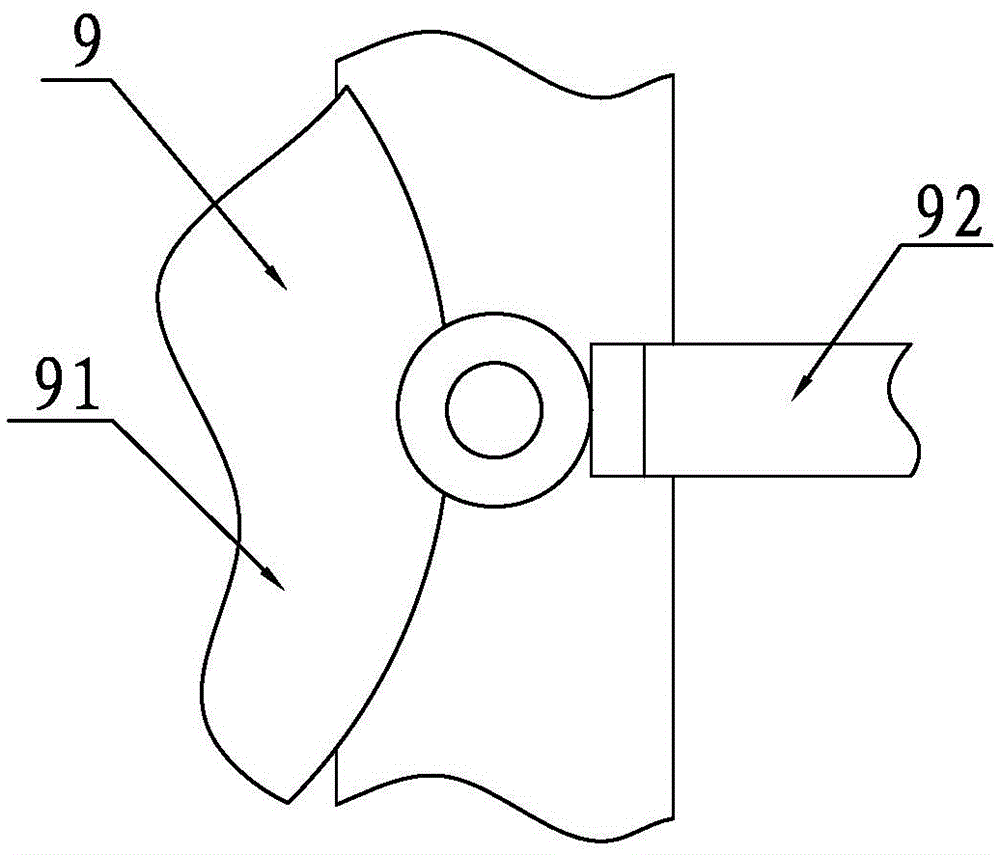

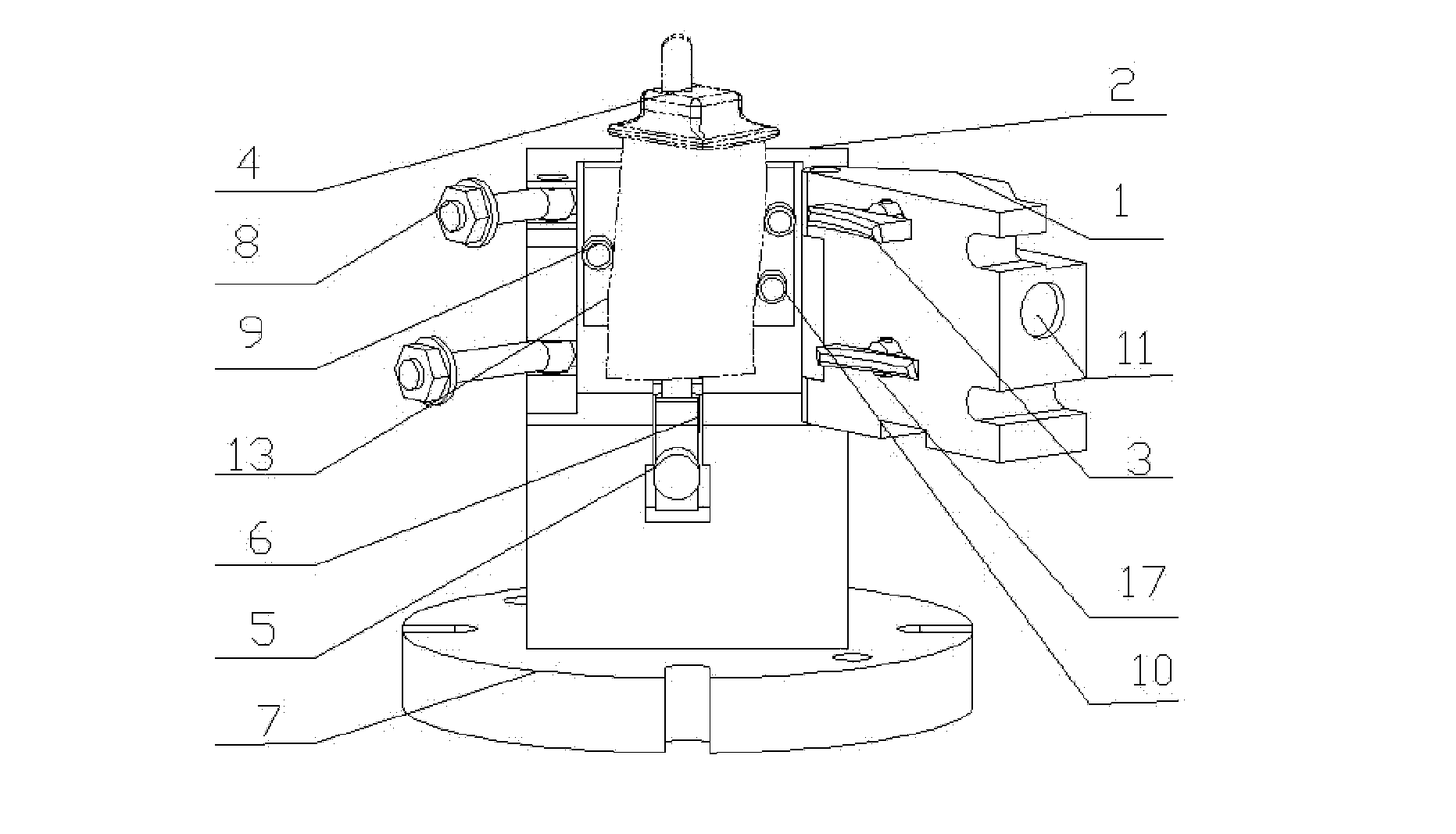

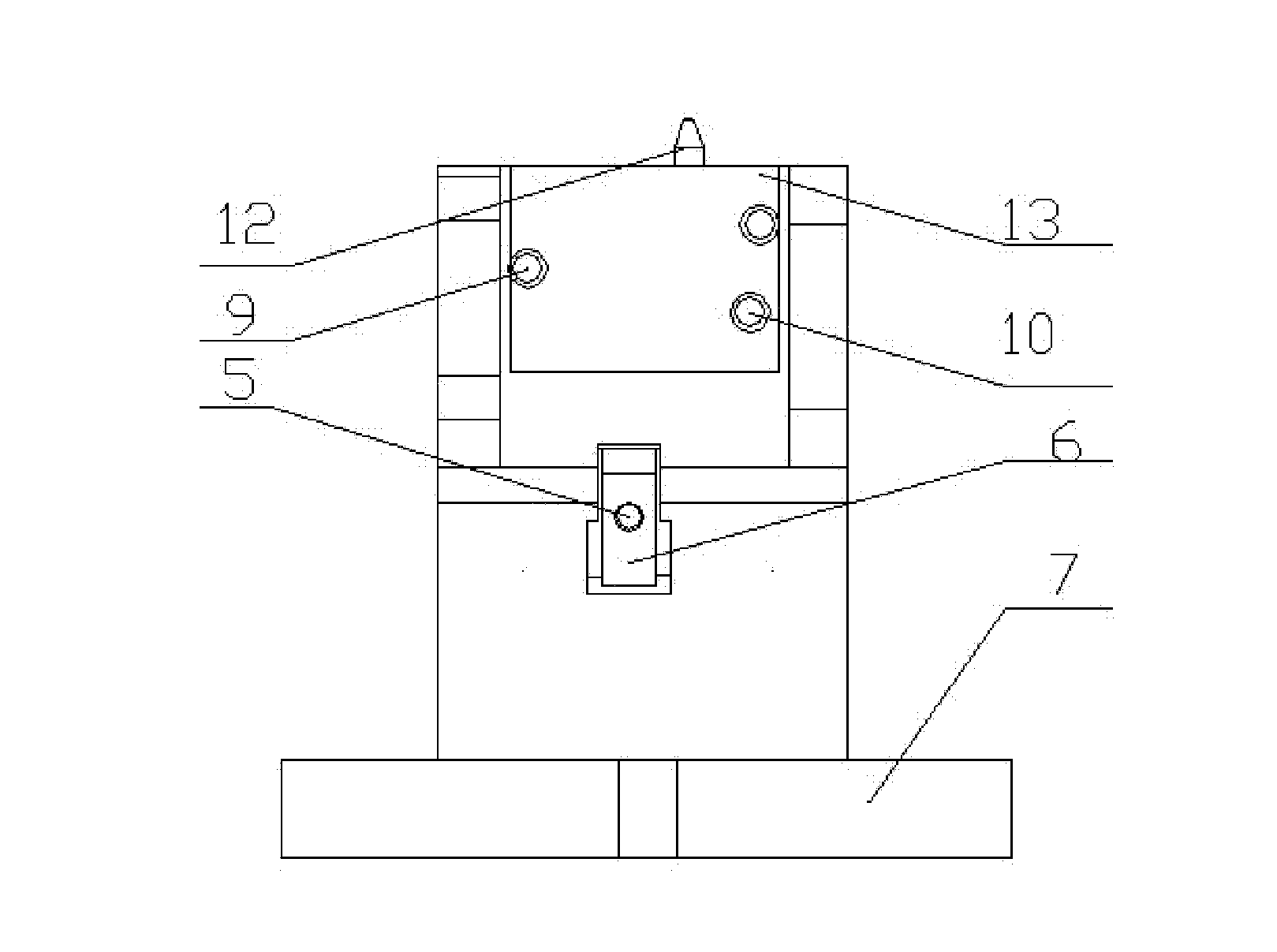

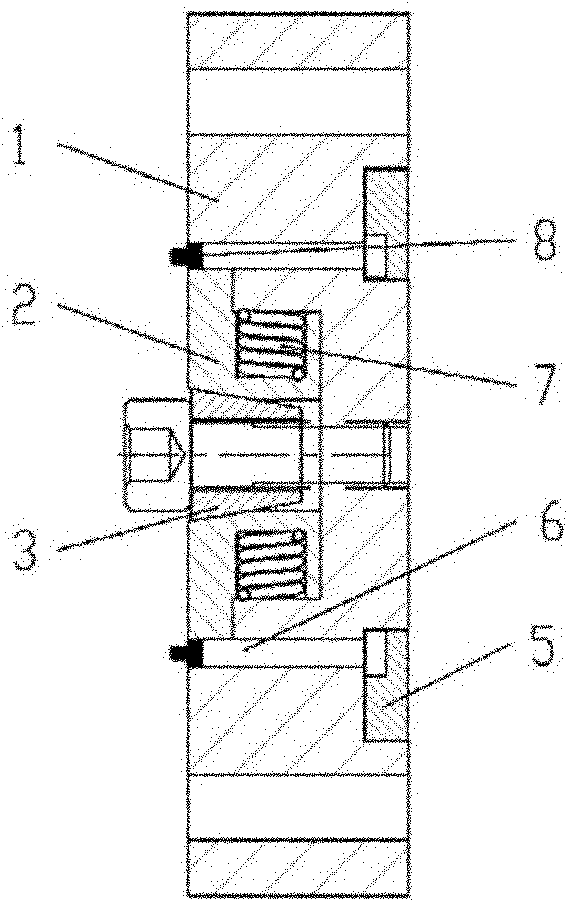

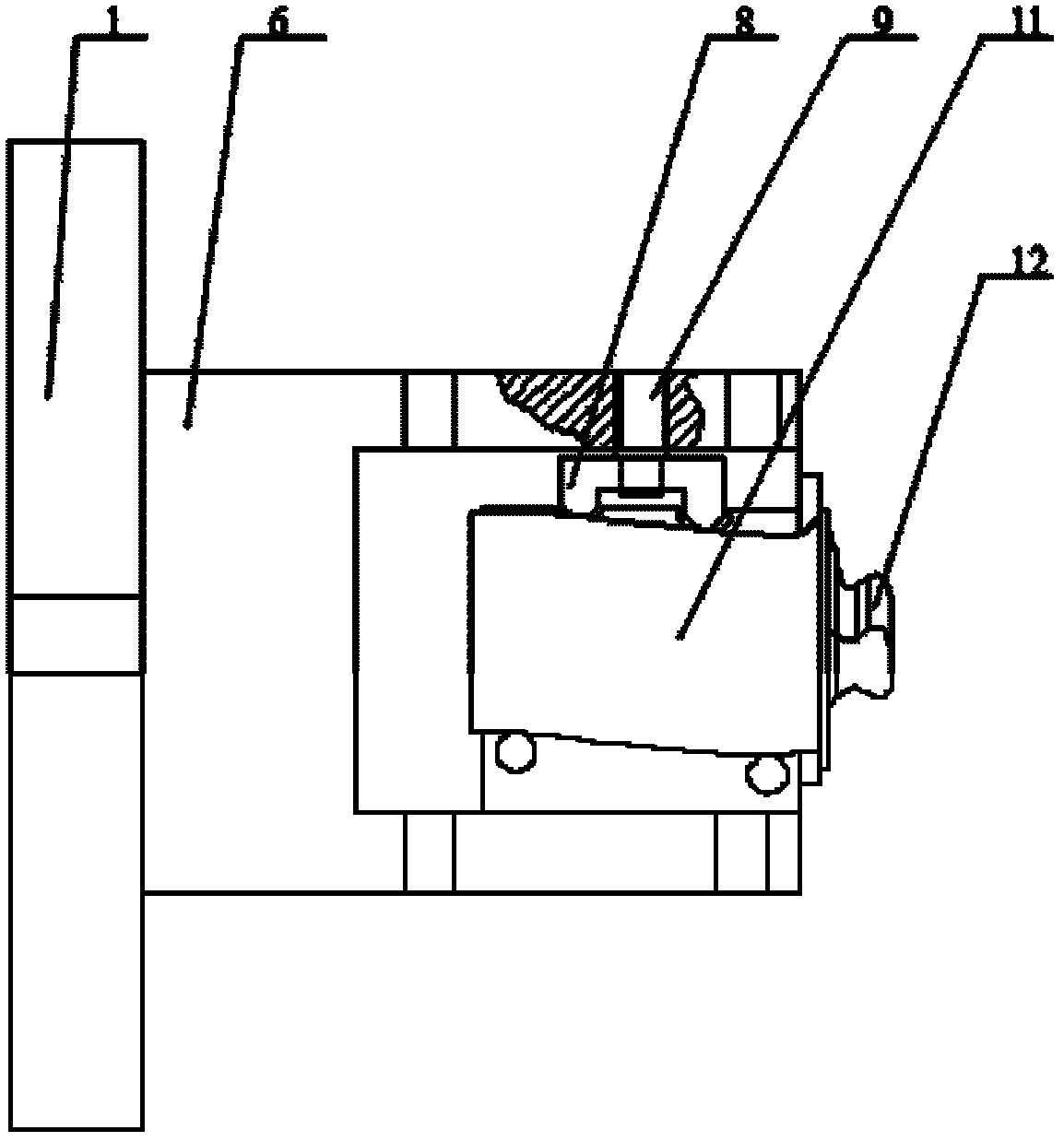

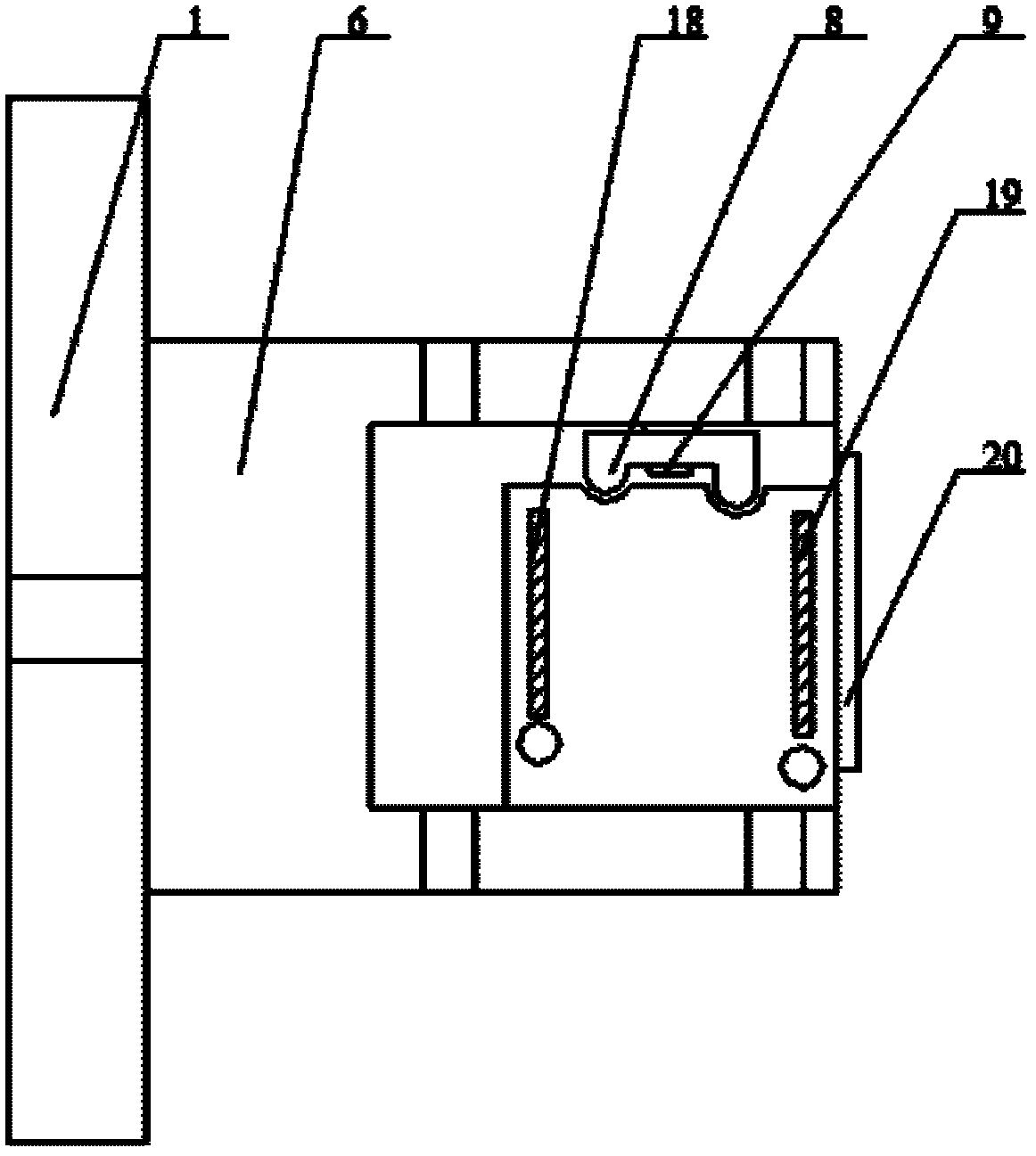

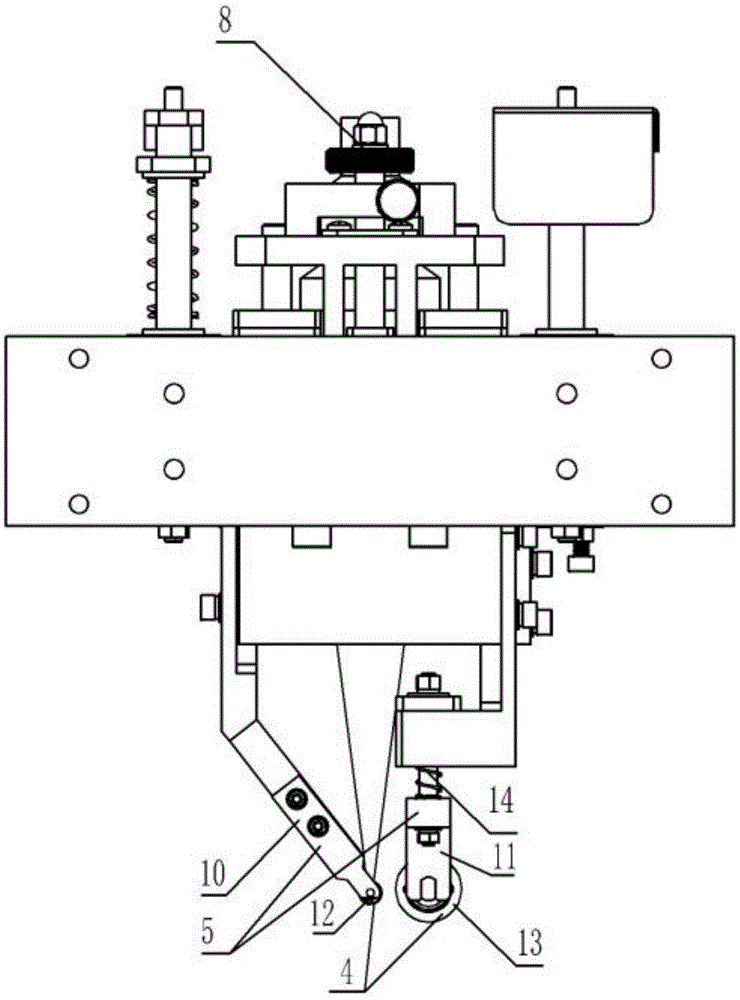

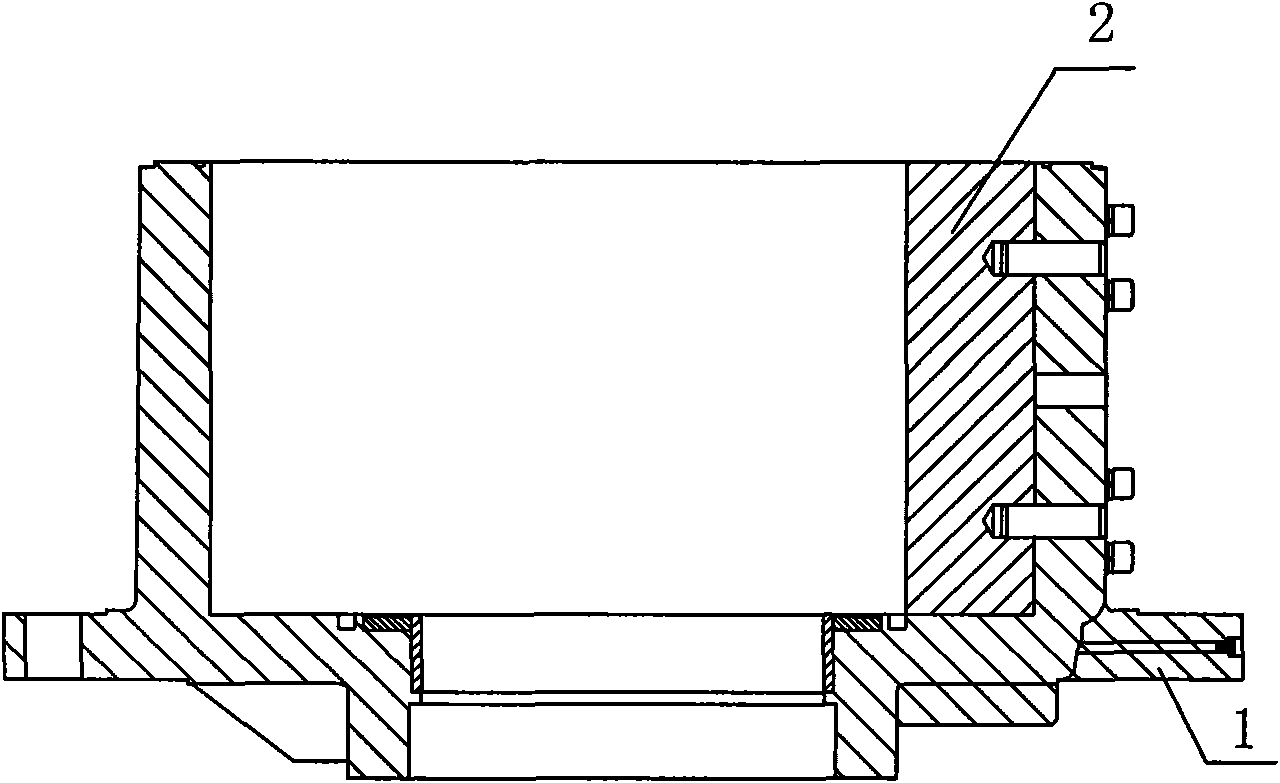

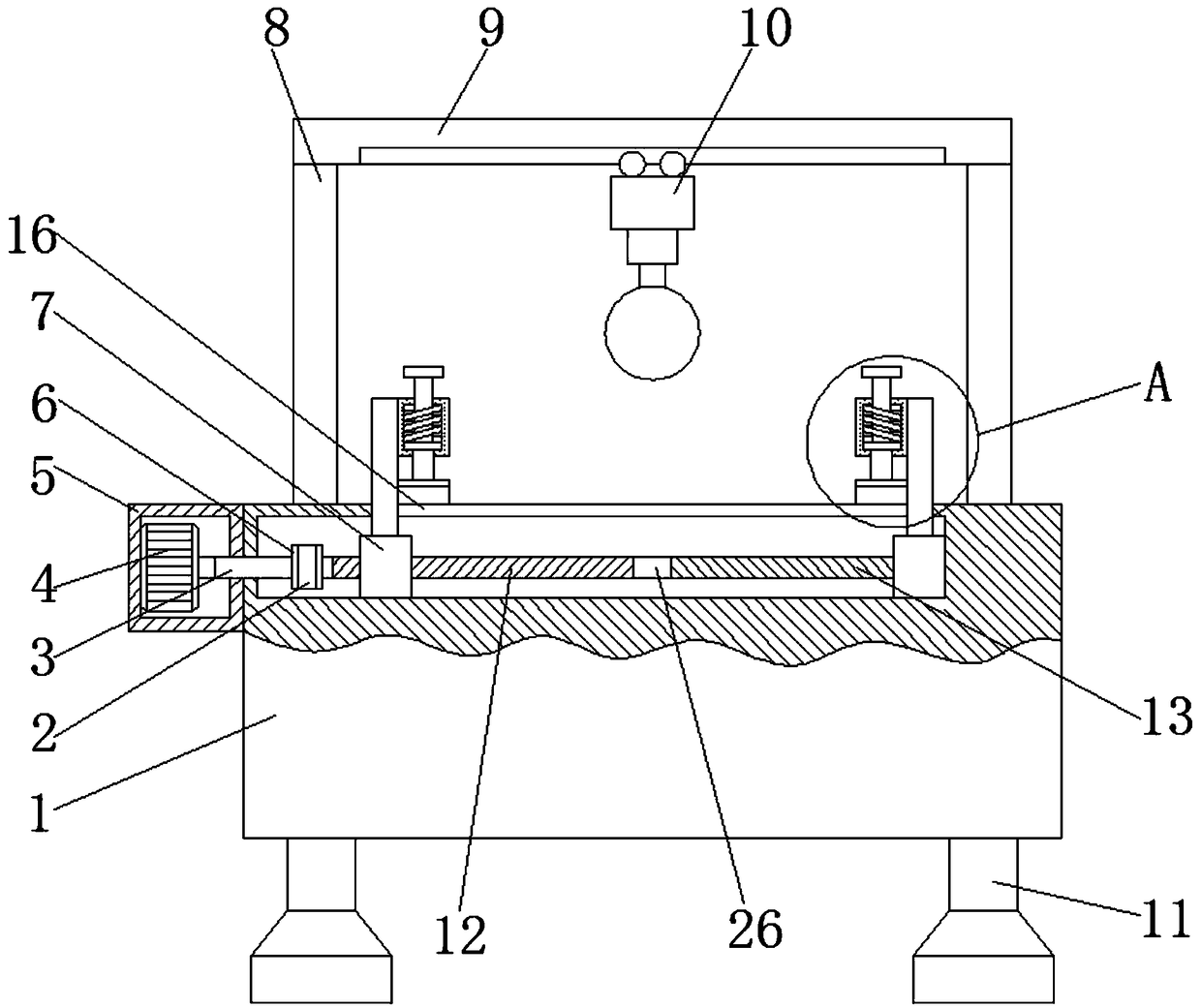

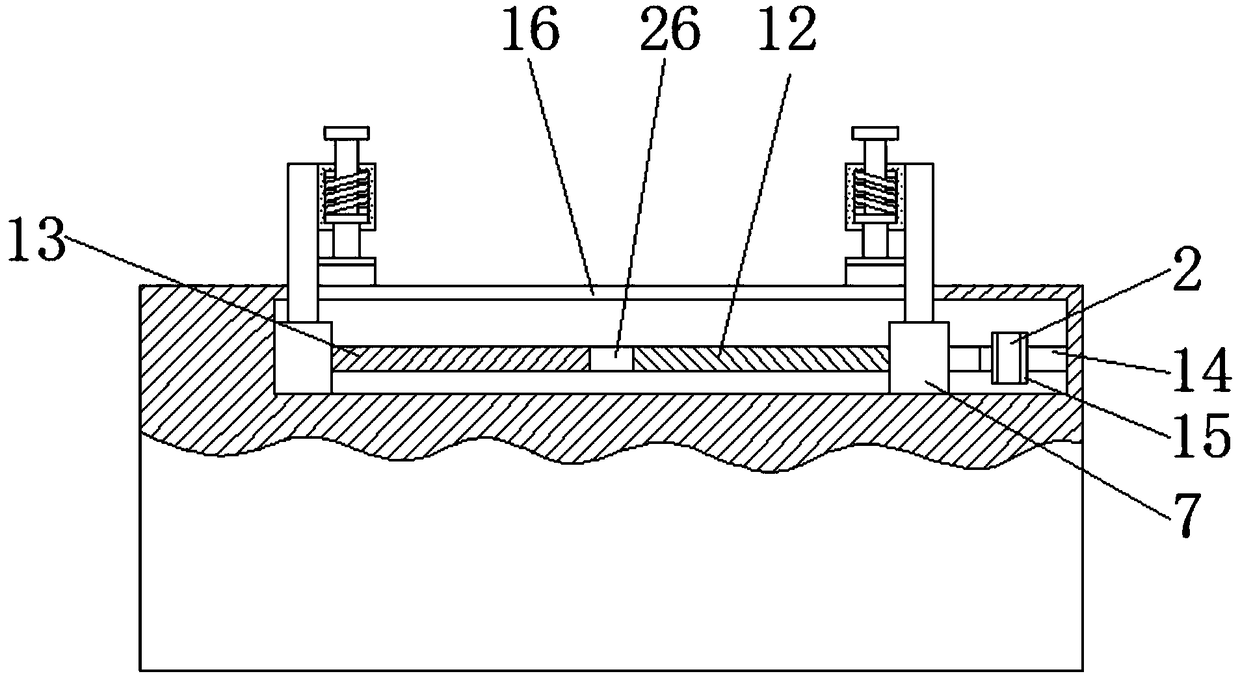

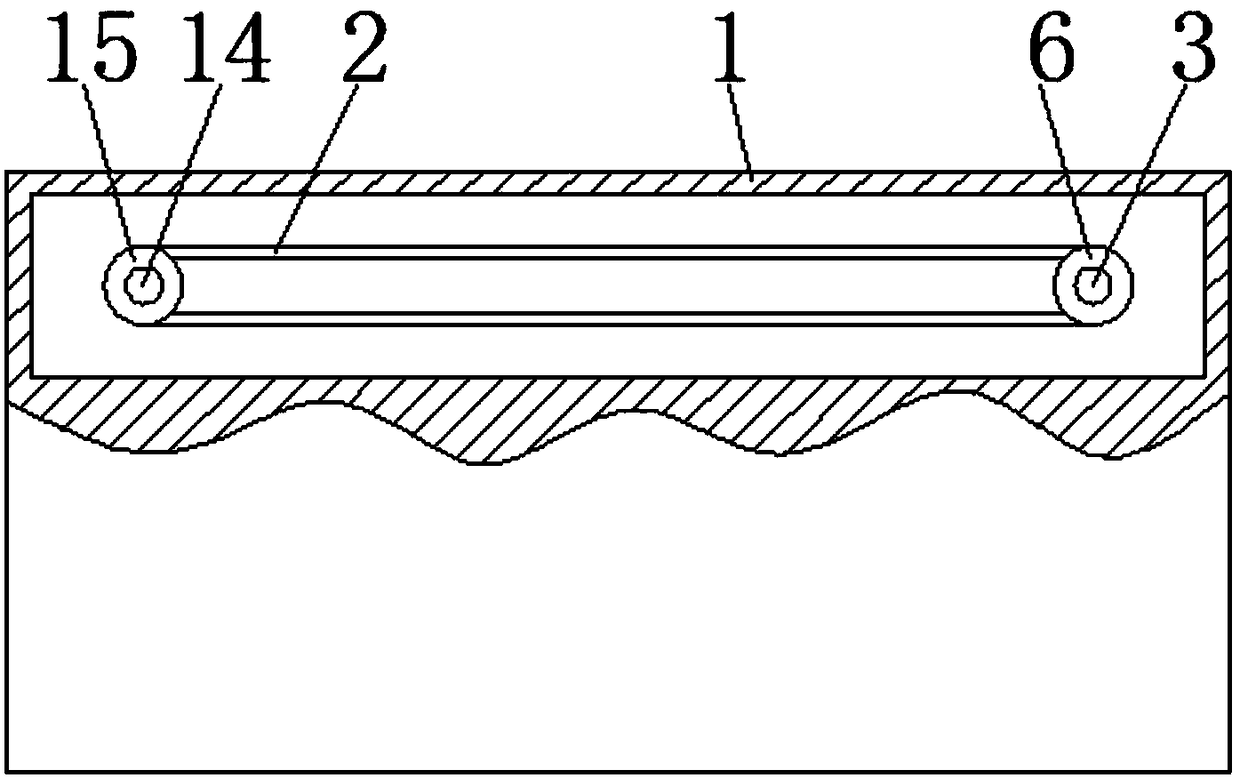

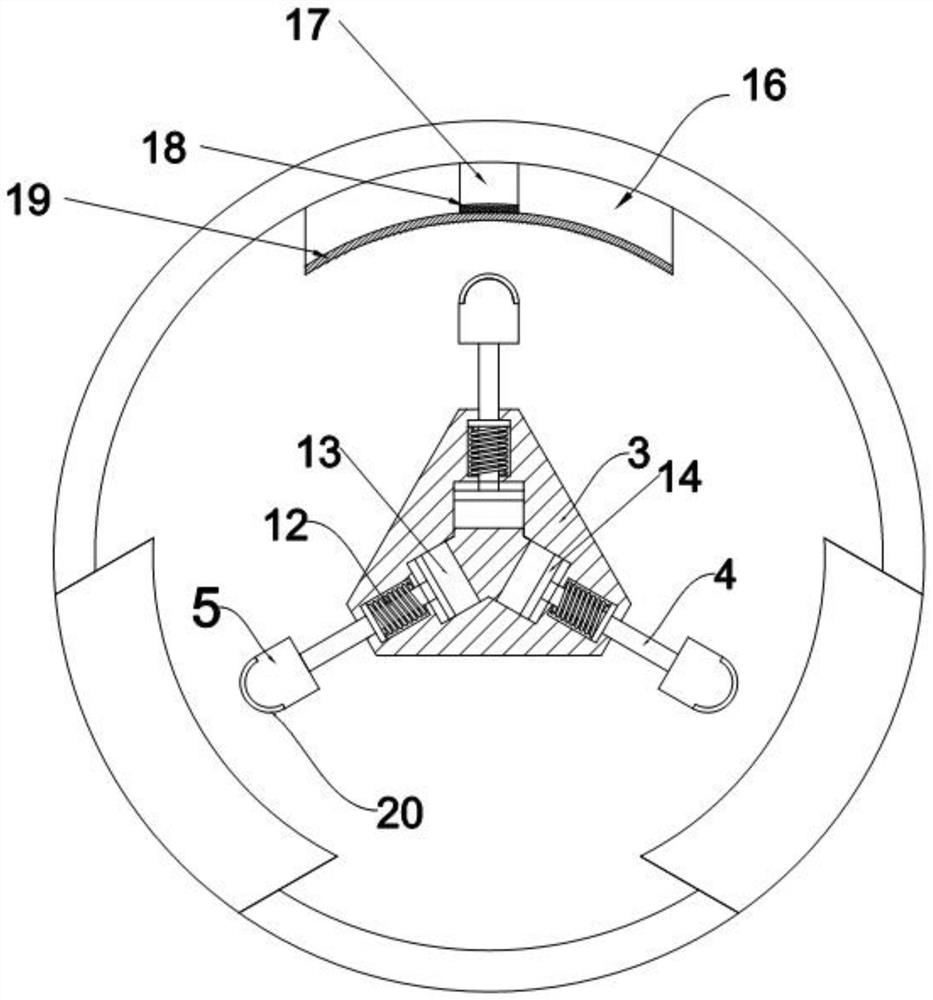

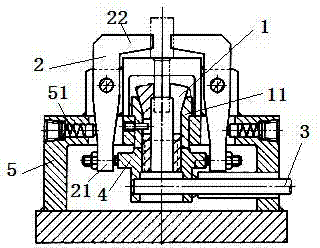

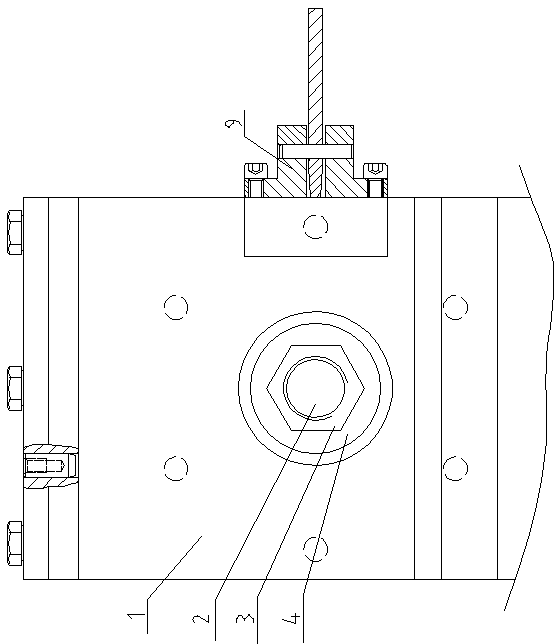

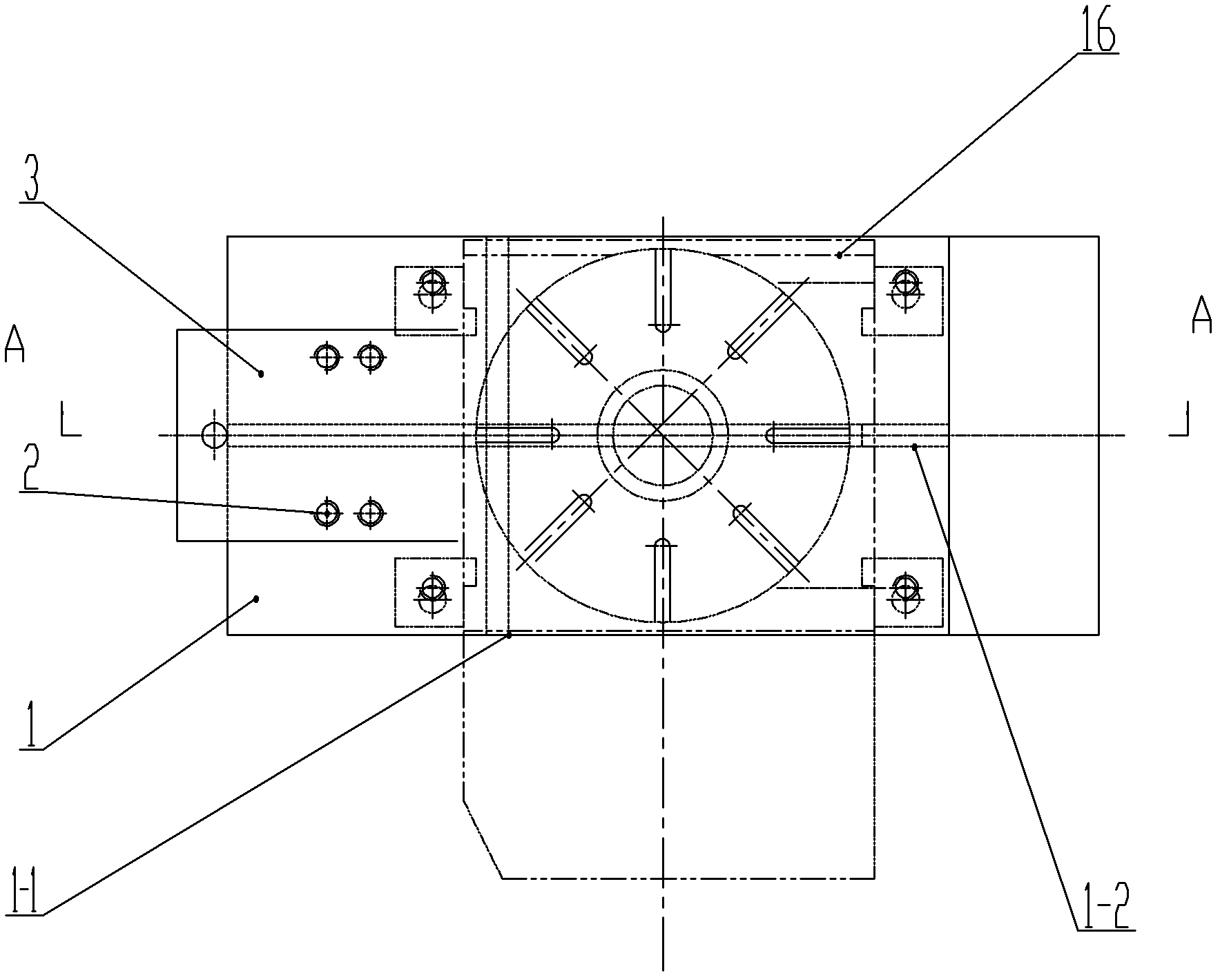

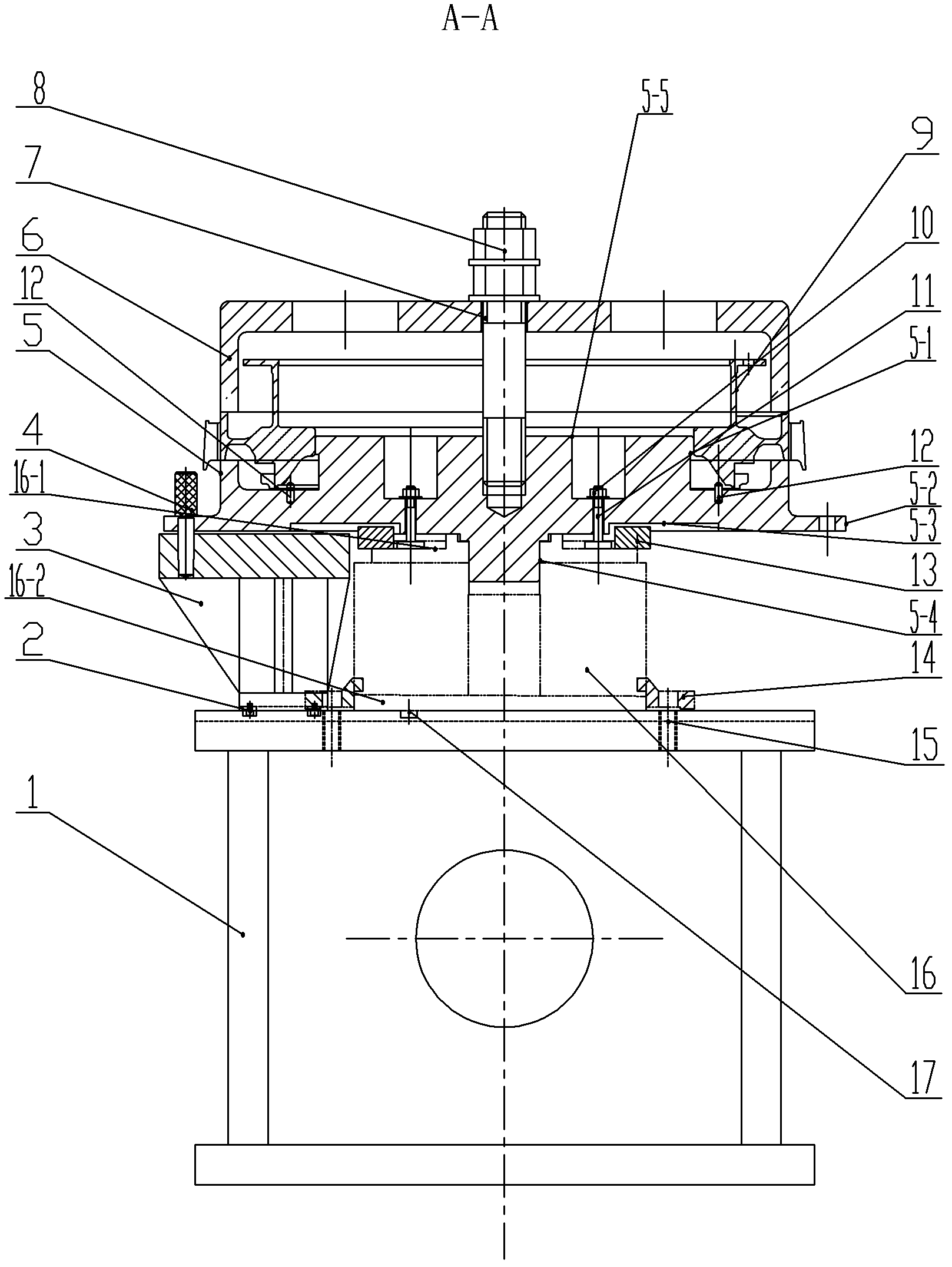

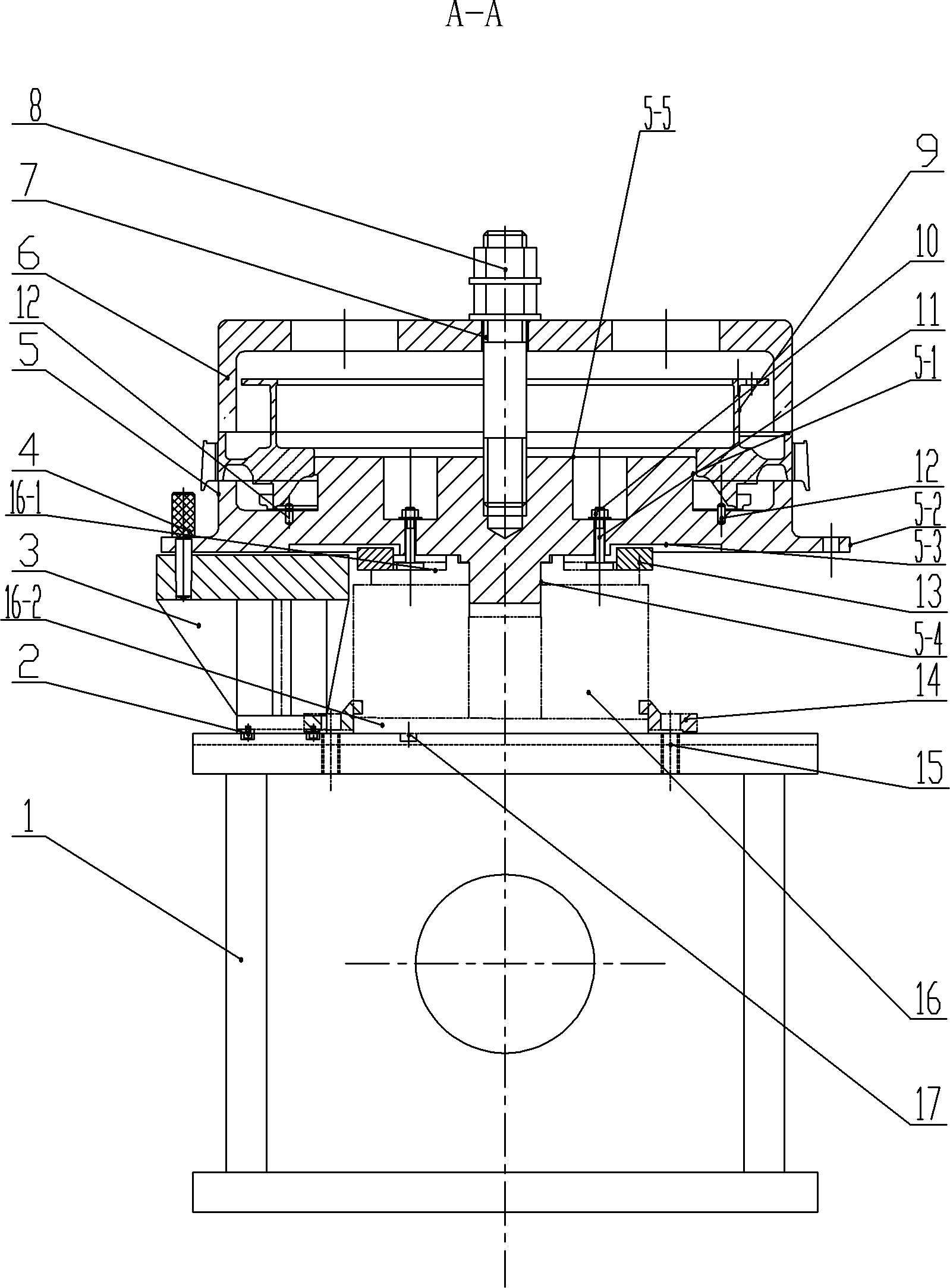

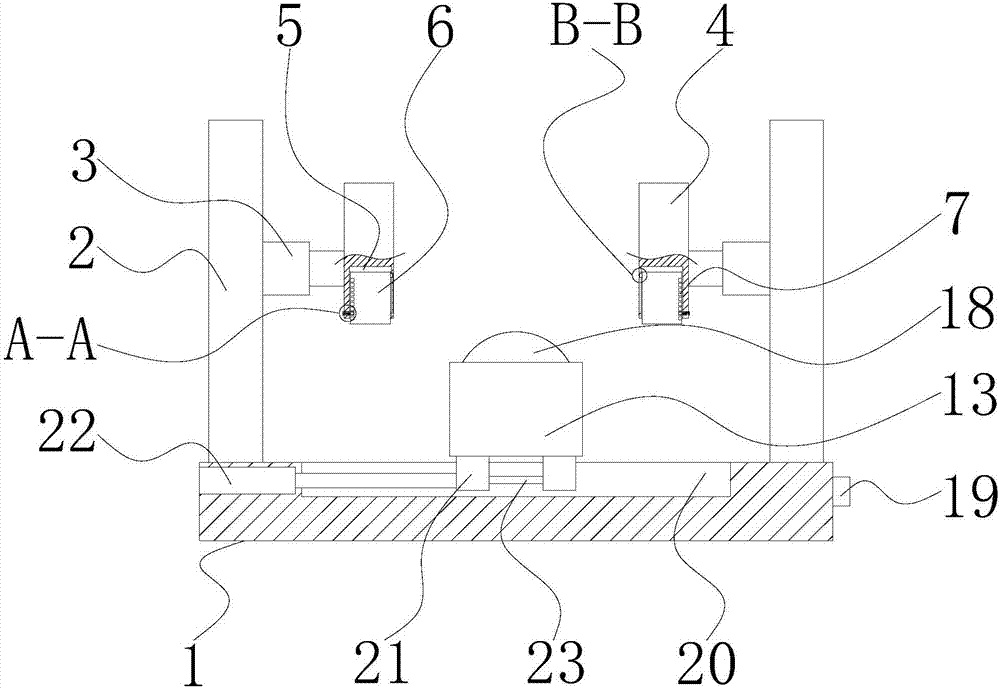

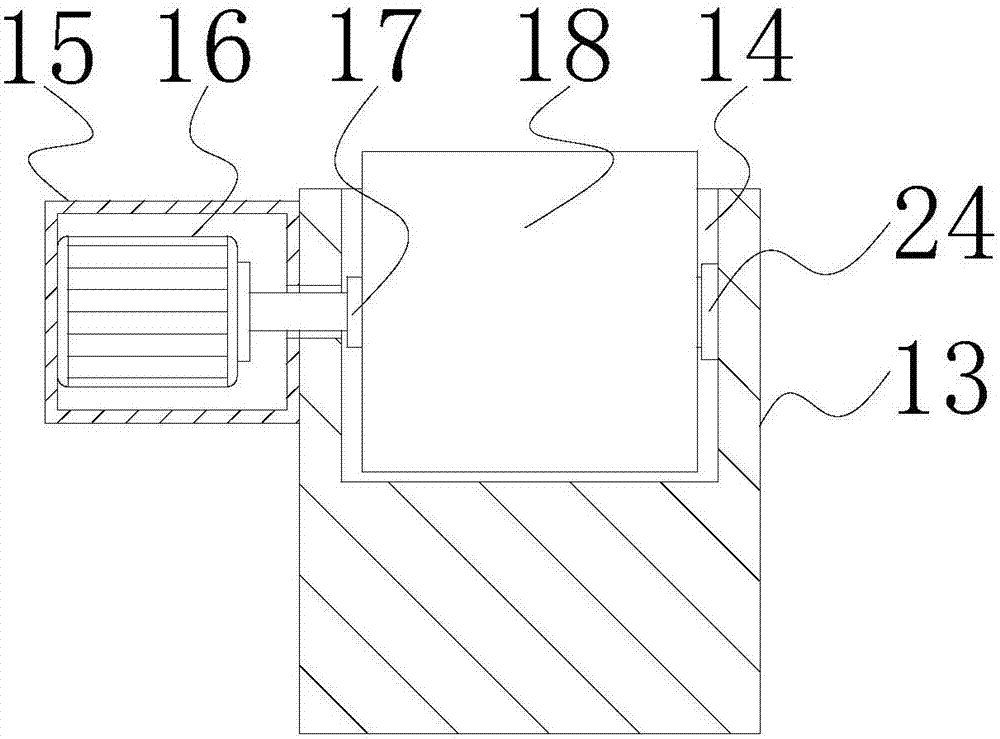

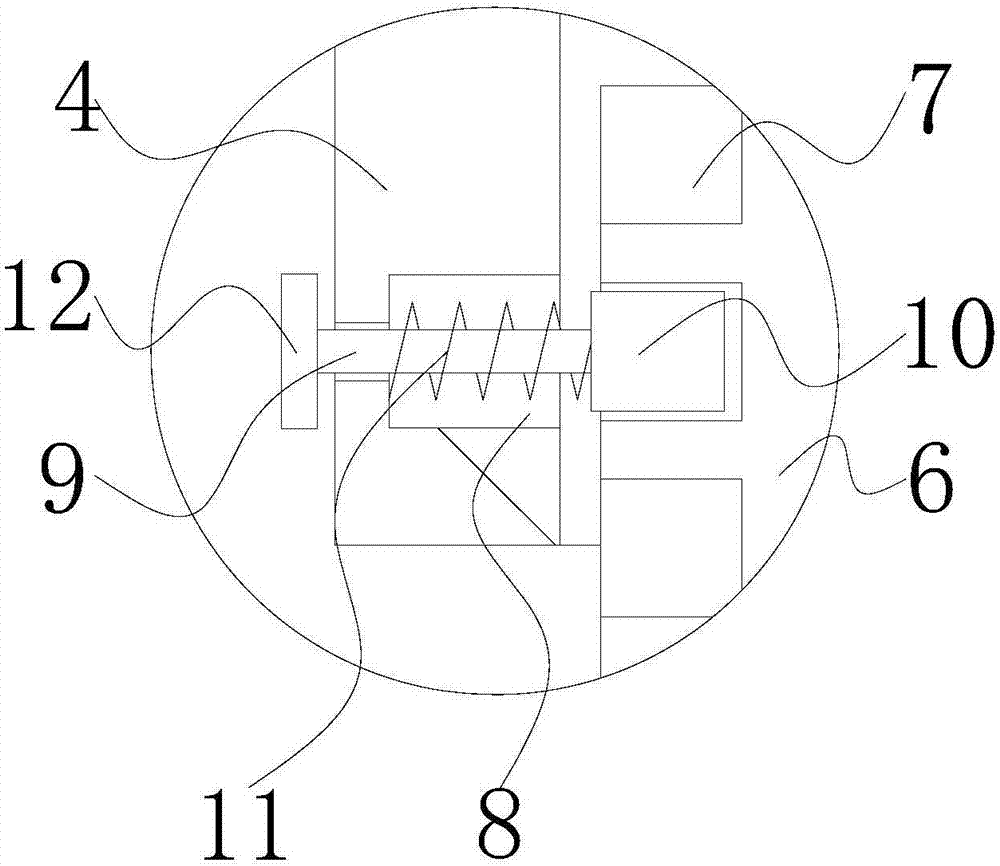

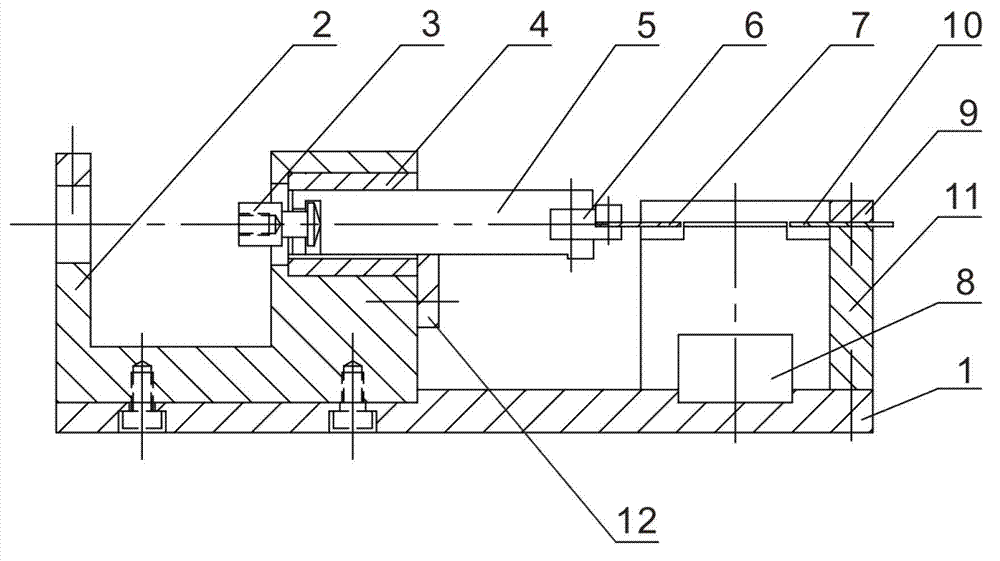

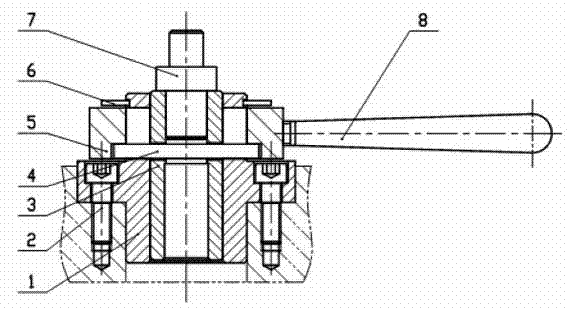

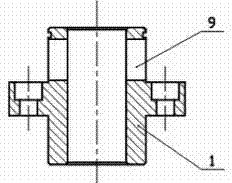

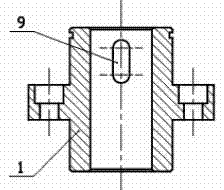

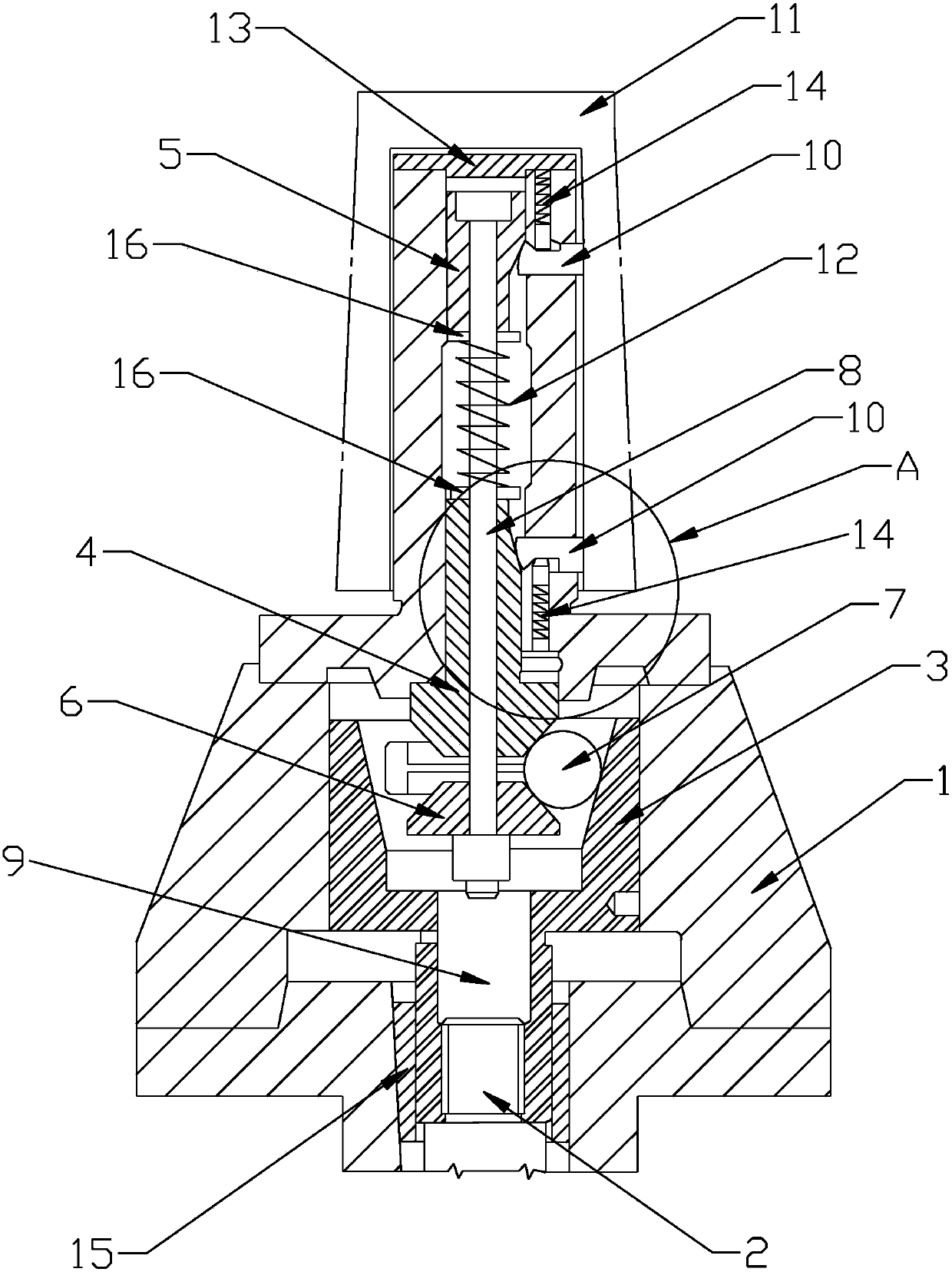

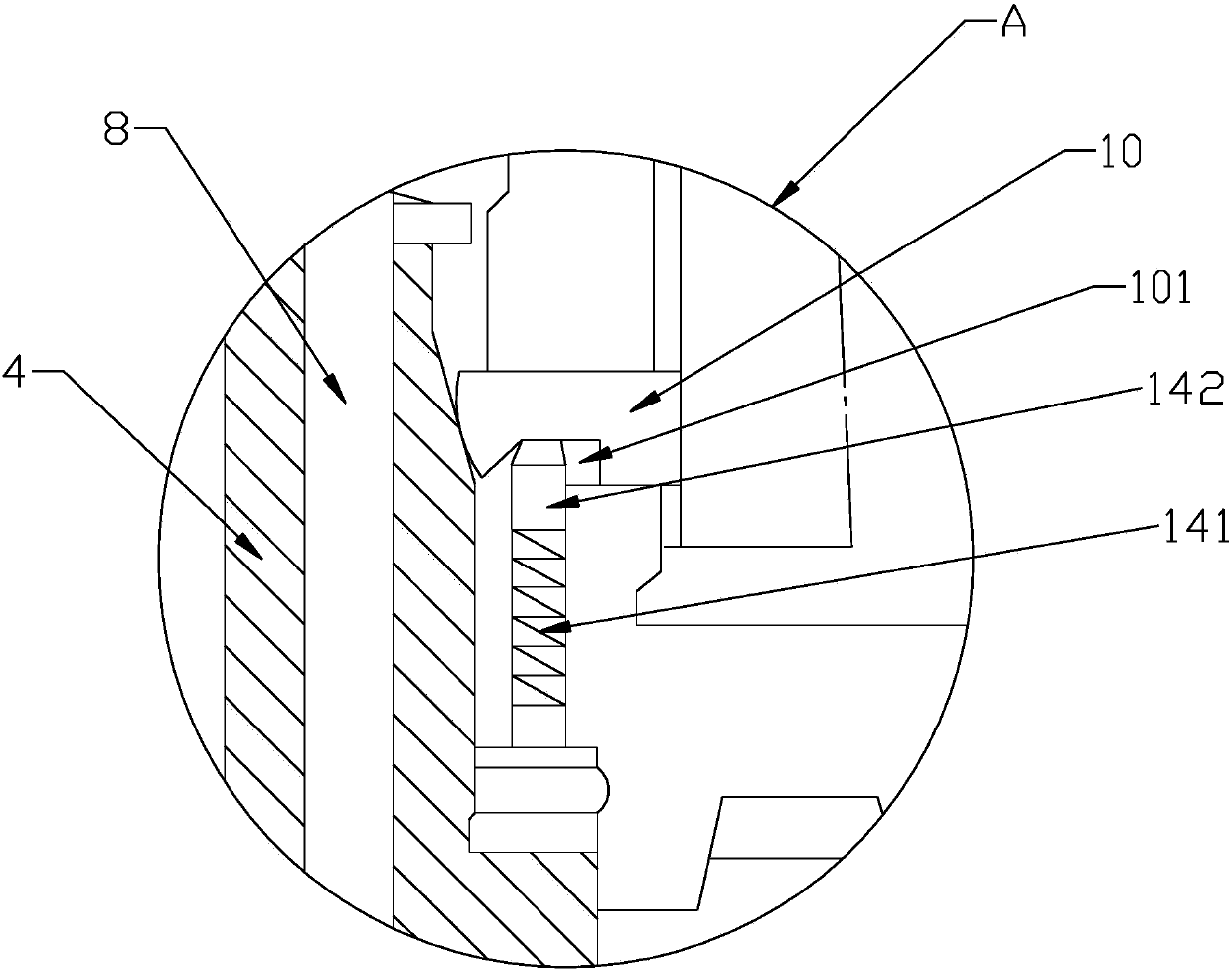

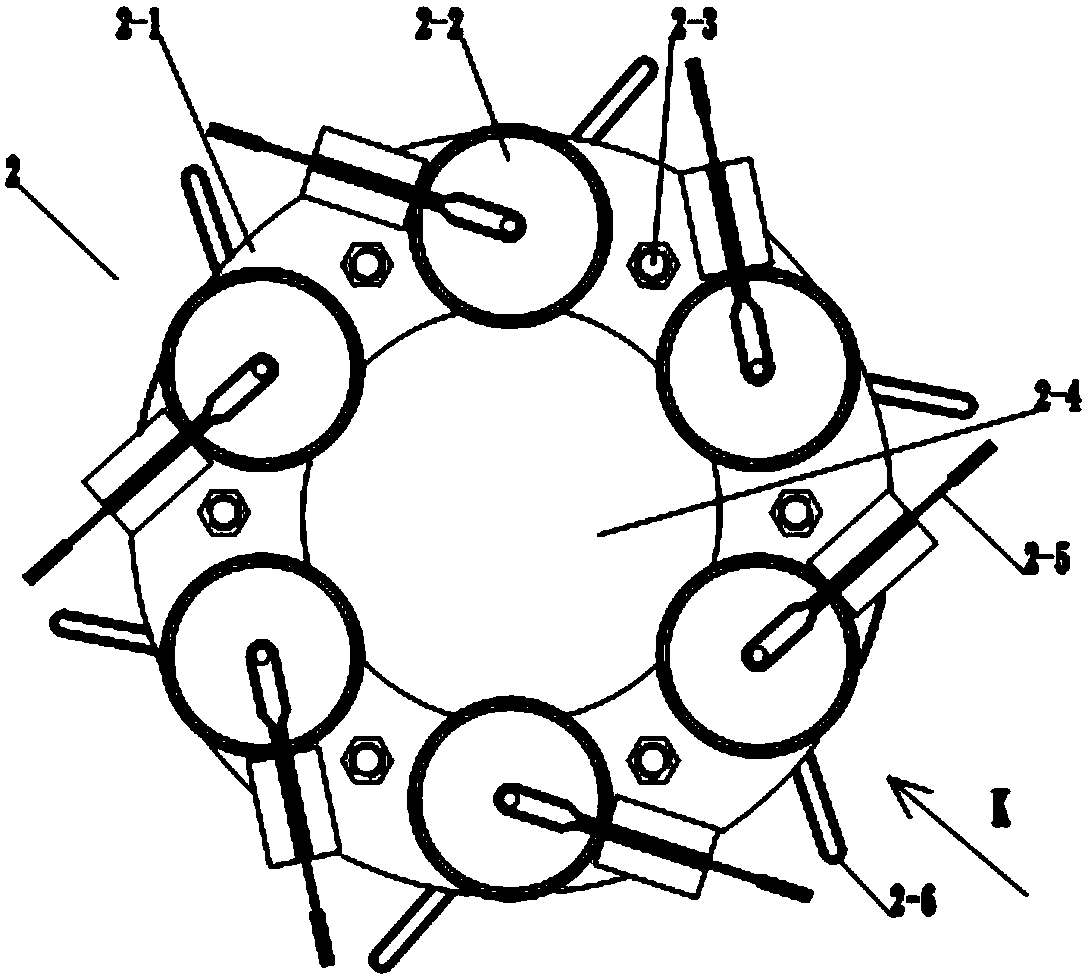

Clamp device for carrying out groove milling on wheel disk of gas turbine

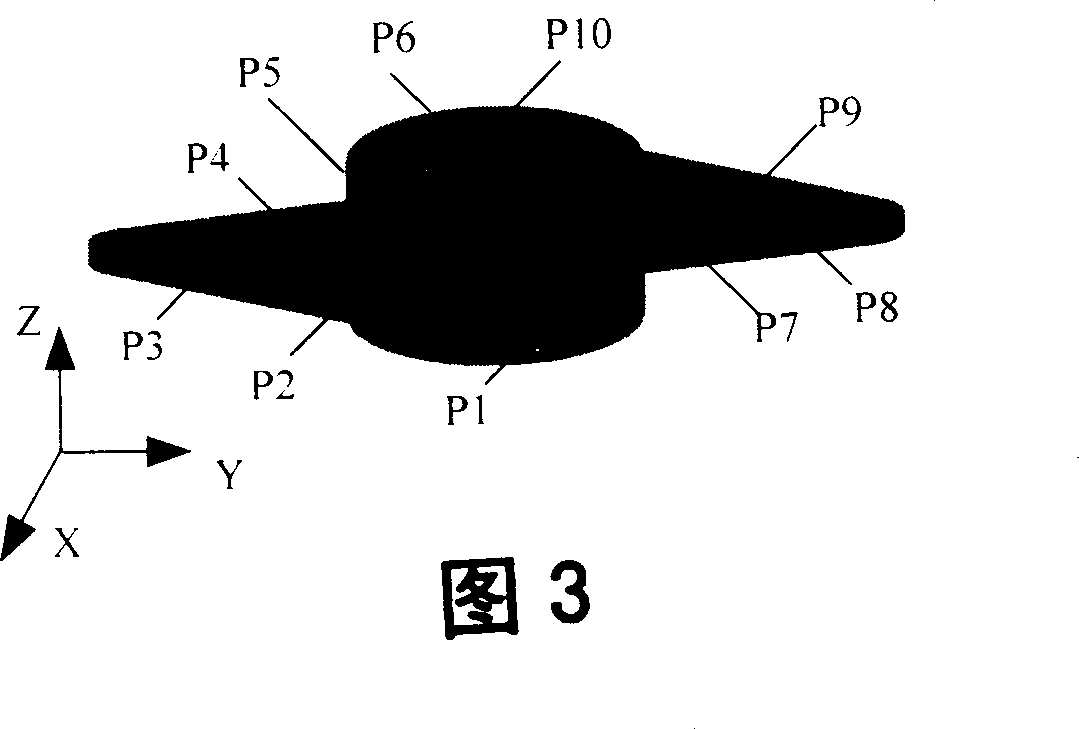

InactiveCN102320007AAccurate connectionSolve the clamping problemPositioning apparatusMetal-working holdersEngineeringMachining process

The invention discloses a clamp device for carrying out groove milling on a wheel disk of a gas turbine and relates to a clamp device. The invention solves the problem of difficulty in positioning and clamping in the machining process of the wheel disk of the existing gas turbine. A base (1), an indexing table (16), a clamp body (5) and a gland (6) of the clamp device are arranged sequentially from bottom to top. The base (1) and the indexing table (16) are relatively fixedly arranged through a plurality of pressure plates (14). The indexing table (16) and the clamp body (5) are relatively positioned through a plurality of positioning keys (13). The clamp body (5) and the gland (6) are relatively positioned through a plurality of positioning pins (12). The clamp body (5) and the gland (6) are relatively fixed through a double-thread screw (7) and a nut (8). A support frame (3) is arranged between the base (1) and the clamp body (5). The clamp body (5) and the support frame (3) are relatively positioned through a positioning inserted pin (4). The clamp device is suitable for the positioning and clamping of the wheel disks of various types of gas turbines.

Owner:HARBIN TURBINE

Machining method used for steel 35 and 3Cr13 metal material welding rack

ActiveCN104907774ASolve Welding ProblemsGuaranteed welding effectMachine framesStands/trestlesSand blastingMetallic materials

The invention relates to a machining method used for a steel 35 and 3Cr13 metal material welding rack. The machining method includes steps of 1) feeding parts; 2) welding, to be specifically, a) welding by a manual electric arc welding method, and b) selecting welding rods, selecting J507 steel welding rods for welding a frame base material, and selecting Ao302 welding rods for welding the combined portion of the frame base material and the insert material; c) welding according to the processes including firstly fixing welding parts on a welding platform by a rigid fixing method and welding the welding parts symmetrically, to be specifically, welding four corners of the welding parts symmetrically, cooling the parts to be welded and then welding inwards layer by layer, welding the first layer and welding the next layer after the parts to be welded are cooled; after welding, eliminating welding stress by vibration distressing; 3) thermally treating; 4) spraying sand; 5) detecting flaw; 6) scribing by a bench worker; 7) milling; 8) finely machining; 9) detecting and measuring. The machining method is reasonable in technique, and machining accuracy and welding quality of the welding rack of two metal materials are guaranteed.

Owner:XIAN NORTH ELECTRO OPTIC TECH DEFENSE

Metal polisher

InactiveCN106975993ATo achieve the mobile effectTo achieve the storage effectEdge grinding machinesGrinding carriagesEngineeringMetal polisher

The invention discloses a metal grinding machine, comprising a base, a support plate is fixedly connected to both sides of the top of the base, a cylinder is fixedly connected to one side of the support plate, and a cylinder is fixedly connected to an end far away from the support plate. The first splint, the bottom of the first splint is provided with a long hole, the inside of the long hole is provided with a second splint, the side of the second splint close to the cylinder is provided with a slot, the bottom of the surface of the first splint and There is a first groove on the side close to the cylinder; the invention achieves the effect of driving the movement of the first splint by setting the cylinder, the effect of storing the second splint through the long hole, and the effect of fixing the clamping block through the spring , through the block and slot, the effect of fixing the second splint can be achieved, and the effect of increasing the area of the splint can be achieved through the first splint and the second splint, which can clamp metals of different sizes, which is convenient for users to adjust the splint of different sizes. metal for grinding.

Owner:长兴达程科技有限公司

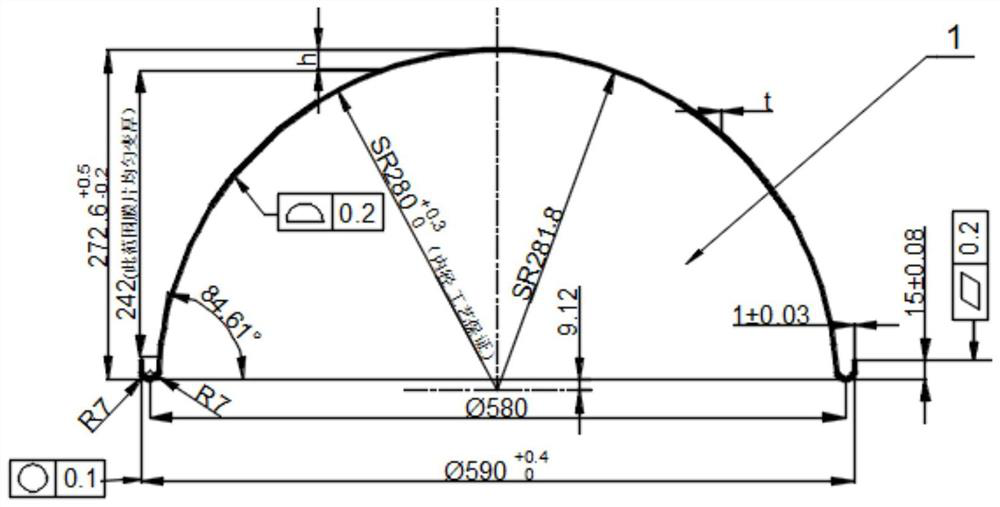

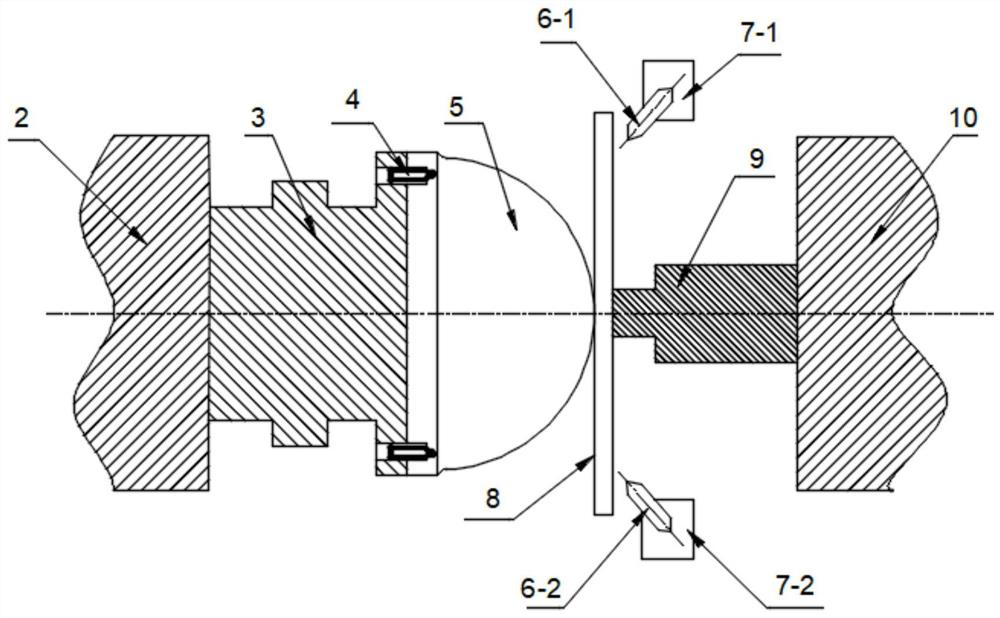

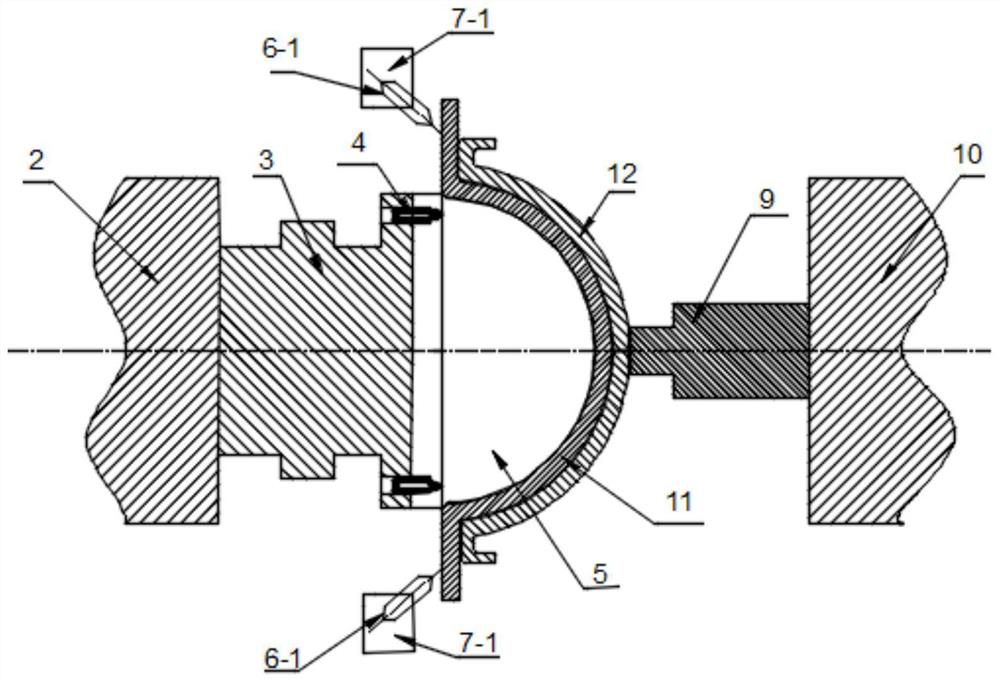

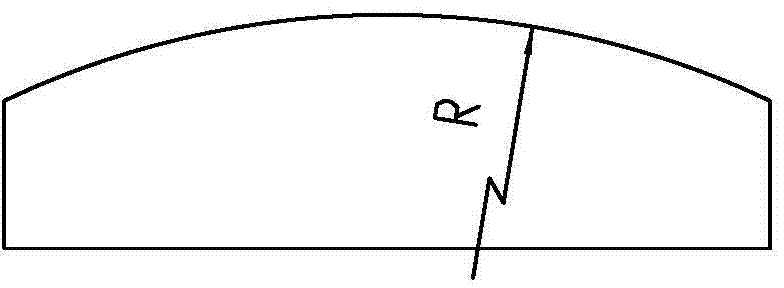

Precise forming method for large-size variable-curvature thin-wall storage tank diaphragm

The invention discloses a precise forming method for a large-size variable-curvature thin-wall storage tank diaphragm. The precise forming method comprises the following steps that a circular plate-shaped blank is spun into a hemispherical shell with a flanging on the end surface; a plane reference of the end surface is processed after heat treatment; an outer spherical surface reference is processed by using the plane reference; an inner spherical surface, a flanging outer spherical surface and a maximum outer circular surface are processed by using the outer spherical surface reference; and an outer spherical surface and a flanging inner spherical surface are processed by using the plane reference. Compared with traditional punch forming, by means of spinning forming, raw materials can be greatly saved, forming processing can be carried out through thin blanks, a special tool clamp is designed and manufactured, a vacuum suction cup is adopted for adsorption, and the problems of thickness control and clamping of a large-size variable-curvature thin-wall part are successfully solved; and through precise matching of the spherical tool and the inner and outer spherical surfaces of the part, the deformation problem of the thin-wall part during processing is effectively solved.

Owner:GUIZHOU AEROSPACE TIANMA ELECTRICAL TECH

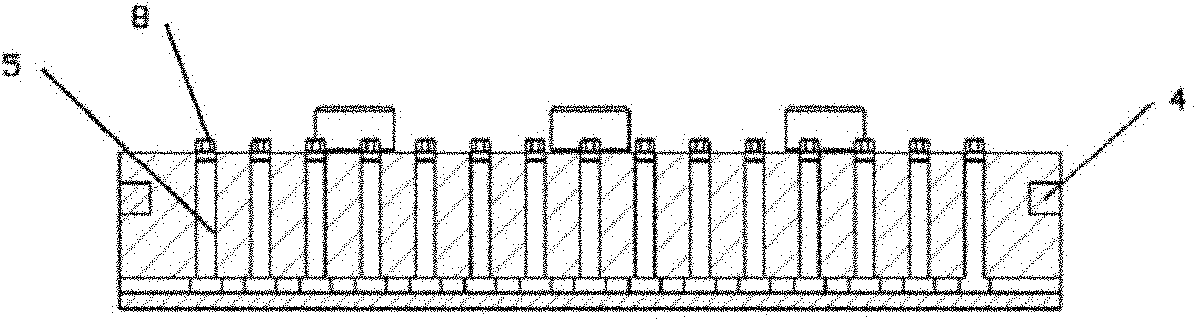

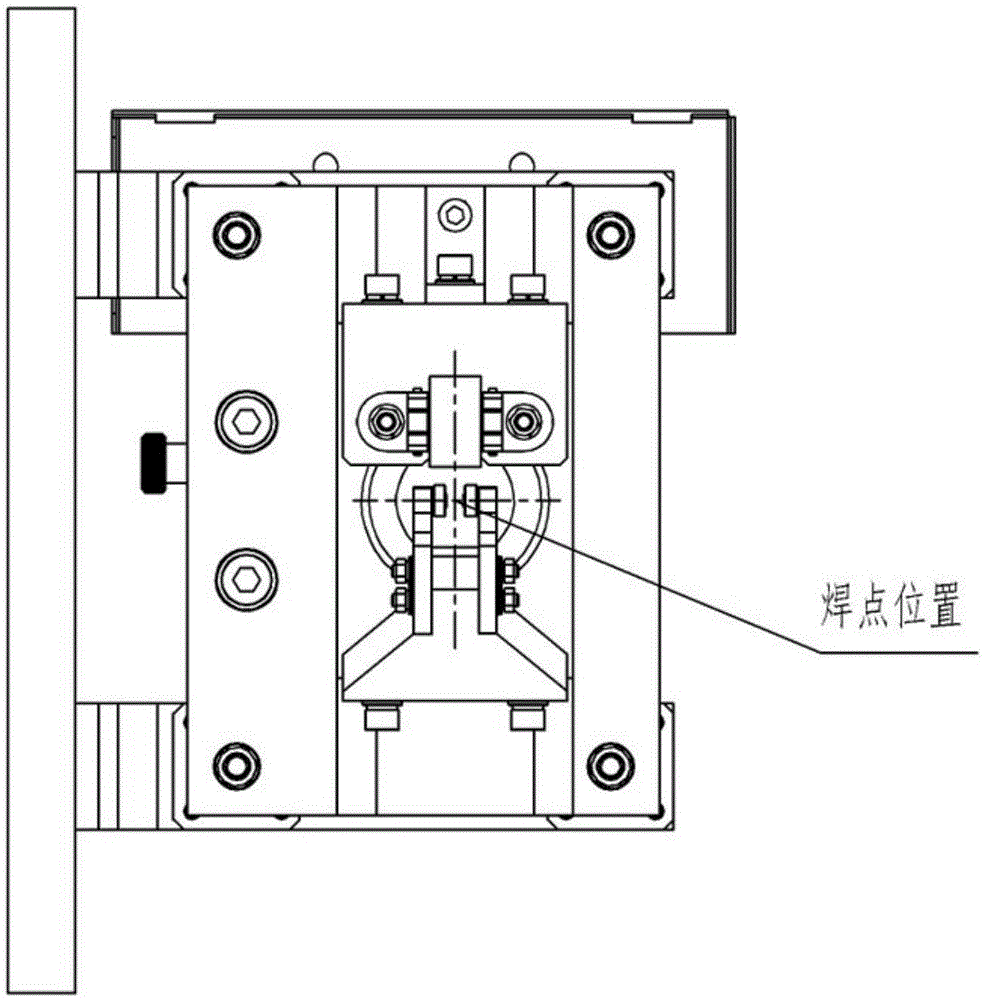

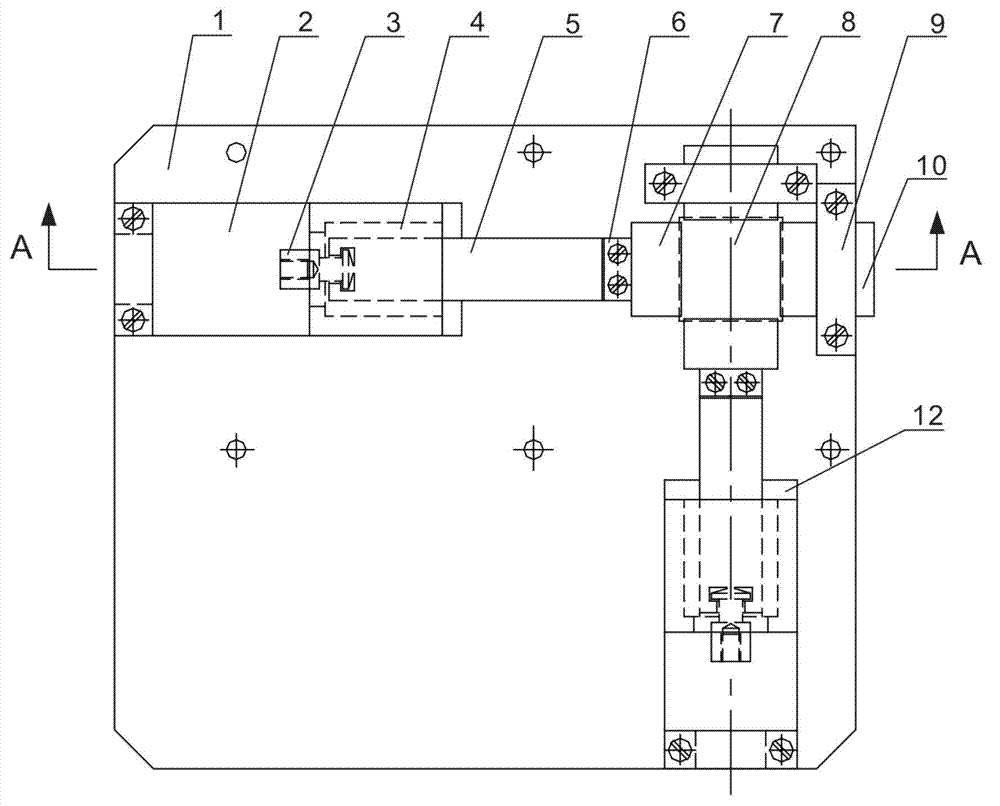

Laser welding clamp of sealed relay

ActiveCN103240534ASolve the clamping problemAvoid wasting time and effortWelding/cutting auxillary devicesAuxillary welding devicesLaserWelding

The invention discloses a laser welding clamp of a sealed relay, the laser welding jig comprises a base plate, cushion blocks, and two groups of positioning mechanisms and clamping mechanisms which are respectively vertical to each other. The cushion block is mounted on the base plate and arranged between the positioning mechanisms and the clamping mechanisms. Changeable positioning press plates, sliding press plates and a large-stroke pneumatic clamping are adopted to position and clamp the sealed relays in different shapes and sizes, so that the problem about waste time and energy for entirely dismounting the laser welding clamp is avoided, tool cost is reduced, times for dismounting and mounting the clamp and adjusting welders are reduced, working efficiency is improved, and production cost is reduced.

Owner:GUIZHOU TIANYI ELECTRICAL

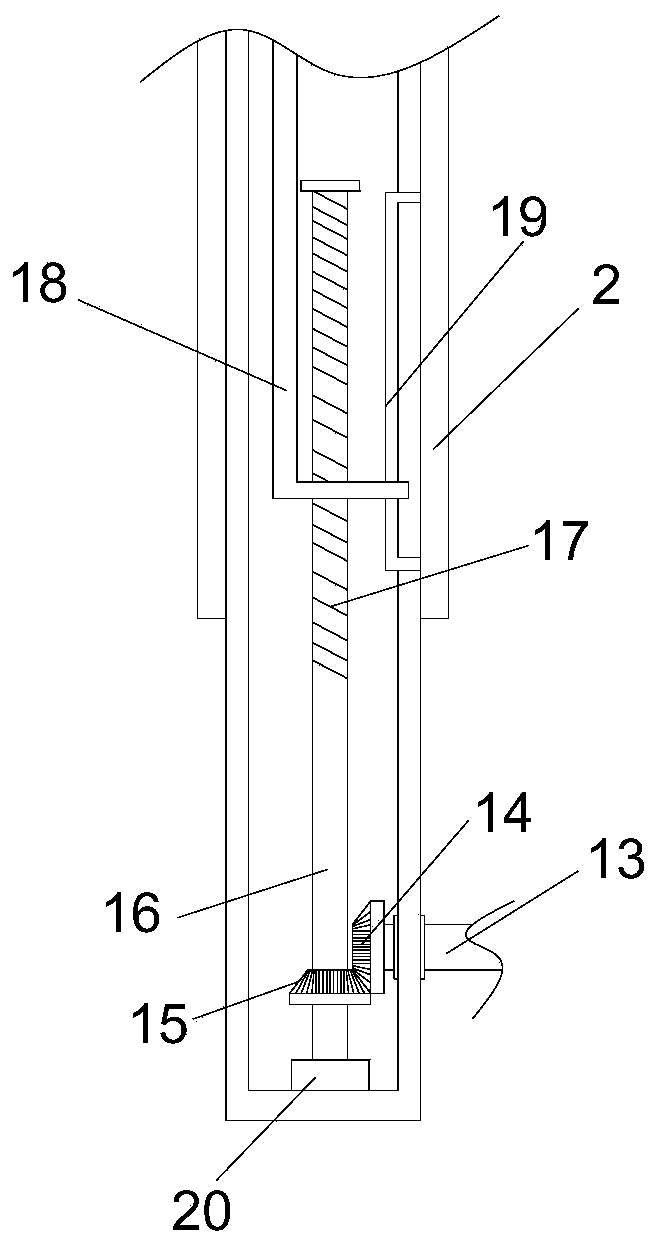

Lifting locating pin

ActiveCN104500532ASolve the clamping problemEasy to operateBoltsPositioning apparatusEngineeringLarge size

A lifting locating pin comprises a locating seat which is fixed to a bottom plate, wherein the locating seat comprises a barrel; a flange which outwards protrudes and is used for being fixed with the bottom plate is arranged on the outer wall of the barrel; a lifting pin sleeve is mounted in the barrel of the locating seat; a locating pin is inserted into the upper end of the lifting pin sleeve; two vertical guide slots which are symmetrical with respect to the central axis of the barrel are formed in the barrel and above the flange of the locating seat; two assembly holes are formed in positions, corresponding to the lower parts of the vertical guide slots, of the lifting pin sleeve; a rotating ring sleeves the outside of the barrel part above the flange of the locating seat; two spiral guide slots are correspondingly formed in the inner wall of the rotating ring; a bayonet lock is inserted into the vertical guide slots and the two assembly holes of the lifting pin sleeve; two ends of the bayonet lock are arranged in the spiral guide slots in the inner wall of the rotating ring. According to the invention, a workpiece clamping problem on a workpiece processing line is solved, time is saved, the work efficiency is improved, the product quality is ensured, bump is effectively prevented, and the lifting locating pin is particularly suitable for one-face two-pin location of a heavy product with a relatively large size.

Owner:XINXING HEAVY IND HUBEI 3611 MECHANICAL

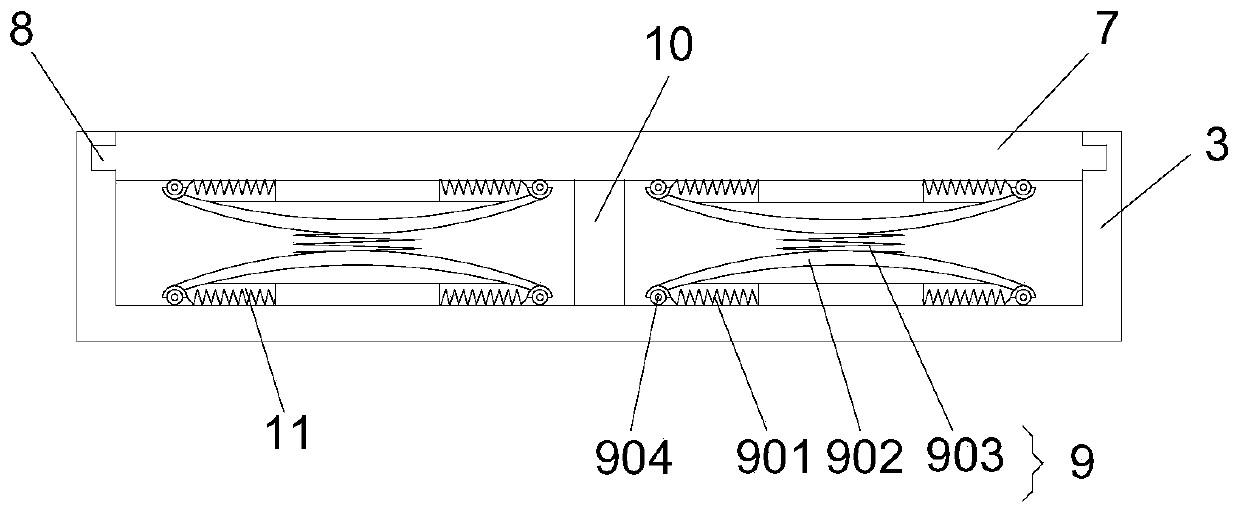

Casting machine cooling mechanical arm with motion track memory function

ActiveCN110653833AWith memory motion track functionSolve instabilityGripping headsRobot handEngineering

The invention relates to the technical field of a casting machine cooling mechanical arm, and discloses a casting machine cooling mechanical arm with a motion track memory function, which includes brackets, fixing plates, a horizontal driving mechanism, an overturning mechanism, a receiving plate and a clamping rod; lifting pillars are arranged at the top ends of the four bracket; the two fixing plates are respectively and fixedly mounted at the top parts of the four lifting pillars on the left side and the right side; the horizontal driving mechanism is fixedly mounted at the top parts of thetwo fixing plates; a vibration damping plate is arranged at the top surface of each fixing plate, and is clamped at the inner top of the cavity of the corresponding fixing plate; a vibration dampingpiece and a rubber plate are fixedly mounted at the bottom of each vibration damping plate; each vibration damping piece consists of a limiting spring, an arc block, a damping spring and a roller. The casting machine cooling mechanical arm with the motion track memory function realizes that vibration caused by operation of the horizontal driving mechanism is completely buffered and reduced underthe combined action of the vibration damping plates and the vibration damping piece, and solves the problem of unstable object clamping of the bottom caused by operation vibration of the horizontal driving mechanism.

Owner:唐山旺发压铸有限公司

Automatic rubberizing method and equipment for lithium battery

InactiveCN110911758ASolve the loop problemImprove orderNon-aqueous electrolyte cellsFinal product manufactureAdhesive beltEngineering

The invention relates to the field of battery production mechanical automation, in particular to lithium battery automatic adhesive tape sticking equipment which comprises a conveying device, an adhesive tape preparation device, an adhesive tape sticking device and an adhesive tape pressing and wrapping device. The conveying device is of a rotary disc structure, jigs are arranged on the conveyingdevice, and the conveying device conveys a battery to be machined into the glue preparing device, the glue pasting device and the glue pressing and wrapping device through the jigs to be machined formachining. The adhesive tape preparation device is arranged in an adhesive tape pasting area of the conveying device and is used for feeding and cutting an adhesive tape; the adhesive tape sticking device is connected to the adhesive tape preparation device and is used for sticking the cut adhesive tape to the battery in the adhesive tape sticking area; the adhesive pressing and coating device isarranged in the adhesive pressing and coating area, and is used for pressing the front surface of the adhesive tape and coating the redundant adhesive tape on the back surface of the battery; and after the glue pressing and the glue coating are completed, the conveying device discharges the processed batteries. The battery gluing device has the technical effects that the battery is limited throughthe jig, so that the gluing accuracy is ensured; and the back surface of the battery is coated with rubber through the rubber folding mechanism and the rubber coating mechanism, so that equipment functions are enriched.

Owner:张俊

Floating inner support positioning clamping device

InactiveCN107617755AImprove clamping effectSolve the clamping problemExpansion mandrelsArchitectural engineeringSteel ball

The invention relates to the technical field of clamping devices, in particular to a floating inner support positioning clamping device. The device comprises a base, a driving rod, a first expansion block, a second expansion block, a third expansion block, a linkage block, a steel ball and a connecting rod; the base is of a cavity structure, the driving rod is fixedly connected with the first expansion block, the outer wall of the first expansion block is in sliding connection with the inner wall of the base, the inner wall of the first expansion block is in sliding fit with the steel ball, the steel ball abuts against the second expansion block and the wedge face of the linkage block at the same time, the linkage block is fixedly connected to the lower end of the connecting rod, a cavityallowing the connecting rod to move downwards is formed in the first expansion block, the middle and the upper portion of the connecting rod are sleeved with the second expansion block and the third expansion block correspondingly, and the second expansion block and the third expansion block are in sliding fit with the connecting rod. The floating inner support positioning clamping device in the technical scheme has the beneficial effects of being good in fixing clamping effect and capable of effectively ensuring workpiece machining quality.

Owner:成都中源红科技有限公司

Device for turning and grinding outer cylindrical surfaces

InactiveCN104723151ASolve the clamping problemAppropriate dimensionsWork clamping meansPositioning apparatusEngineeringMachine tool

The invention relates to a device for turning and grinding outer cylindrical surfaces. The device is used for machining the outer cylindrical surfaces of outer cylindrical surface class workpieces with the central angle being smaller than 180 degrees. The device comprises a clamp body and a fixing piece, the two ends of the clamp body are each provided with a section of cylinder, and center holes are formed in the end faces of the cylinders. A clamp main body is arranged in the middle of the clamp body, workpiece locating surfaces are arranged on the clamp main body, and the fixing piece and the clamp main body are matched so that the workpieces can be located and clamped on the workpiece locating surfaces. The device for turning and grinding the outer cylindrical surfaces solves the clamping problem for machining the outer cylindrical surfaces of non-whole-cylindrical-face class workpieces on a machine tool, the workpieces can be used for one-piece blanking according to the appearances of the workpieces, the appearance sizes of the workpieces are made more appropriate, raw materials are saved, meanwhile, the machining amount and machining difficulty are reduced, two or more workpieces can be clamped to be machined at the same time, and thus the machining efficiency is improved.

Owner:LUOYANG INST OF SCI & TECH

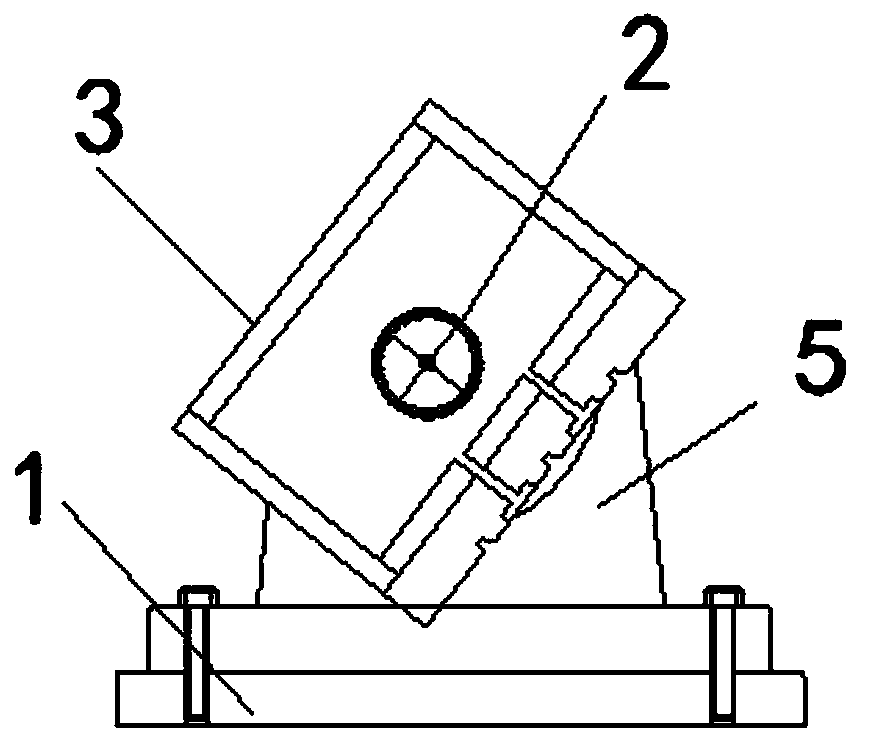

Rotary type vacuum adsorption die

PendingCN109048438ASimple structureSimple and fast operationPositioning apparatusMetal-working holdersEngineeringMachining

The invention discloses a rotary type vacuum adsorption die. An adsorption die is arranged on the outer periphery of a vacuum vent pipe in a sleeving manner. The two ends of the vacuum vent pipe are installed on a first bearing support seat and a second bearing support seat through bearings correspondingly. One end of the vacuum vent pipe is closed, and the other end of the vacuum vent pipe is provided with a vacuumizing connector. The side wall of the vacuum vent pipe is provided with multiple vent holes. The outer surface of the adsorption die is provided with multiple adsorption through holes and multiple grooves to form an adsorption surface, and the adsorption surface is used for holding a to-be-machined furniture component. According to the machining demand of the furniture component, the rotary type vacuum adsorption die is fixed to a table top of a three-dimensional machining center, through the vacuumizing connector, the inner portion of the vacuum vent pipe is vacuumized, theto-be-machined furniture component is adsorbed to the adsorption surface, the vacuum vent pipe is rotated to adjust the rotation inclination angle of the to-be-machined furniture component, so that the four-dimension machining demand of the to-be-machined furniture component, the to-be-machined component, can be met, and therefore the locating and clamping problems existing when a three-dimensionmachining center machines a four-dimension space furniture component are solved.

Owner:HEBEI BLUEBIRD FURNITURE CO LTD

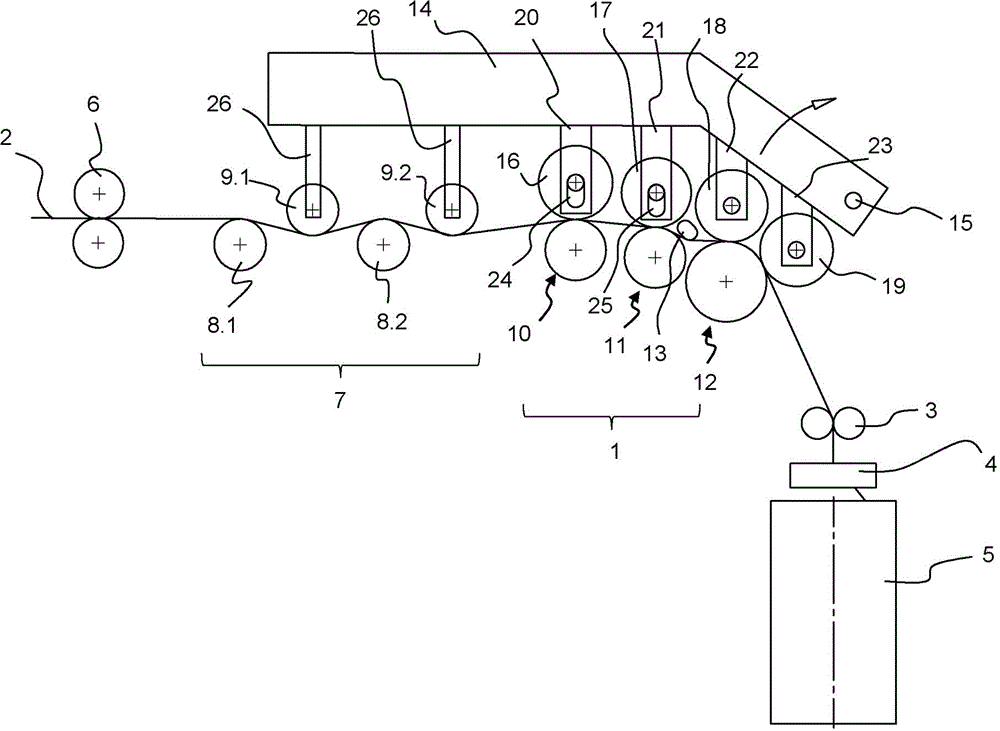

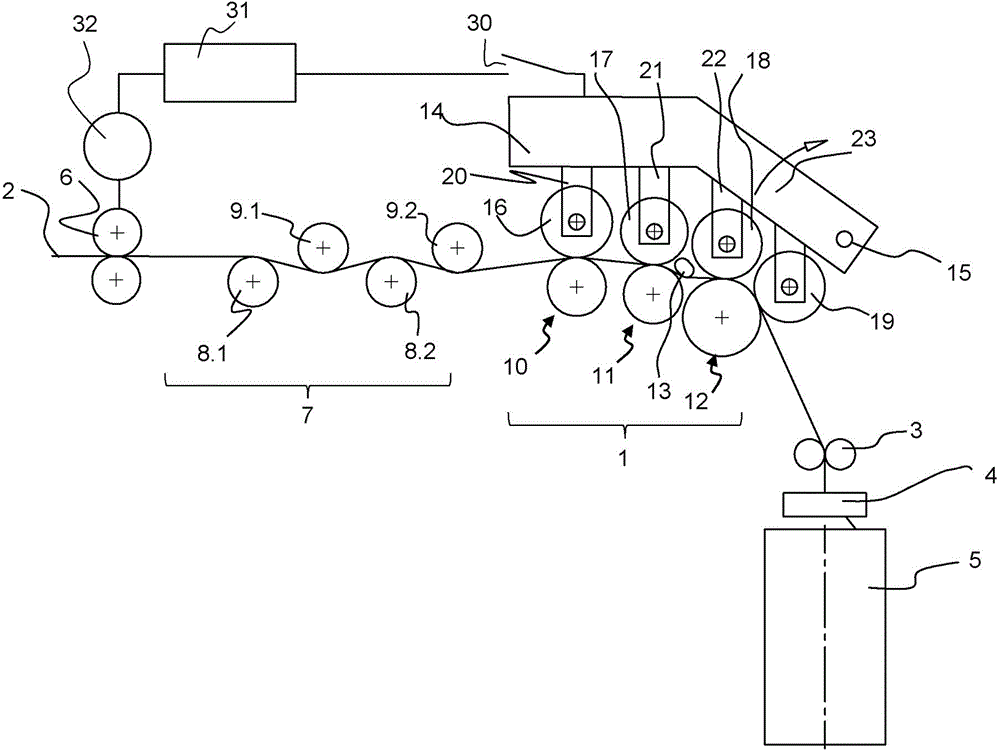

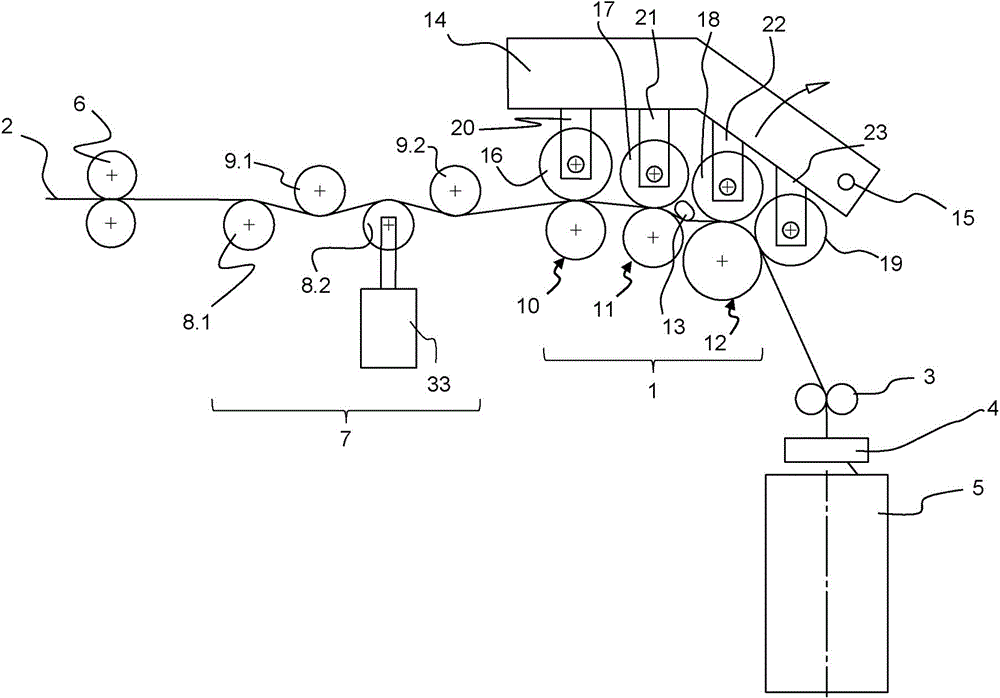

Method for opening a drafting system

In a method for opening a drafting arrangement (1) with a plurality of pairs of rollers for drawing a sliver (2), the fiber tape (2) between a pair of transport rollers (6) and an at least one input and a pair of output rollers (10, 12), a preferably input, at least one central and a pair of output rollers (10, 11, 12) comprising a drafting unit (1) taut, wherein each roller pair of the drafting unit (1) has at least one upper and one lower roll. Before opening of at least the input and / or middle roller pair (10, 11) of the drafting arrangement (1), the tension of the sliver (2) between the transport roller pair (6) and the drafting unit (1) is reduced, in particular released. In a corresponding drafting arrangement by means of a mechanical or electrical coupling or ; Control prior to the opening of at least the input and / or middle roller pair (10, 11) of the drafting arrangement (1), the tension of the sliver (2) between the transport roller pair (6) and the drafting unit (1) is reduced, in particular released.

Owner:RIETER INGOLSTADT GMBH

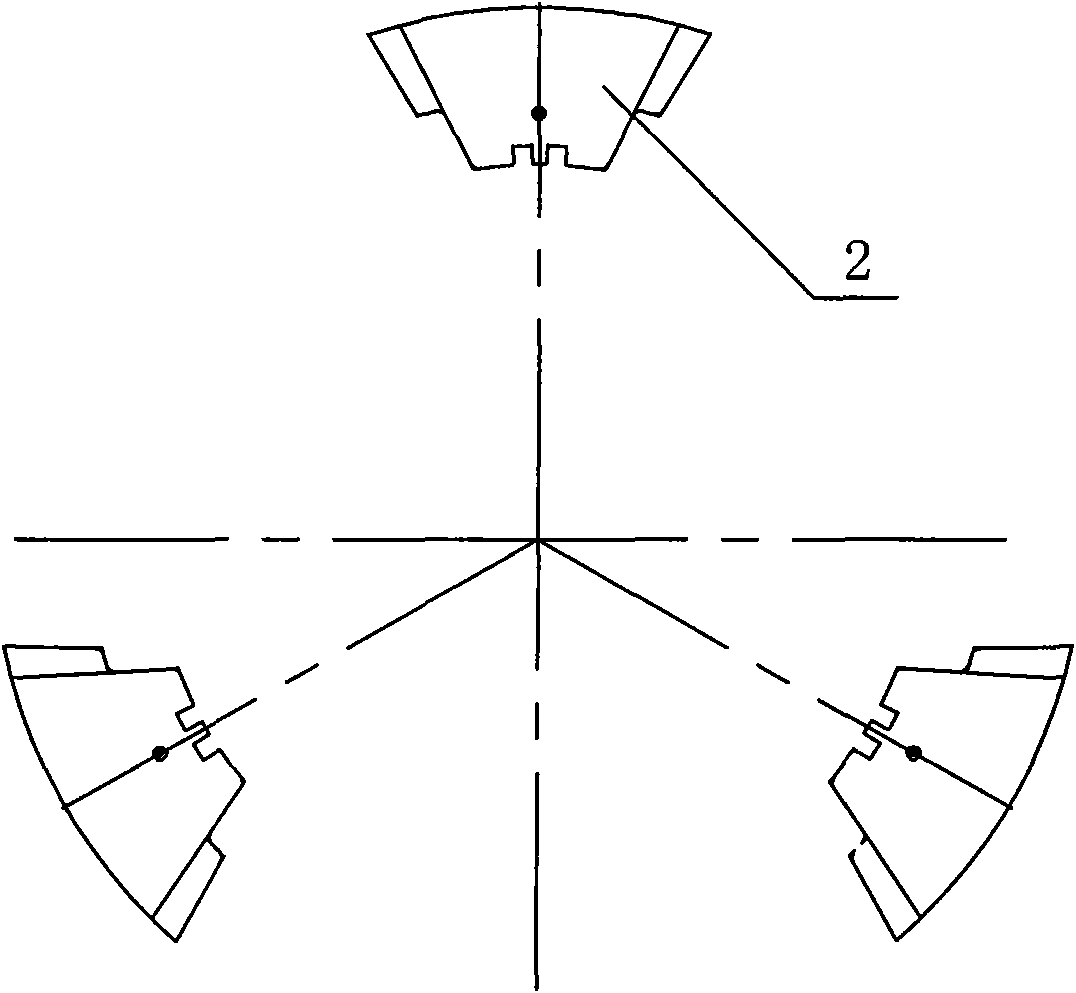

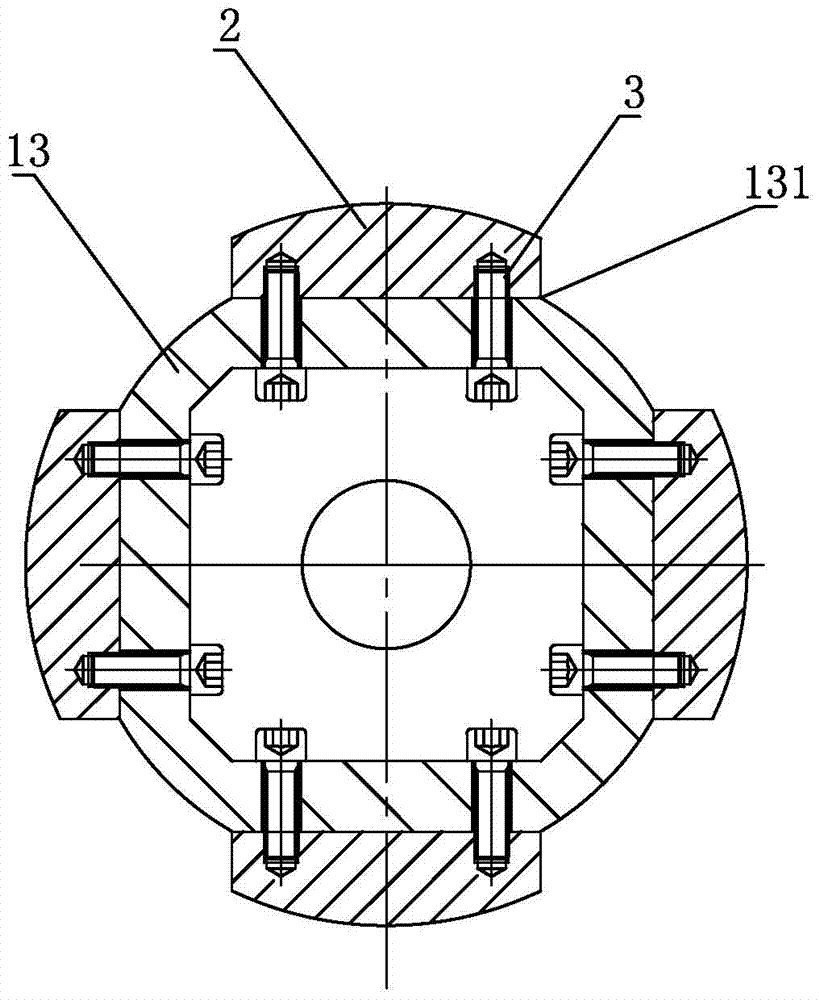

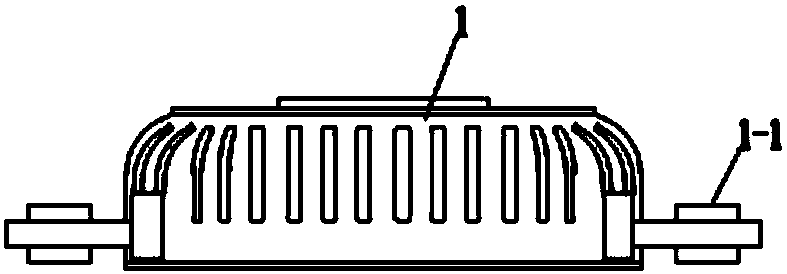

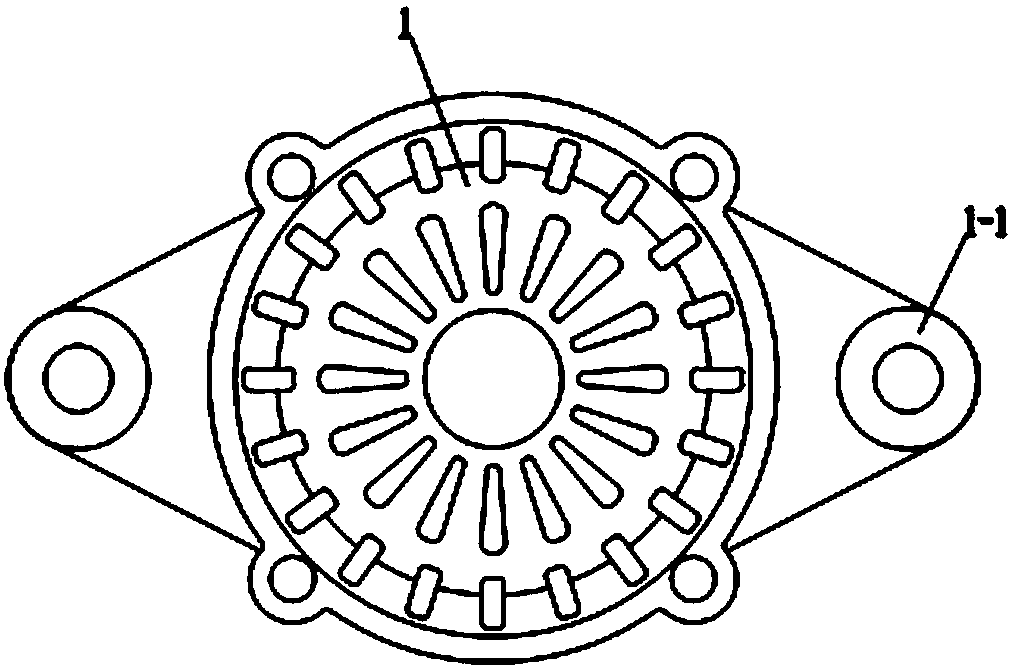

Clamping and positioning device for automobile generator end cover machining

PendingCN108080991ARealize simultaneous clampingSolve the clamping problemPositioning apparatusMetal-working holdersEngineeringMachining process

A clamping and positioning device for automobile generator end cover machining is of a vertically arranged double-layer structure, and is composed of a first workpiece clamping mechanism and a secondworkpiece clamping mechanism. An upper fixing plate of a circular ring structure is arranged in the first workpiece clamping mechanism. Upper clamping assemblies and first workpiece positioning seatsare evenly arranged on the upper end face of the upper fixing plate in the circumference direction, and each upper clamping assembly and the first workpiece positioning seat opposite to the upper clamping assembly form an upper clamping unit. Second workpiece positioning seats matched with the second workpiece clamping mechanism are evenly arranged on the bottom face of the upper fixing plate in the circumference direction. The second workpiece clamping mechanism is provided with a lower fixing plate of a disc structure, lower clamping assemblies are evenly arranged at the circumferential edgeposition of the lower fixing plate, and each lower clamping assembly and the second workpiece positioning seat opposite to the lower clamping assembly form a lower clamping unit. By means of the clamping and positioning device for automobile generator end cover machining, multiple workpieces can be clamped in the automobile generator end cover machining process, and the purposes of improving theworking efficiency and ensuring consistency with normal production takt are achieved.

Owner:玉田县华兴压铸有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com