Lifting locating pin

A technology of lifting positioning and positioning seat, applied in the field of positioning device and mechanical parts processing, can solve the problems such as the process hole and the positioning pin cannot be overlapped, the positioning pin is easy to break, the clamping and positioning are difficult, etc., and the structure is simple and not easy to bump. , the effect of low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

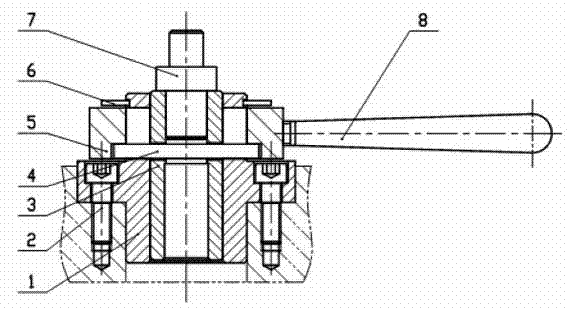

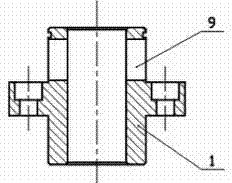

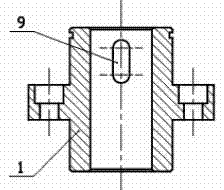

[0013] figure 1 Among them, the positioning seat 1 is fixed on the bottom plate by the screw 2, the lifting pin cover 3 is installed in the inner hole of the positioning seat 1, the bayonet pin 4 is inserted into the vertical guide groove 9 of the positioning seat 1 and the side hole of the lifting pin cover 3, and the rotation The ring 5 is set on the positioning seat 1, the bayonet pin 4 is inserted into the spiral guide groove 10 of the rotating ring 5, and there is a clamp spring 6 for the shaft preventing the rotating ring 5 from falling off from the positioning seat 1 above the rotating ring 5, and the handle 8 passes through the screw thread. Fixed on the rotating ring 5, the positioning pin 7 is interference fit in the lifting pin sleeve 3 holes.

[0014] Rotate the handle 8 on the rotating ring 5, and the helical guide groove 10 in the rotating ring 5 promotes the bayonet pin 4 to move up and down, and the bayonet pin 4 drives the lifting pin sleeve 3 to move up and d...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com