Rotary type vacuum adsorption die

A vacuum adsorption and rotary technology, applied in the direction of manufacturing tools, clamping, supporting, etc., can solve the problems that are unfavorable for the survival and development of furniture manufacturers, the requirements for the operator's technical level are also high, and cannot meet the processing needs, etc., to achieve Solve the problem of positioning and clamping, the structure is simple and reasonable, and the effect of low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

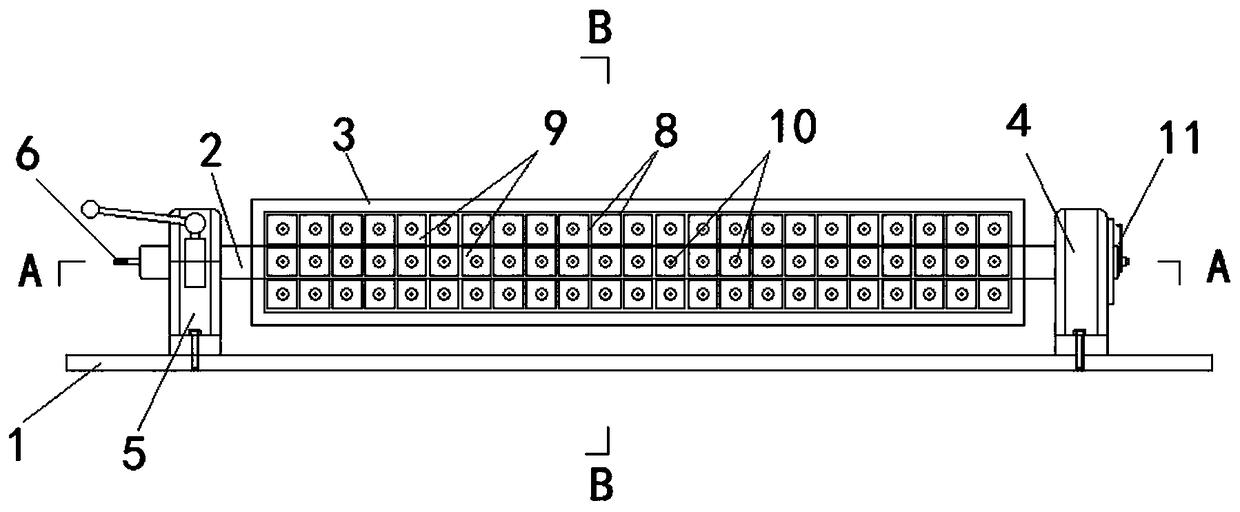

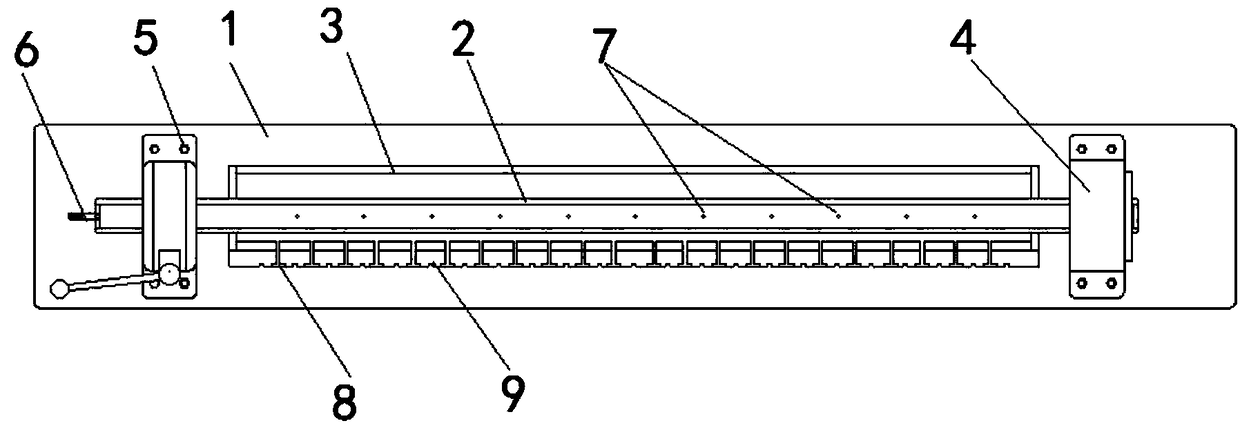

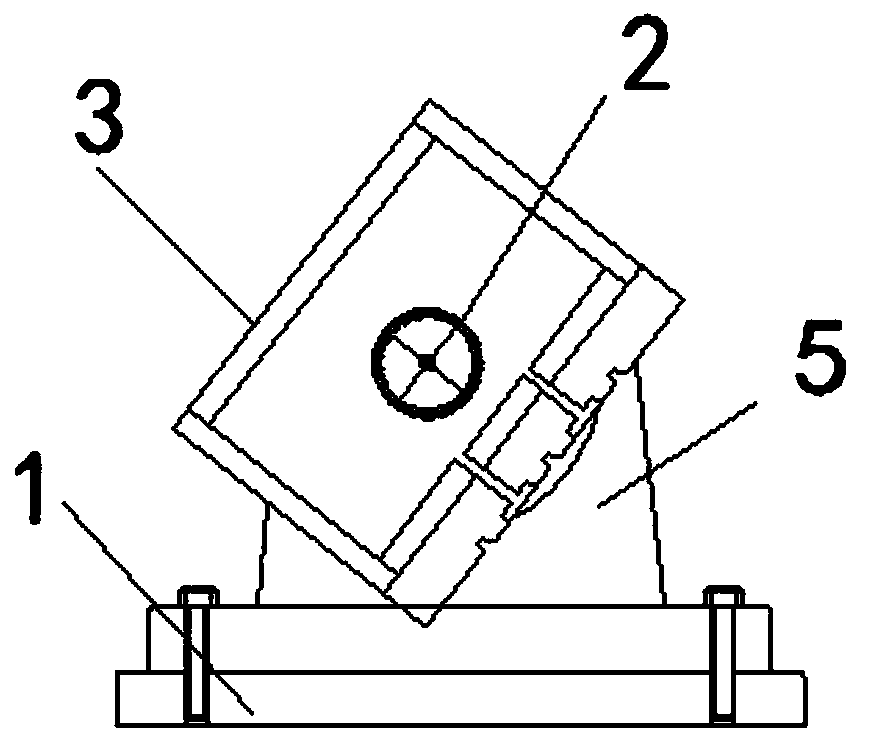

[0031] like Figure 1~4 As shown, the present embodiment provides a rotary vacuum adsorption mould, including a support base 1, a vacuum ventilation pipe 2 and an adsorption mold 3, the adsorption mold 3 is sleeved on the outer periphery of the vacuum ventilation pipe 2, and the two ends of the adsorption mold 3 are connected to the The outer walls of the vacuum vent pipe 2 are sealed, and the two ends of the support base 1 are respectively provided with a first bearing support 4 and a second bearing support 5, and the two ends of the vacuum vent pipe 2 are respectively installed on the first bearing support through bearings. 4 and the second bearing support 5, wherein the installation method of the bearing used to realize the vacuum vent pipe 2 is a conventional bearing method, and the bearing types that can realize the rotation of the vacuum vent pipe 2 can be adaptively applied to this embodiment , no longer go into details here; one end of the vacuum vent pipe 2 is closed,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com