Method for processing mounting system based on active addressing and position memory

A technology of installation system and processing method, applied in the field of workpiece processing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

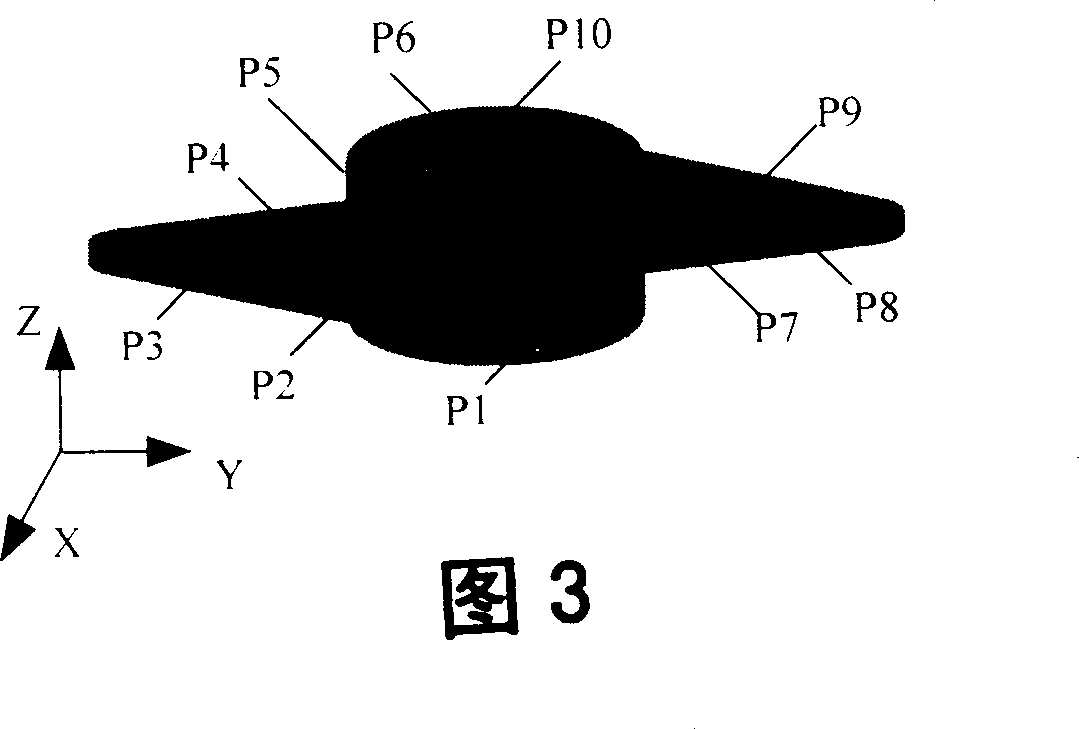

[0068] Taking the processing of the workpiece of the double-wing plunger seat as an example and referring to the accompanying drawings, the processing method based on the active positioning and position memory installation system of the present invention will be described in detail.

[0069] (1) Analysis of processing objects: (see Figure 3) It can be seen from the working drawing and design requirements of the double-wing insert rod seat that the workpiece has poor rigidity and is not α- and β-symmetrical, and its main processing features are the upper and lower end faces, holes, and the upper and lower sides of the wings. and its surrounding contours. The material of the workpiece is 45 steel, and its relevant design dimensions are shown in Table 2. The roughness (Ra) of all processed surfaces is required to be 1.6 μm.

[0070] (2) Blank design: According to the design requirements and process characteristics, the profile is selected as the blank of the double-wing inserting...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com