A clamping device for elastic material radial milling

A clamping device and elastic material technology, applied in the field of mechanical processing, can solve the problems of large processing deformation, difficult precision, and difficult clamping of parts, and achieve the effects of small clamping deformation, improved milling efficiency and reliable performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

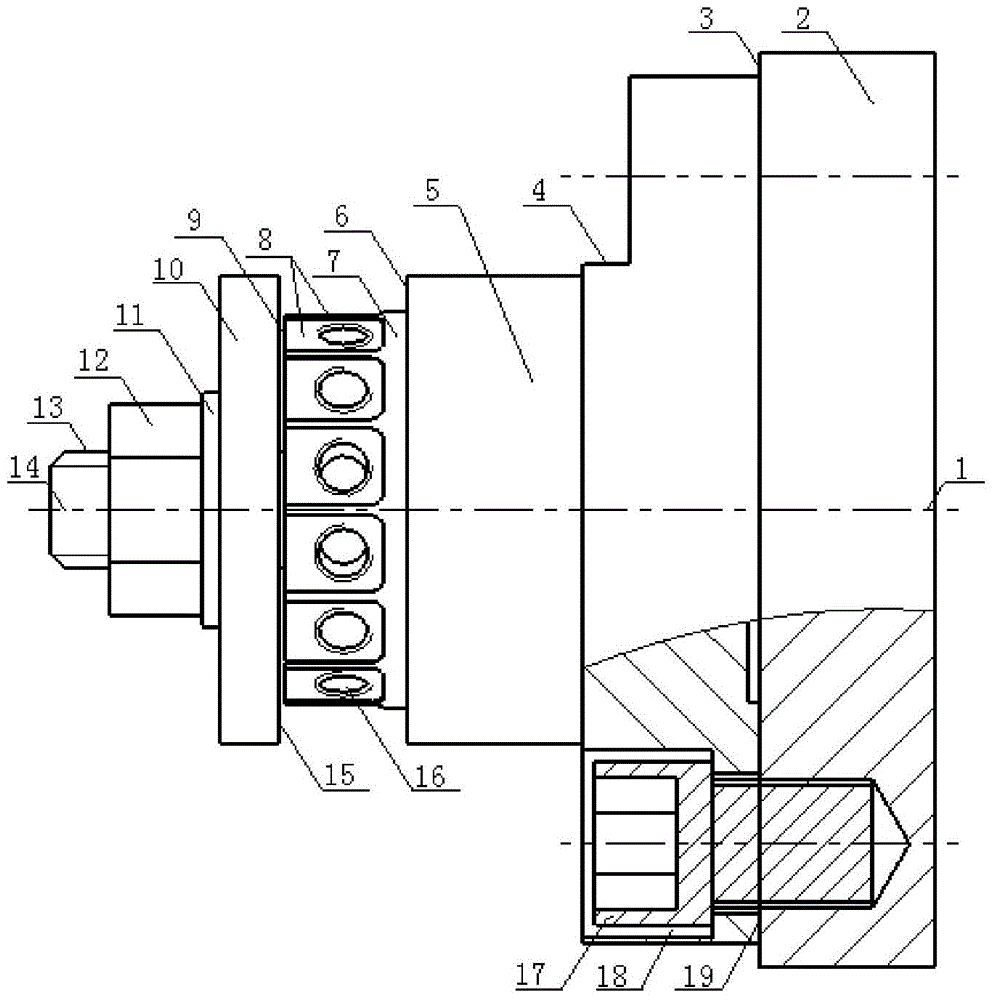

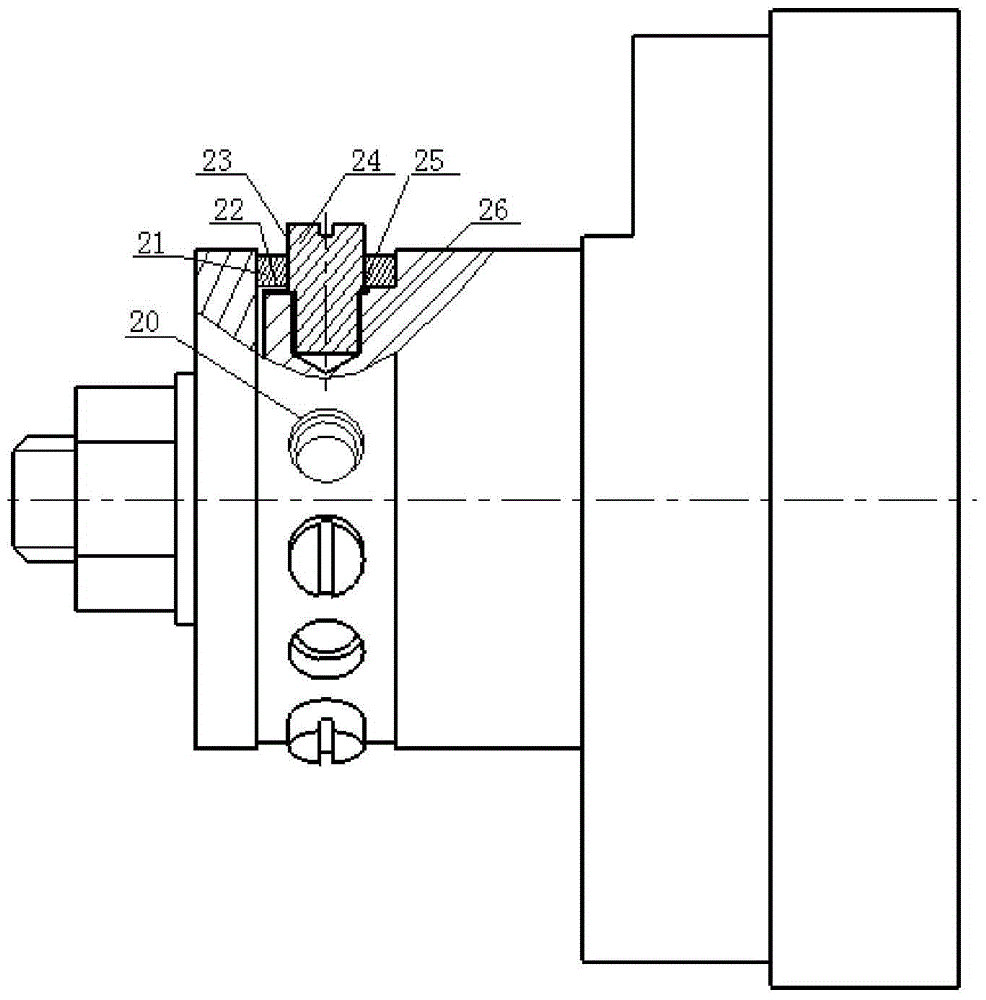

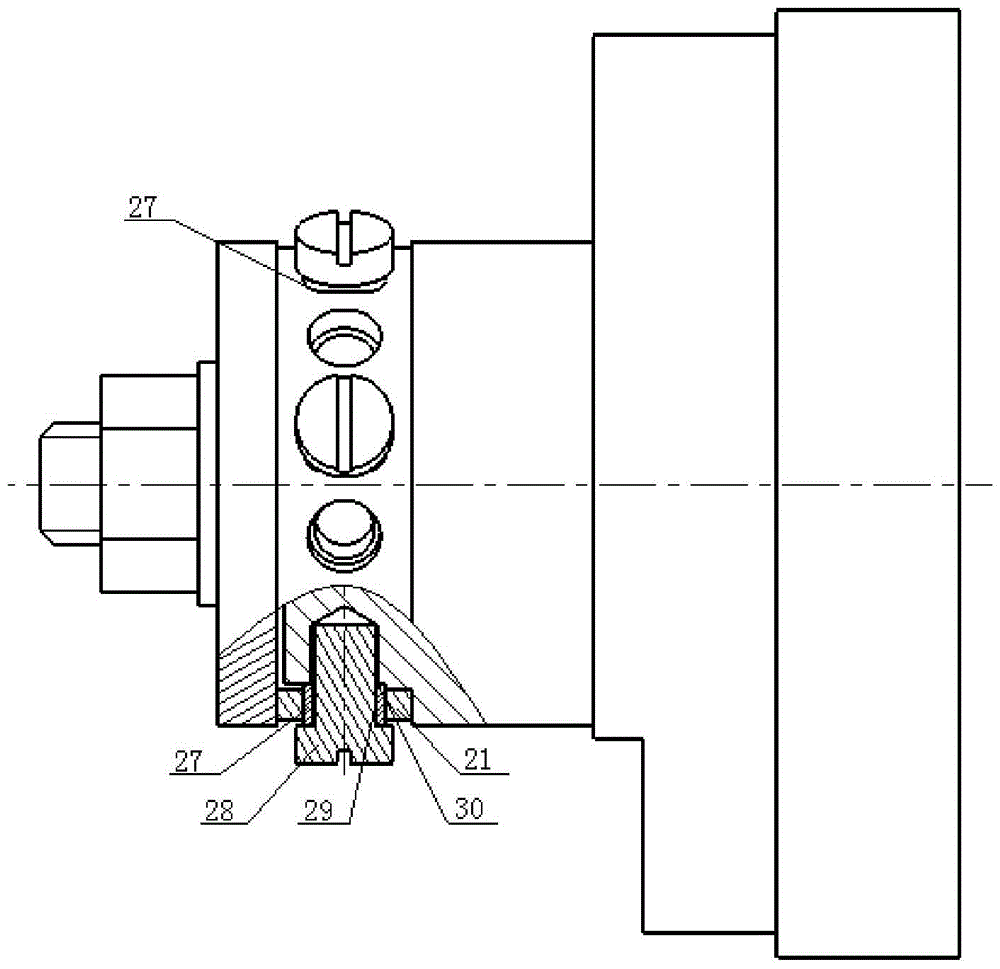

[0056] In order to make the purpose, technical solutions and advantages of the present invention clearer, the following in conjunction with specific examples, and with reference to the appended Figure 1 to Figure 4 Shown, the specific embodiment of the present invention will be further described.

[0057] The figure shows that the elastic material radial milling device involves: a base body 5, a pin 24, a square plate 27, a cover plate 10, a nut 12, a CNC dividing head workbench 2, and parts to be processed 21;

[0058]On the body of the base body, there are base external thread 13, base body left end face 9, axial positioning surface 6, radial positioning face 7, square sink platform 8, front face 4, base body right end face 19; Substrate screw hole 16;

[0059] The pin body is provided with a pin outer circle 23, a pin positioning surface 25, and a pin external thread 26;

[0060] A square plate positioning surface 30 and a through hole 29 are arranged on the square plate...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com