Design method of composite transformer water cooling tool

A composite transformer and design method technology, applied in workpiece clamping devices, manufacturing tools, etc., can solve the problems of reduced overall performance of tooling, low rigidity of tooling body, reduced machining accuracy, etc., so as to reduce machining costs and material costs. , the effect of reducing the use of materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

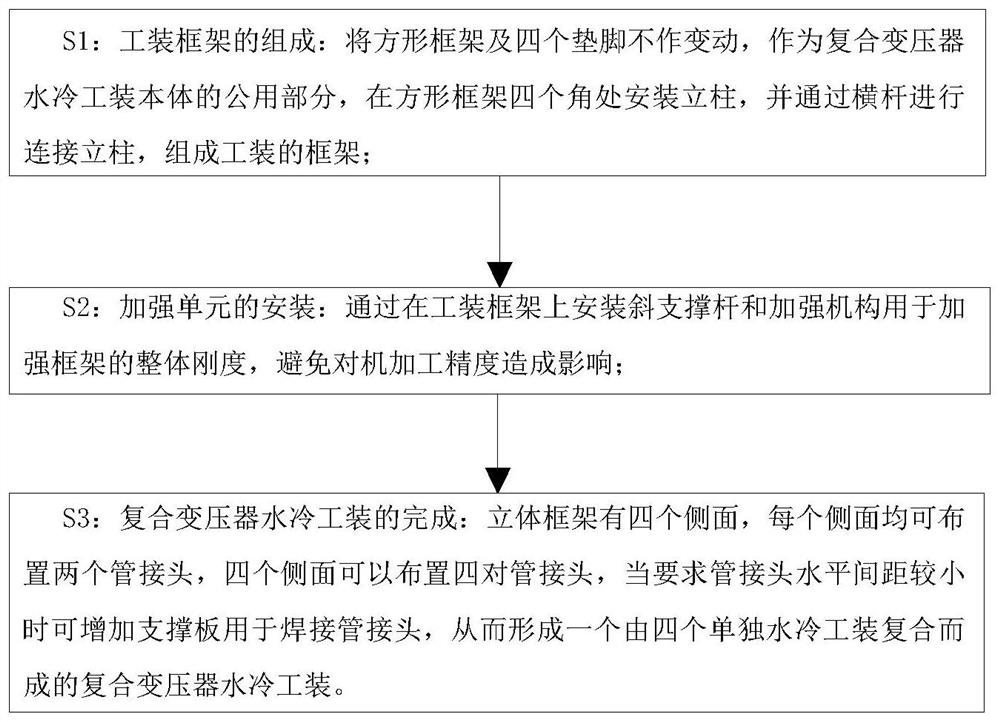

[0033] see Figure 1-7 As shown, a design method of composite transformer water-cooled tooling, the design method includes the following steps:

[0034] S1: The composition of the tooling frame: the square frame and four feet are not changed, and as the common part of the composite transformer water-cooled tooling body, columns are installed at the four corners of the square frame, and the columns are connected by cross bars to form the frame of the tooling;

[0035] S2: Installation of strengthening unit: Installing inclined support rods and strengthening mechanisms on the tooling frame is used to strengthen the overall rigidity of the frame to avoid affecting the machining accuracy;

[0036] S3: Completion of the composite transformer water-cooling tooling: the three-dimensional frame has four sides, and two pipe joints can be arranged on each side, and four pairs of pipe joints can be arranged on the four sides. When the horizontal distance between the pipe joints is requir...

Embodiment 2

[0047] see Figure 8 As shown in Comparative Example 1, as another embodiment of the present invention, an anti-skid pad 25 is fixedly attached to the bottom of the feet 5; the anti-skid pad 25 is made of rubber; 25 Increase the frictional force between the pad foot 5 and the contact part of the placement plane, so that the overall placement of the frock is more stable and not easy to slip.

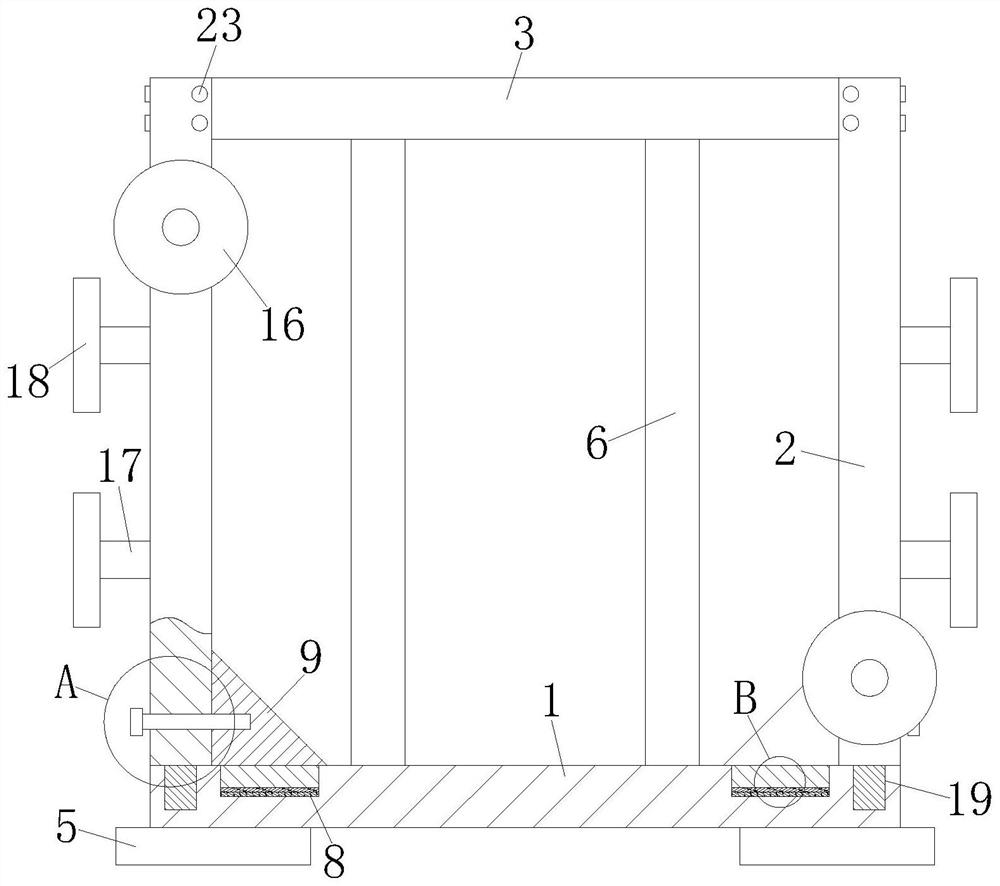

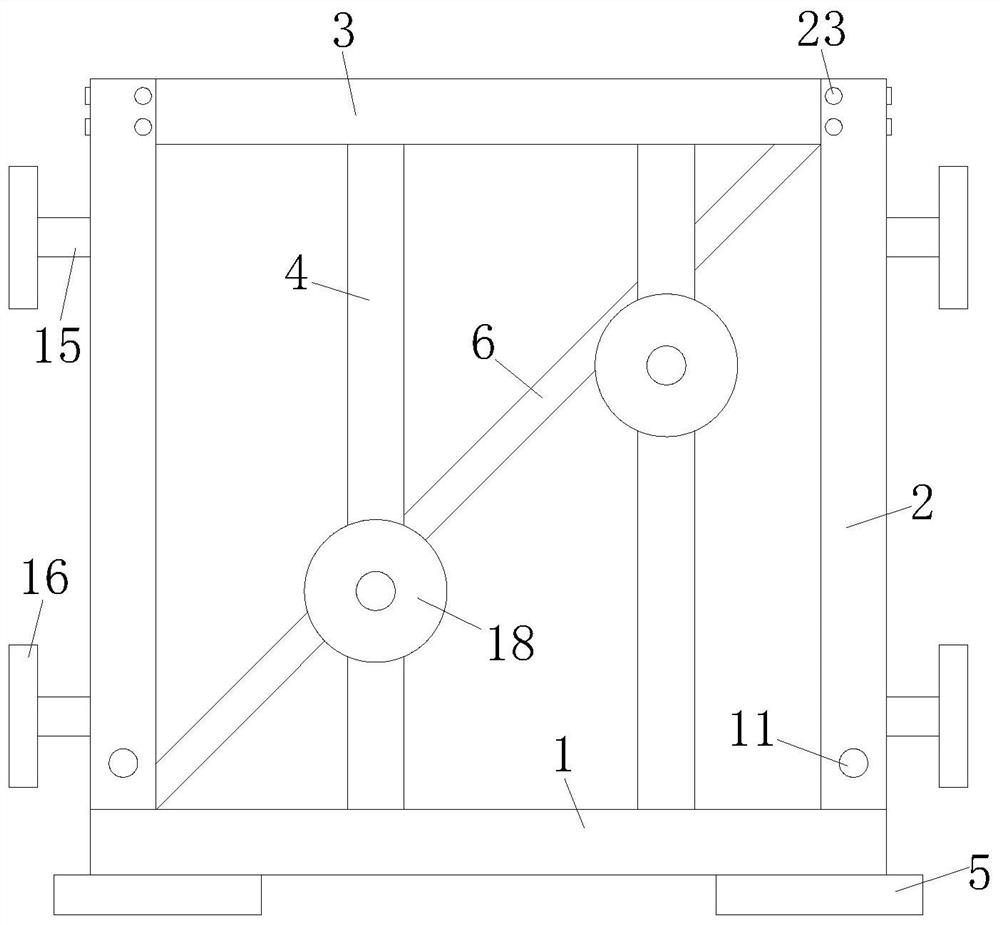

[0048] Working principle: insert the second threaded rod 20 into the third threaded hole 19, through the cooperation between the second threaded rod 20 and the third threaded hole 19, the column 2 is fixedly installed on the top of the square frame 1, the installation method is simple and convenient, convenient Disassemble, so that the columns 2 are located at the four corners of the square frame 1, and then insert the end of the cross bar 3 into the placement groove 21, so that the threaded through hole 22 is aligned with the fourth threaded hole 24, and turn the third threaded rod 23 ,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com