Stamping device

A stamping and platform technology, applied in special foundation layout, spring/shock absorber design features, supporting machines, etc., can solve the problems of large noise and vibration, easy damage to molds, high strength, and achieve reliable position and avoid machining accuracy. Influence, Operation Reliable Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

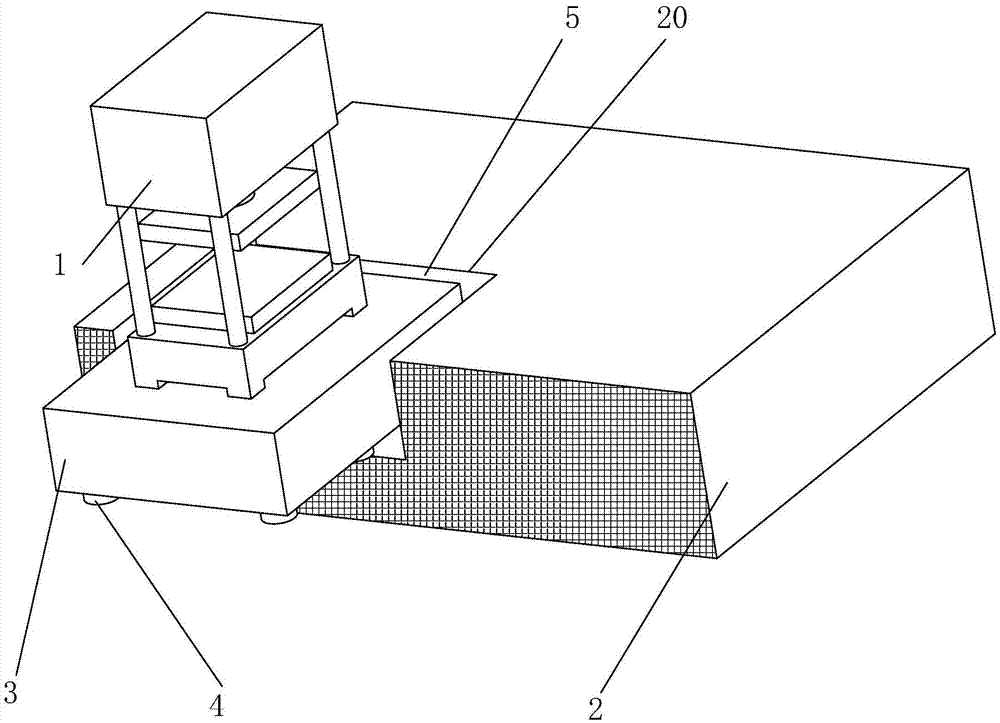

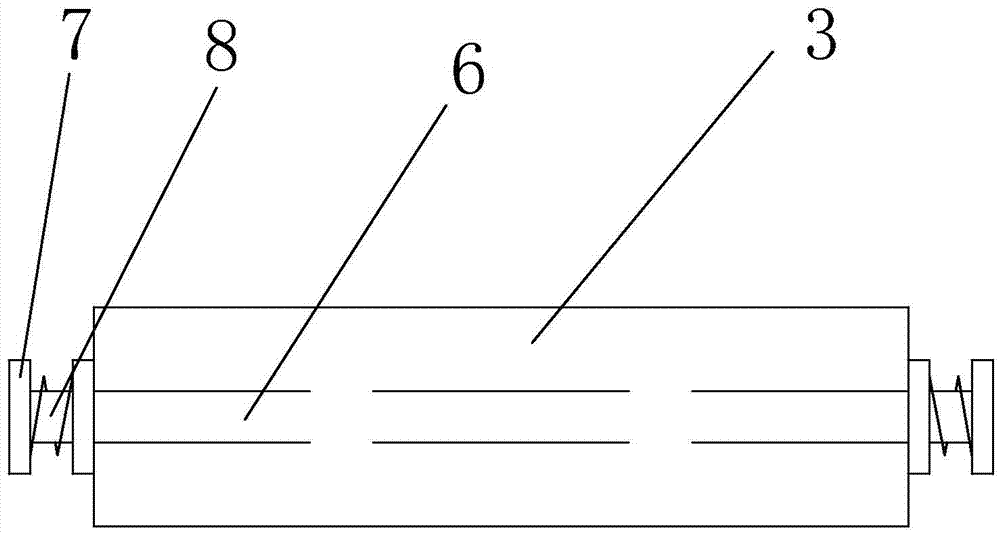

[0013] The present invention as Figure 1-2 As shown, it includes a stamping processing unit and a vibration isolation mechanism. The stamping processing unit 1 (ie, a press) is set on the foundation 2 through a vibration isolation mechanism. The vibration isolation mechanism is: the foundation 2 is provided with an isolation Vibration tank 20 , the stamping processing unit is set in the vibration isolation tank through the counterweight platform 3 . The counterweight platform can be a reinforced concrete structure. The function of the counterweight platform is to reduce the ground vibration caused by the impact load of the press, and reduce the vibration transmission of the press vibration to the surrounding foundation. The vibration isolation groove is to further prevent the transmission of vibration to the surrounding foundation. . Large-mass counterweight platform is extremely beneficial for vibration isolation.

[0014] The counterweight platform is provided with a perf...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com