Machining method used for steel 35 and 3Cr13 metal material welding rack

A technology of metal materials and processing methods, which is applied in the direction of machines/brackets, engine frames, supporting machines, etc., to achieve the effects of reducing errors, reducing processing deformation, and stabilizing dimensions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0042] The specific steps of a processing method for welding frame bodies of steel 35 and 3Cr13 are as follows:

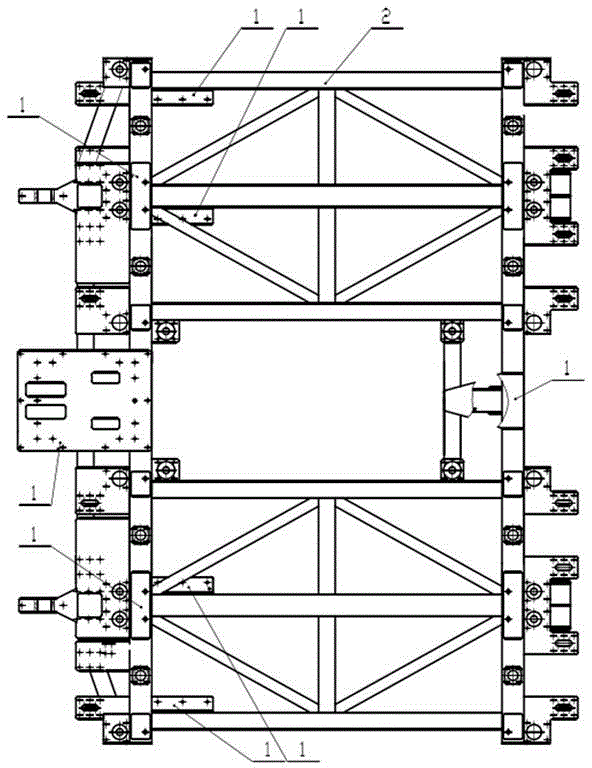

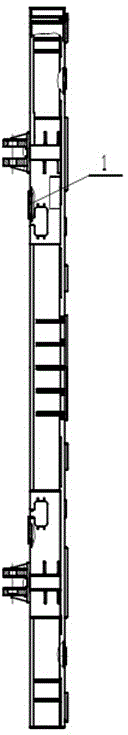

[0043] 1) Part blanking: blank steel 35 and 3Cr13 metal materials according to the specified size and requirements of the frame; figure 1 As shown, the frame base material 2 is steel 35, and the material of each insert 1 is stainless steel 3Cr13;

[0044] 2) Welding:

[0045] a) Welding method: manual arc welding welding method;

[0046] b) The selection of welding rods: J507 steel welding rod for welding between frame base materials, and Ao 302 welding rod for welding between frame base materials and insert materials; this ensures the uniformity of each weld structure and reduces alloy elements To avoid the cracks caused by the thinning, it not only ensures the weld structure and performance, but also ensures the welding quality of the product;

[0047] c) Welding process: first use the rigid fixing method to fix the welded parts on the welding platform, and then use symme...

Embodiment 2

[0067] On the basis of Example 1, the specific steps of the method are as follows:

[0068] 1. Blanking: Complete the blanking of the workpiece with the serial number shown in the drawing according to the drawing;

[0069] 2. Welding:

[0070] a. The manual arc welding method is adopted, welding can be carried out in all positions, and the welding speed can be easily controlled. It can be changed according to the size and length of the part and the weld to ensure the quality of the weld and the height of the weld;

[0071] b. Welding materials are selected from two types of welding rods containing high Cr A302 (A302) welding rod and structural steel welding rod J507. The frame base part is all steel 35 material, which is welded with structural steel welding rod J507, and the joint of the two materials is welded with stainless steel welding rod A302. This ensures the uniformity of the structure of each weld, reduces the thinning of alloy elements, and avoids the cracks caused by thinni...

Embodiment 3

[0090] Vibration aging is abbreviated as VSR (Vibratory Stress Relief), which uses a strictly controlled vibration energy to process metal workpieces to solve the dimensional changes and changes in load resistance caused by internal residual stress during and after the workpiece processing. problem. VSR has a significant effect on eliminating, reducing or homogenizing the residual stress in the metal workpiece, improving the resistance of the workpiece to dynamic and static load, deformation resistance, and stabilizing the dimensional accuracy.

[0091] In order to verify the effect of vibration aging, comparative tests were carried out in two states of stress relief by heat treatment and stress relief by vibration. 3 test pieces (160mm×350mm×10mm, wall thickness 2mm) were taken for each state. Use the same 2A12 (LY12) aluminum plate to blank, and then rough machining (leave 3mm allowance on one side), semi-finishing (leave 1mm allowance on one side), and finish machining. In or...

PUM

| Property | Measurement | Unit |

|---|---|---|

| angle | aaaaa | aaaaa |

| surface smoothness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com