Precise forming method for large-size variable-curvature thin-wall storage tank diaphragm

A technology of precision molding and variable curvature, which is applied in the field of precision molding of large-size variable-curvature thin-wall tank diaphragms, and can solve the problems of difficult and difficult-to-achieve large-size variable-curvature thin-wall tank diaphragm forming processes , to achieve the effect of solving the problem of forming processing technology, less spinning passes, and preventing deformation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

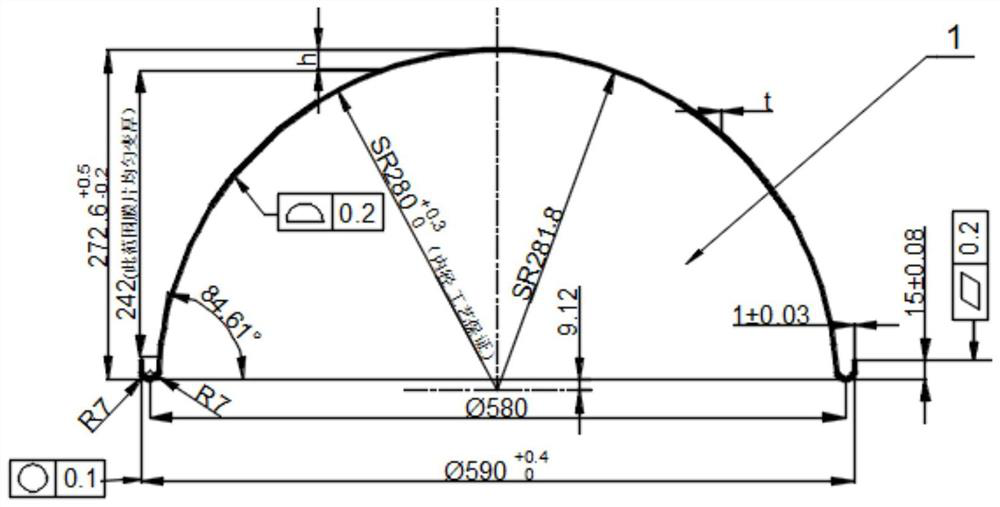

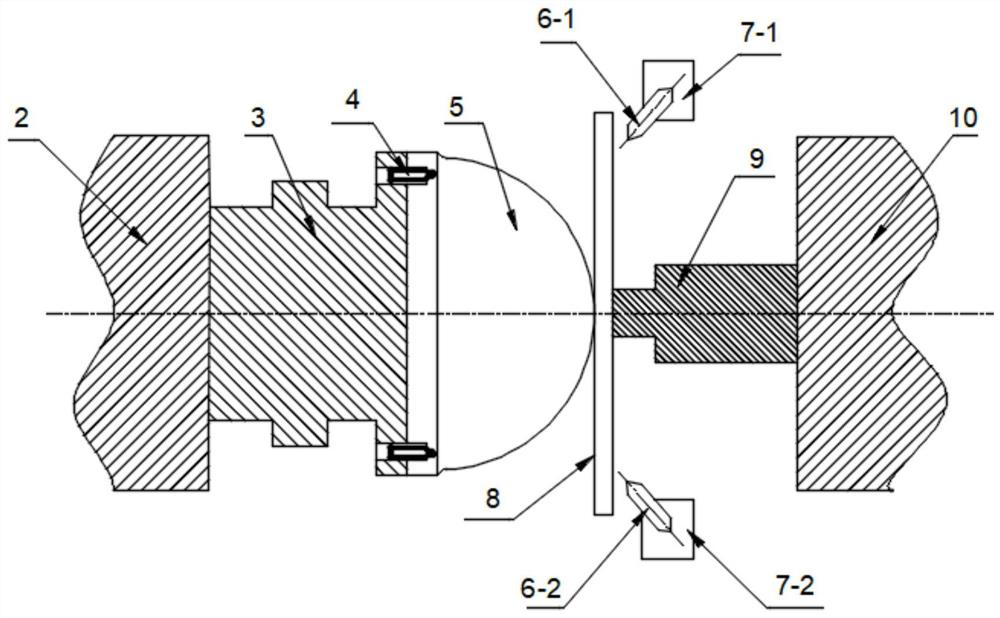

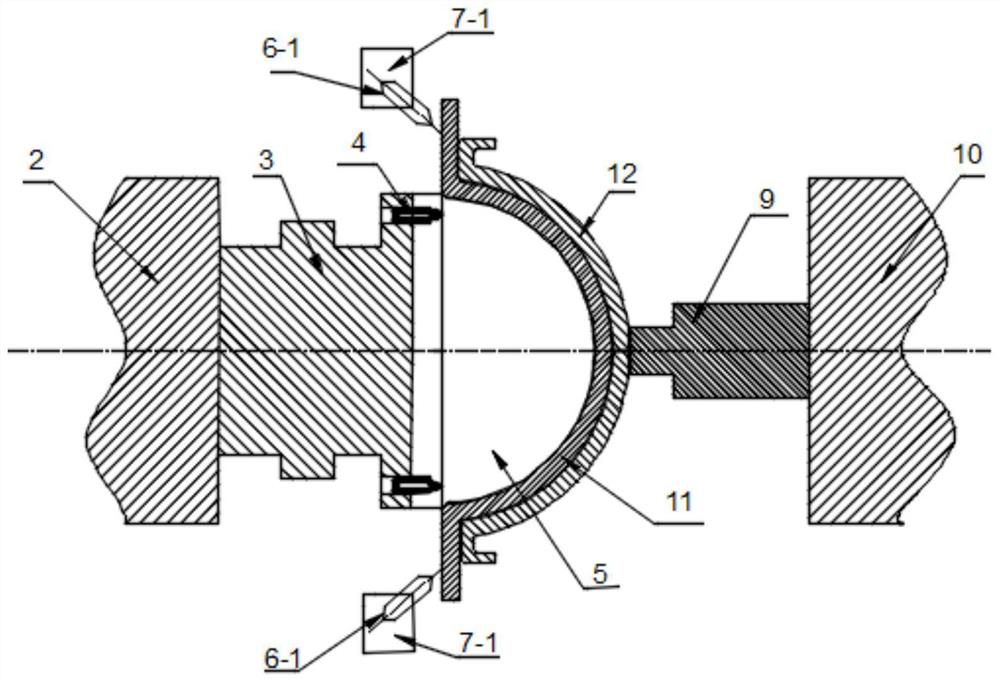

[0032] In this embodiment, the maximum diameter of the large-size variable-curvature thin-wall tank diaphragm is The roundness is 0.1mm, and the wall thickness gradually changes from 1.8mm to about 1mm. The tank diaphragm requires high dimensional accuracy, and the forming process is extremely difficult, especially the material used is pure titanium, which has low strength and is easy to deform during forming process. And titanium starts to absorb hydrogen from 250°C and oxygen from 400°C, so industrial pure titanium is easily polluted by impurities and becomes brittle during processing and forming. Hot forming is required during processing, which further increases the difficulty of forming processing; this application intends to use a special thickness gauge to measure the thickness and design and manufacture a special tooling fixture for spinning processing and forming. The roundness can reach 0.1mm, and the spherical profile can reach 0.2mm. Tensile strength σ b Not less t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| Circularity | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com