Full-automatic filter element winding machine

A winding machine, fully automatic technology, applied in the direction of winding strips, thin material handling, transportation and packaging, etc., can solve the problems of low efficiency, troublesome operation, and failure to put into use normally, so as to improve production efficiency and reduce Labor intensity, the effect of improving production efficiency and product quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0053] The embodiments of the present invention are described in detail below in conjunction with the accompanying drawings, but the present invention is not limited to the following embodiments, and all other embodiments obtained by persons of ordinary skill in the art without creative work belong to the present invention scope of protection.

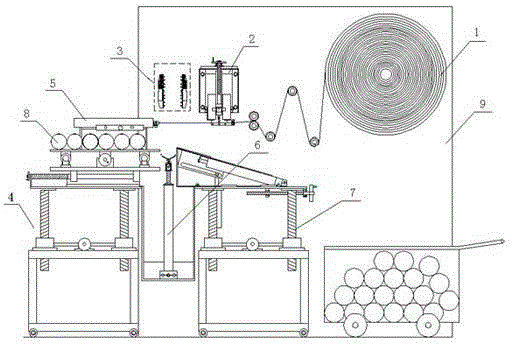

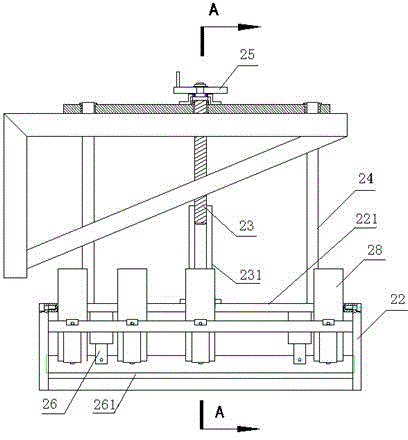

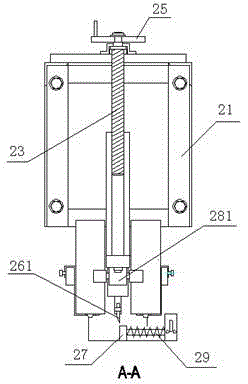

[0054] Examples such as Figure 1 to Figure 12 As shown: the present invention relates to a fully automatic filter paper winding machine, which includes a filter paper unwinding mechanism 1, a glue dispensing and cutting mechanism 2, a clamping drive mechanism 3, a three-dimensional lifting platform 4, a filter paper clamping traction device 5, a filter paper Net lifting mechanism 6, inclined top unloading mechanism 7 and central control cabinet 9 are eight major parts.

[0055] Such as figure 1 with Figure 12 As shown: the filter paper unwinding mechanism 1 includes an air expansion shaft 11 and a rolling guide post 12 , the filt...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com