Patents

Literature

212results about How to "Avoid wasting time and effort" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

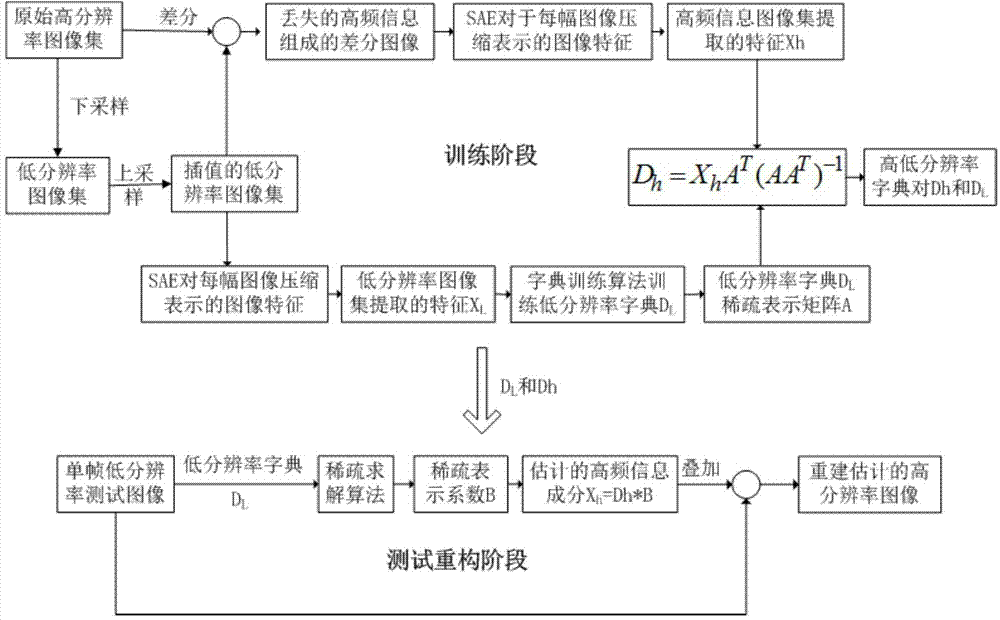

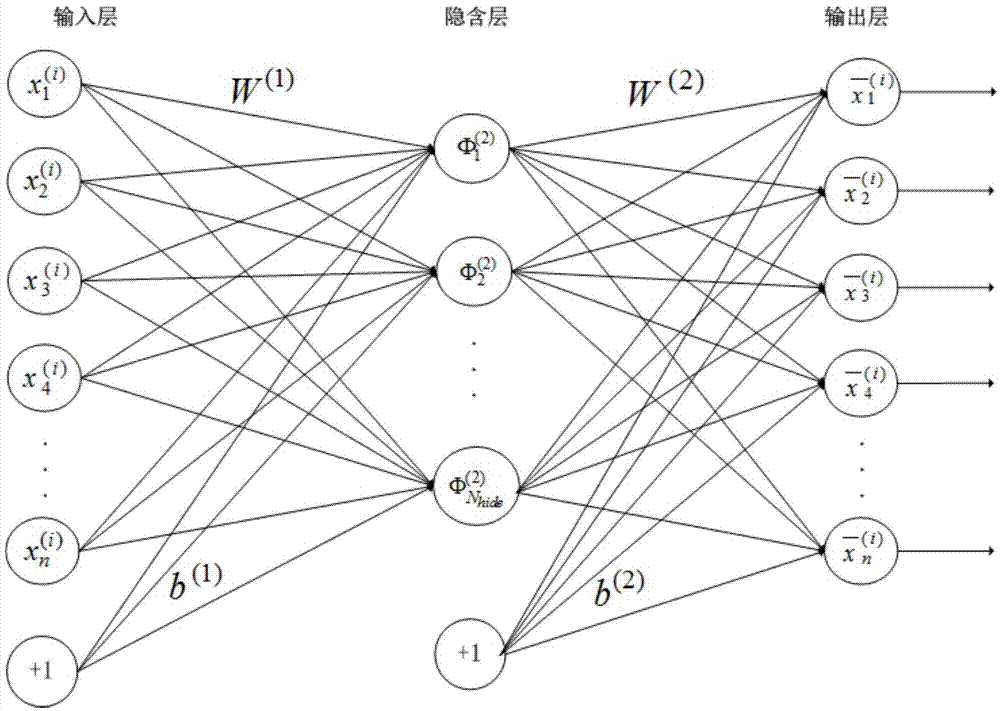

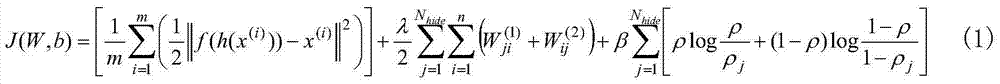

Image super-resolution method based on SAE and sparse representation

InactiveCN104778671AImplement a compressed representationEasy to trainImage enhancementGeometric image transformationImaging processingImage resolution

The invention discloses an image super-resolution method based on SAE and sparse representation, and belongs to the field of image processing. The image super-resolution method mainly comprises an off-line training stage and a test refactoring stage, wherein in the off-line training stage, image characteristics extracted by an SAE (Sparse Auto Encoding) model are subjected to dictionary training, and a dictionary pair reflecting corresponding relations of high-resolution images and low-resolution images is established; in the test refactoring stage, low-resolution images inputted by a user are subjected to super-resolution reconstruction by the obtained dictionaries and a sparse representation method. Through the application of the image super-resolution method, unsupervised learning training is performed on original image sampling data by using the SAE model, so that the defects that manually designed operator characteristic extraction is time-consuming and strenuous and the extracted characteristics are single are avoided, meanwhile, image characteristics represented by SAE compression are directly used for training of the high-low-resolution dictionary pair, the dictionary training is facilitated, lost detail components in the images can be estimated by the sparse representation method, and higher-quality high-resolution images can be restored from the low-resolution images conveniently.

Owner:CHONGQING UNIV

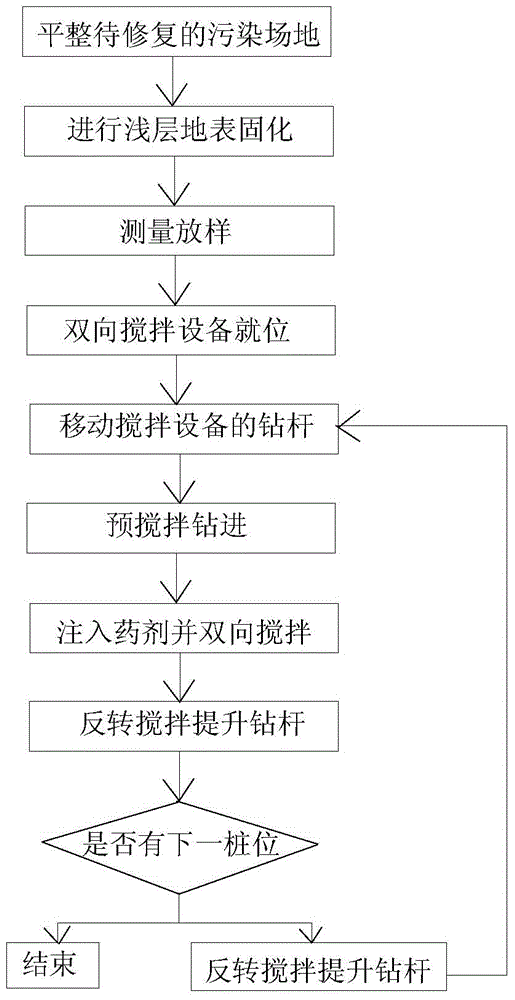

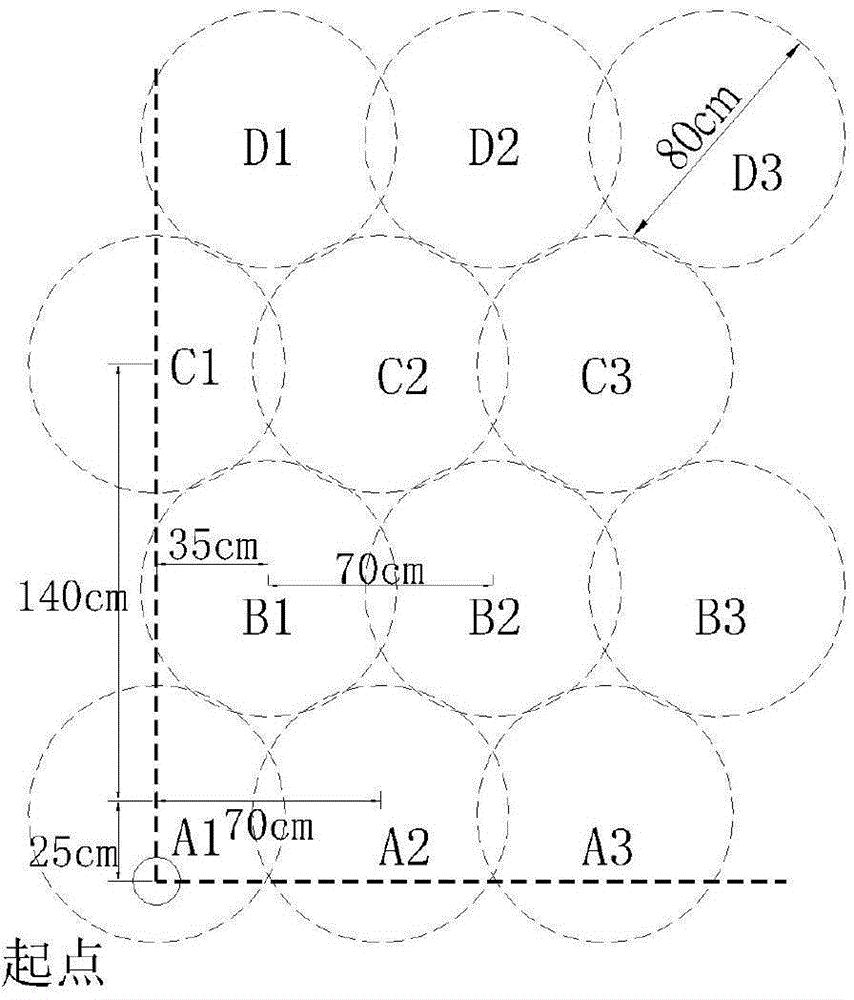

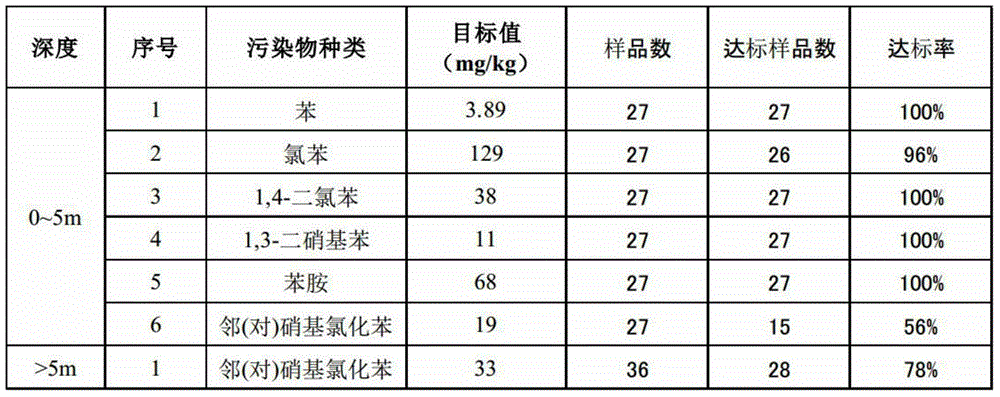

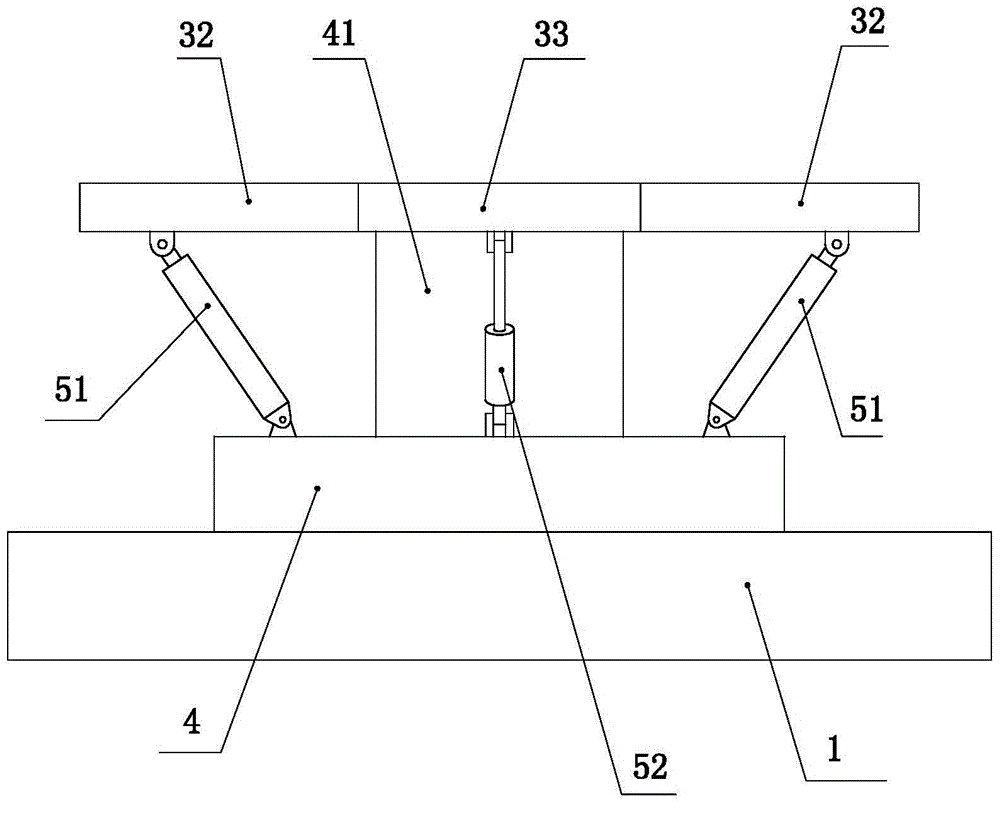

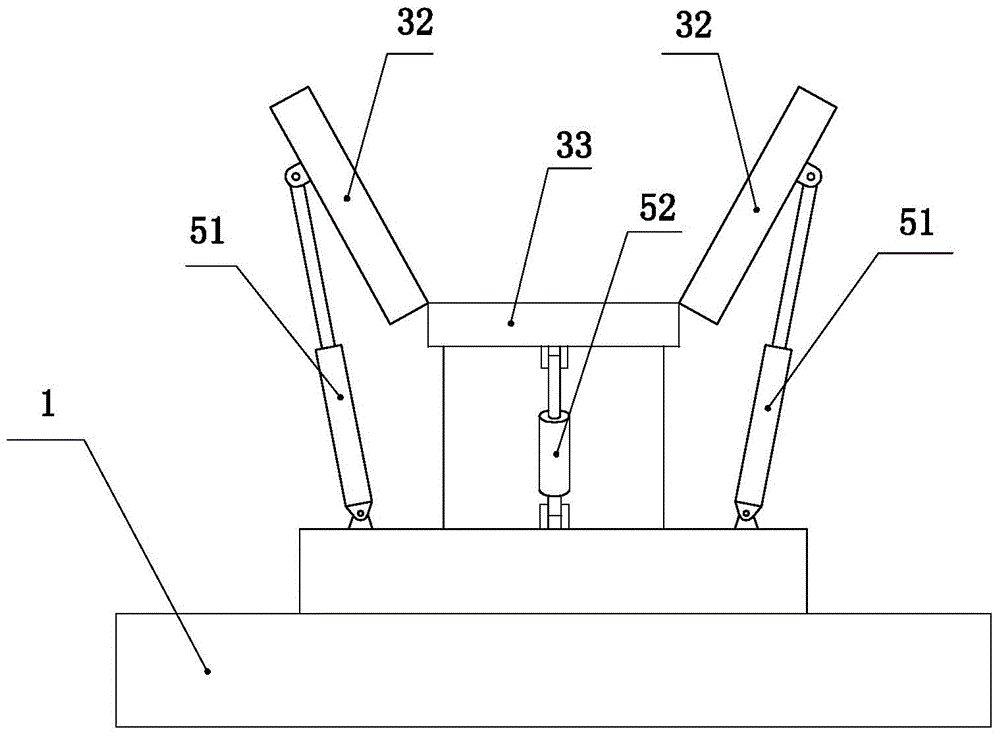

Method for remedying organism contaminated field by using bidirectional stirring injection method

ActiveCN104624629AImprove utilization efficiencyReduce lossesContaminated soil reclamationDrillInjections methods

The invention discloses a method for remedying an organism contaminated field by using a bidirectional stirring injection method. The method comprises the following steps: (1) flattening the contaminated field; (2) performing shallow layer ground hardening; (3) staking out in survey; (4) locating bidirectional stirring equipment in place; (5) moving a drilling rod of the bidirectional stirring equipment; (6) performing pre-stirring drilling; (7) drilling a drill rod, injecting a medicine and stirring bidirectionally, namely, injecting the medicine through an inner tube of a conveying pipeline, injecting a mixed solution of a catalyst and a buffer agent from a pipeline between the inner tube and the outer tube of the conveying pipeline, and mixing and stirring the medicine, the catalyst, the buffer agent and soil at the bottom of the conveying pipeline; (8) lifting up the drill rod through opposite stirring; and (9) moving the drill rod to a next pile site, and repeating the step (5) to (8) until the soil in all pile sites is remedied. By adopting the method, the loss of ground mixed medicines can be reduced, the reaction velocity and the reaction time can be effectively controlled, the problem that grout spills out and turns up from the ground surface can be effectively solved, and the remediation efficiency can be improved.

Owner:SOUTHEAST UNIV +2

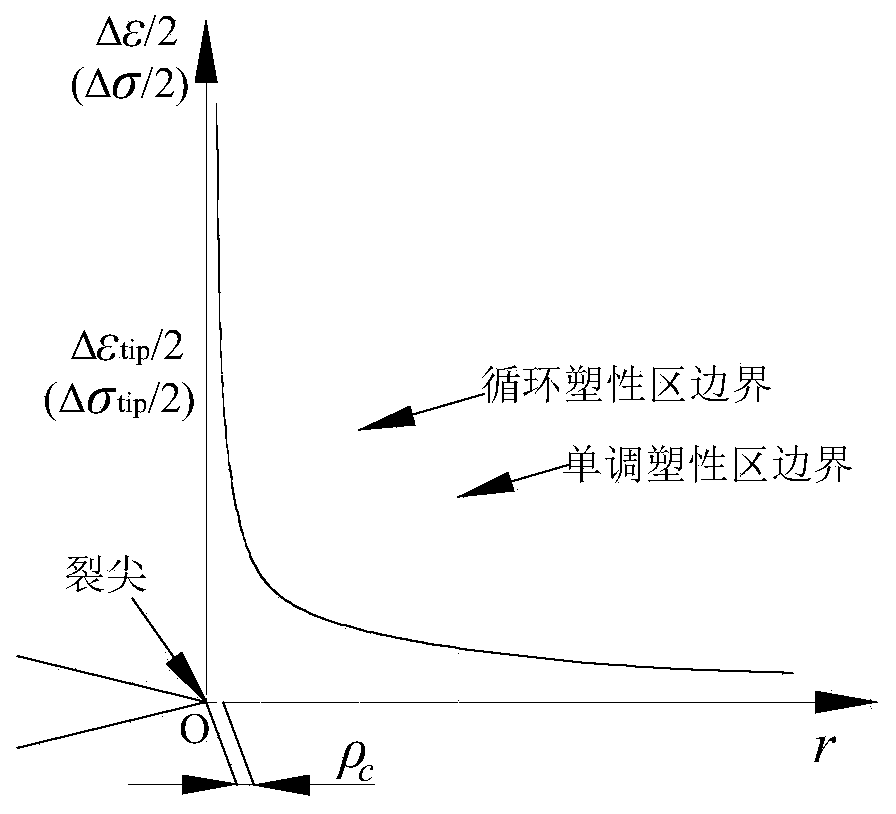

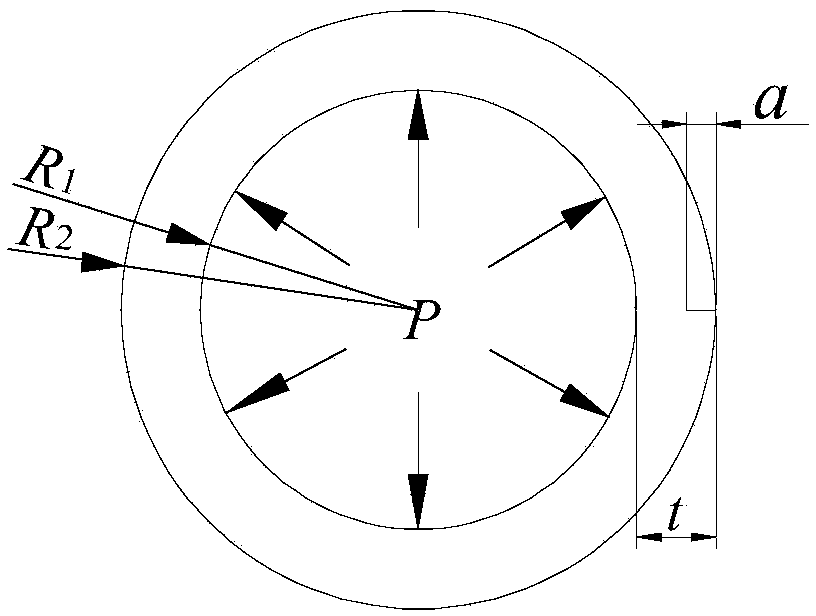

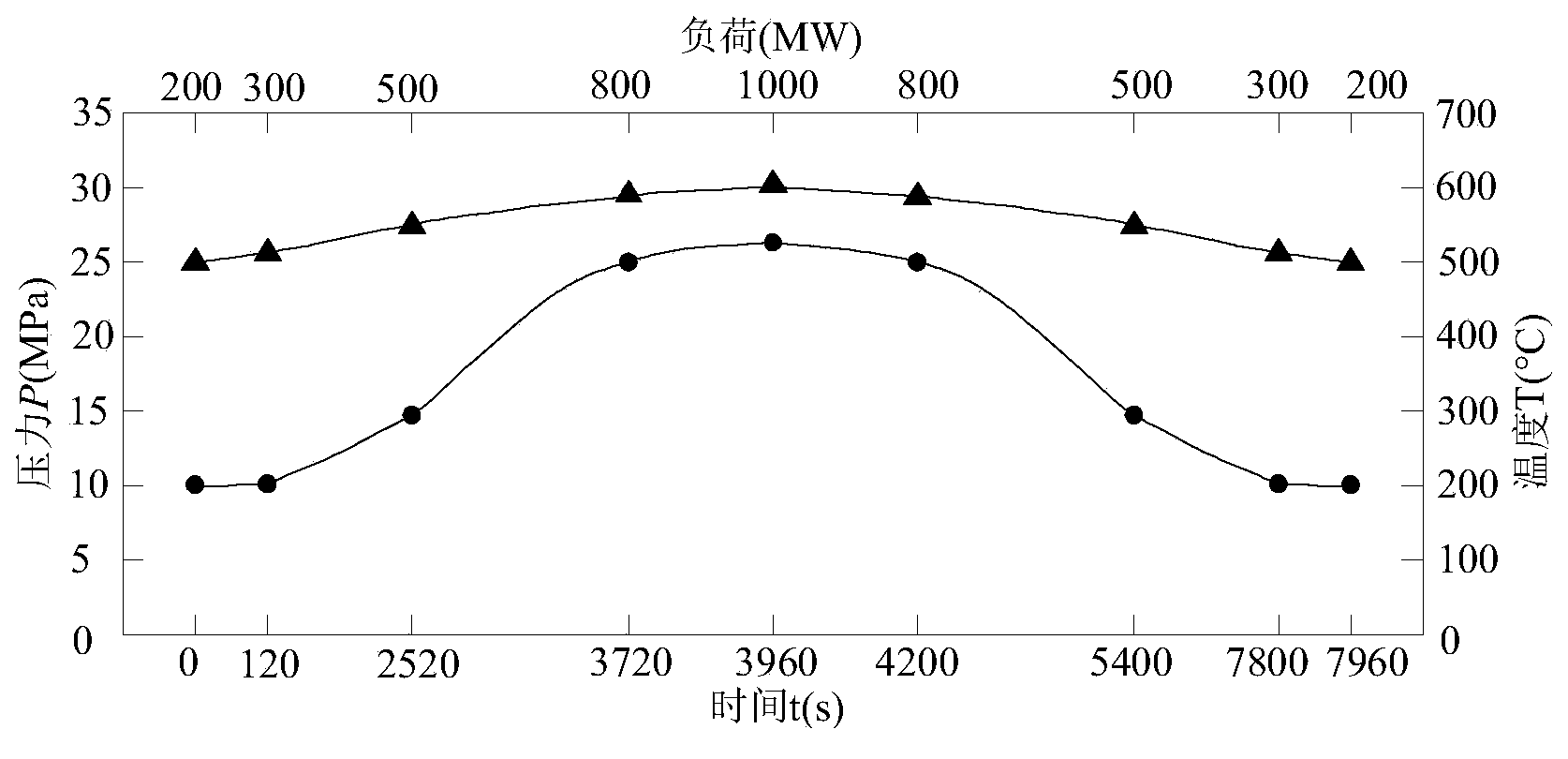

Ultra supercritical boiler super-heat and re-heater heating surface life evaluation method

ActiveCN104142272AAvoid wasting time and effortAvoid the problem of too much errorMaterial strength using tensile/compressive forcesLife evaluationEngineering

The invention discloses an ultra supercritical boiler super-heater and re-heater heating surface life evaluation method. The method comprises the steps (1) a mathematic relation between a fatigue damage accumulation process and the crack growth rate is determined based on the circulation crack tip fatigue damage continuous accumulation process and the linear damage accumulation theory; (2) a polynomial is adopted for carrying out fitting on a da / dN-a curve, the maximum curvature point is obtained, the crack length a of a fatigue crack growth rate acceleration turning point is obtained, and the crack length a is the critical crack length; (3) after the crack length a of the turning point is determined, the ratio a / (S-a0) of the a to the difference (S-a0) between the heating surface pipeline wall thickness S and the initial crack length a0 is obtained, and then the fatigue crack growth service life loss of the heating surface pipeline on the actual running condition is a / (S-a0); the fatigue crack growth residual service life of the heating surface pipeline on the actual running condition is obtained by carrying out numerical integration between the turning point crack length a and the pipeline wall thickness S. According to the ultra supercritical boiler super-heater and re-heater heating surface life evaluation method, service life losses produced on any load and overload condition can be described, time and materials are saved, and the effective result is obtained.

Owner:ELECTRIC POWER RES INST OF GUANGDONG POWER GRID +1

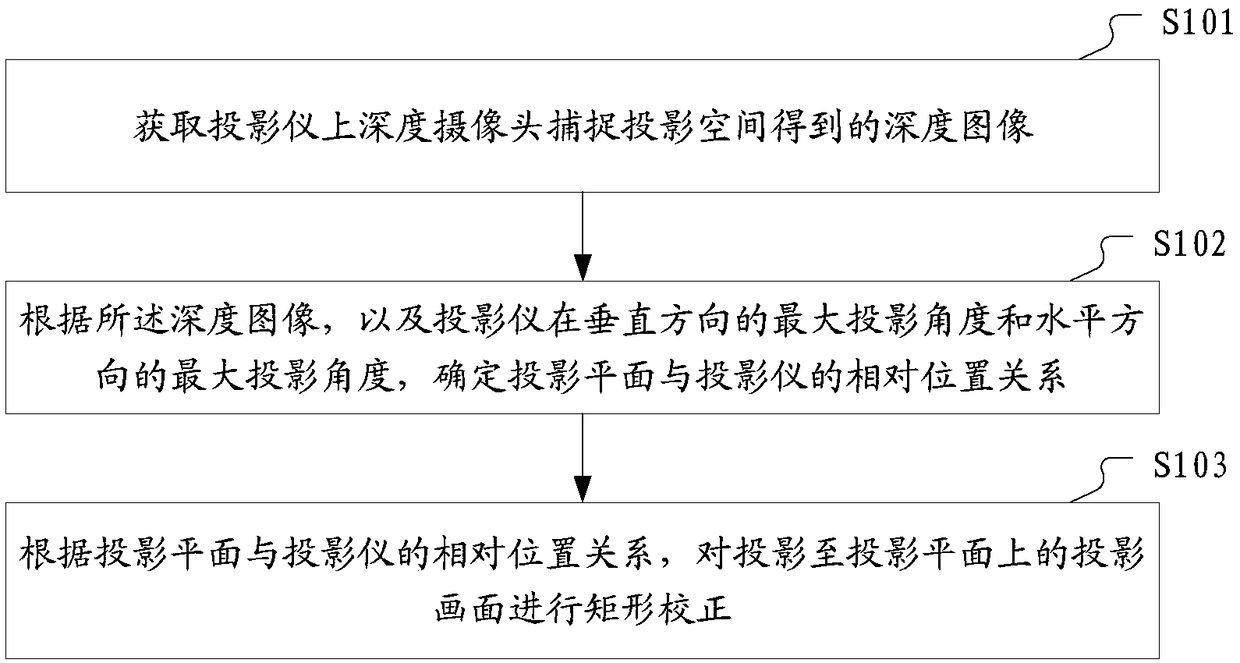

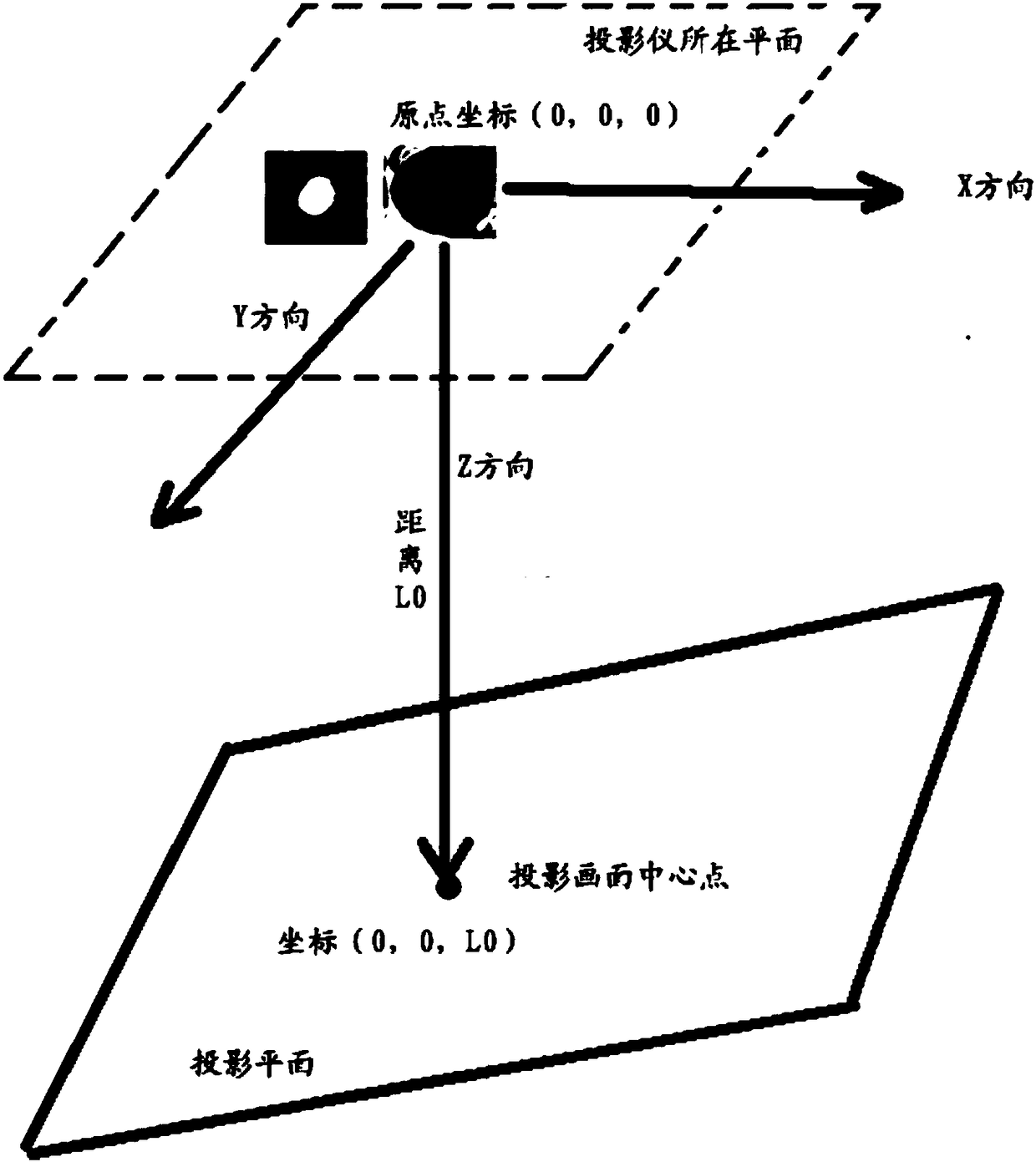

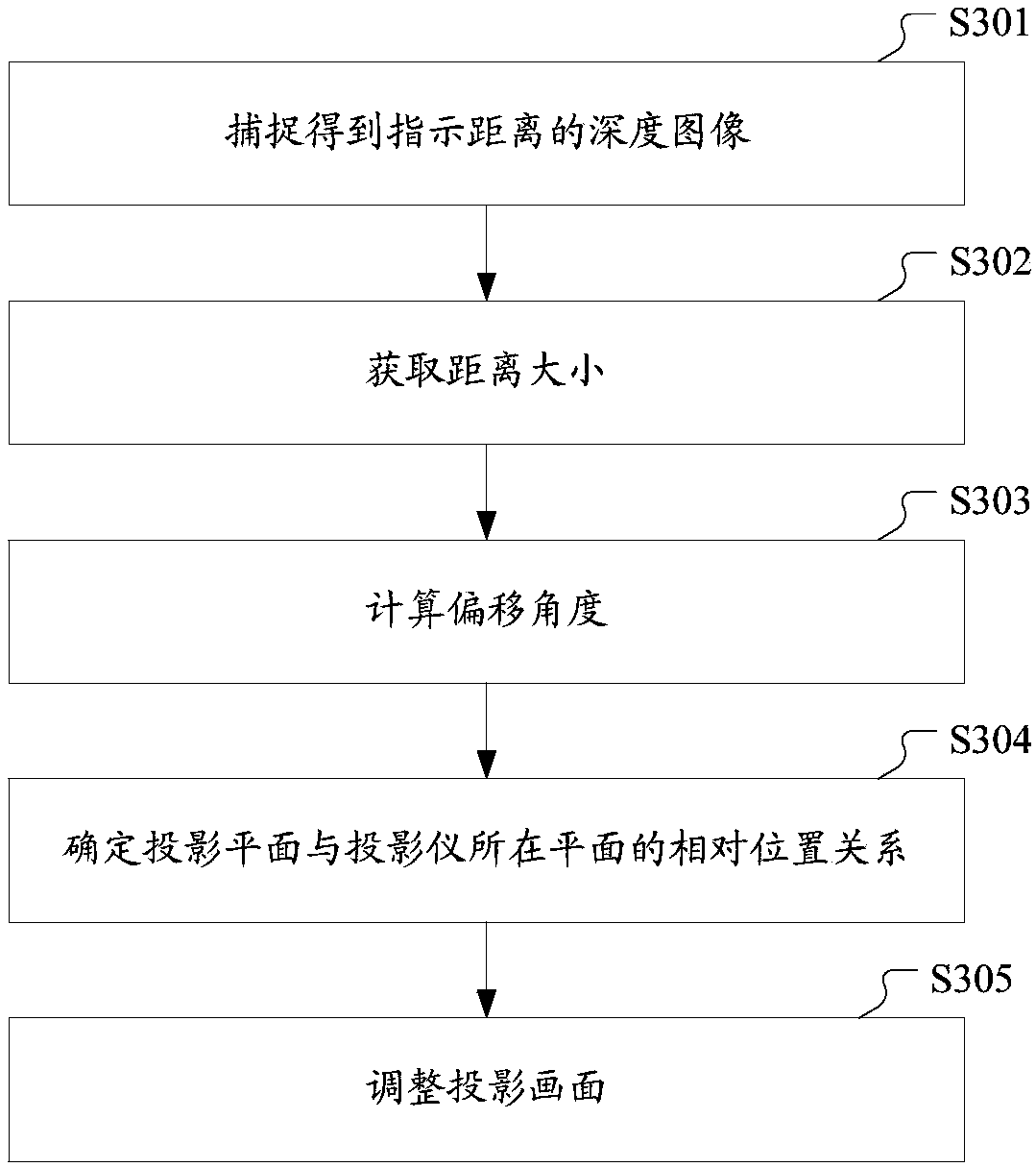

Projection frame automatic correction method and device

ActiveCN108289208AAvoid wasting time and effortImprove user experiencePicture reproducers using projection devicesProjection spaceCorrection method

The present invention discloses a projection frame automatic correction method and device. The method comprises the steps of: obtaining a depth image obtained by capturing a projection space by a depth camera on a projector, and determining a relative position relation of the projection plane and the projector according to the depth image, the maximum projection angle of the projector in a vertical direction and the maximum projection angle of the projector in a horizontal direction; and performing rectangular correction of the projection frame projected on the projection plane according to the relative position relation of the projection plane and the projector. The projection frame automatic correction method and device provided by the embodiment of the invention automatically process the projected frame to obtain an appropriate frame after rectangular correction so as to avoid the problems of time and labor waste caused by manual regulation of the projection frame, meet the actual demand, improve the user experience and improve the competitiveness of the projector.

Owner:GOERTEK INC

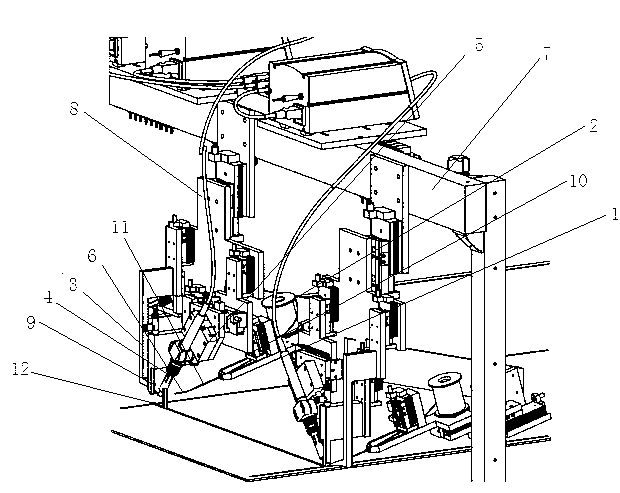

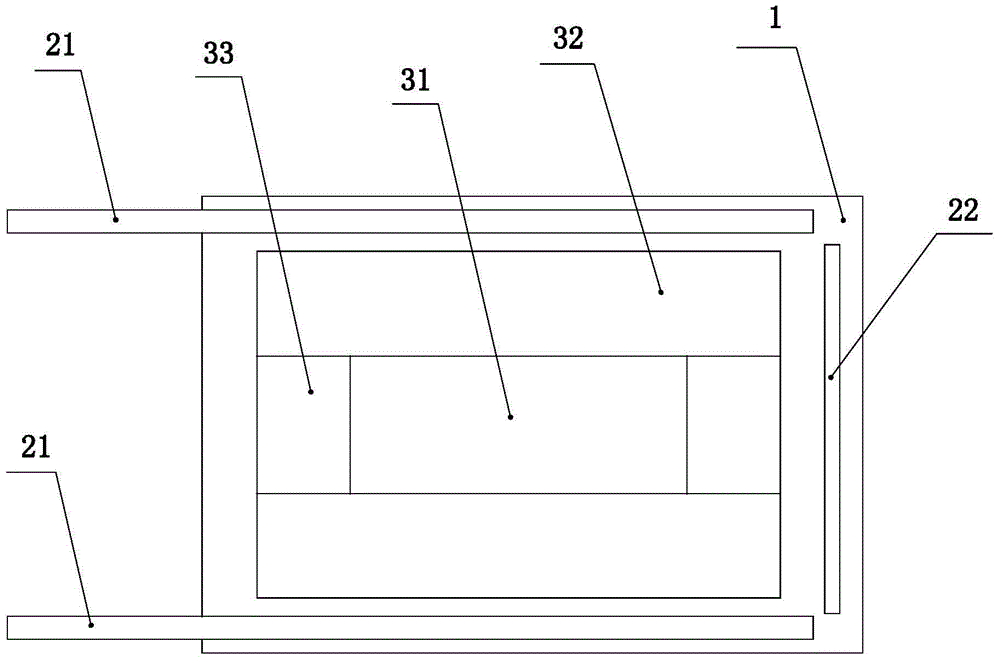

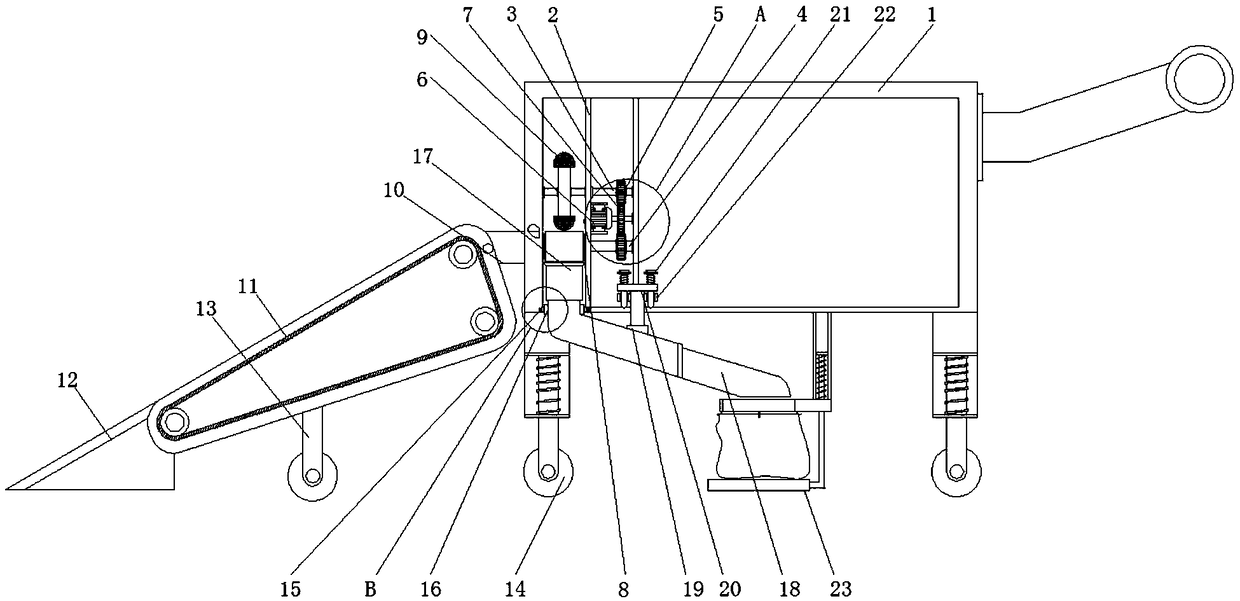

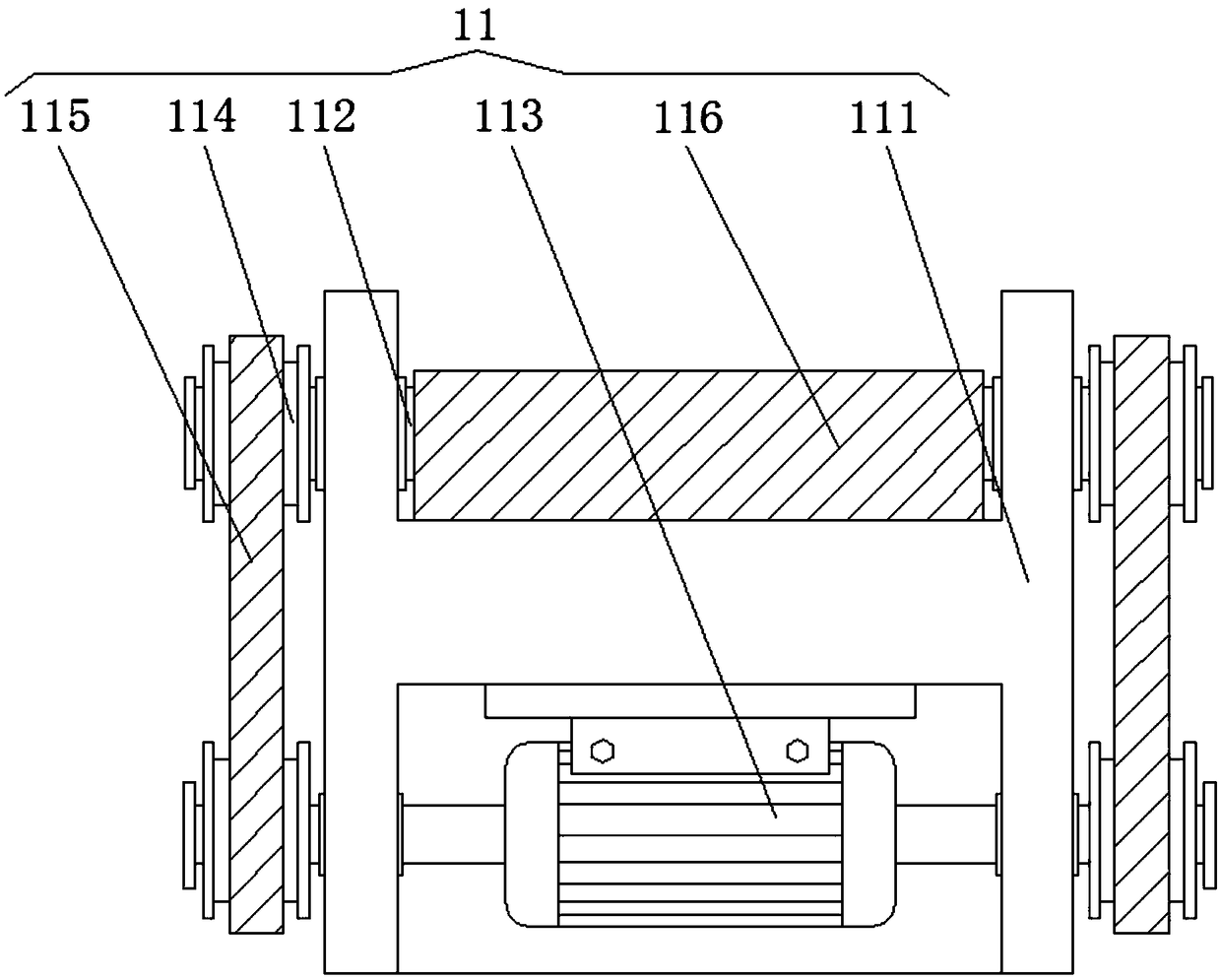

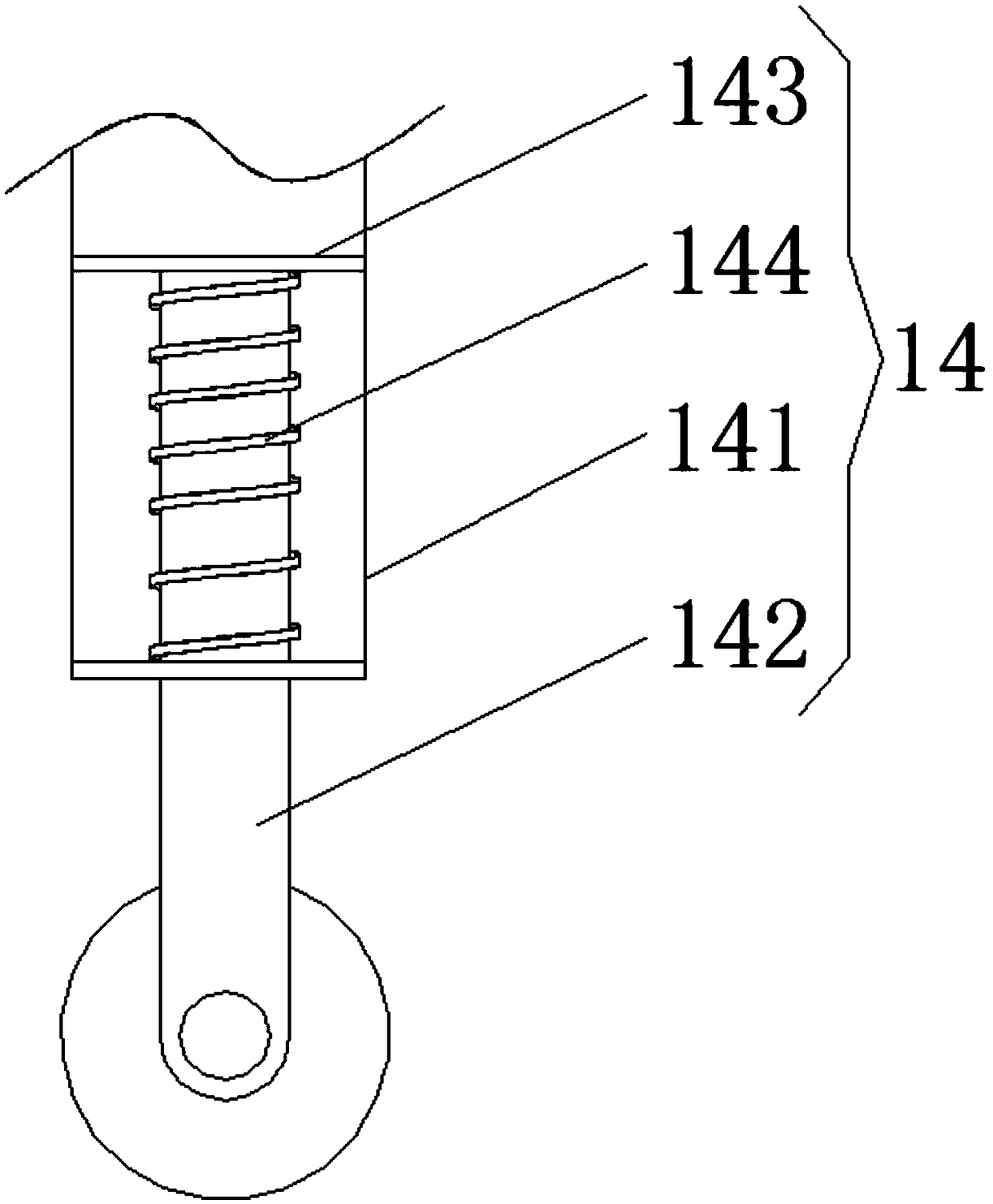

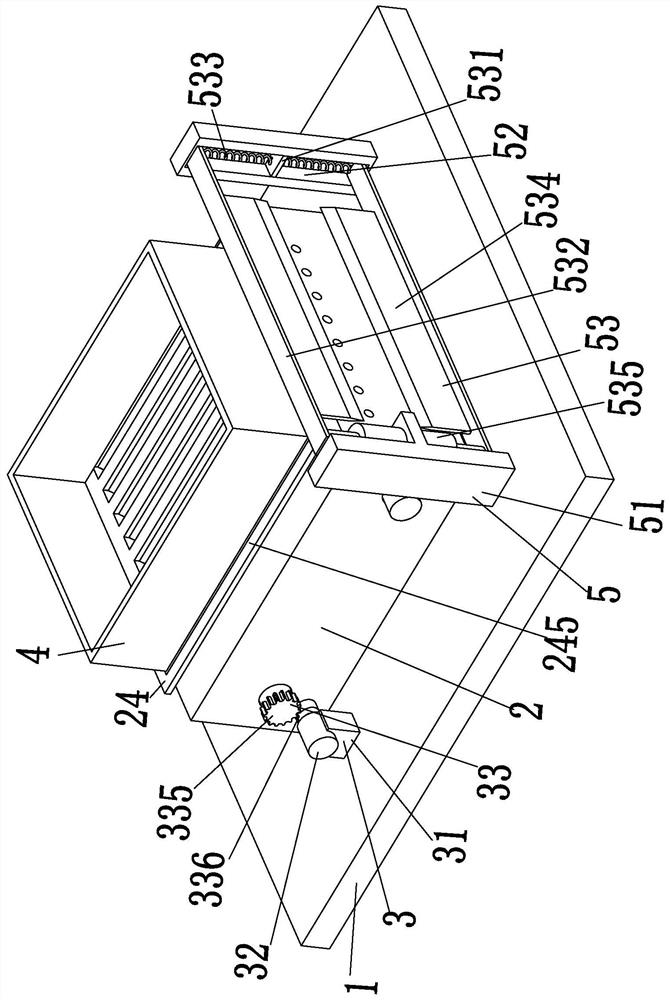

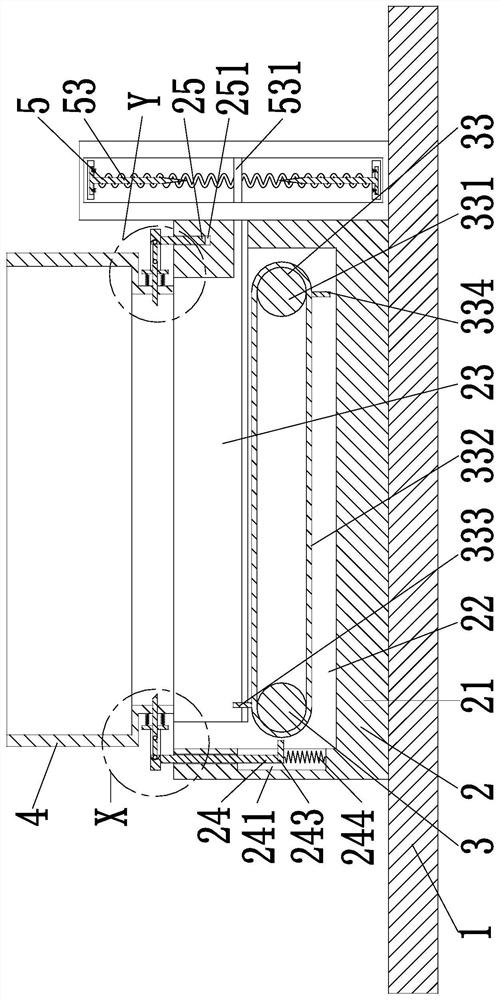

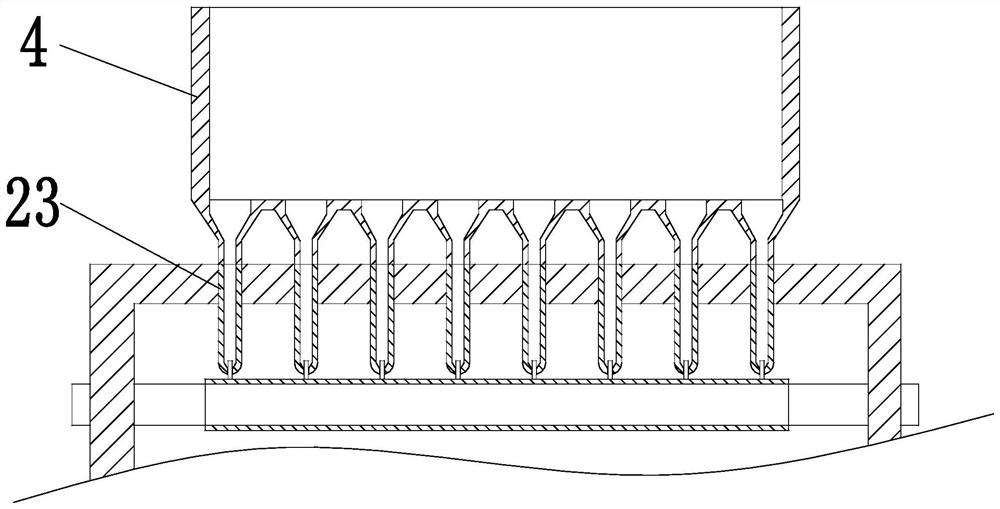

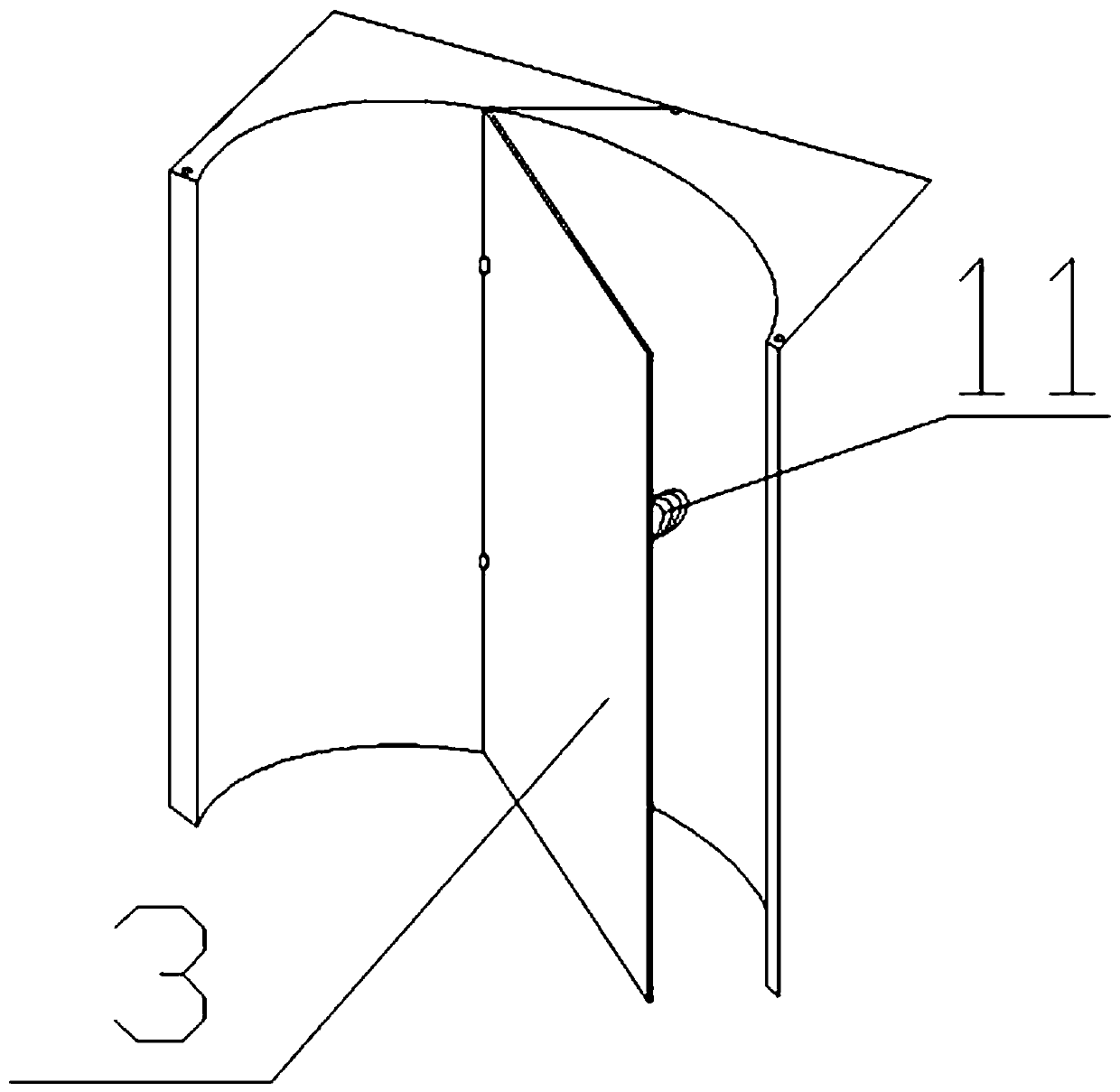

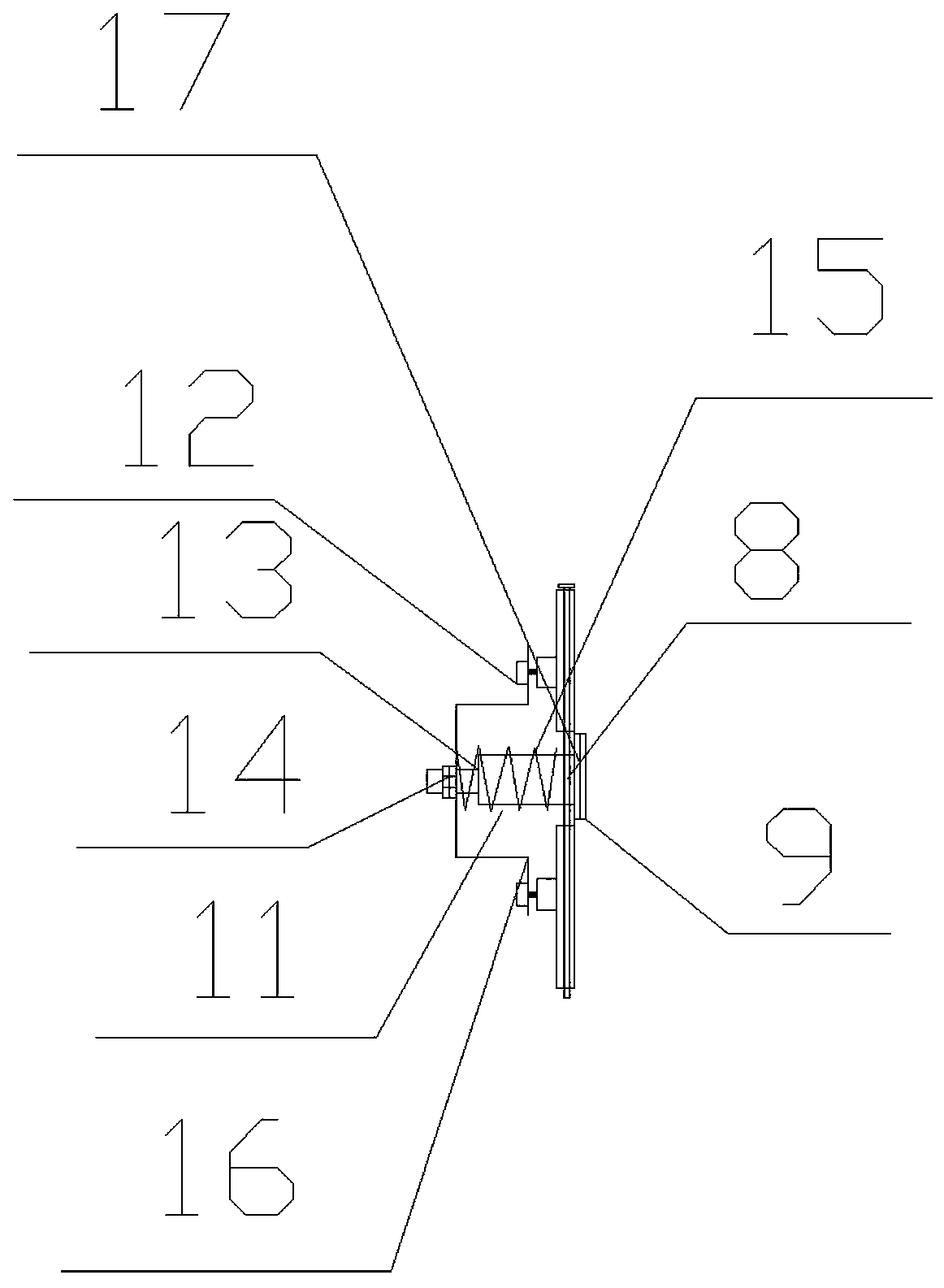

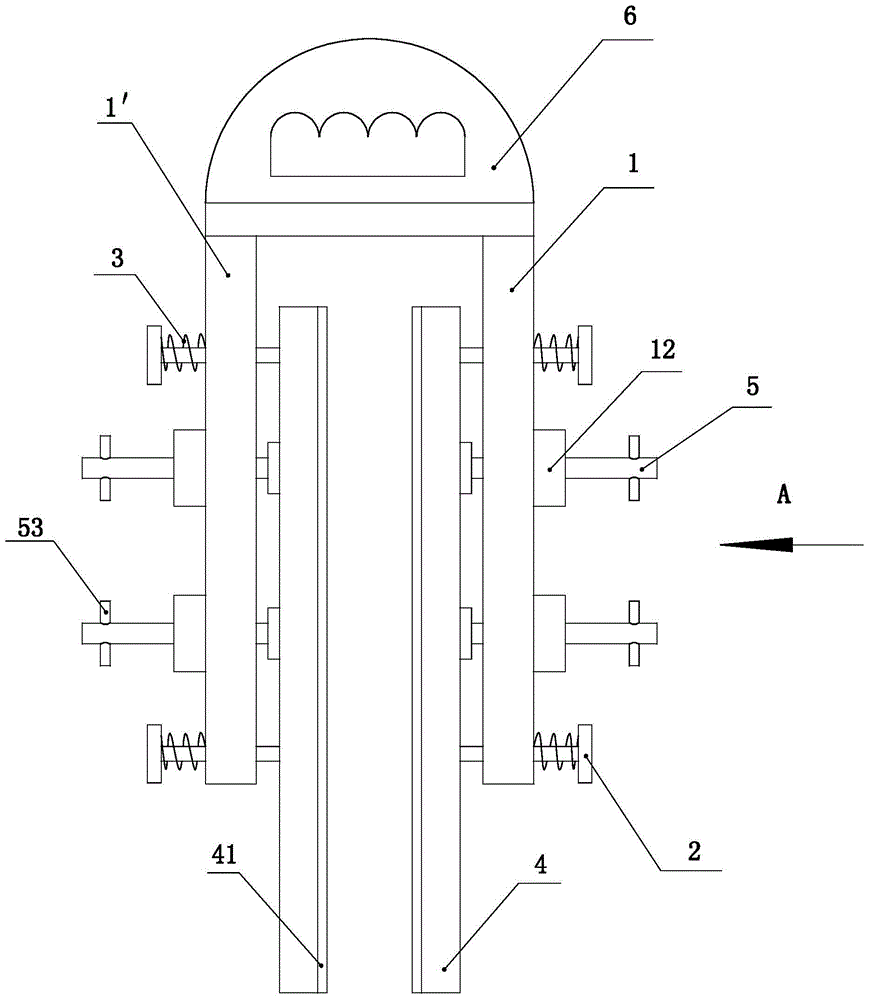

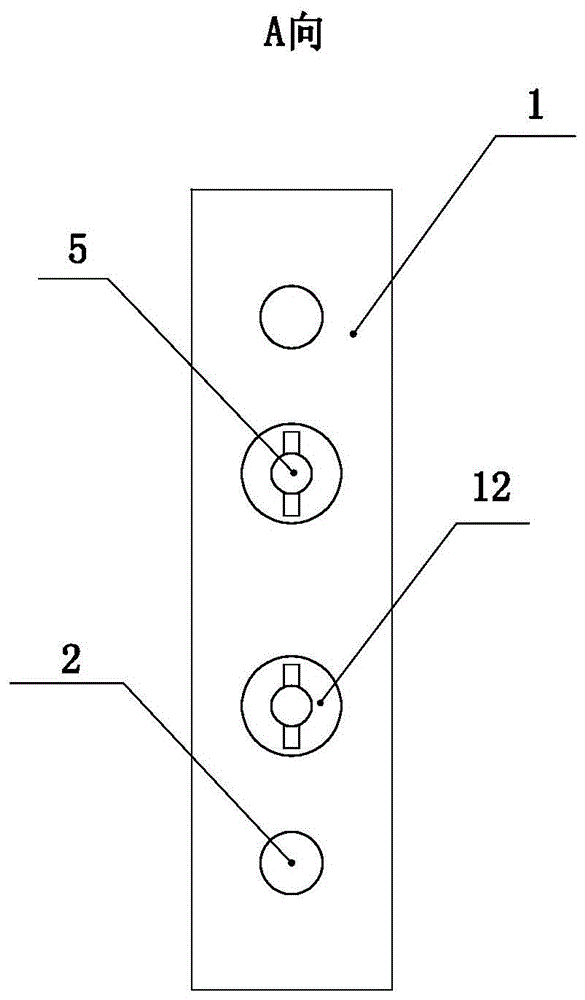

Crimping assisting device and crimping method for power transmission line

ActiveCN109713542AAvoid wasting time and effortLine/current collector detailsGrinding machinesTransmission lineEngineering

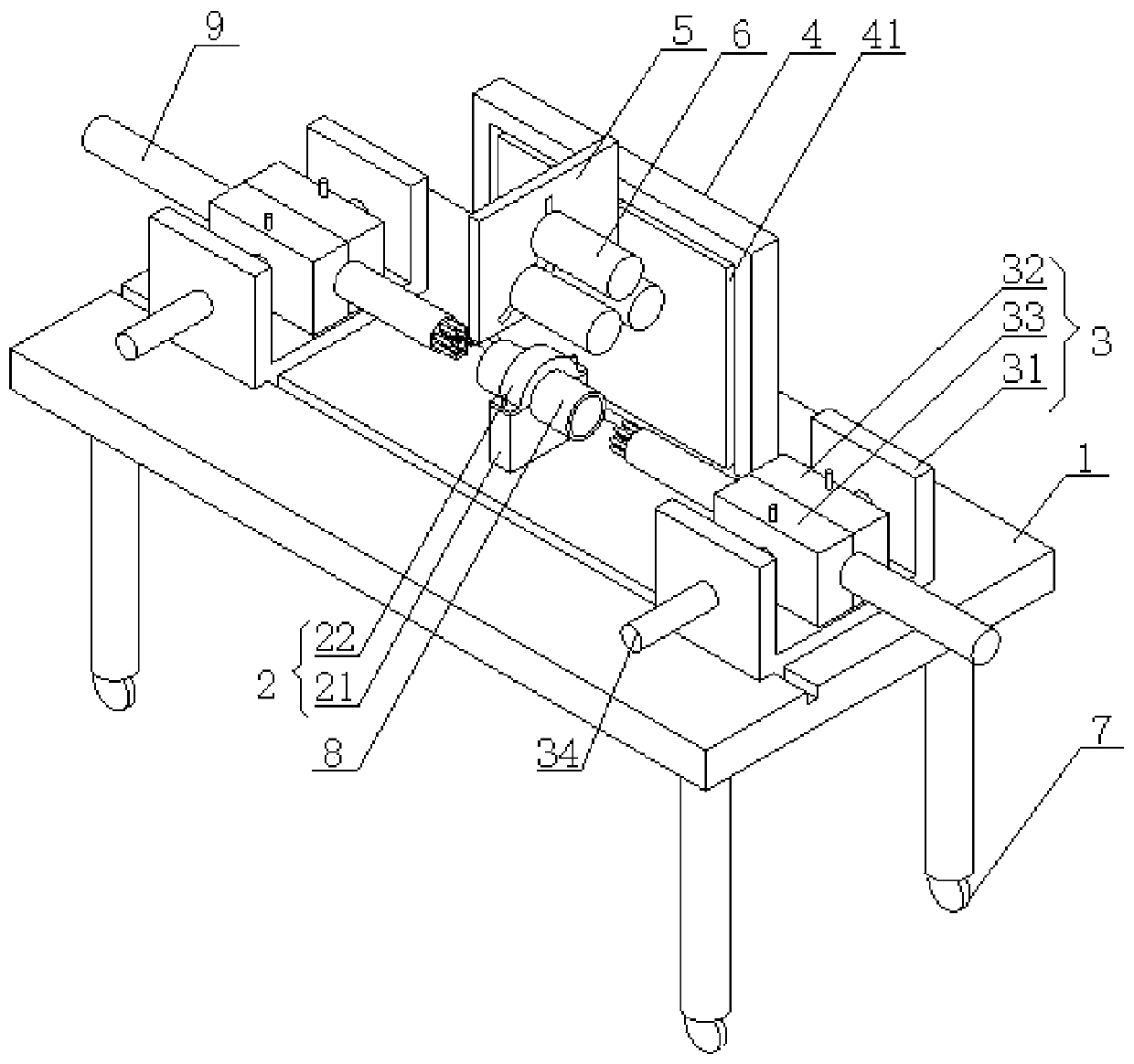

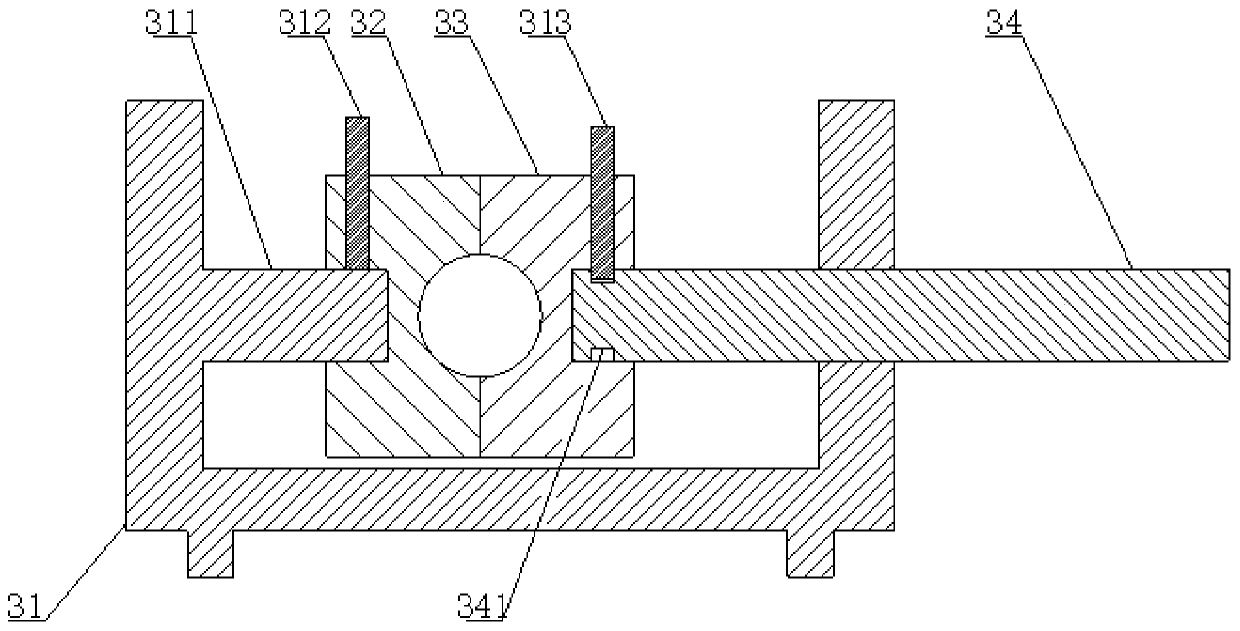

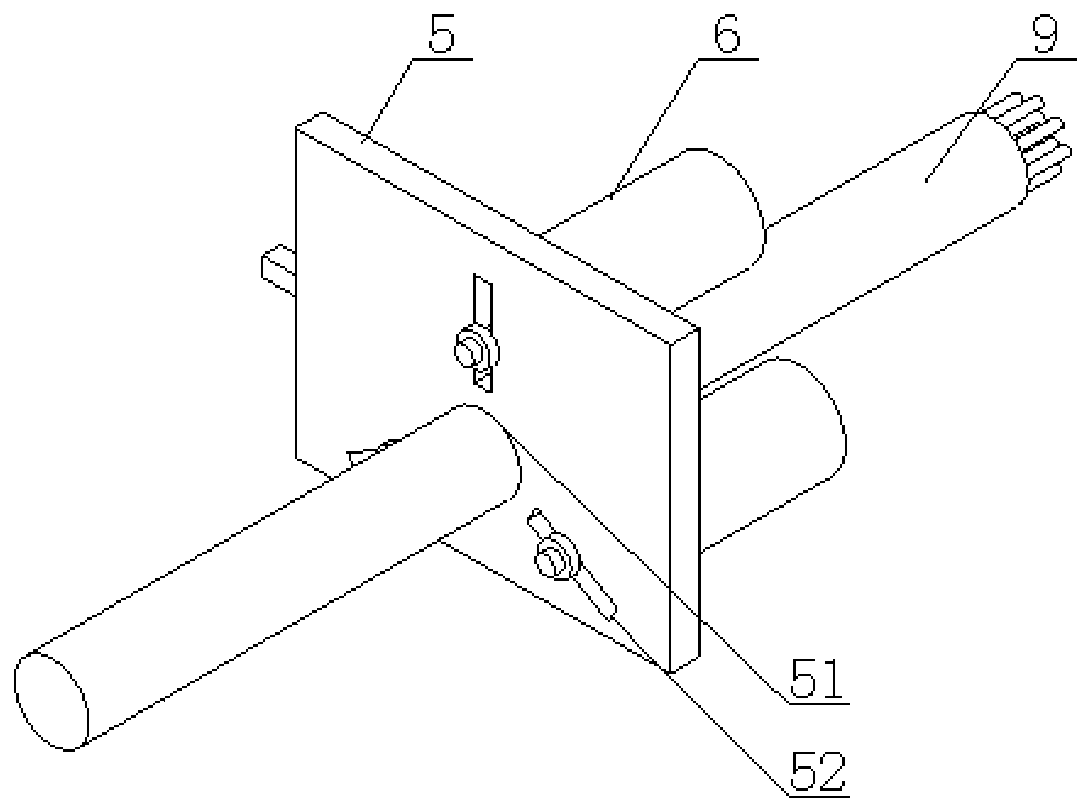

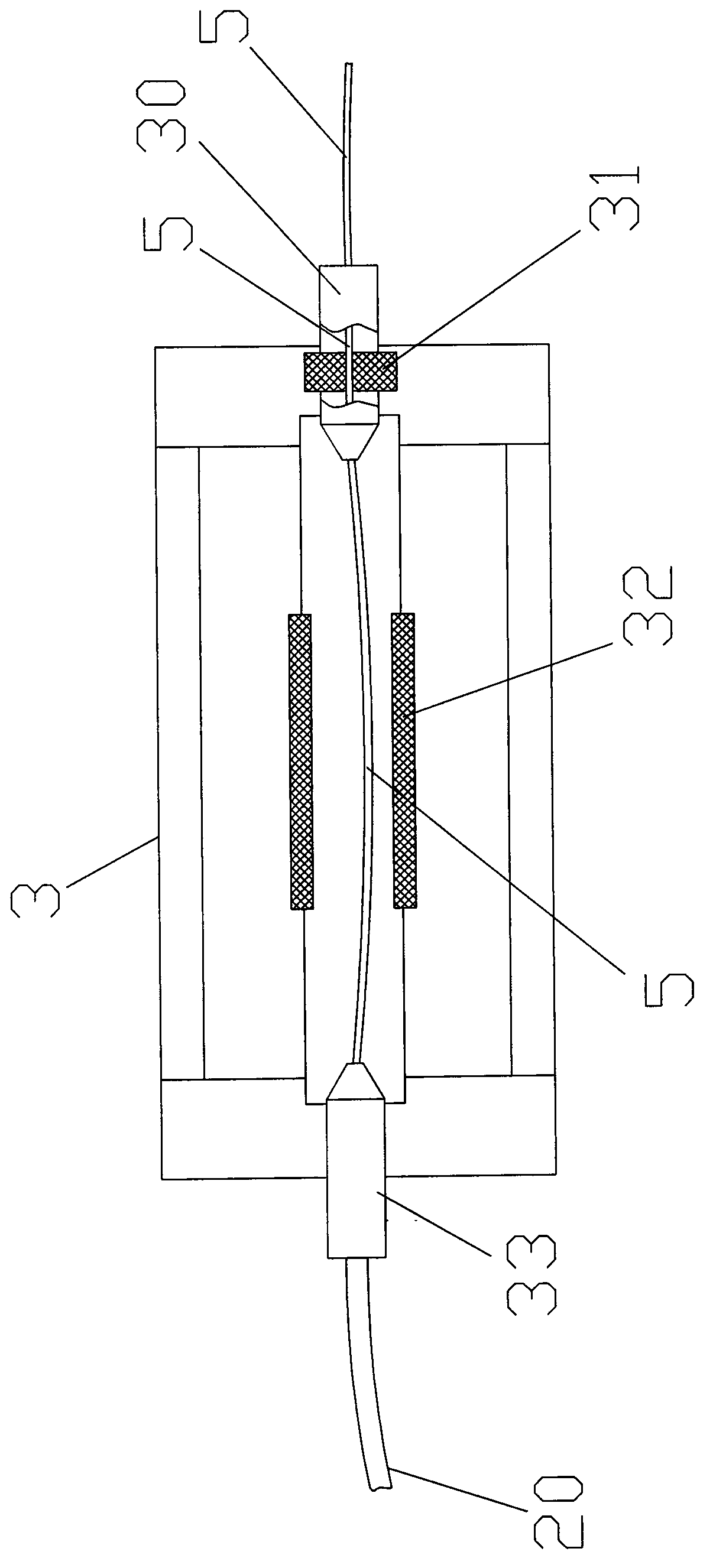

The invention provides a crimping assisting device and crimping method for a power transmission line, and belongs to the technical field of power construction. The crimping assisting device comprisesa workbench, a first clamping assembly and two second clamping assemblies. The first clamping assembly is fixedly arranged on the workbench and is used for fixing a steel splicing sleeve. The two second clamping assemblies are respectively arranged at the two sides of the first clamping assembly in a sliding mode, and the clamping center lines of the two second clamping assemblies coincide with the clamping center line of the first clamping assembly. The two second clamping assemblies are used for fixing power transmission lines and driving the power transmission line to penetrate into the steel splicing sleeve. According to the invention, the two second clamping assemblies slide to approach the first clamping assembly, so that the two power transmission lines can enter into the steel splicing sleeve, and an operator does not need to hold the power transmission lines by hands, thereby solving the problem of time and labor waste in the prior art.

Owner:STATE GRID CORP OF CHINA +2

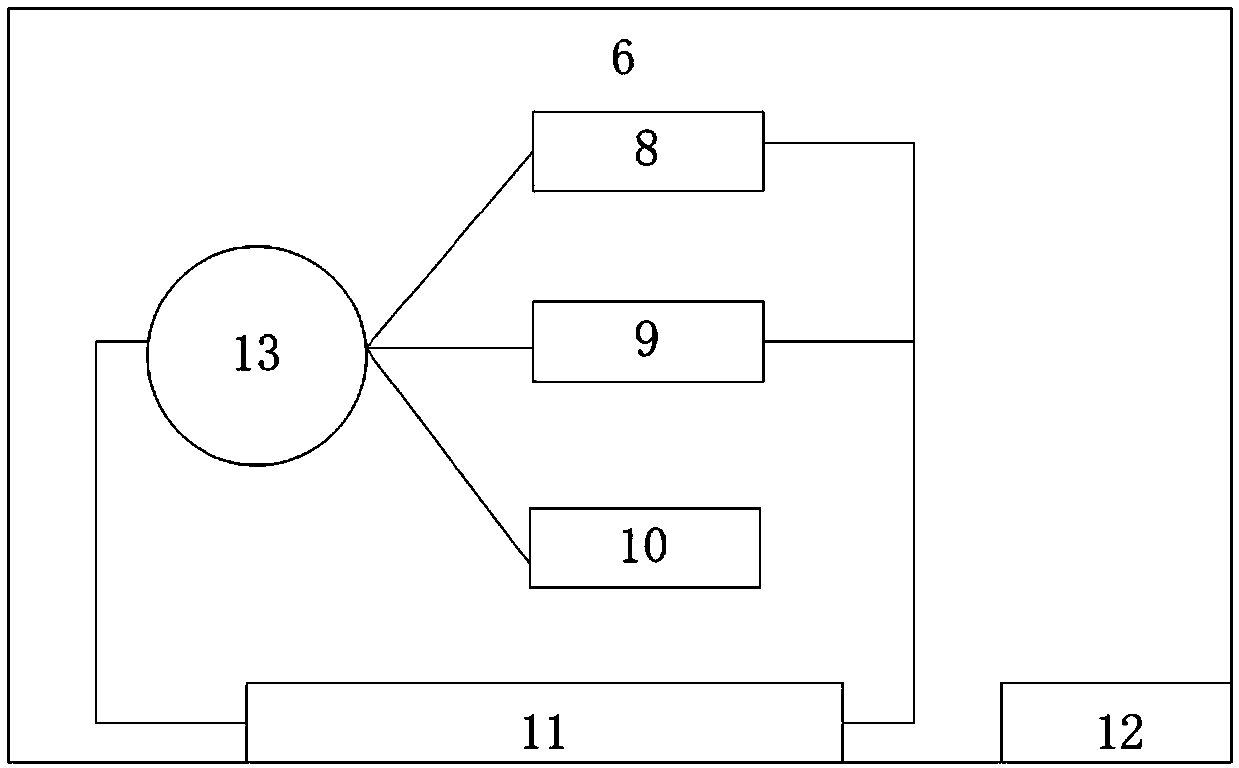

Intelligent supermarket shopping guidance system and method

InactiveCN107609943ARecommend objectiveRecommend humanizationNavigational calculation instrumentsParticular environment based servicesCosine similarityGuidance system

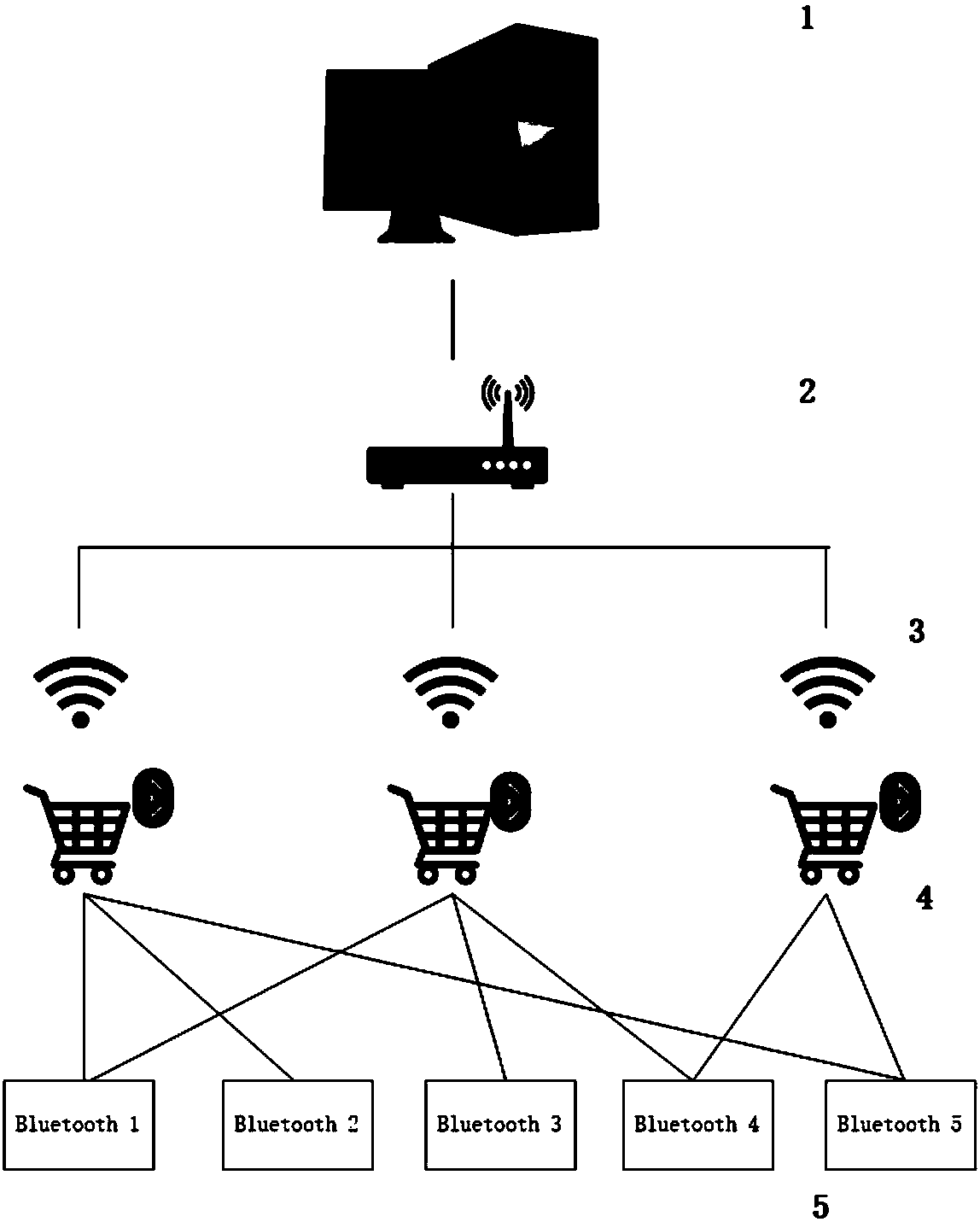

The invention discloses an intelligent supermarket shopping guidance system and method. The system includes a server, a plurality of first Bluetooth modules and a plurality of intelligent shopping carts. According to the system and method, a Dijkstra's shortest path algorithm is applied to supermarket shopping, a supermarket plan is innovatively divided into a specific topological network, the Dijkstra's algorithm is applied to provide a shortest buying path for a customer, and time spent for finding a commodity is saved; and at the same time, a corrected cosine similarity collaborative-filtering recommendation algorithm is applied to pushing of supermarket commodity information, more outstanding commodities are more objectively recommended in more humanized manner for the customer on thebasis of scores of the customer on commodities, and thus increasing sale numbers of supermarket commodities is facilitated. According to the intelligent supermarket shopping guidance method of the invention, shopping of people is enabled to be convenient and quick, a congestion degree of a supermarket is decreased, shopping efficiency of the supermarket is improved, and shopping comfort sensationsof the people are improved.

Owner:SHANDONG JIANZHU UNIV

Waste recycling device and method for plastic product production

PendingCN110076935APromote softeningStickyPlastic recyclingMechanical material recoveryRecovery methodWaste recycling

The invention belongs to the technical field of plastic products, and particularly relates to a waste recycling device for plastic product production. The waste recycling device comprises a base, wheels are fixedly installed at the bottom of the base, a push rod is fixedly installed on one side of the top of the base, and a supporting frame is fixedly connected to the top of the base. A treatmentbox is fixedly arranged inside the supporting frame, an absorbing mechanism is arranged at the top of the treatment box, and a crushing mechanism is arranged in the treatment box. A movable plate is fixedly arranged at the bottom of the crushing mechanism, and an adjusting rod is fixedly connected to one side of the movable plate. According to the waste recycling device and method for plastic product production, a softening mechanism is arranged so that wastes can be conveniently softened in the waste recycling process, the wastes can have certain viscidity and can be tightly combined when extruded, the problem that gaps are generated between the wastes is avoided, and the compactness of the wastes is improved.

Owner:荆州市今缘塑料股份有限公司

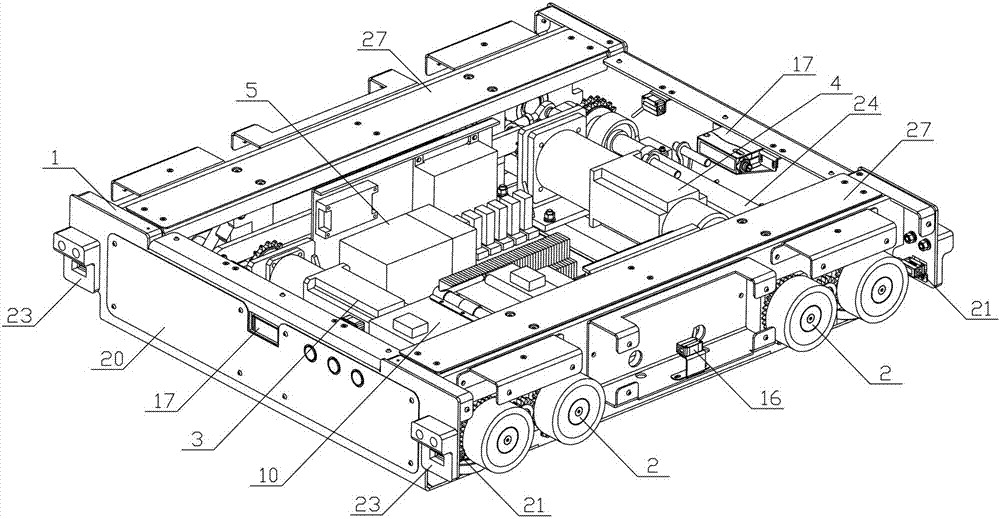

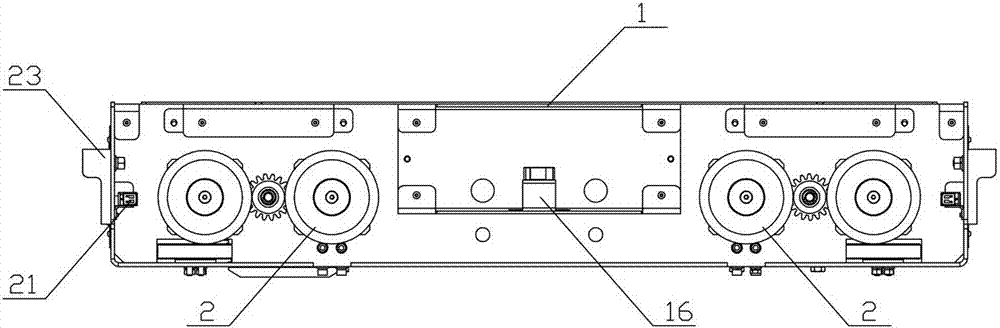

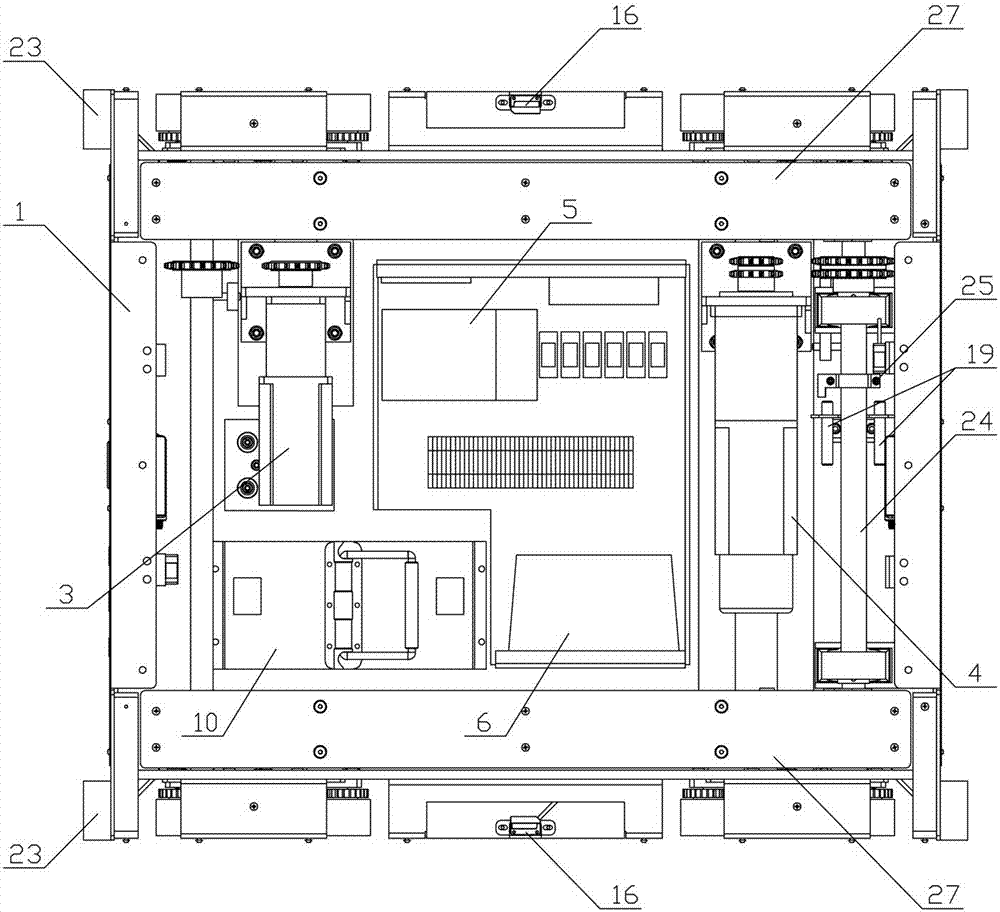

Intelligent shuttling trolley applied to stacker

PendingCN107444823AImprove operational efficiencyEasy to controlStorage devicesLaser rangingVehicle frame

The invention relates to the technical field of logistics warehousing, in particular to an intelligent shuttling trolley applied to a stacker. The shuttling trolley comprises a frame and a plurality of sets of traveling wheels, a traveling motor, a lifting motor and a lifting mechanism are installed in the frame, driving connection is formed by the traveling motor and one set of the traveling wheels, and anti-collision devices are arranged on the front and back sides of the frame respectively; a power distribution unit, a PLC, a servo driver, a wireless communication terminal and a wireless remote control terminal are installed in the frame, and a remote monitoring terminal is configured; laser distance measuring sensors and an encoder which are used for controlling working trends of the traveling motor and a location sensor which is used for controlling working trends of the lifting motor are installed on the frame. According to the shuttling trolley, the structure is simple, the design is compact, the equipment input cost is low, intelligent quick charging on the shuttling trolley is achieved, and precise control and remote monitoring are conducted on working trends and lifting trends of the shuttling trolley, so that the efficiency of operation and use of a stereoscopic warehouse is greatly improved.

Owner:湖北三丰小松物流技术有限公司

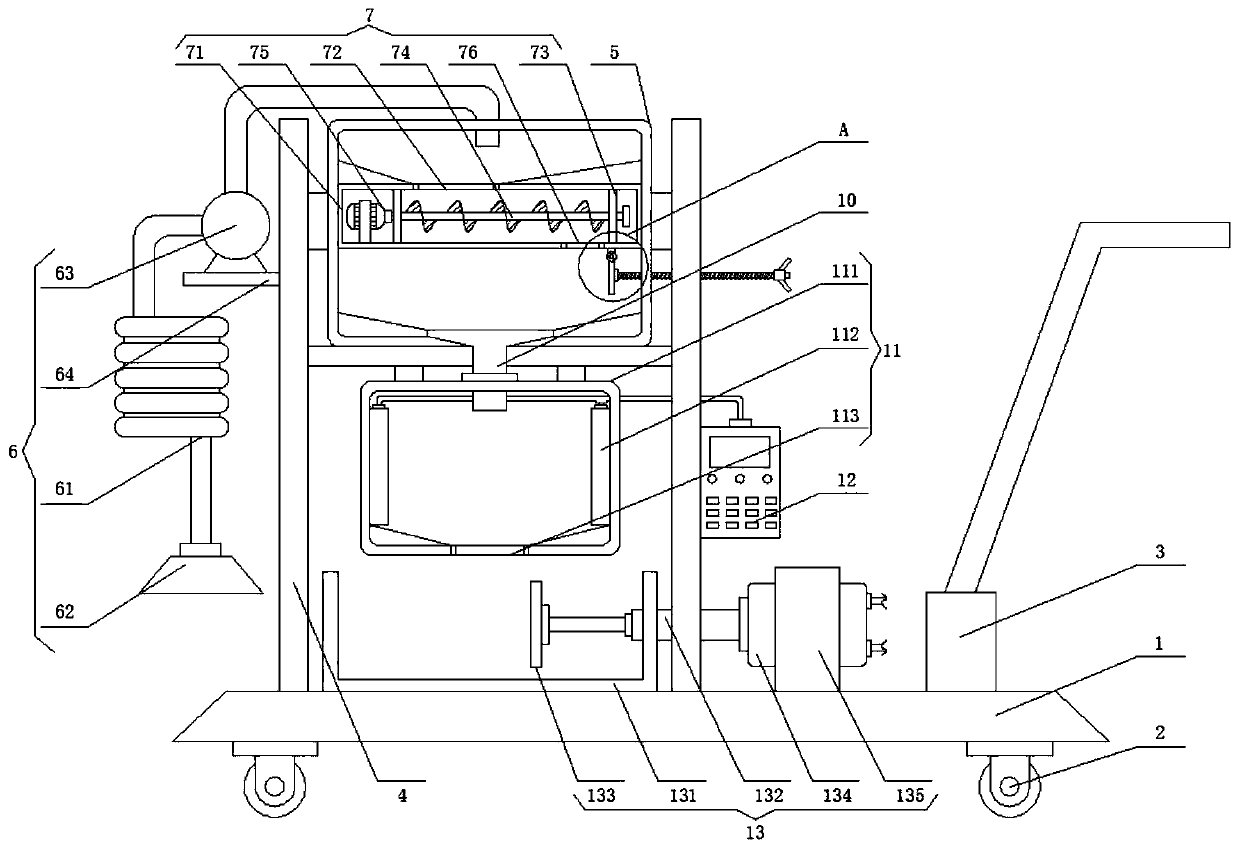

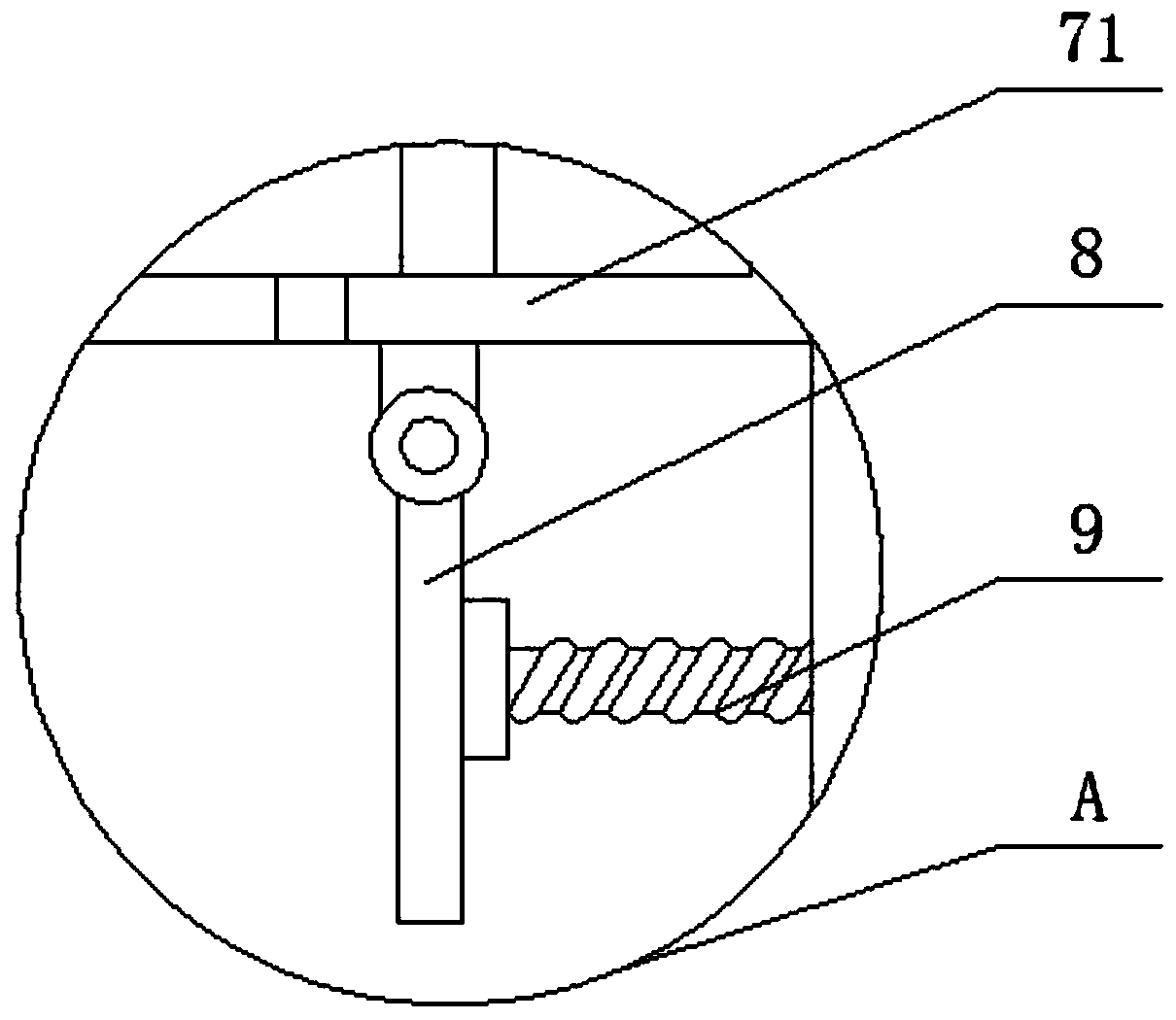

Automatic wire feeding system of automatic laser welding machine

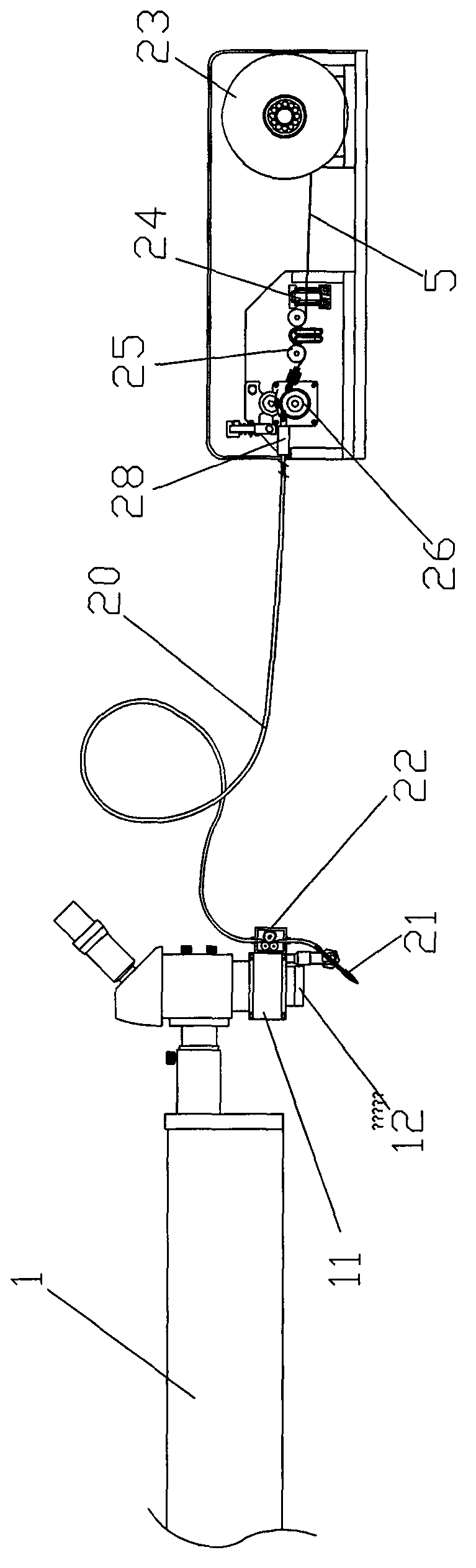

The invention relates to an automatic wire feeding system of an automatic laser welding machine. The automatic wire feeding system is matched with a laser head for use. The automatic wire feeding system of the automatic laser welding machine comprises a welding wire drum, a welding wire correcting mechanism, a welding wire straightening mechanism, an air blowing and wire feeding device, a tail end wire feeding speed control mechanism and a control driving unit in sequence, wherein the welding wire drum is provided with a wound welding wire, the welding wire correcting mechanism is used for correcting the welding wire, the tail end wire feeding speed control mechanism is used for precisely controlling the wire feeding speed, the control driving unit is connected with the welding wire correcting mechanism, the welding wire straightening mechanism, the air blowing and wire feeding device and the tail end wire feeding speed control mechanism and is used for controlling the speed, the air blowing and wire feeding device is provided with a wire blowing pipe used for blowing and feeding the welding wire and is connected with a wire feeding hole of the wire blowing pipe, the tail end of the wire blowing pipe is provided with a welding wire outlet end which is fixedly connected with an end laser head, and the port axis of the welding wire outlet end penetrates through a laser condensation welding focus on the optical axis of the laser head. The automatic wire feeding system can be used for automatically conveying the welding wire to a welding point, and operating personnel do not need to convey the welding wire by hand, so that the condition that time and effort are consumed due to the fact that the welding wire is manually and imprecisely conveyed is avoided, the labor cost is reduced, the welding quality is conveniently ensured, and the application range of the laser welding machine is enlarged.

Owner:SHENZHEN TONGFA LASER EQUIP

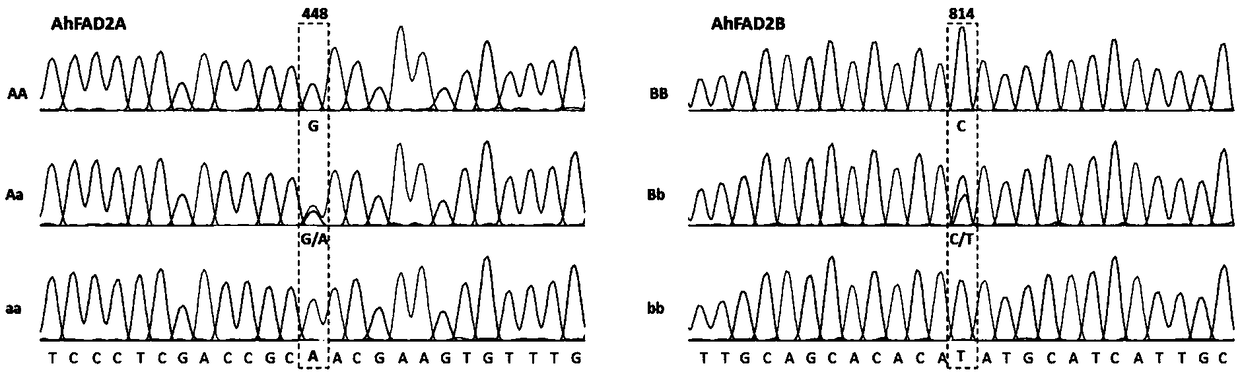

Molecular marker method for detecting high oleic acid content of peanuts and application

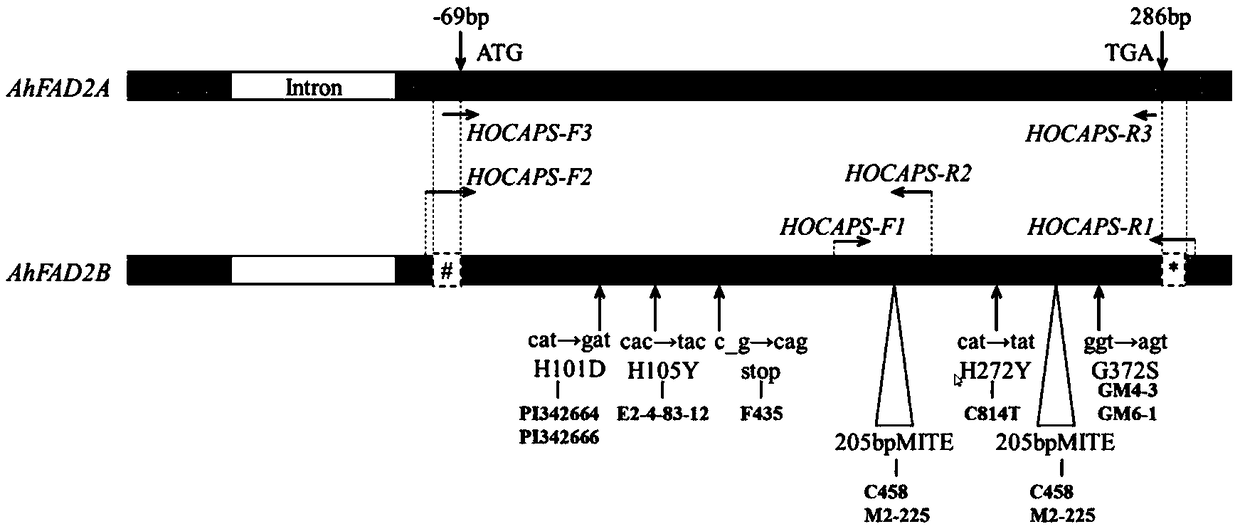

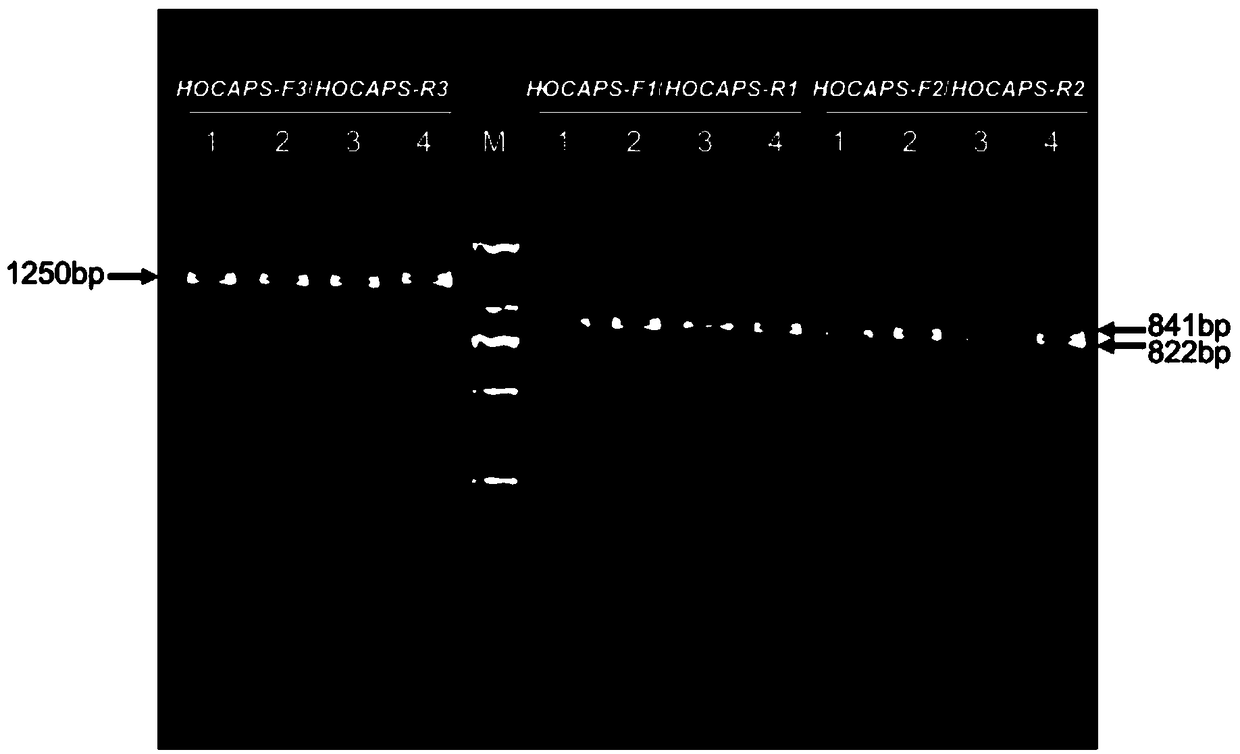

ActiveCN108893551AAvoid wasting time and effortAvoid phenotypingMicrobiological testing/measurementPopulationDigestion

The invention discloses a molecular marker method for detecting high oleic acid content of peanuts and application and belongs to the technical field of molecular breeding of crops. The method comprises the following steps: aiming at mutation sites of nucleotide sequences of AhFAD2B genes with high oleic acid content of peanut seeds, amplifying and coding nucleotide sequence fragments of AhFAD2B genes by adopting primer pairs, and selecting corresponding restriction enzymes to perform digestion on amplification products, so that the mutation sites of the nucleotide sequences of the AhFAD2B genes with high oleic acid content of peanut seeds can be marked. According to the method disclosed by the invention, CAPS makers are successfully designed and developed for novel mutant genes of high-oleic-acid peanuts, and a kit for detecting the mutation sites is developed. The homozygous type and hybrid type of high oleic acid can be clearly identified, and genotyping can be performed in bred offspring segregation population, so that high oleic acid allelic individual plants or strains carrying out mutant genes are screened; and moreover, time- and labor-consuming phenotype identification canbe avoided, the breeding efficiency of high oleic acid peanut varieties is improved, and the breeding service life is shortened.

Owner:河北省农林科学院粮油作物研究所

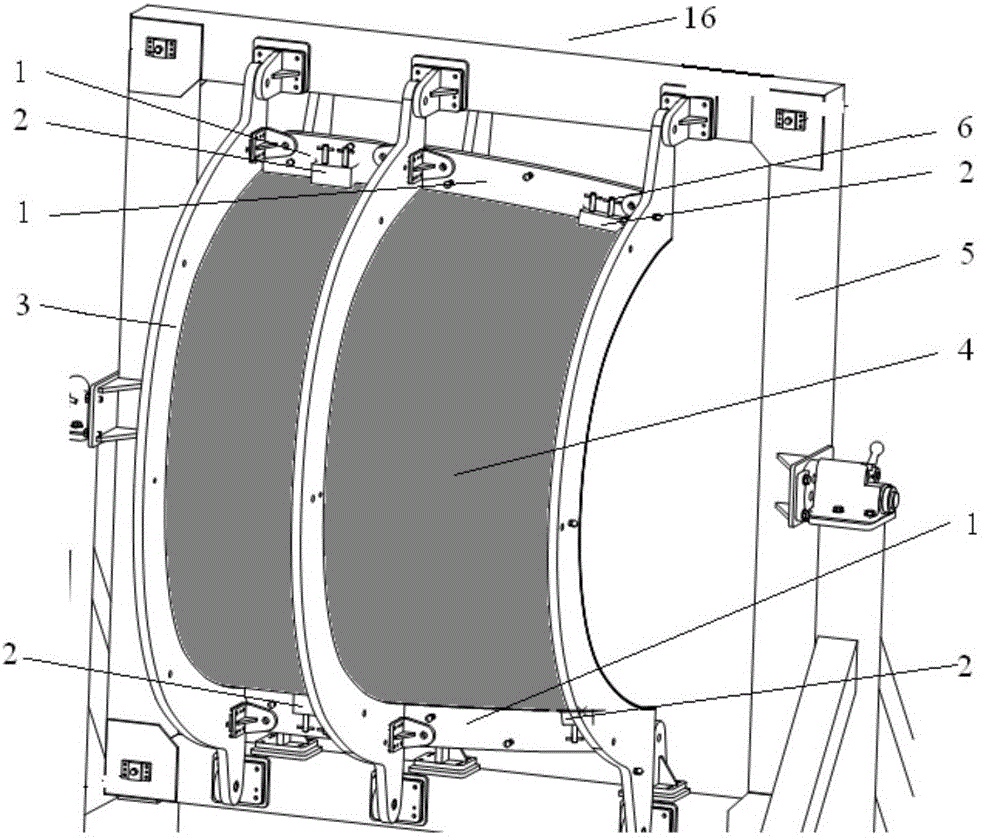

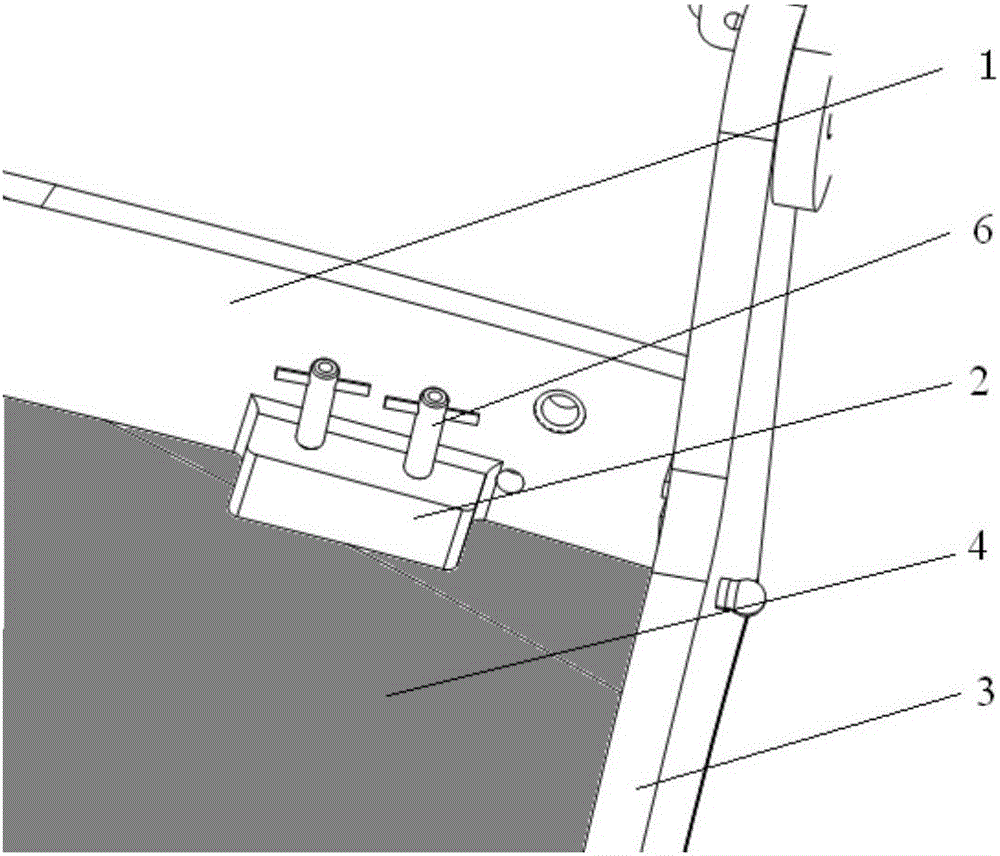

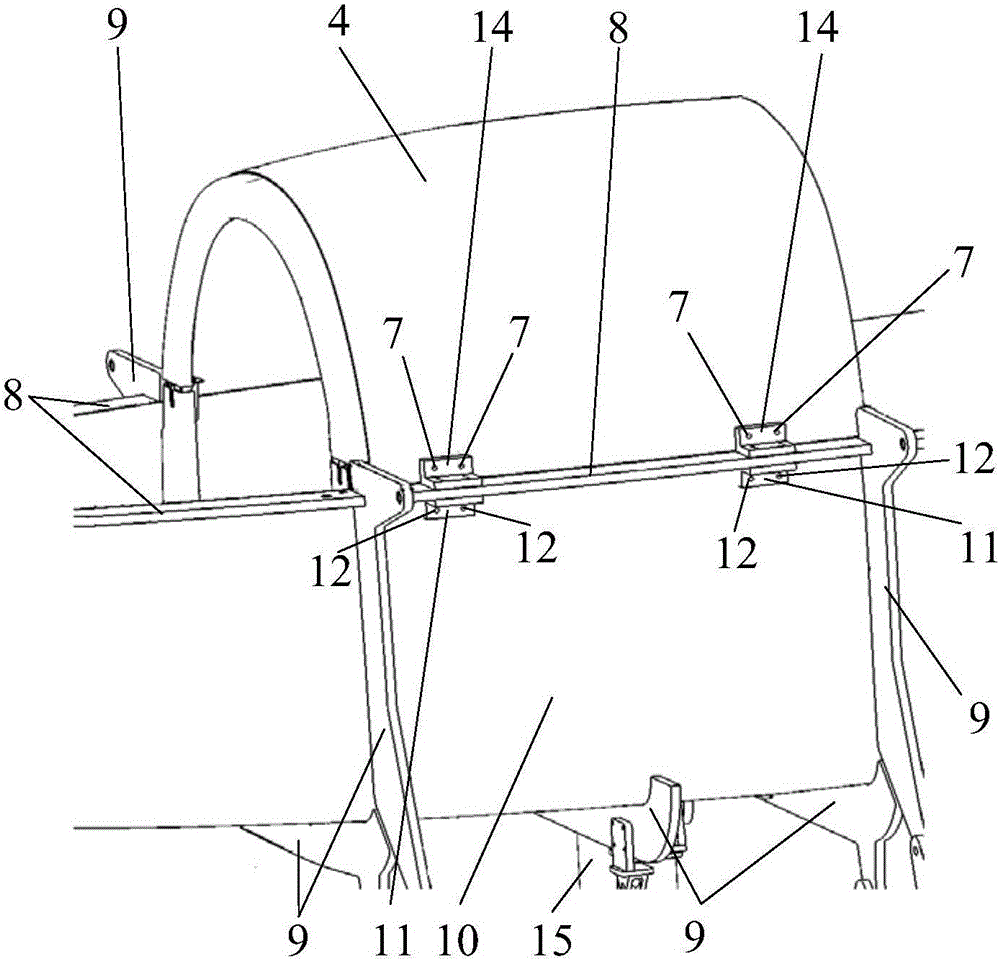

Composite material skin net edge coordination tools and assembling method for skins

The invention relates to composite material skin net edge coordination tools and an assembling method for skins. The method comprises following steps: 1) arranging coordinators on the skin assembling tools, wherein the coordinators are provided with coordination holes; 2) mounting the skins on corresponding assembling racks, and prepositioning and clamping the skins; 3) drilling technologic holes in the skins through the coordination holes in the net edge coordinators; 4) positioning and fixing the skins on the corresponding racks through the coordination holes in the skins; 5) drawing net edge lines on the surfaces of the skins by the use of line drawing templates; 6) performing trimming based on the net edge lines after the skins are disassembled; and 7) assembling and positioning the different skins on an assembly frame through butt joint coordination holes. According to the invention, the net edge size of the skins are determined through the cooperation of the net edge coordinators and the line drawing templates, and the skins are positioned through the butt joint coordination holes in an assembling process, so that the accuracy of the net edge size of the composite material skins is improved, the structure of the frame is simplified, the operation is easy and visual, and the assembling efficiency is improved.

Owner:AEROSPACE RES INST OF MATERIAL & PROCESSING TECH +1

Thin film solar cell bus bar intersection automatic hot welding device

InactiveCN103121135ARealize welding automationAvoid wasting time and effortWelding/cutting auxillary devicesAuxillary welding devicesPhysicsLinear drive

The invention relates to a thin film solar cell bus bar intersection automatic hot welding device and belongs to the field of semiconductor welding equipment. The device comprises a thin film solar cell transmission positioning mechanism, wherein a wire feeding sliding plate driven by a linear driving mechanism is arranged above the transmission positioning mechanism, a welding wire wheel is arranged on the wire feeding sliding plate in a rotary model through a shaft, a welding presser foot is arranged above a thin film solar cell bus bar intersection and is driven by the linear driving mechanism, and a welding gun is arranged on a welding gun sliding plate driven by a welding gun sliding plate linear driving mechanism. In a welding process, the linear driving mechanism of the wire feeding sliding plate drives the wire feeding sliding plate to send a welding wire to the intersection, the linear driving mechanism drives the welding presser foot to be pressed on the welding wire, the linear driving mechanism of the welding gun sliding plate drives the welding gun on the welding gun sliding plate to reach to the intersection, and then hot welding is achieved. The thin film solar cell bus bar intersection automatic hot welding device is good in welding quality, high in welding speed, applicable to large-scale thin film solar cell production, and capable of effectively improving product quality and production efficiency.

Owner:河南新能光伏有限公司

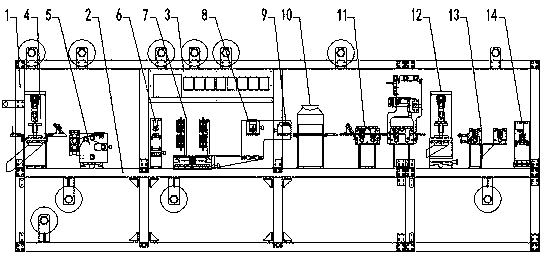

Disposable electrocardio-electrode dotter

InactiveCN107661098AHigh degree of automationAvoid wasting time and effortDiagnostic recording/measuringSensorsDouble rowSmall hole

The invention discloses a disposable electrocardio-electrode dotter. The dotter comprises a rack, a working platform and a control panel. The working platform is located in the middle of the rack, andproduction devices which can produce electrocardio electrodes in double rows at the same time are mounted on the working platform, and the production devices comprise a punching mechanism, a mark pulling mechanism, a small hole punching mechanism, a dotting mechanism, an energization device, an adhesive dripping mechanism, a curing device, a blister mechanism, a contour punching mechanism and a dotted line cutting mechanism which are arranged from one end to the other end in sequence. Raw material foam passes through the production devices in sequence and are processed into electrocardio electrode finished products. The disposable electrocardio-electrode dotter is high in automation degree, achieves double-row simultaneous production and can complete combination of the whole disposable electrocardio electrode in the mode that a person operates on a production line, the phenomena of wasting time, labor and resources caused by manual operation in the past are avoided, the yield is improved, and the disposable electrocardio-electrode dotter is convenient to operate, greatly improves the working efficiency and the productivity and saves the production cost.

Owner:张坤芝

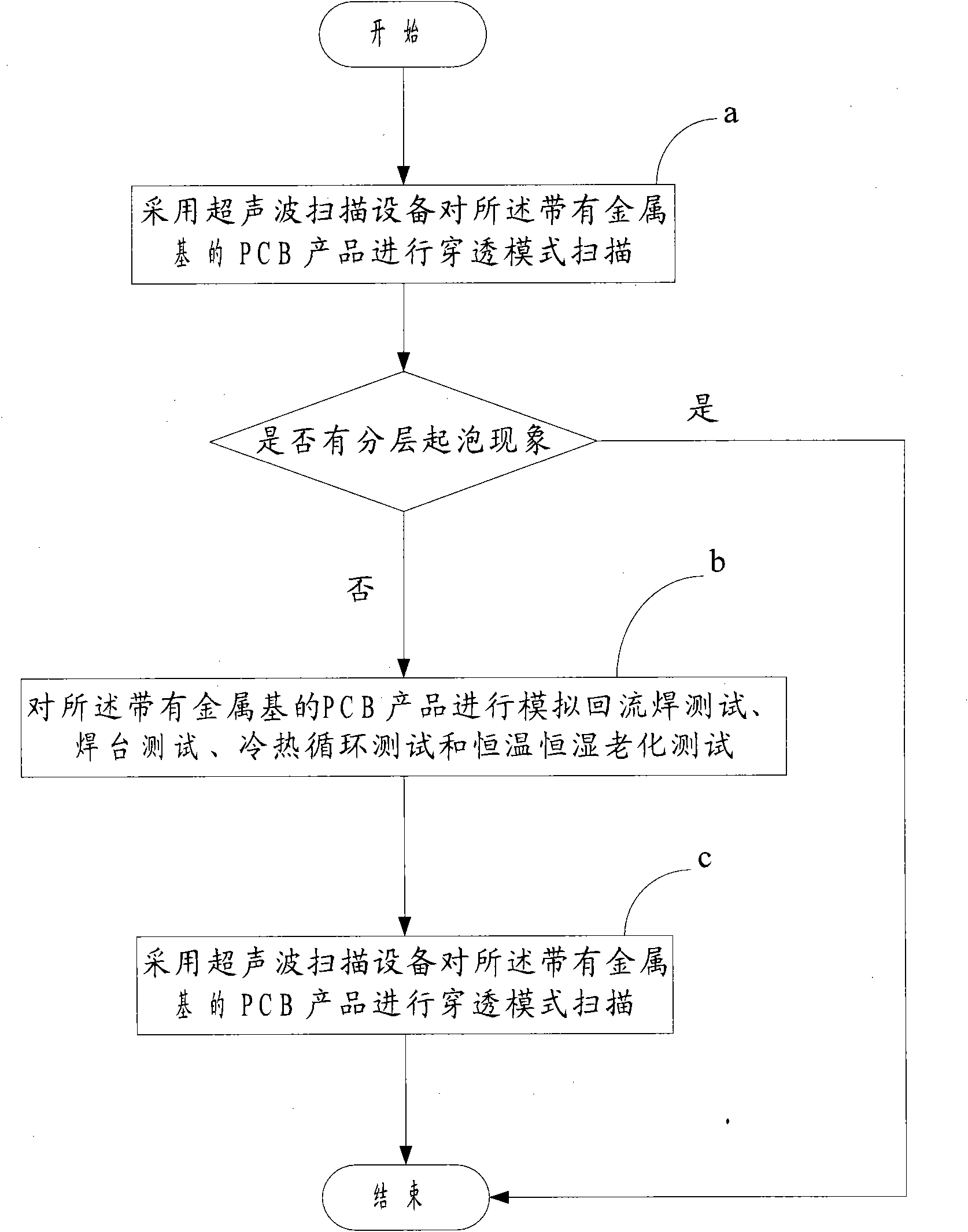

Method for detecting reliability of printed circuit board (PCB) product with metal substrate

InactiveCN101936954AIntegrity guaranteedAvoid wasting time and effortAnalysing solids using sonic/ultrasonic/infrasonic wavesWeather/light/corrosion resistanceMetal substrateThermal cycle test

The embodiment of the invention discloses a method for detecting the reliability of a printed circuit board (PCB) product with a metal substrate, which comprises the following steps of: a, performing transmission-mode scanning on the PCB product with the metal substrate by adopting ultrasonic scanning equipment, finishing the detection if the layering and blistering of the PCB product with the metal substrate are detected, otherwise, entering a step b; b, performing simulation on the reflow soldering test, soldering station test, thermal cycle test and constant-temperature and constant-humidity aging test of the PCB product with the metal substrate; and c, performing the transmission-mode scanning on the PCB product with the metal substrate by adopting the ultrasonic scanning equipment. In the reliability detection method provided by the embodiment of the invention, two failure modes of the PCB product with the metal substrate are taken into full account, test simulation is performed on the two failure modes, and finally the layering and blistering of the PCB product are detected to comprehensively evaluate the reliability of the PCB product with the metal substrate.

Owner:SHENNAN CIRCUITS

Urethral catheterization device for urological clinical operation

InactiveCN110841119AConvenient CatheterizationPrevent backflowMedical devicesIntravenous devicesPlastic materialsUrological surgery

The invention discloses a urethral catheterization device for a urological clinical operation. The device comprises a base and a vertical plate vertically arranged at the right end of the upper surface of the base, a urethral catheterization device body is fixedly arranged on the left side of the vertical plate and made of transparent plastic materials, a support fixedly mounted on the vertical plate is arranged above the urethral catheterization device body, a rotating motor is fixedly mounted on the support, and a cam is fixedly connected on an output shaft of the rotating motor. According to the urethral catheterization device for the urinary surgery clinical operation, catheterization can be conveniently and rapidly implemented in the body of a patient, and the device solves the problems that time and labor are wasted, and urethral catheterization efficiency is low as urethral catheterization is manually implemented by a doctor. Workload of the doctor is relieved, working efficiency is improved, urine in a temporary storage cavity can be prevented from returning into the body of the patient from a urethral catheter, namely, return of the urine in the urethral catheter is avoided, and normal urethral catheterization of people can be guaranteed.

Owner:郝东方

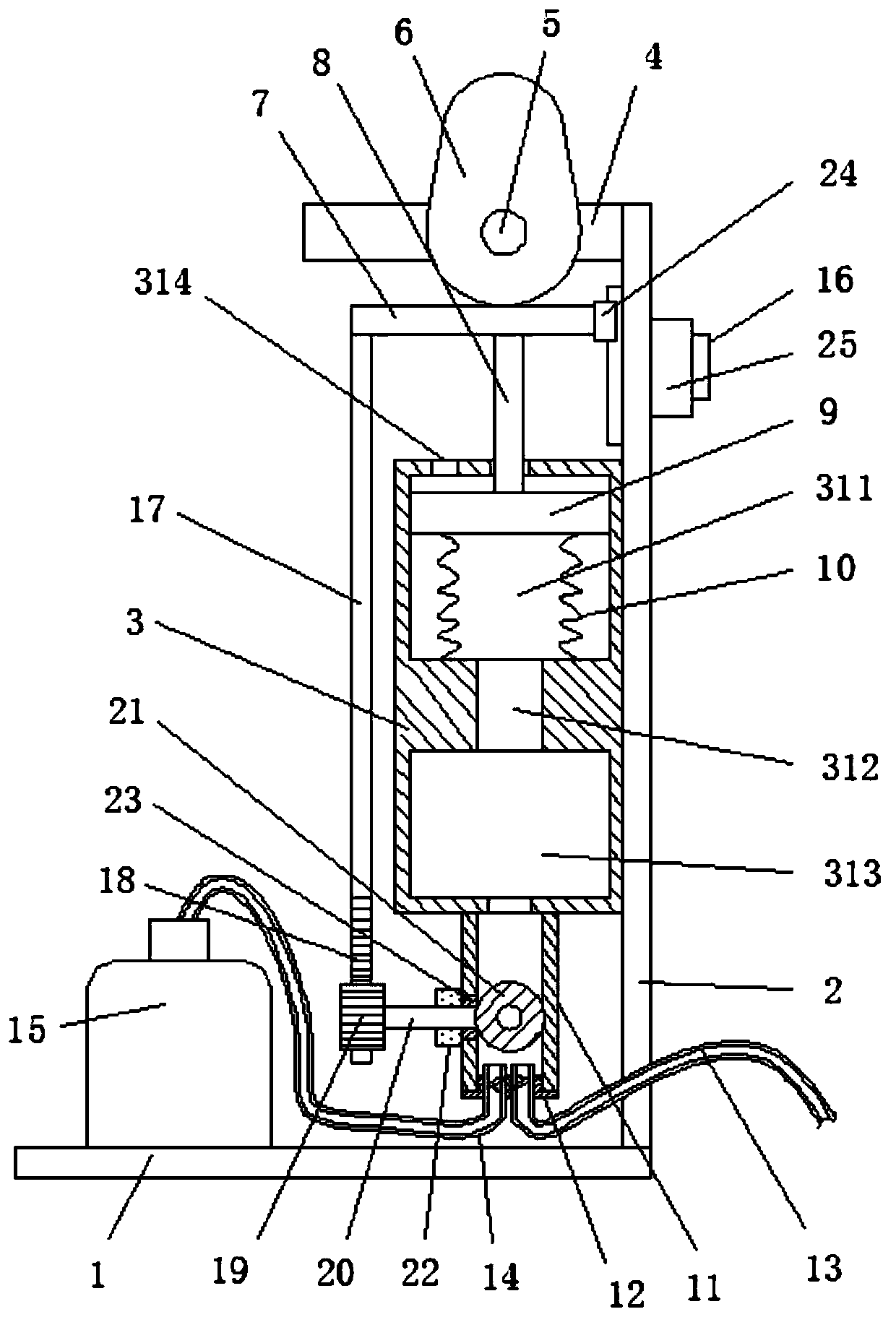

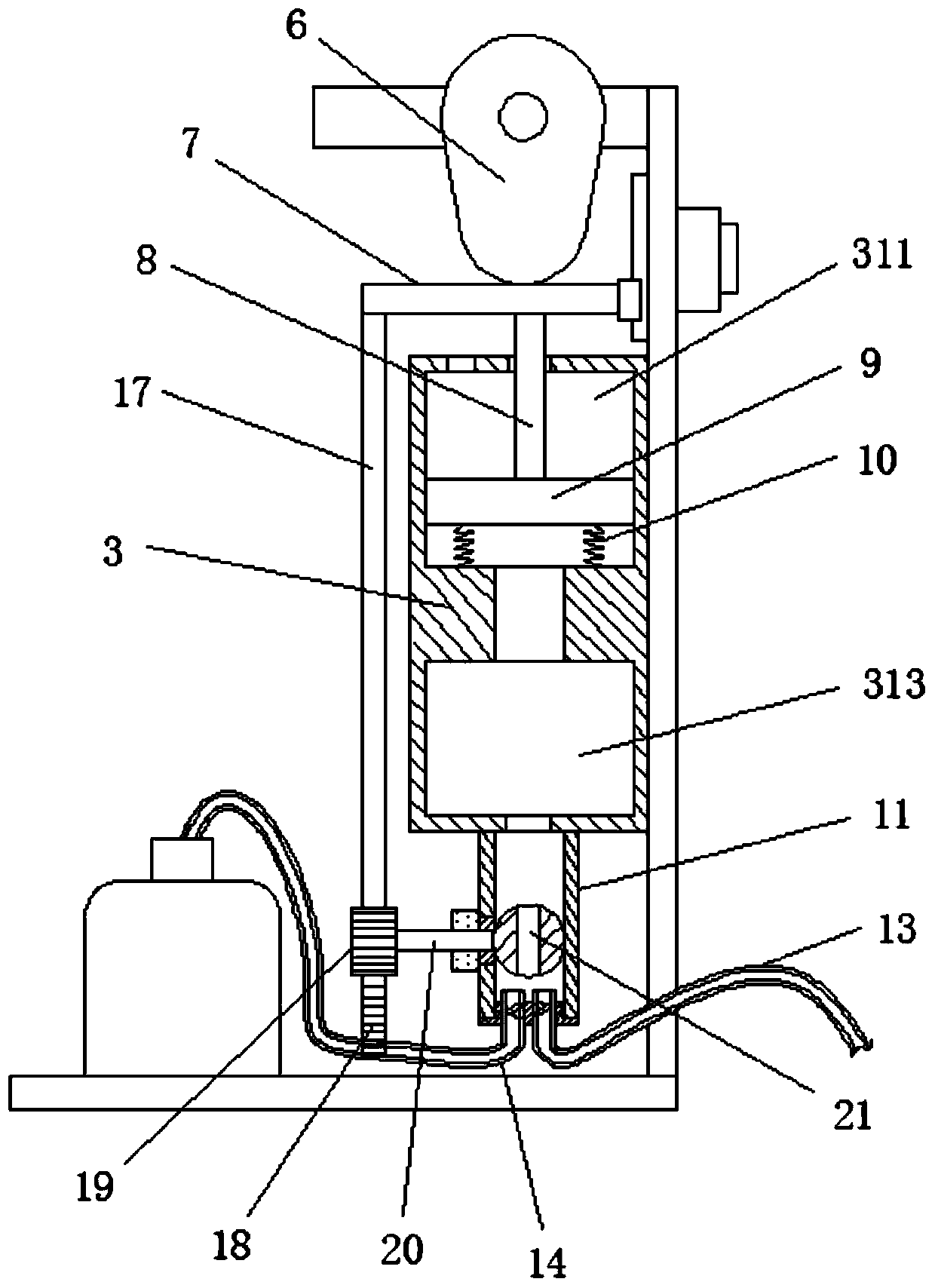

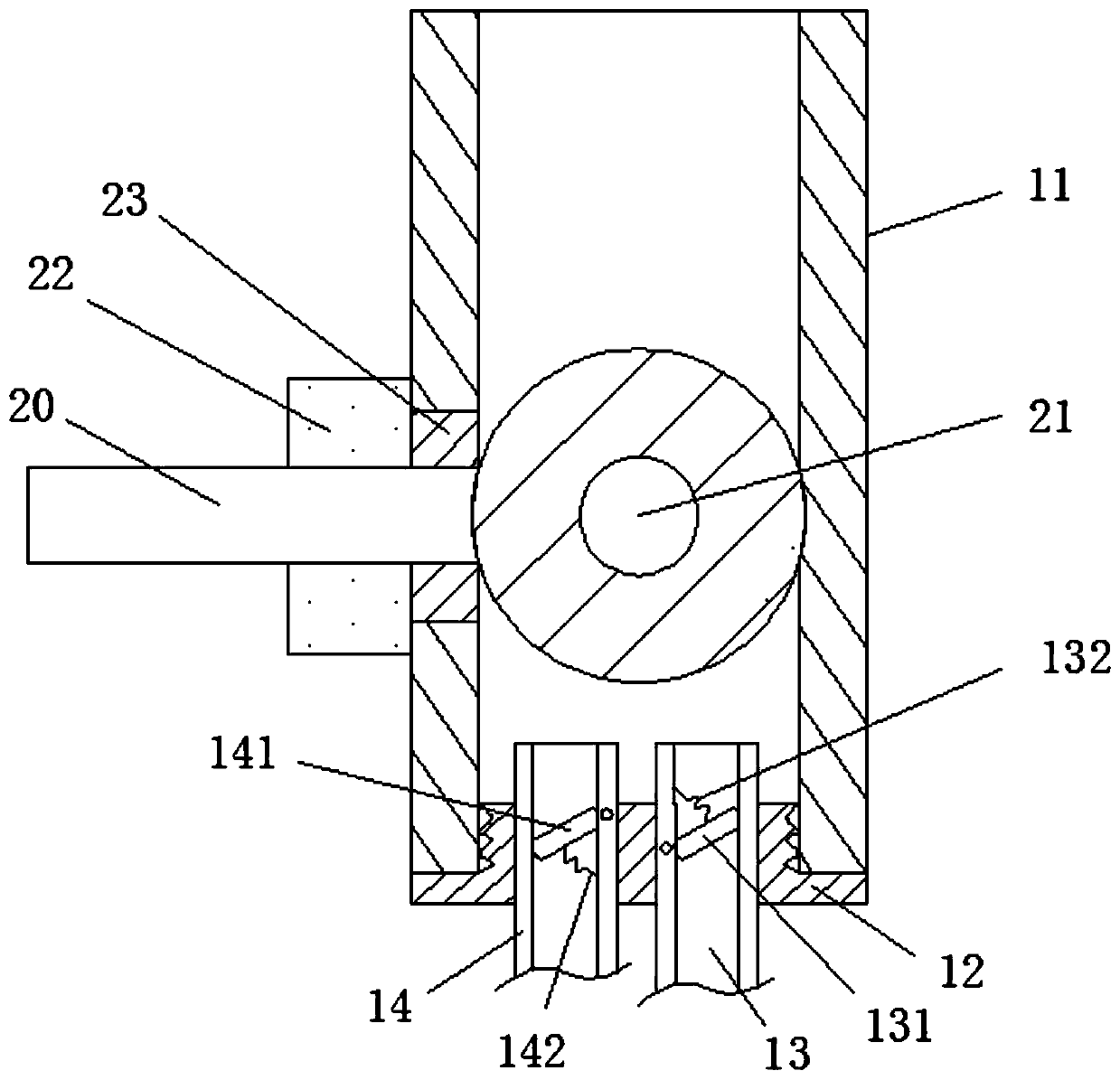

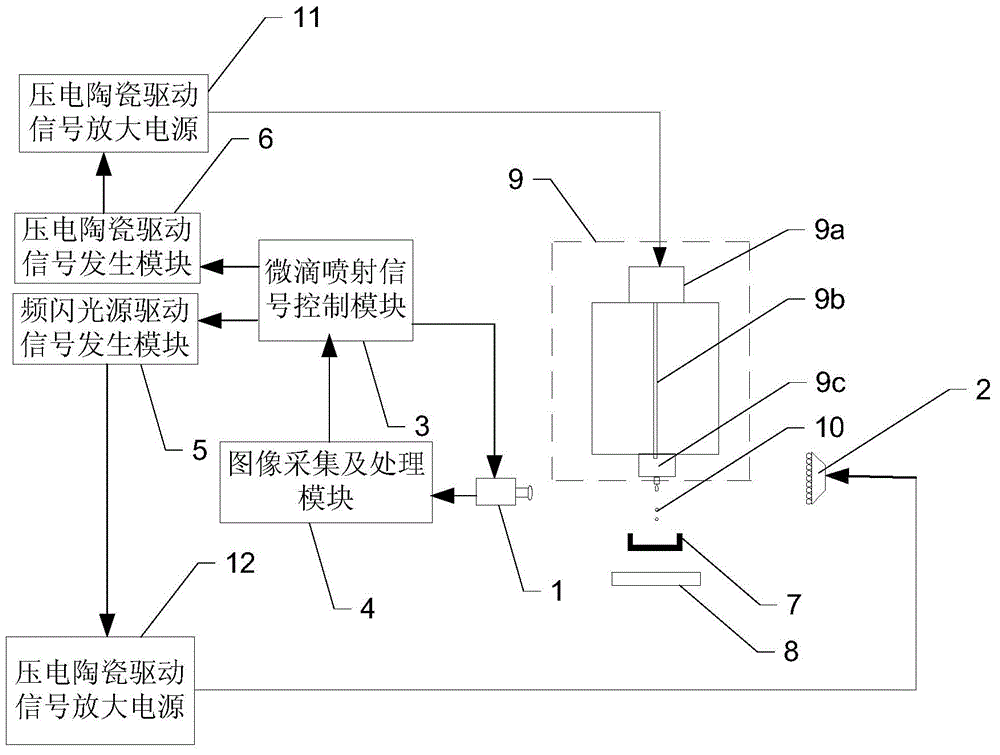

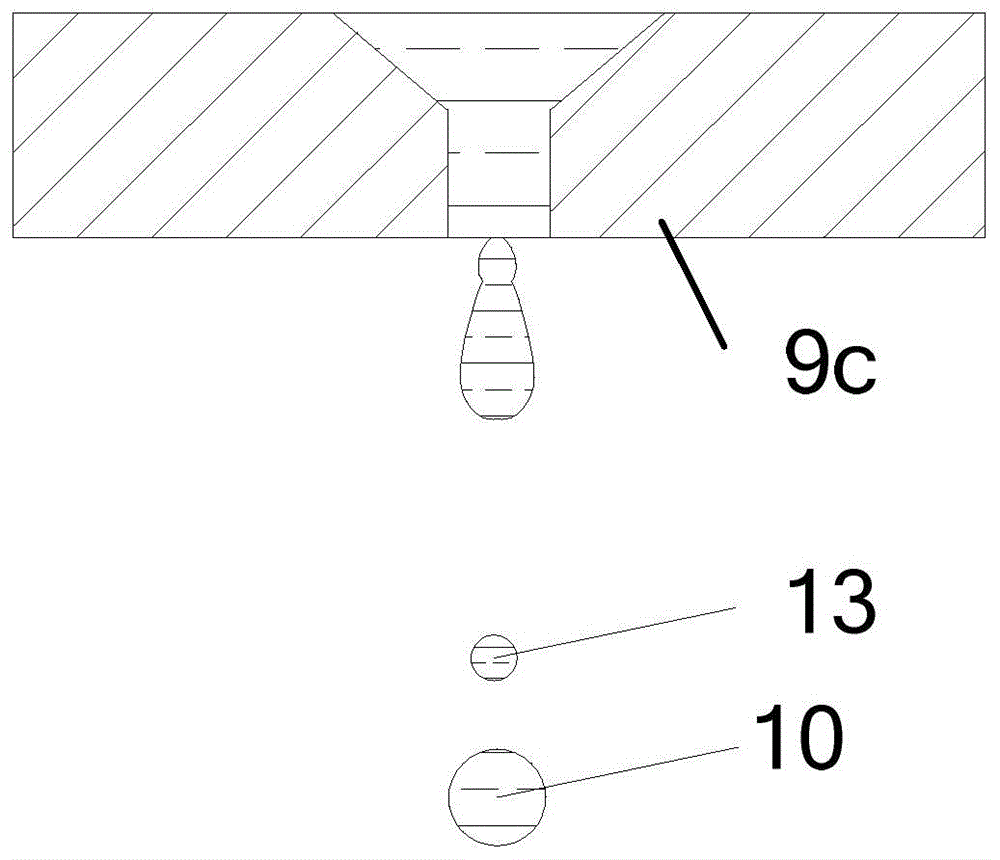

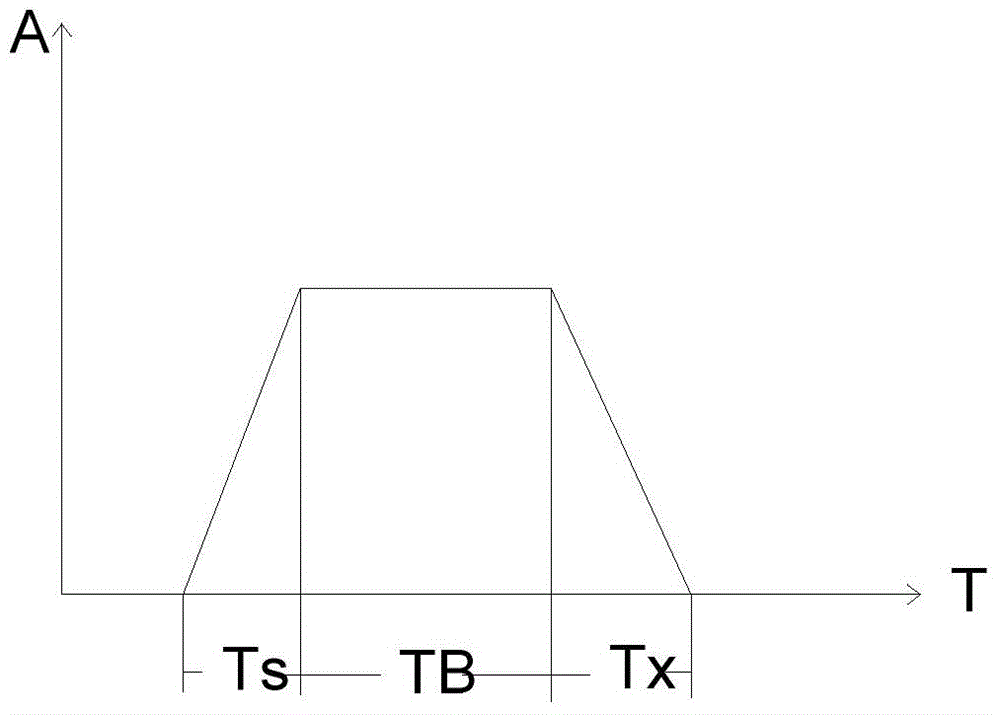

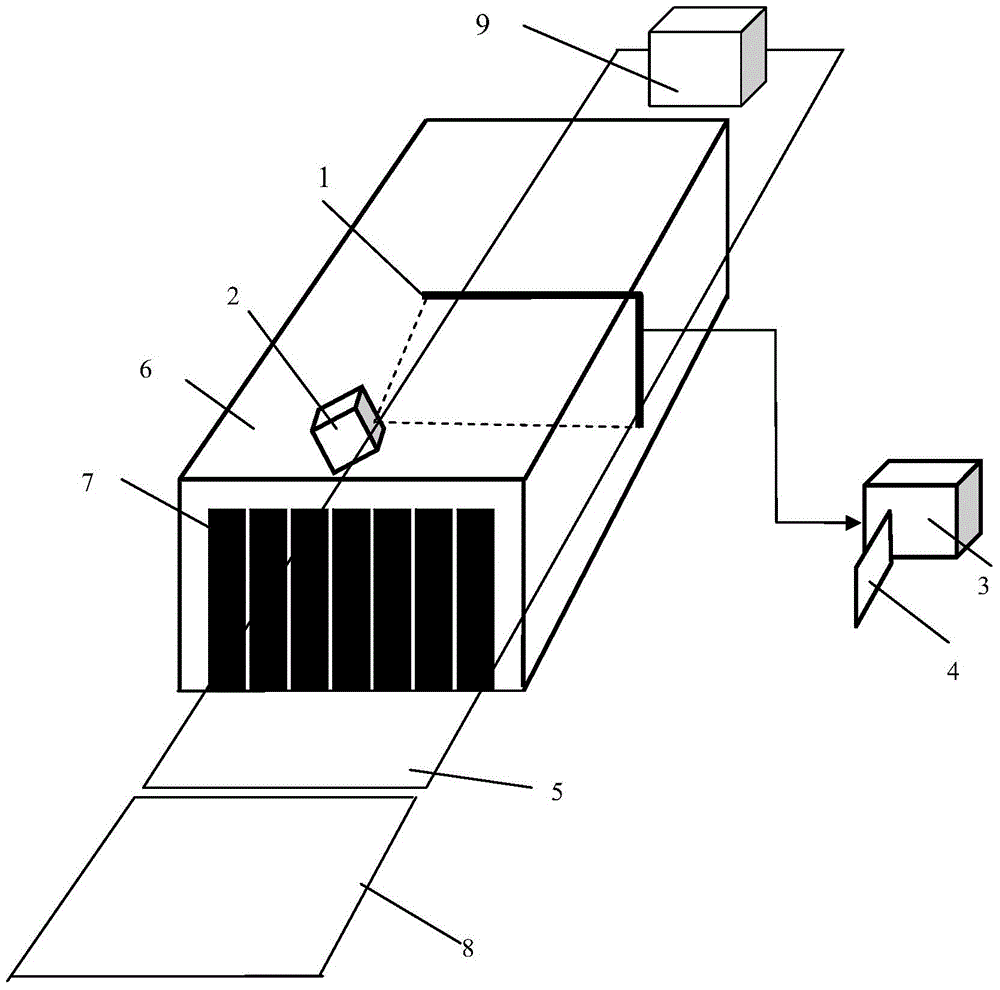

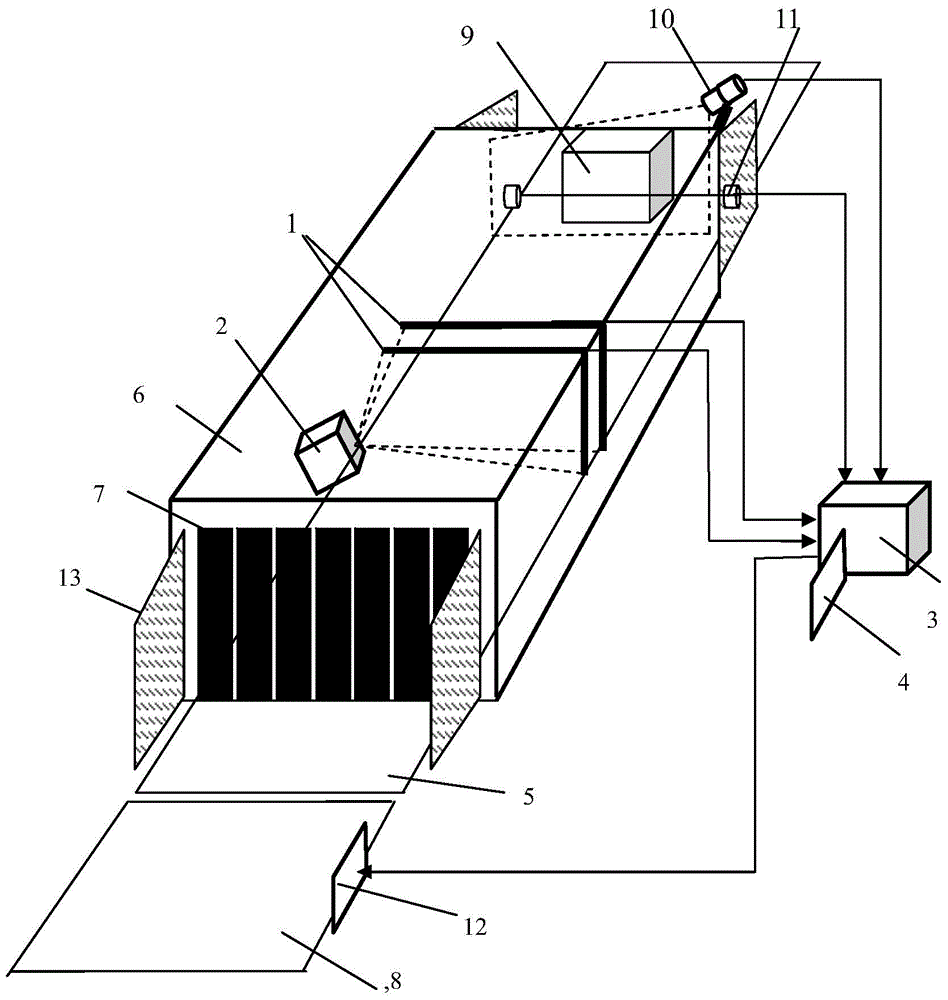

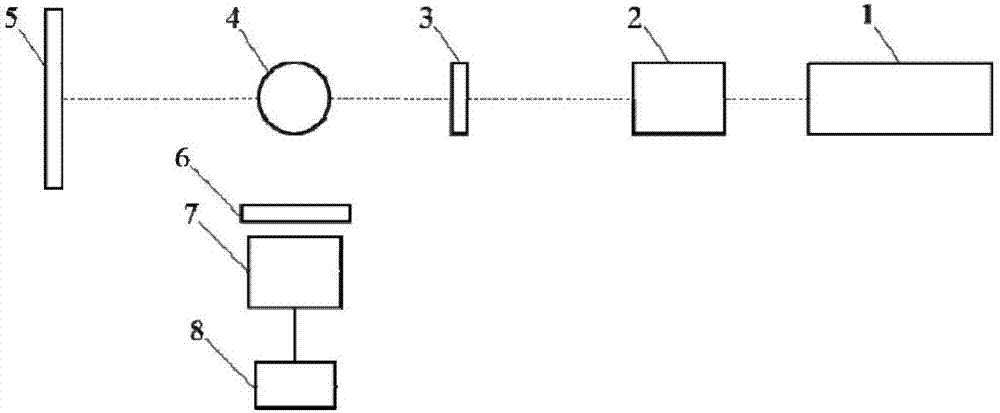

Measuring and controlling device for on-demand micro drop injection process based on image processing and measuring and controlling method thereof

The invention discloses a measuring and controlling device for on-demand micro drop injection process based on image processing and a measuring and controlling method thereof and belongs to the on-demand injection printing technical field. In order to solve the problems the time and energy are wasted for manually regulating the metal micro drop injection device for gradually achieving the stable state, the stability of the injection process cannot be guaranteed at real time and the accuracy control requirement is difficult to achieve. The shooting device and the stroboscopic light source being synchronous with the micro drop injection are adopted for obtaining the real time image of the micro drop injection process, the image is processed by an image collecting and processing module for obtaining the real time information of the micro drop injection process, a micro drop injection signal module 3 judges whether the index of the metal micro drop satisfies the preset condition according to the image extractive characteristic, and the micro drop injection signal control module changes the corresponding parameter of the drive signal for adjusting until that the index satisfies the presser condition; injecting, printing and depositing. The metal micro drop injection device is regulated for gradually achieving the stable state for the on-demand injecting and printing operation.

Owner:NORTHEAST FORESTRY UNIVERSITY

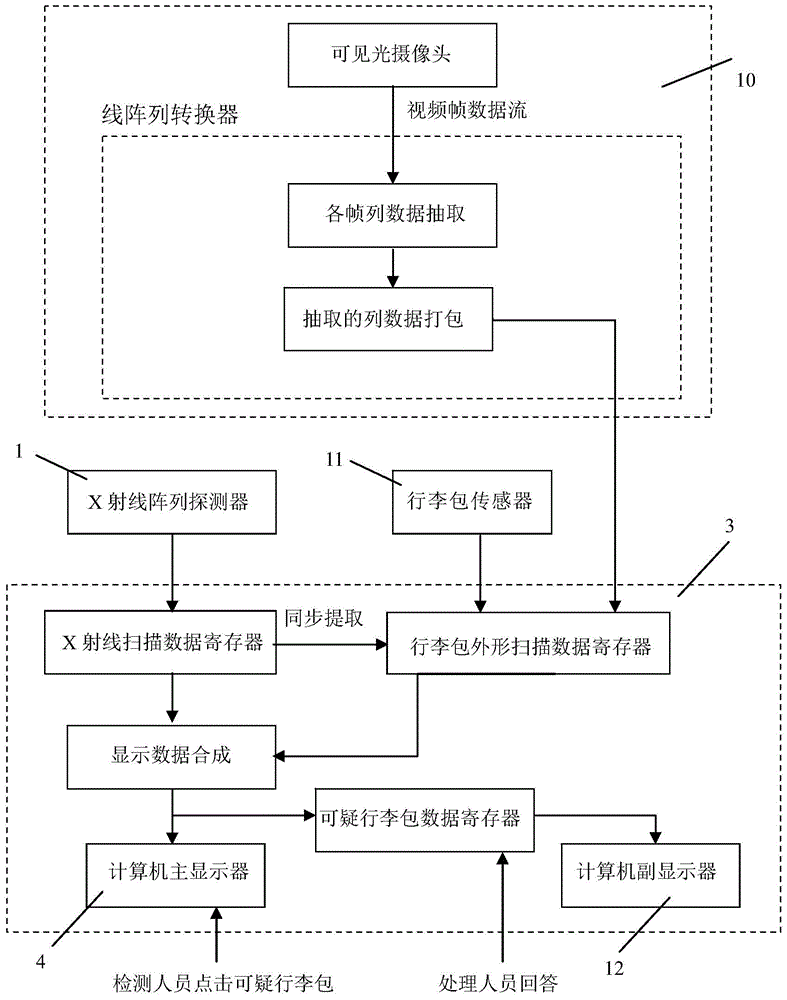

X-ray luggage bag inspection system with function of synchronous display of luggage bag shape

InactiveCN104991282AImprove work efficiencyAvoid wasting time and effortNuclear radiation detectionPhysicsRadiation protection

The invention relates to an X-ray luggage bag inspection system with a function of synchronous display of the luggage bag shape, and belongs to the technical field of radiation imaging. The system is made by adding a visible light luggage bag scanner, a luggage bag sensor, an auxiliary display and radiation protection plates on the basis of an existing X-ray luggage bag inspection system. The auxiliary display faces luggage bag open-package inspection personnel. The radiation protection plates are arranged at the two sides of the entrance and the exit of an inspection channel. The visible light luggage bag scanner is mounted above the entrance of the inspection channel, and scanning data of the visible light luggage bag scanner is input to a computer through a network cable. The luggage bag sensor is mounted above a conveyor belt below the field of vision of the luggage bag scanner, and signals of the luggage bag sensor are input to the computer in the form of switching value. An inspection program built in the computer synthesizes X-ray scanning data of a luggage bag and shape scanning data of the luggage bag column by column, the X-ray scanning data and the shape scanning data are displayed on a main display synchronously, and a suspicious luggage shape image is added with an identifier and then transmitted to the auxiliary display to help open-package inspection personnel to identity and inspect a suspicious luggage bag.

Owner:北京睿思厚德辐射信息科技开发有限公司

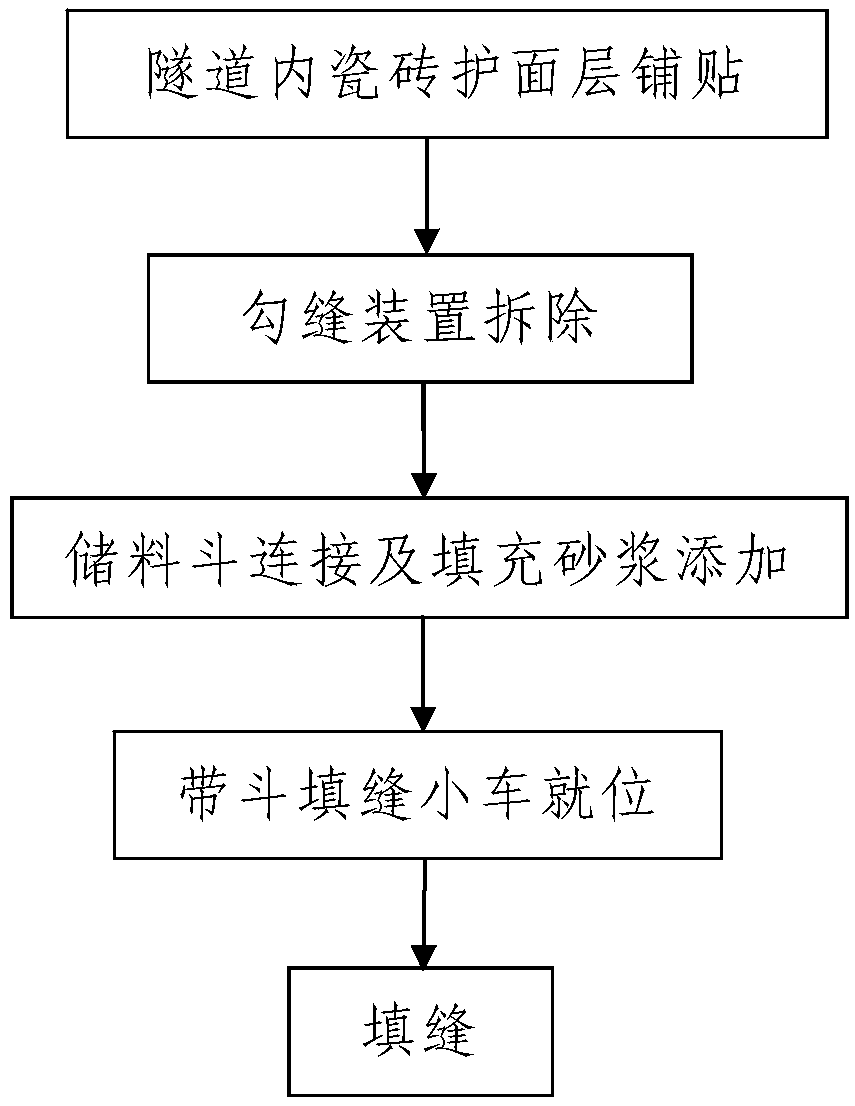

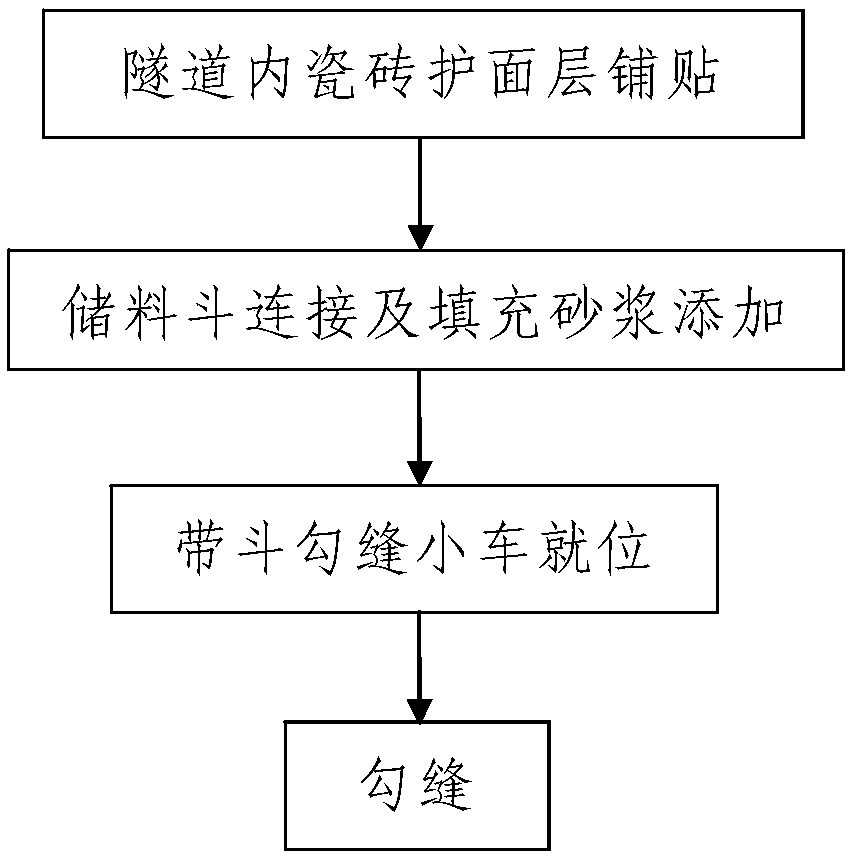

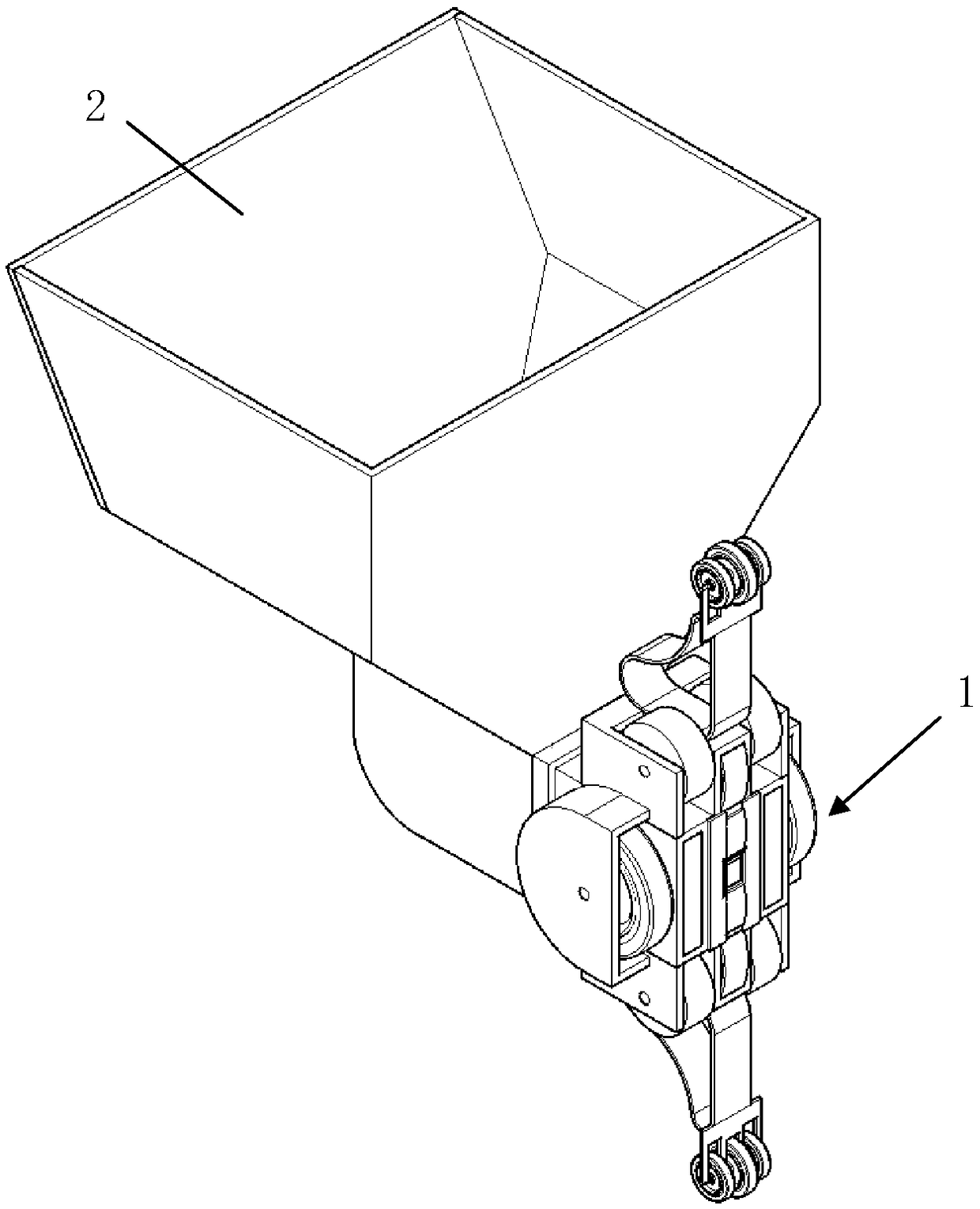

Caulking and jointing construction method for brick joints of tiles in tunnel

ActiveCN109296184AThe method steps are simpleReasonable designBuilding constructionsBrickMechanical engineering

The invention discloses a caulking and jointing construction method for brick joints of tiles in a tunnel. The caulking and jointing construction method is characterized in that a brick joint caulkingand jointing device is adopted to caulk or joint the brick joints of the tiles in the tunnel; the brick joint caulking and jointing device includes a caulking and jointing trolley capable of moving back and forth on the surface of a masonry structure and a storage hopper for storing filling mortar which is used for filling the brick joints; when caulking is actually performed, the steps of jointing device removal, storage hopper connection, filling mortar adding, being-in-place of a caulking trolley with a hopper and caulking are included; and when jointing is actually performed, the steps ofstorage hopper connection, filling mortar adding, being-in-place of a jointing trolley with a hopper and jointing are included. The caulking and jointing construction method has reasonable design, simple and convenient construction, high construction efficiency and good use effect, the movable brick joint caulking and jointing device is used for caulking or jointing the brick joints, the fillingmortar can be automatically fed into the treated brick joints, compaction and groove pressing forming can be performed on the filling mortar fed into the brick joints, and the quality of caulking andjointing can be ensured.

Owner:CHINA RAILWAY FIRST GRP CO LTD +1

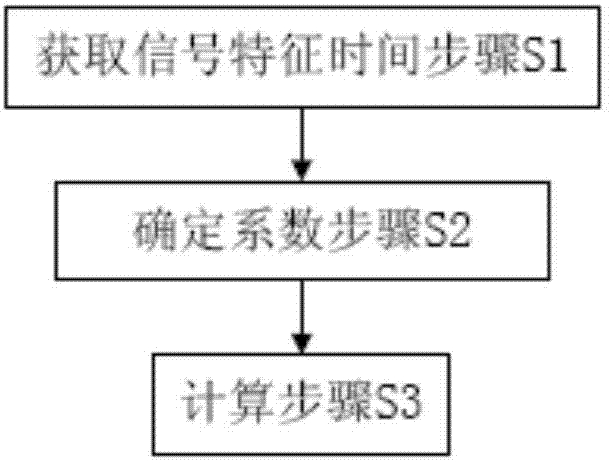

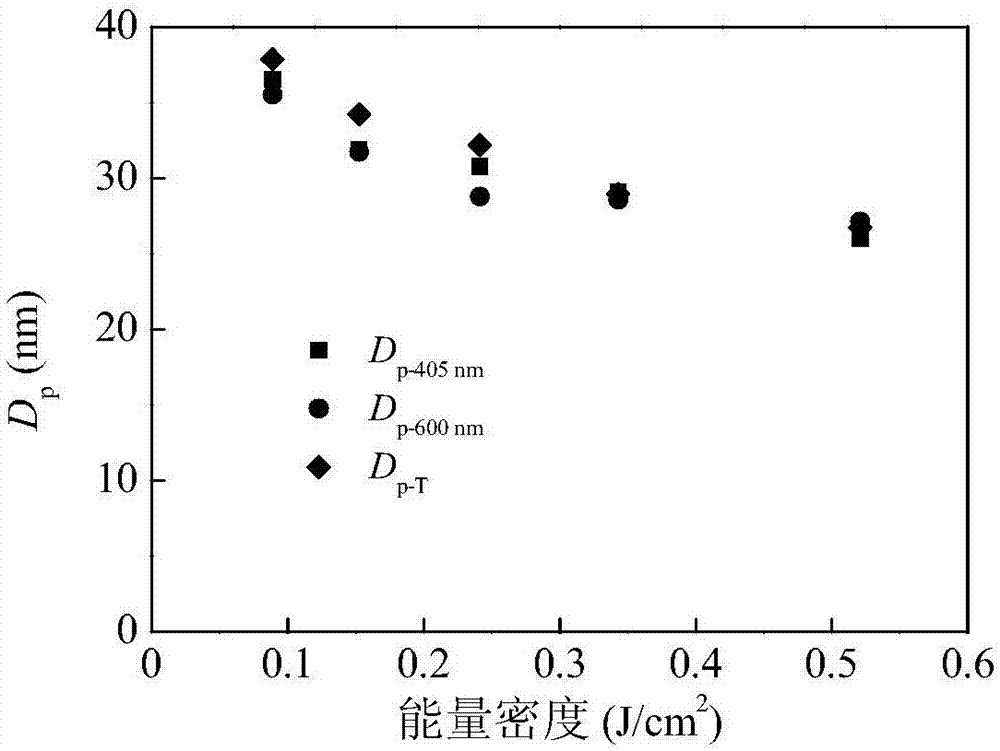

Monochrome laser induced incandescent light nano-grade soot grain diameter measurement device and method

ActiveCN107976384AAccurate measurementAvoid wasting time and effortParticle size analysisMeasurement deviceOptoelectronics

The invention discloses a monochrome laser induced incandescent light nano-grade soot grain diameter measurement device and method and belongs to a grain diameter measurement technology of soot particles. The measurement device comprises a flame generation unit, a laser device for heating the soot particles of flame, a capturing unit for capturing an incandescent light signal in the flame, an oscilloscope for displaying and recording a relationship between the captured incandescent light signal and time, and a processing unit which is in communication connection with the oscilloscope, whereinthe processing unit comprises a storage device and a processor; the storage device is used for storing a computer program; when the computer program is executed by the processor, the following steps can be realized: defining time needed for reducing the strength of the laser induced incandescent light signal of the soot particles to 1 / e of a peak value as signal characteristic time; obtaining thegrain diameter of the soot particles in the flame based on a grain diameter calculation model comprising a relationship between the grain diameter of soot and the signal characteristic time; obtaininga more accurate grain diameter value by utilizing a method for calibrating physical parameters, so as to conveniently and rapidly obtain two-dimensional grain diameter distribution of the soot.

Owner:ZHEJIANG UNIV

Suckling pig weighing device

InactiveCN104913835APrevent tamperingAvoid inaccurate weighingWeighing apparatus for materials with special property/formEngineeringMechanical engineering

A suckling pig weighing device is used to conveniently weigh a suckling pig. The suckling pig weighing device comprises a base, a weighing machine, a supporting part, a platform, and guard bars. The weighing machine is arranged on the base, the platform is arranged above the weighing machine, and the supporting part is arranged between the platform and the weighing machine. The platform includes a fixed plate, side plates, and pedal plates. The fixed plate is disposed in the middle. The two side plates are respectively hinged to the front and rear sides of the fixed plate, and a first electric telescopic rod is arranged between the free end of each side plate and the weighing machine. The two pedal plates are respectively hinged to the left and right sides of the fixed plate, and a second electric telescopic rod is arranged between the free end of each pedal plate and the weighing machine. When the piston rods of the first electric telescopic rods completely stretch out, the fixed plate and the two side plates form a V-shaped structure for clamping a suckling pig. The guard bars in U-shaped distribution are arranged on the base at the front, rear and right sides of the platform respectively. By adopting the device, suckling pigs are prevented from moving, and the problem that hugging and putting a suckling pig on the platform is time-consuming and difficult is avoided.

Owner:UNIV OF JINAN

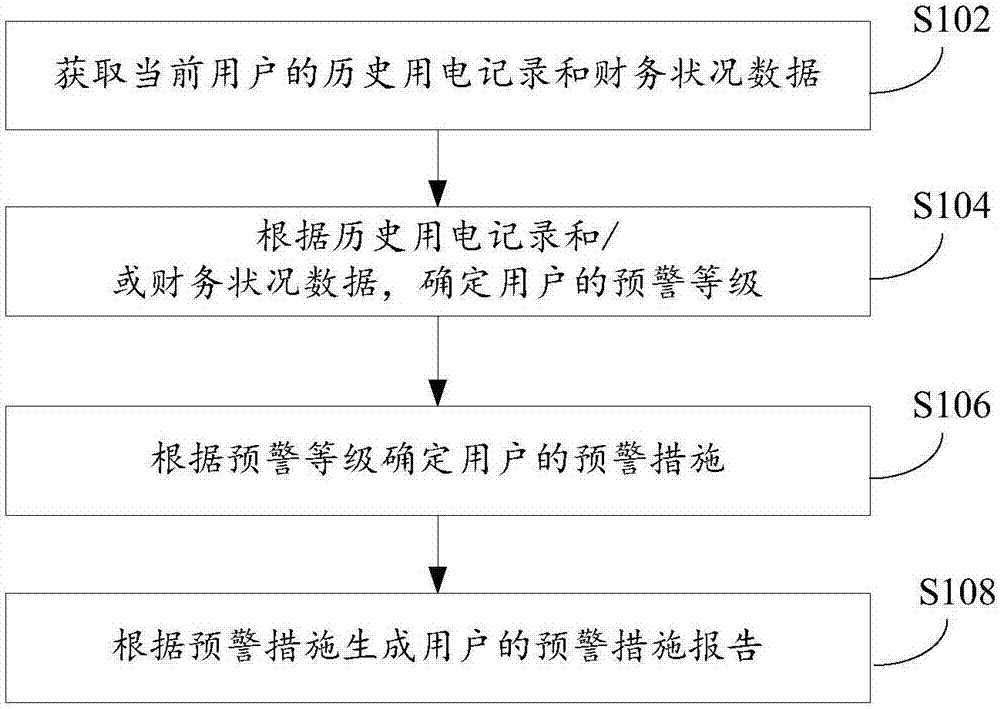

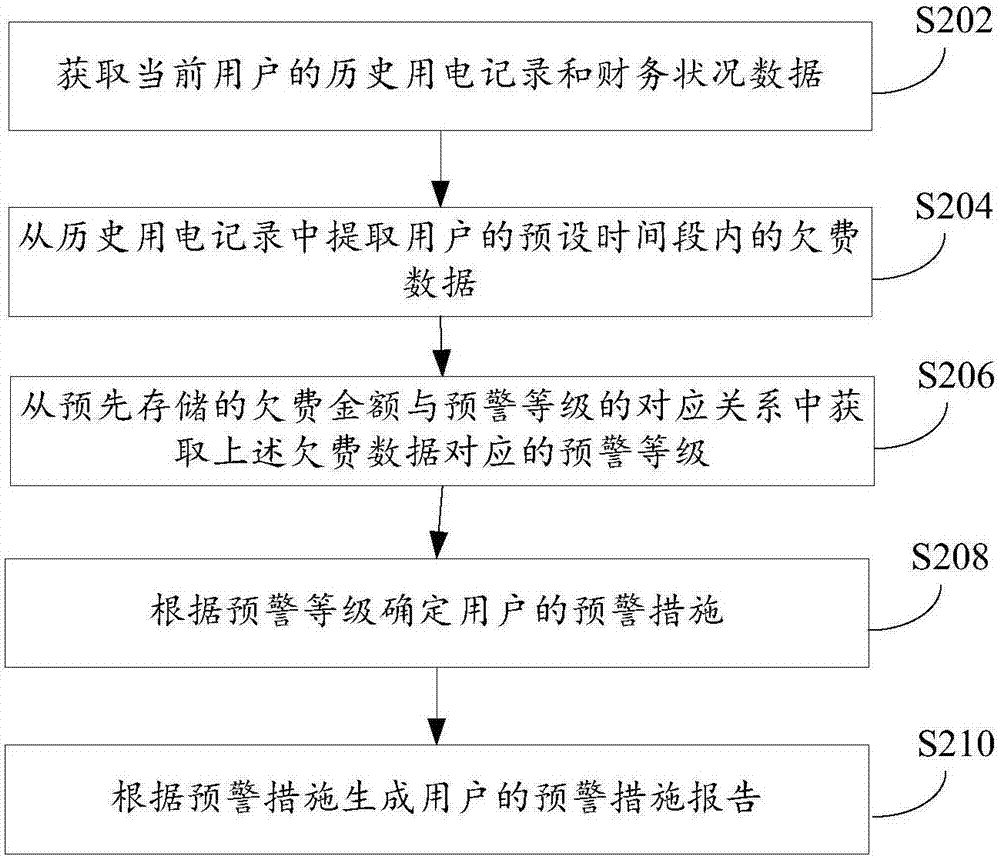

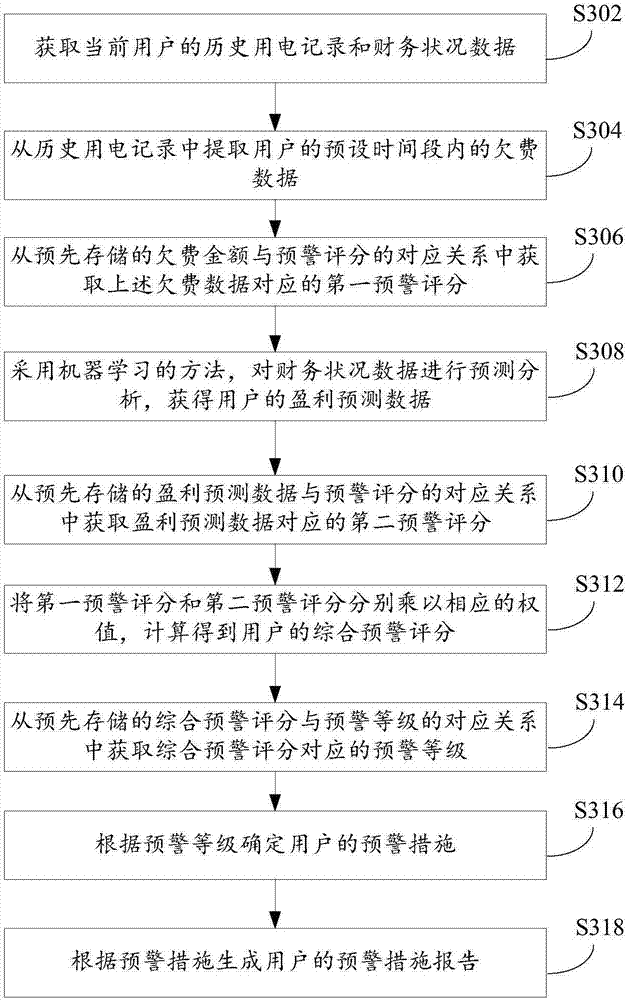

Electricity charge risk early-warning method and device

The invention provides an electricity charge risk early-warning method and device. The method comprises that a historical power utilization record and financial status data of a present user are obtained; an early-warning level of the user is determined according to the historical power utilization record and / or financial status data; an early-warning measure, including a fee paying manner, a prepay proportion and a guarantee sum, of the user is determined according to the early-warning level; and an early-warning measure report of the user is generated according to the early-warning measure. According to the invention, electricity risk early-warning can be raised for different users conveniently and rapidly, and the accuracy of electricity risk early-warning is improved.

Owner:TAIAN POWER SUPPLY CO OF STATE GRID SHANDONG ELECTRIC POWER CO +1

Cleaning device for fallen leaves in garden

InactiveCN108729388AEasy to send and collectSolve efficiency problemsRoad cleaningEngineeringDrive motor

The invention relates to the technical field of garden construction equipment and discloses a cleaning device for fallen leaves in a garden. The device comprises an installation box body. One side ofan inner cavity of the installation box body is fixedly equipped with two mutually-parallel separation boards. The positions between the two separation boards and the inner wall of the installation box body are rotatably connected with a rotary shaft I and a rotary shaft II from the top to the bottom. The rotary shaft I and the rotary shaft II are located at two sections between the two separationboards and fixedly connected with driven gears in a sleeved manner. A driving motor is fixedly installed on the side wall of one separation board. Through cooperative drive between a fallen leave conduction device and a conveyor belt on a drilling roller, fallen leaves on the ground of the garden can be driven and collected conveniently. Therefore, there is no need for a person to manually clampfallen leaves with pliers. The efficiency is high and time and labor are saved. Fallen leaves are easily collected because of mechanization. Meanwhile, large-range operation can be performed for the garden. Fallen leaves can be collected within the shortest period of time. Accordingly, the device is more practical.

Owner:杭州真树园林设计工程有限公司

Rubber bar batch cutting machining device and cutting machining process

ActiveCN111873008ARealize equidistant and precise stackingEasy to packMetal working apparatusMachining processMechanical engineering

The invention relates to rubber bar batch cutting machining device and cutting machining process. The cutting machining device comprises a fixed base, a working frame, an equidistant propelling device, a storage box and a cutting device, the working frame is installed in the middle of the upper end of the fixed base, the equidistant propelling device is arranged in the working frame, the storage box is installed at the upper end of the working frame, a cutting device is arranged at the right side of the working frame and installed at the right side of the upper end of the fixed base. The device can solve the problems that according to a traditional rubber bar cutting machining treatment method, rubber bars are stacked on cutting equipment in a unified manner manually and then cut, due to the fact that manual stacking wastes time and labor, the efficiency of the method is low, the cutting machining progress is affected, when the rubber bars are cut and processed, uniform length processing of the rubber bars is generally lacked, and the cut and processed rubber bars are often different in length and are not easy to package, transport and use.

Owner:贵州九洲橡塑科技有限公司

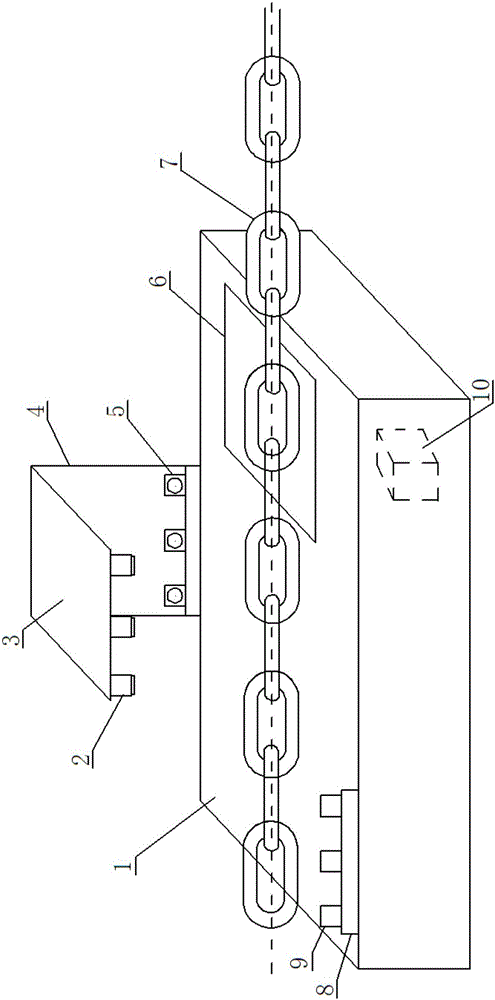

Oil tanker anchor chain nondestructive detection device and detection method thereof

InactiveCN105842340ADetection speedAvoid wasting time and effortAnalysing solids using sonic/ultrasonic/infrasonic wavesOptically investigating flaws/contaminationData transmissionNondestructive testing

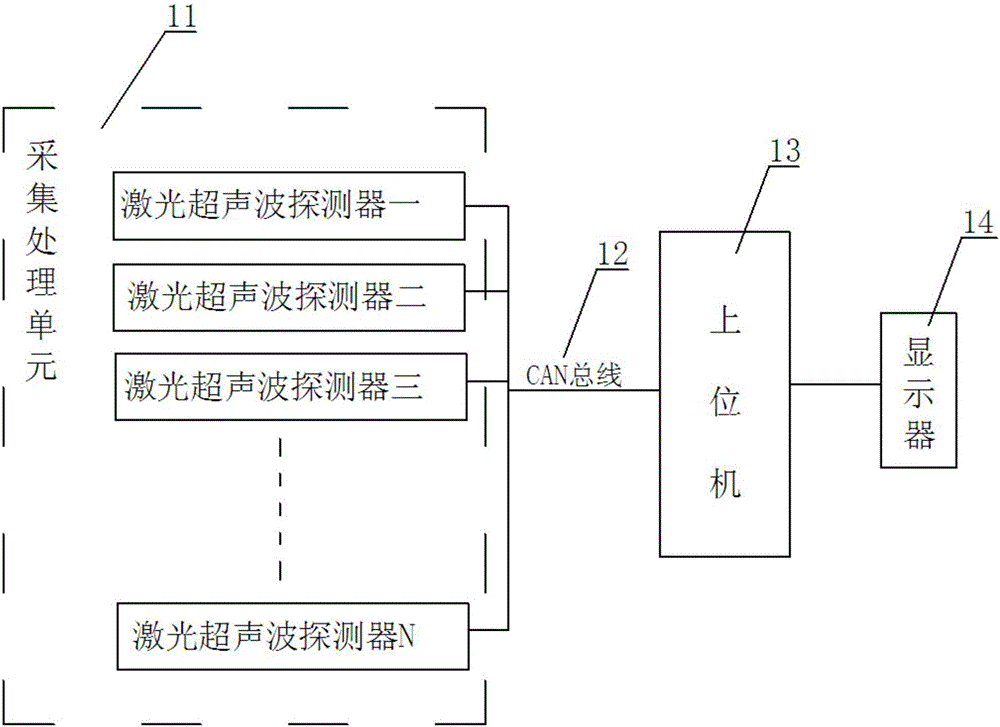

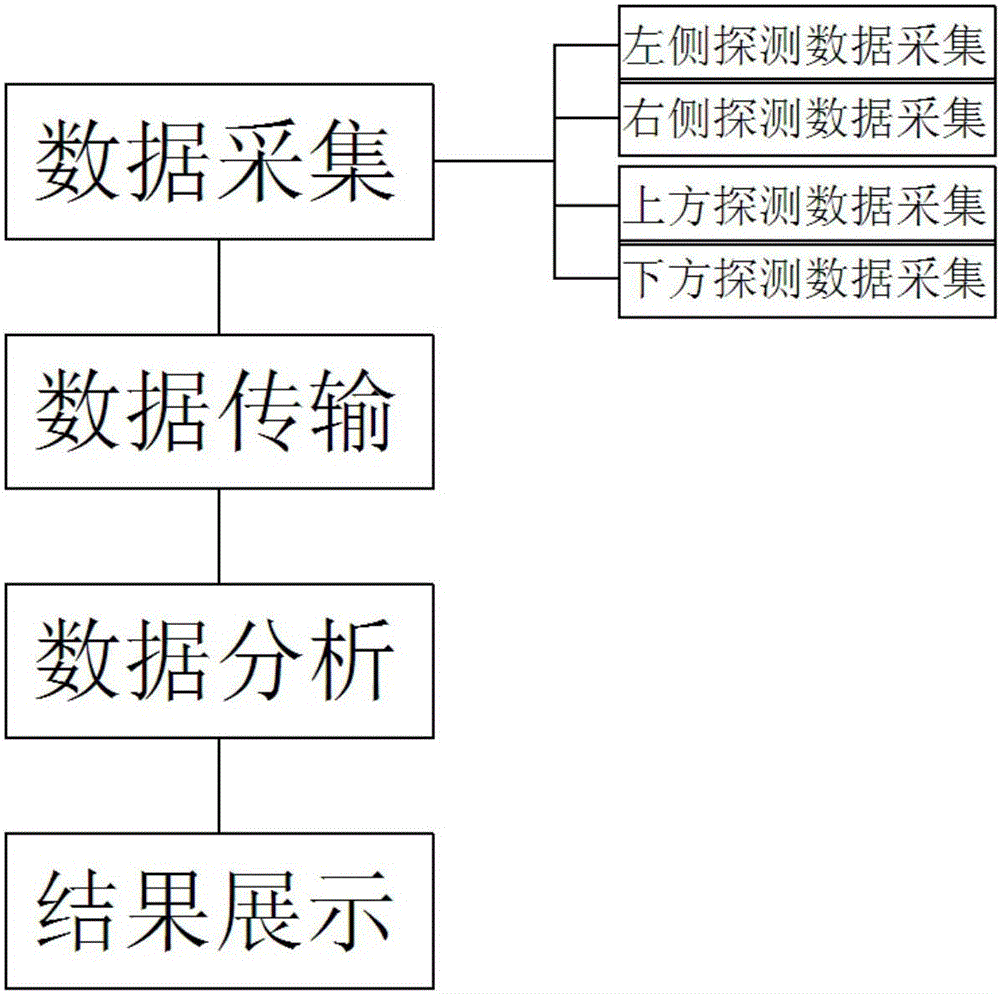

The invention discloses an oil tanker anchor chain non-destructive detection device and a detection method thereof, wherein the oil tanker anchor chain non-destructive detection device includes a workbench for detecting the anchor chain, and multiple sets of laser ultrasonic detectors are arranged on the workbench. The upper surface of the workbench is fixedly provided with brackets, side plates and square openings for assembling the laser ultrasonic detectors; the multiple groups of laser ultrasonic detectors are distributed on the top, bottom, left and right sides of the workbench , are used to detect anchor chains via the top, bottom, left and right sides of the anchor chain, respectively. The invention also discloses a detection method of the oil tanker anchor chain non-destructive detection device, comprising the following steps: (1) data collection; (2) data transmission; (3) data analysis; (4) result display.

Owner:SHENZHEN FAIRNESS MEMBER MACHINERY TECH SERVICE

A wire stock short detection circuit

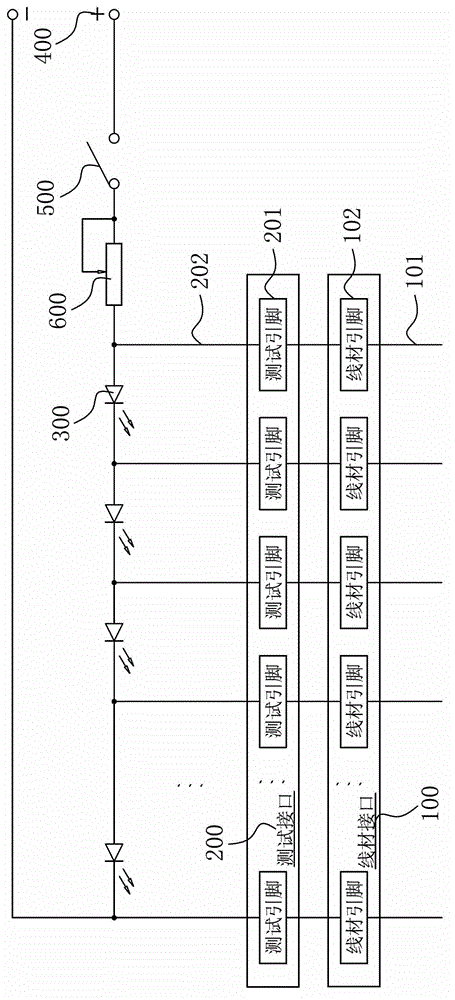

The invention reveals a wire stock short detection circuit. A wire stock contains a wire stock interface and a plurality of connecting lines, the said wire stock interface has a plurality of wire stock pins, and one connecting line extends out from each wire stock pin correspondingly. The detection circuit includes: a testing interface in butt joint with the said wire stock interface, wherein the said testing interface has a plurality of testing pins, and the said testing pins and the said wire stock pins correspond to each other in a one-to-one manner; a plurality of testing lines which are correspondingly extended from the testing pins of the said testing interface in a one-to-one manner; a plurality of display lamps which are respectively located between the ends, which are away from the said testing interface, of the adjacent testing lines; and a power supply which is in bridge connection with the ends, which are away from the said testing interface, of the two testing lines which are on the two sides in the said plurality of testing lines. The wire stock short detection circuit can detect whether the said connection lines of the said wire stock are short or not directly and can solve the problem of time and energy consuming caused by adopting the method which detects the said wire stock pins one by one.

Owner:SHENXUN COMP KUNSHAN

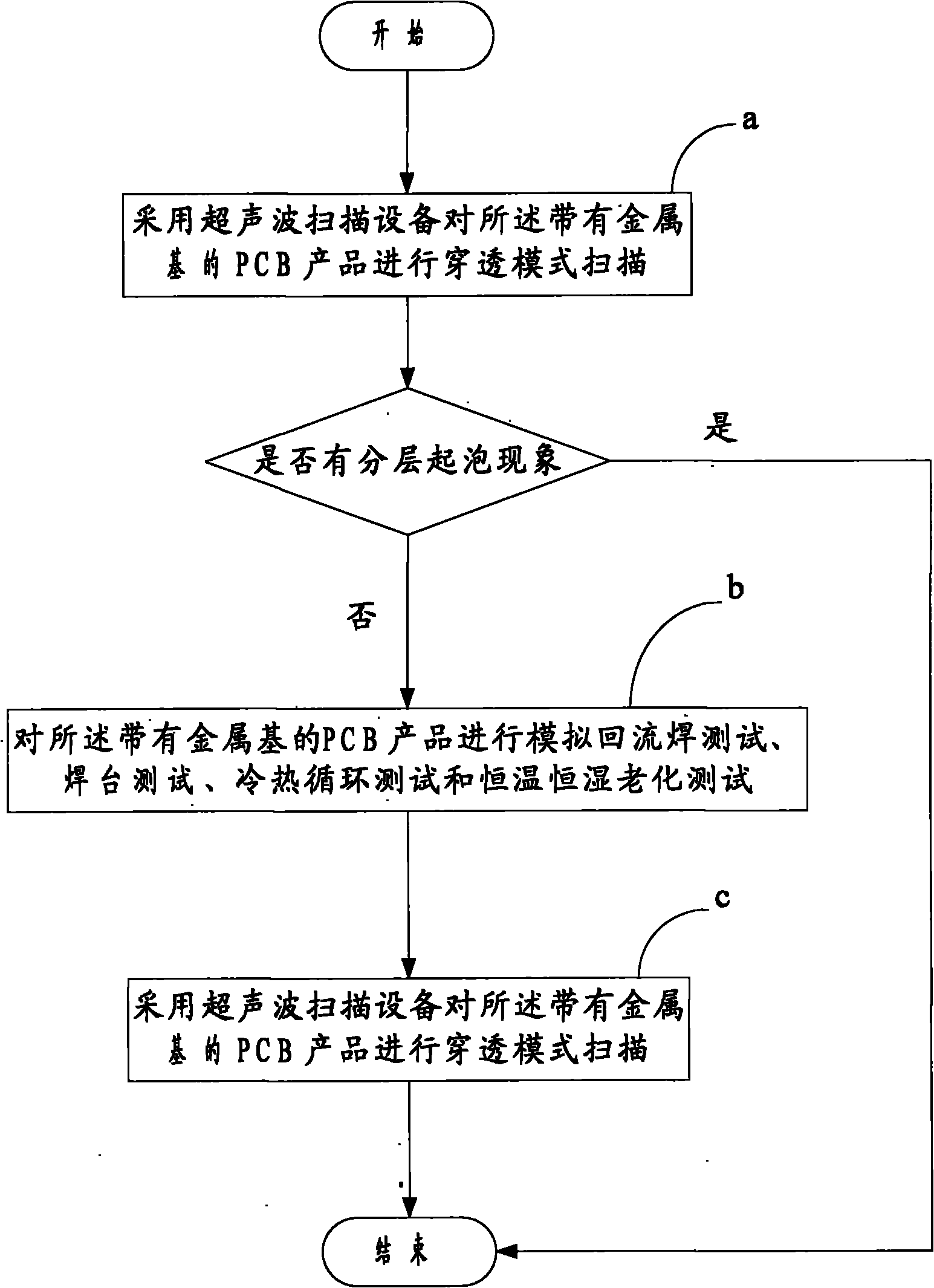

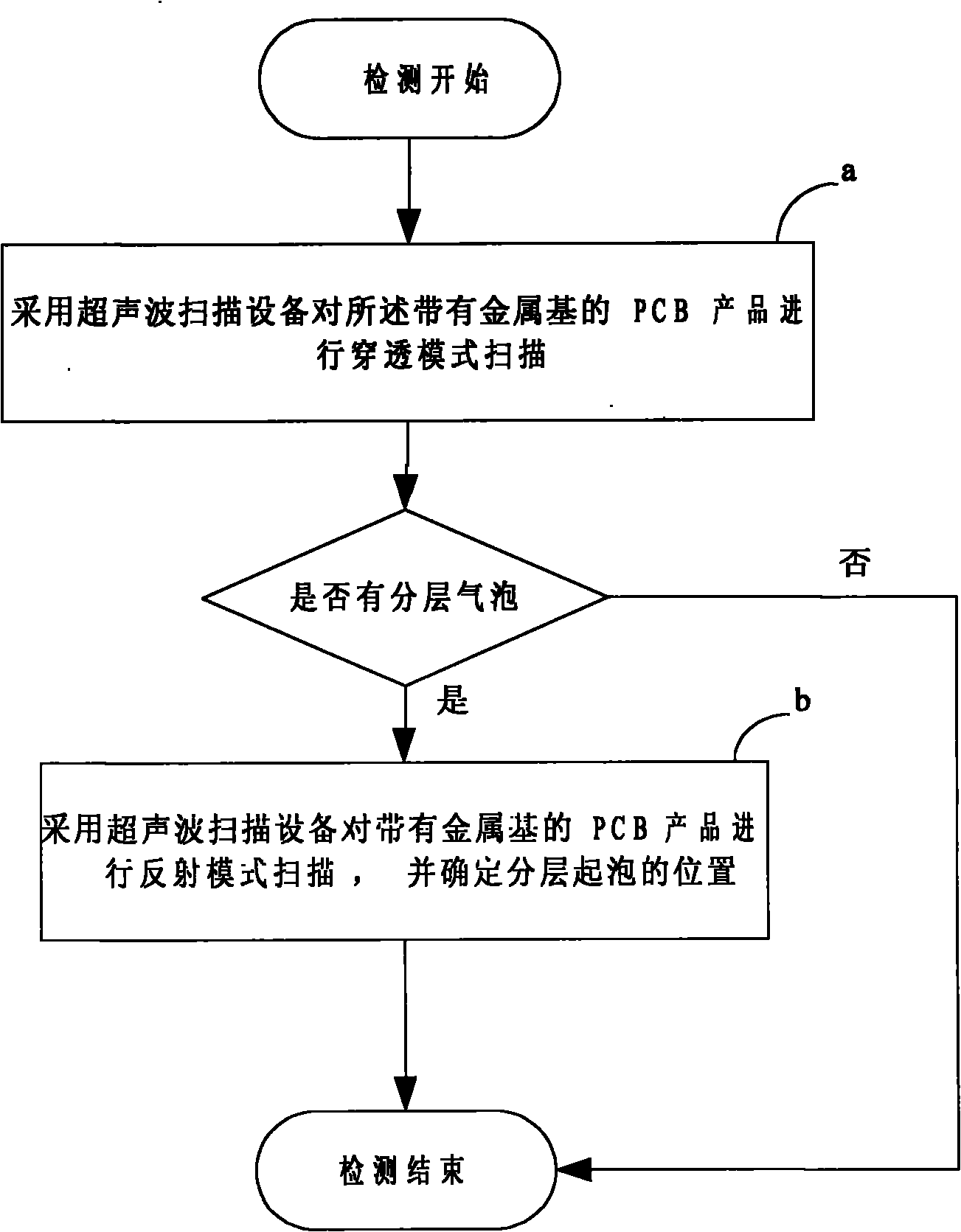

Detection method for interlayer combination of PCB product with metal base

InactiveCN101929983AIntegrity guaranteedAvoid wasting time and effortAnalysing solids using sonic/ultrasonic/infrasonic wavesEngineeringUltrasound scan

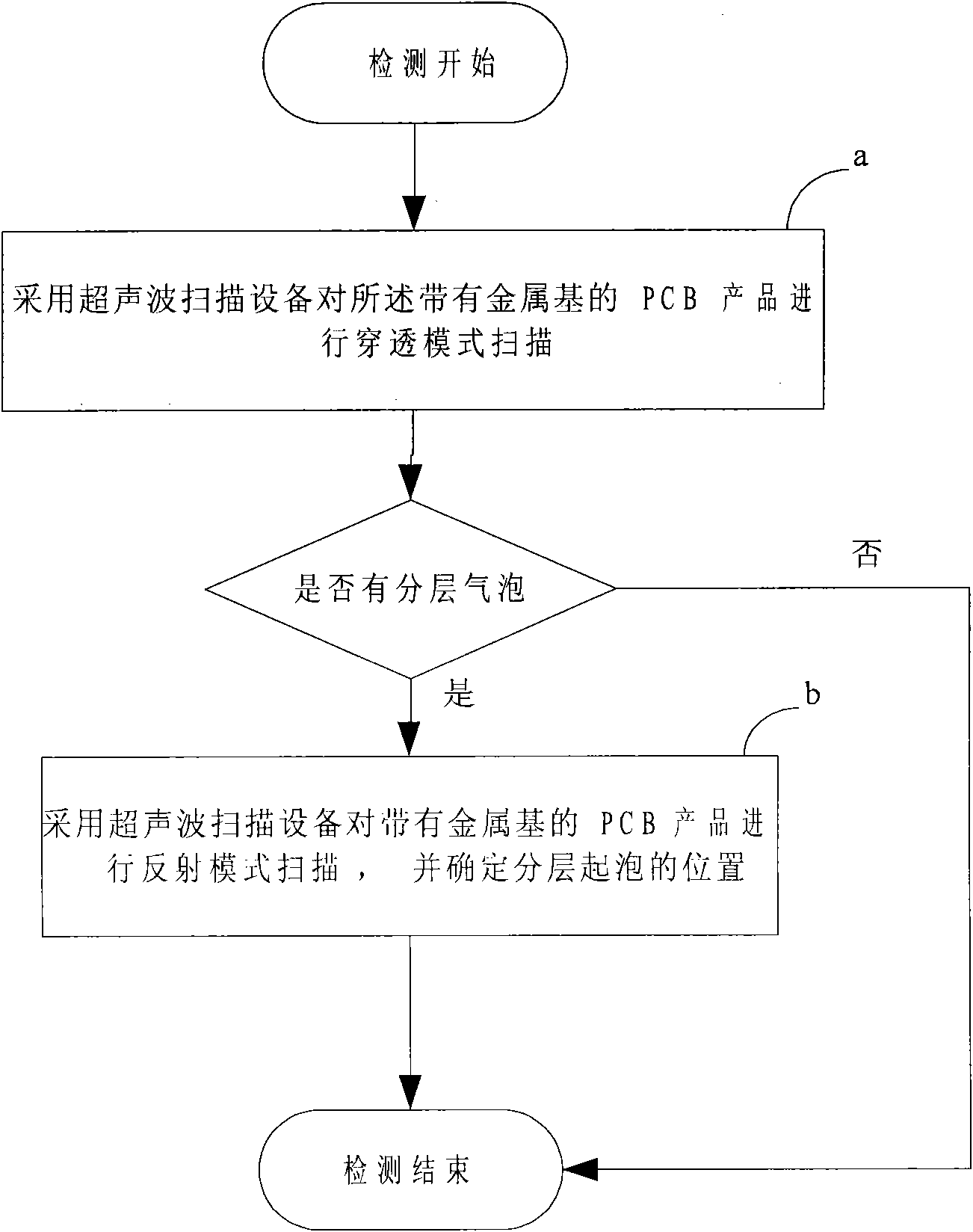

The embodiment of the invention discloses a detection method for the interlayer combination of a PCB product with a metal base. The detection method comprises the following steps of: a, performing transmission mode scanning on the PCB product with the metal base by using ultrasonic scanning equipment; finishing detecting if the PCB product with the metal base has no layered blister phenomenon; and turning to a step b if the PCB product with the metal base has the layered blister phenomenon; and b, performing reflection mode scanning on the PCB product with the metal base by using the ultrasonic scanning equipment; and determining the position of layered blister. In the detection method provided by the embodiment of the invention, the interlayer combination situation of the PCB product with the metal base can be detected accurately and rapidly on the premise of not damaging a sample.

Owner:SHENNAN CIRCUITS

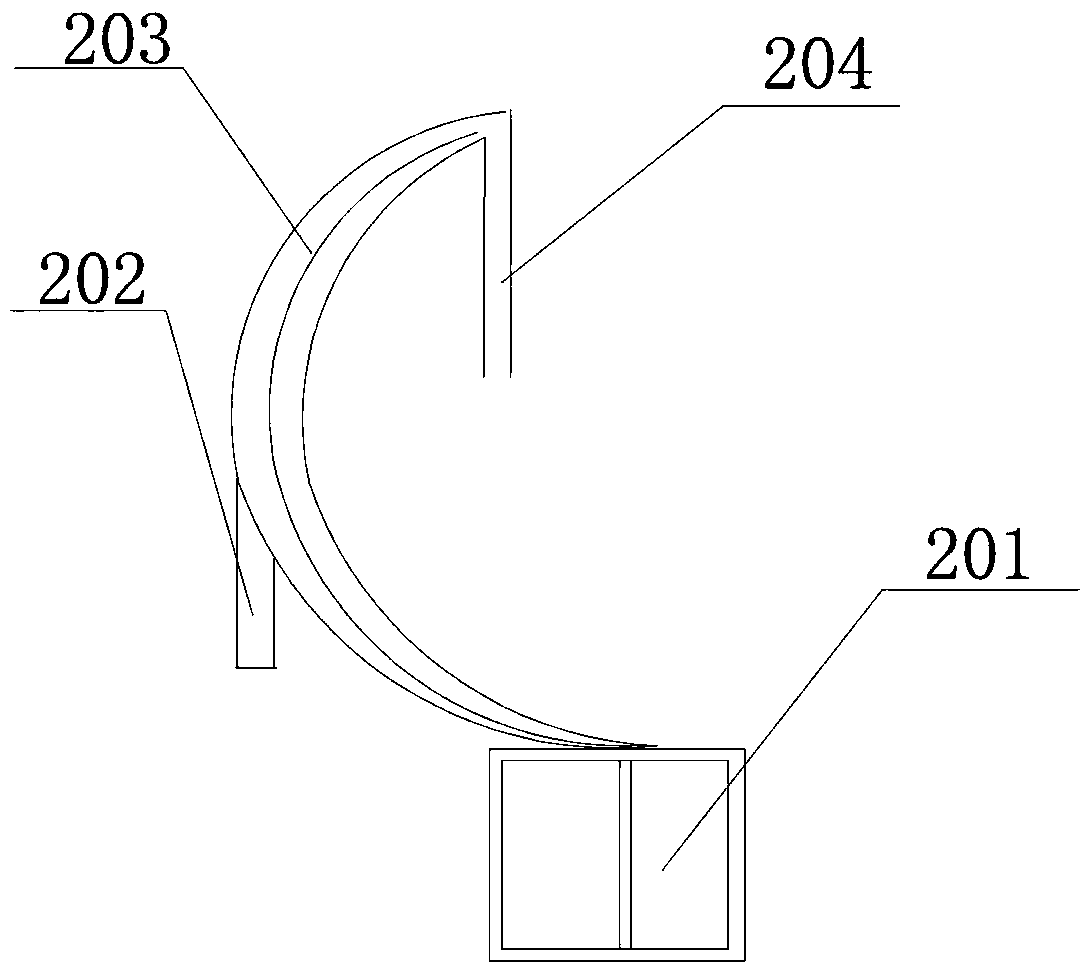

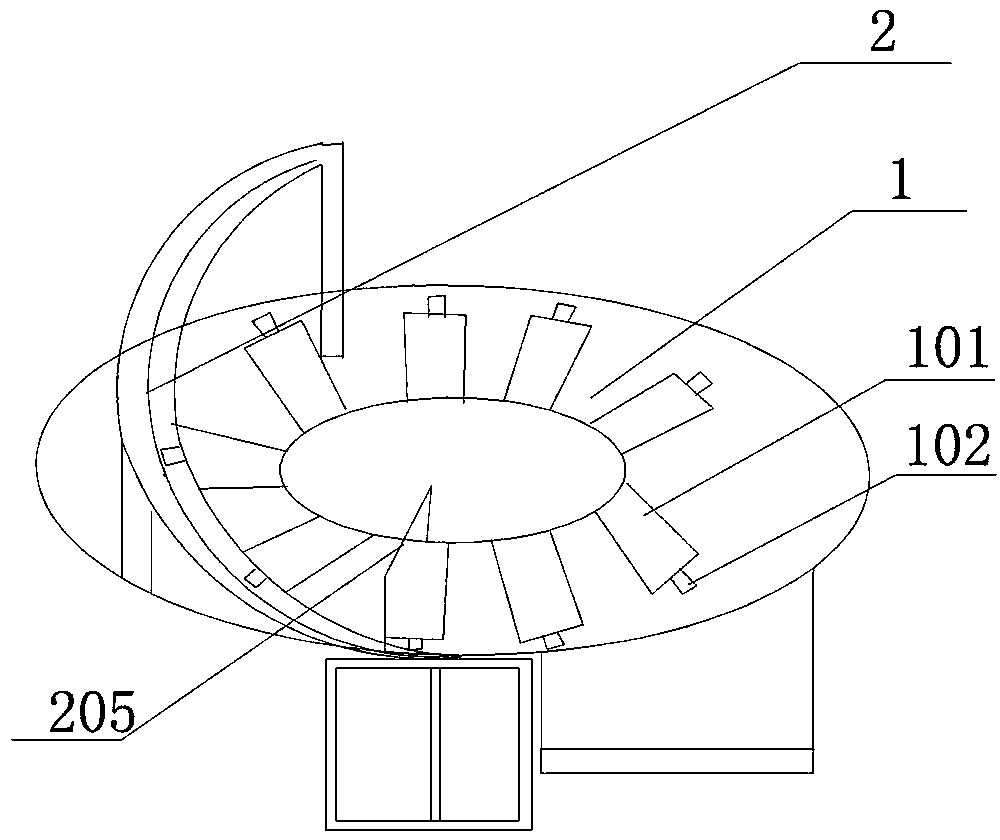

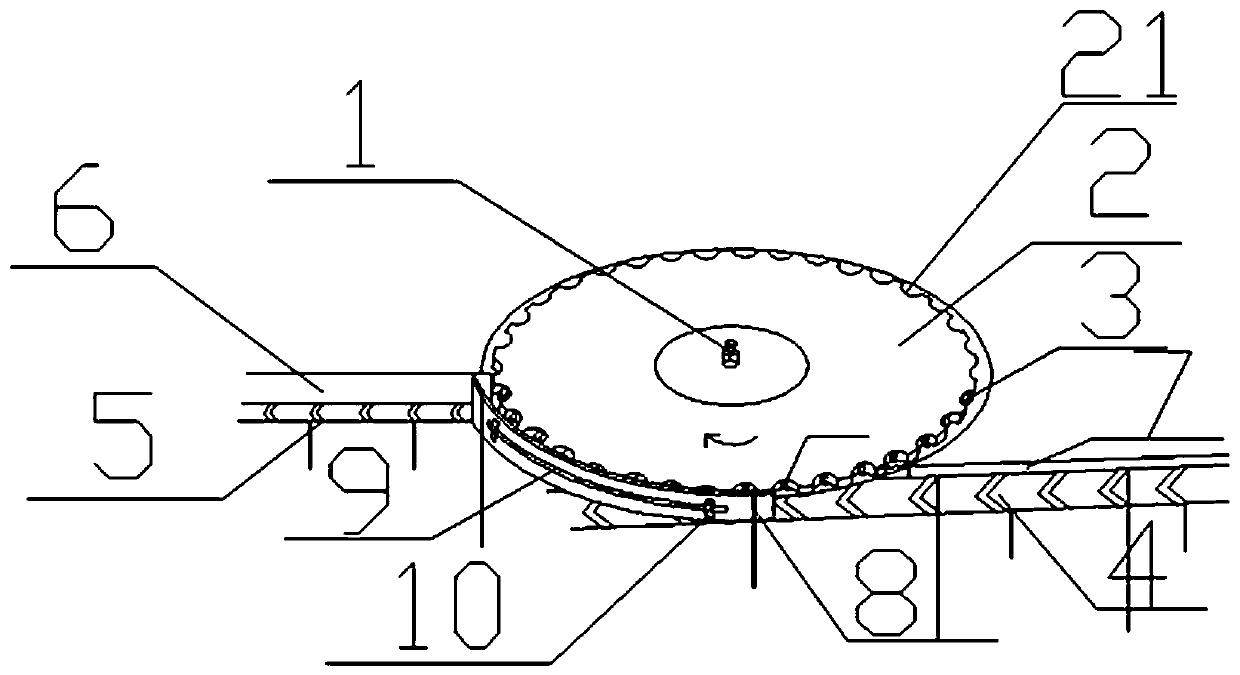

Automatic mold opening device of disc-type sole machine

InactiveCN103552221AIngenious designTime-consuming and laborious to solveDomestic articlesCircular discMachine

The invention relates to an automatic mold opening device of a disc-type sole machine. The automatic mold opening device is installed on the disc-type sole machine. The mold opening device consists of an upper support, a middle support, a front support and an arc track; the upper support is arranged on the inner side of a disc of the disc-type sole machine, the height of the upper support is greater than that of the mold when being completely opened, the middle support is arranged on the outer side of the disc of the disc-type sole machine, and the height of the middle support is half of the height of the mold when being completely opened; the upper end of the front support is connected with the outer side of the disc of the disc-type sole machine, and the lower end of the front support is arranged on the ground; the arc track is arranged on the upper support, the middle support and the front support, and the position on which the lowest end of the arc track stays is located on a rotation locus of a mold opening handle when the disc-type sole machine rotates. The automatic mold opening device is ingenious in design and matched with the disc-type sole machine, so that the problems such as time and labor waste when a mold is opened can be solved, and the scalding in the operating process can be prevented; the safety and the convenience can be realized, and the working efficiency can be improved.

Owner:偃师市金旺鞋业有限公司

Bottle unscrambler

PendingCN110510343AArrange in the same orderAvoid wasting time and effortConveyor partsRotary conveyorsBottleEngineering

The invention discloses a bottle unscrambler, and belongs to the technical field of packaging equipment. A fixed clamping position is uniformly arranged around the outer edge of a turntable of the bottle unscrambler; a clamping device is arranged in the fixed clamping position; the clamping device makes contact with a bottle body groove to clamp a bottle body; the clamping device is capable of elastically moving in the fixed clamping position; the front and back of the bottle unscrambler are respectively connected with a conveyer belt I and a conveyer belt II; guiding plates are arranged around the conveyer belt I, the conveyer belt II and the turntable between the conveyer belt I and the conveyer belt II; fixed buffer strips are arranged on the guiding plates; buffer strip fixing devicesare arranged on the outer sides of the guiding plates; and the buffer strips are fixed and adjusted through the buffer strip fixing devices. When the bottle unscrambler carries out bottle unscrambling, a clamping elastic strip is clamped with the bottle body groove of the packaging bottle, so that the consistency of the bottle-out direction is ensured, and the inconvenience of manually adjusting the packaging bottle direction is avoided.

Owner:JIACHEM DENTBIO CO LTD

A jig for removing air bubbles in glass crevices

A fixture for removing air bubbles in glass cracks, relating to the technical field of glass manufacturing, solves the problem of uneven application of force when the existing fixture clamps the edge of the glass, and solves the time-consuming and laborious problem of manually clamping multiple fixtures on the edge of the glass. The present invention provides a fixture for removing air bubbles in glass gaps. The substrate is the main body. The two substrates are fixedly connected by a handle. Two parallel splints are arranged between the two substrates. There is a ejector rod between the base plate and the corresponding splint, the ejector rod is screwed to the base plate, and the movement of the splint is realized by the movement of the ejector rod, so that the two splints are close to each other and clamp the edge position of the glass, and the splint has a certain length , avoiding the time-consuming and labor-intensive problems caused by using multiple fixtures. At the same time, the splint applies pressure evenly to the glass, avoiding damage to the glass caused by uneven force application.

Owner:SHANDONG WENSHENG GLASS

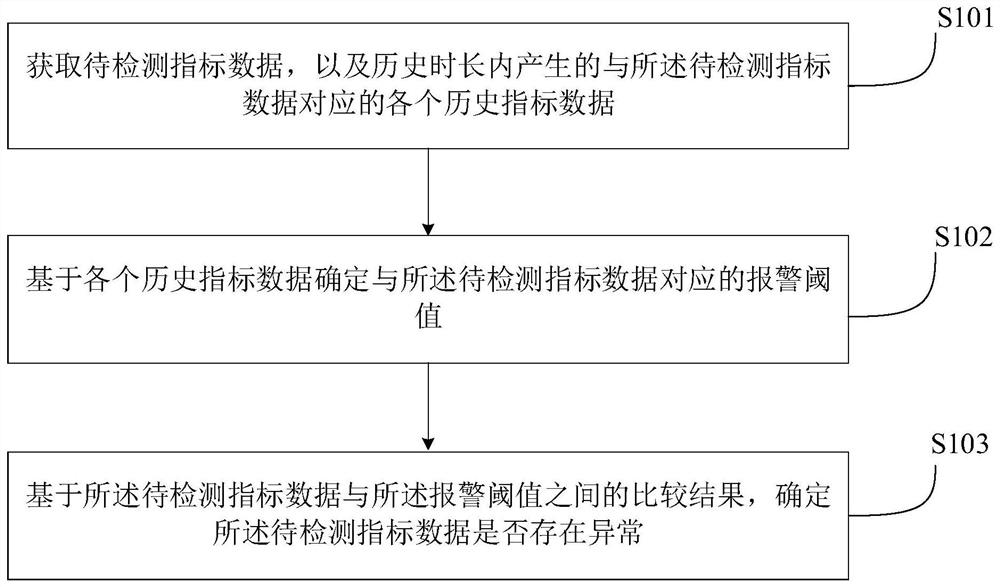

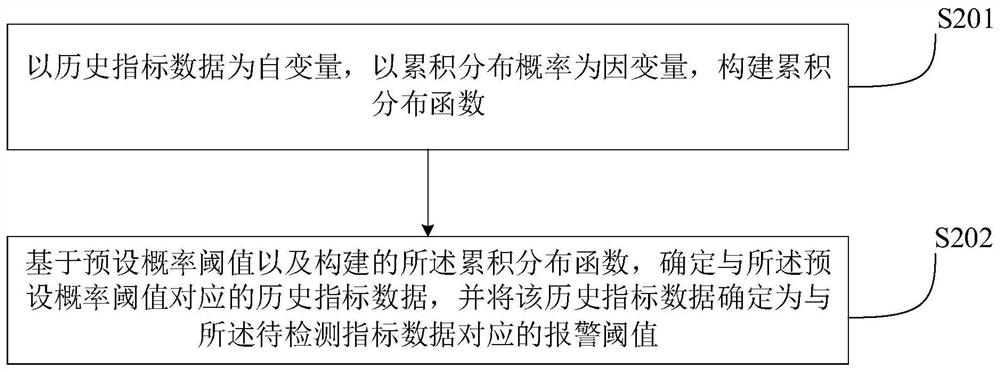

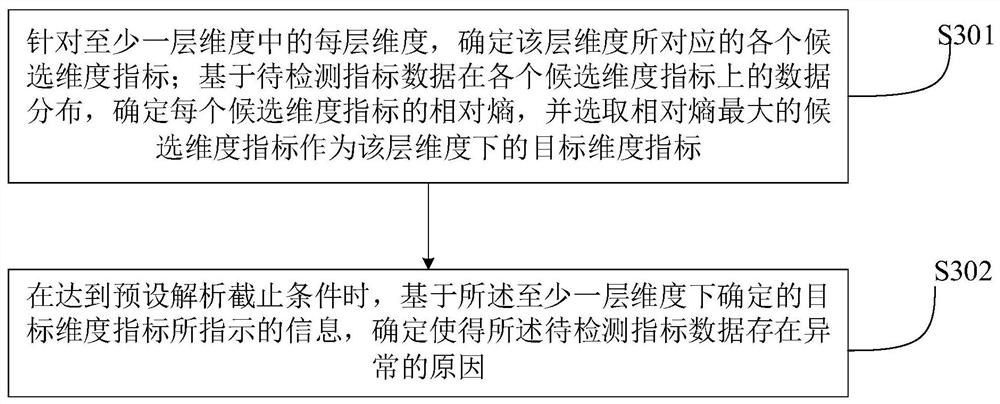

Data processing method and device, electronic equipment and storage medium

PendingCN111831517AAutomatic Anomaly DetectionAvoid wasting time and effortFault responseHardware monitoringAnomaly detectionEngineering

The invention provides a data processing method and device, electronic equipment and a storage medium, and the method comprises the steps of obtaining to-be-detected index data and historical index data which is generated in a historical duration and corresponds to the to-be-detected index data; determining an alarm threshold corresponding to the to-be-detected index data based on each historicalindex data; and determining whether the to-be-detected index data is abnormal based on a comparison result between the to-be-detected index data and the alarm threshold. By adopting the scheme, the alarm threshold value is automatically determined by utilizing the historical index data, so that the problem that time and labor are wasted in a manual setting mode is avoided, automatic anomaly detection can be further realized, and time and labor are saved.

Owner:BEIJING DIDI INFINITY TECH & DEV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com