Patents

Literature

36results about How to "Play a suppressive role" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Method for remedying organism contaminated field by using bidirectional stirring injection method

ActiveCN104624629AImprove utilization efficiencyReduce lossesContaminated soil reclamationDrillInjections methods

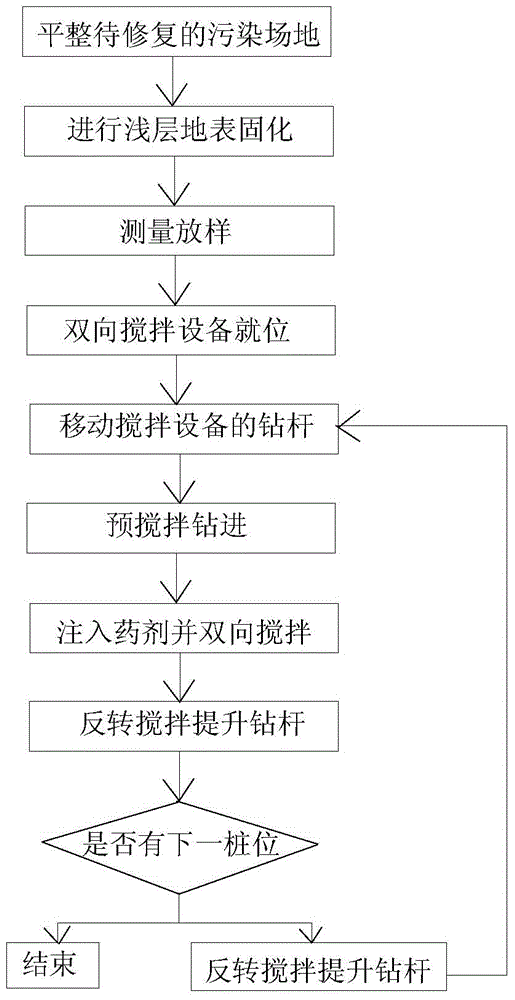

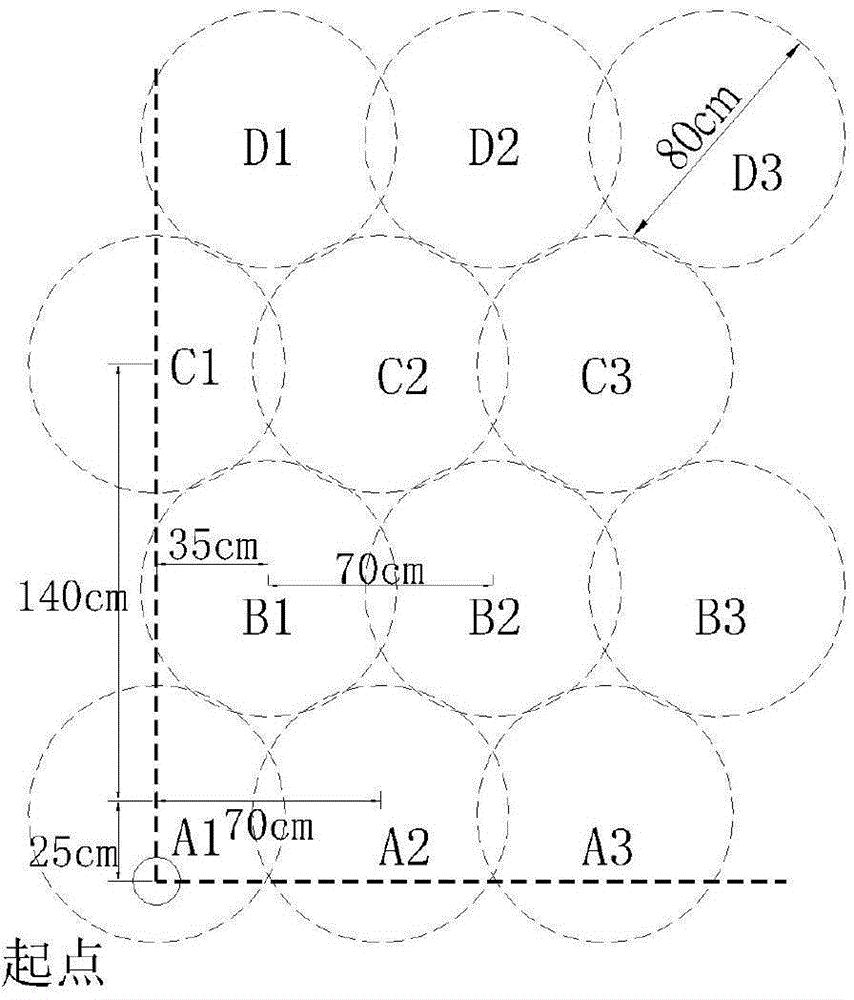

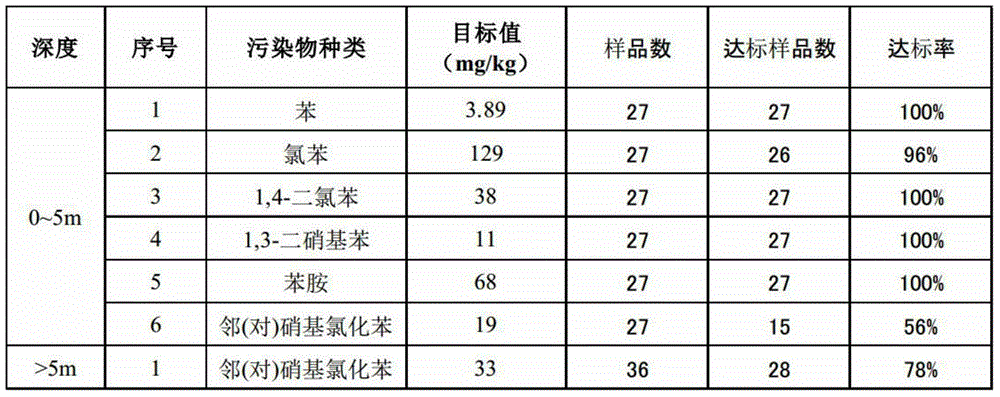

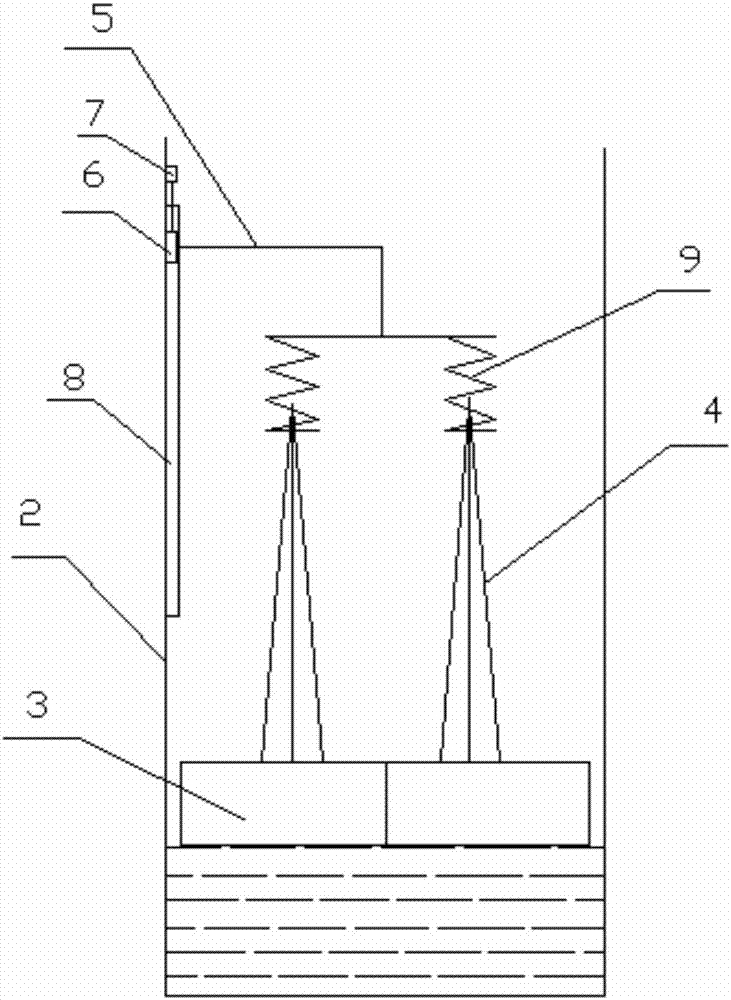

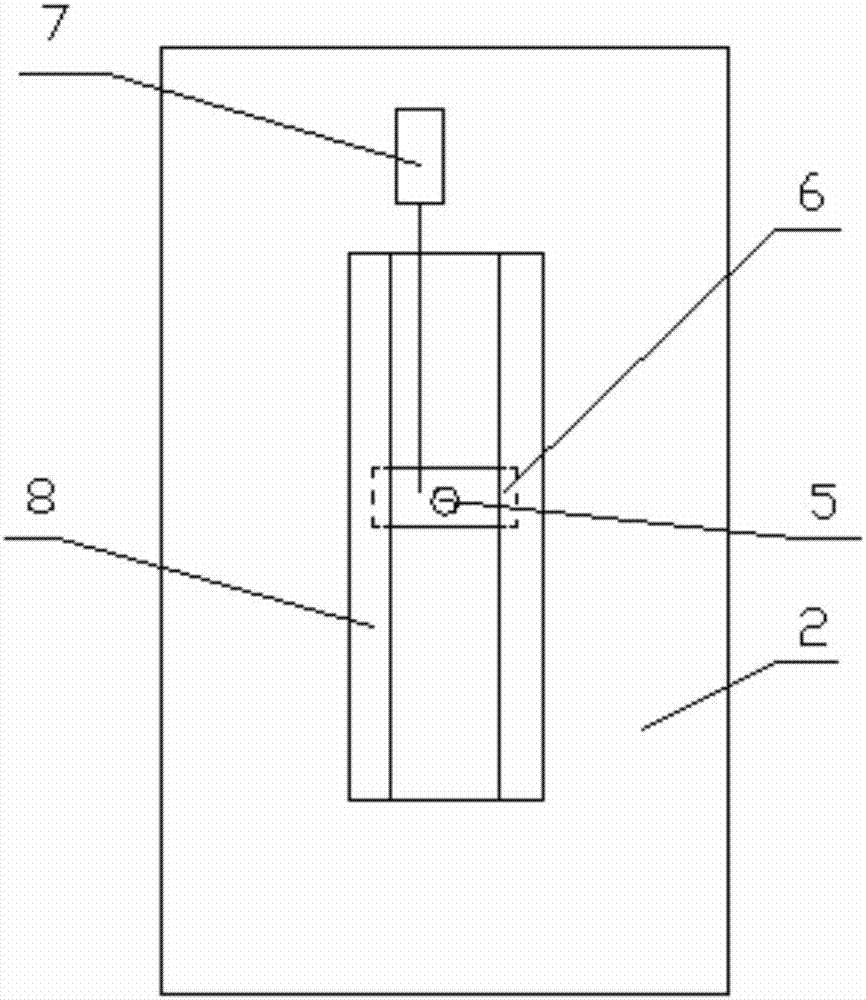

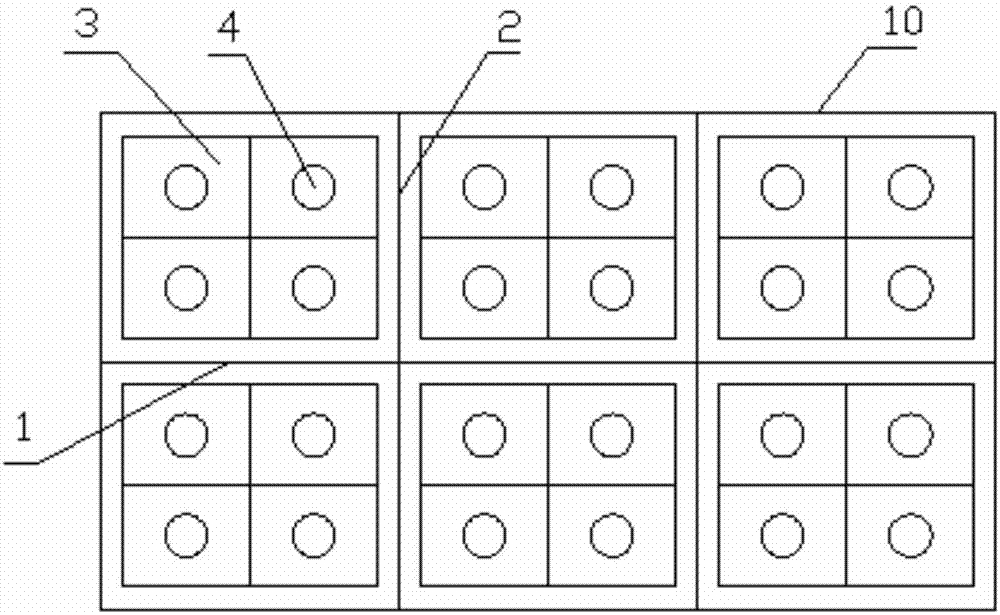

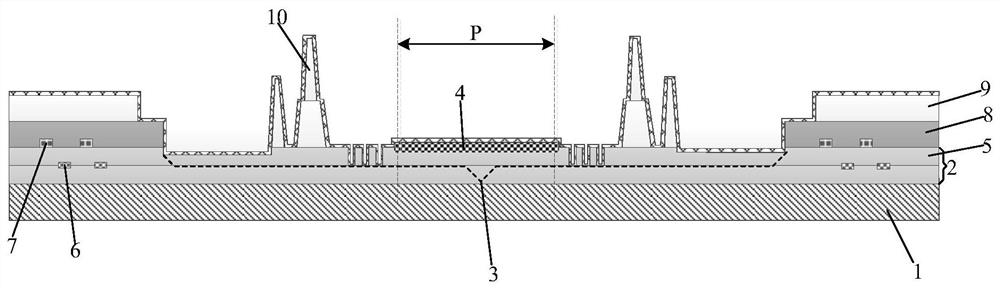

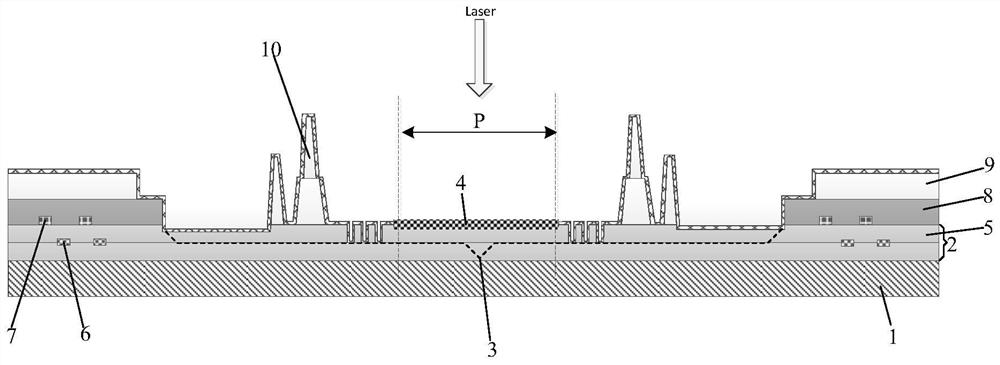

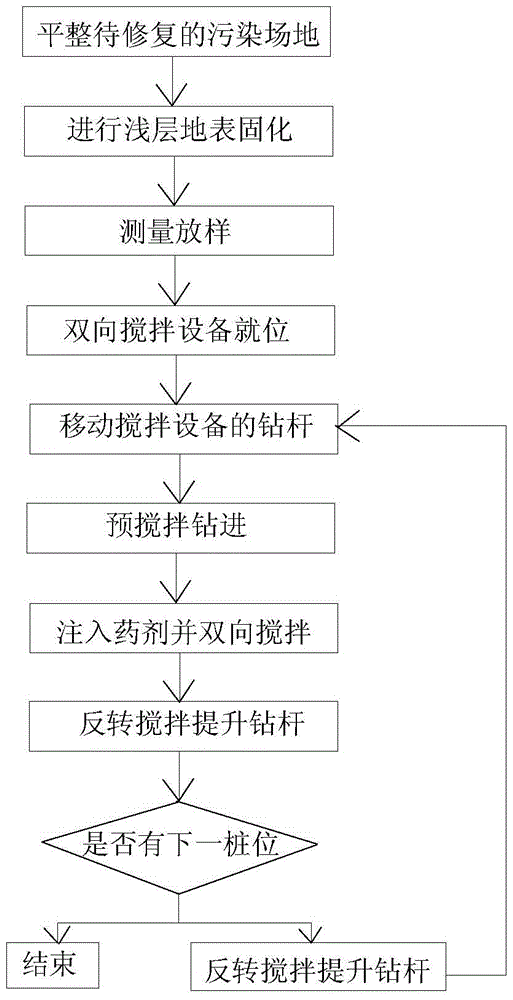

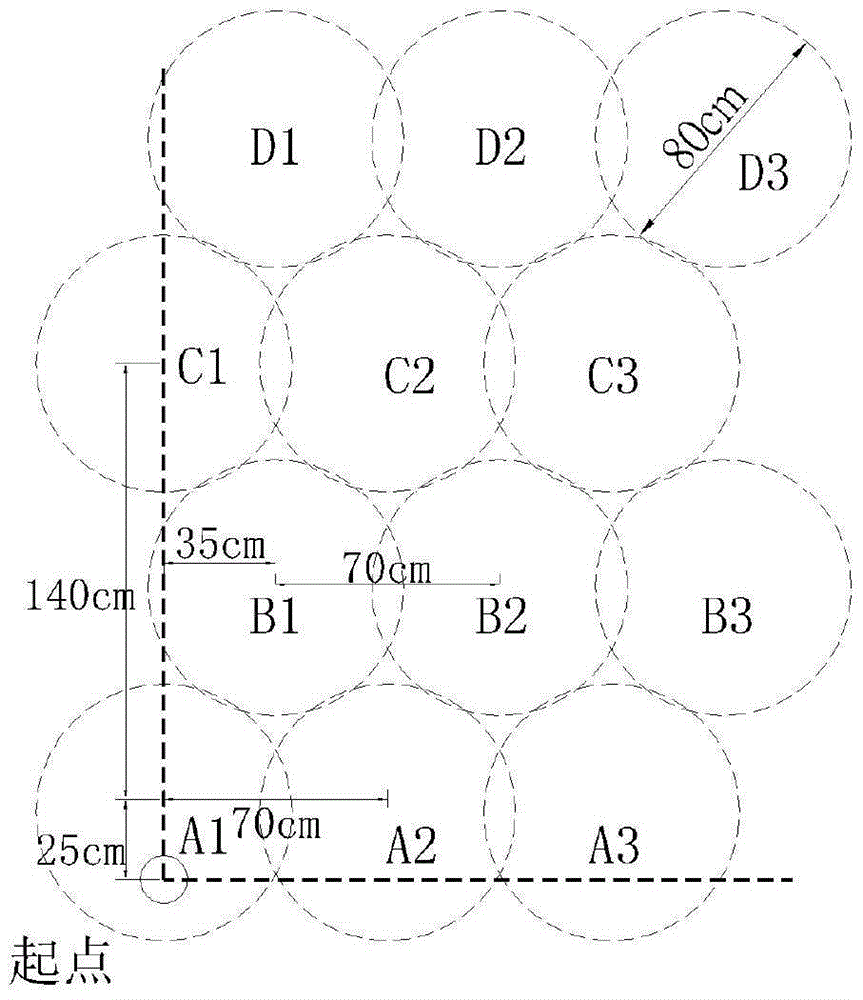

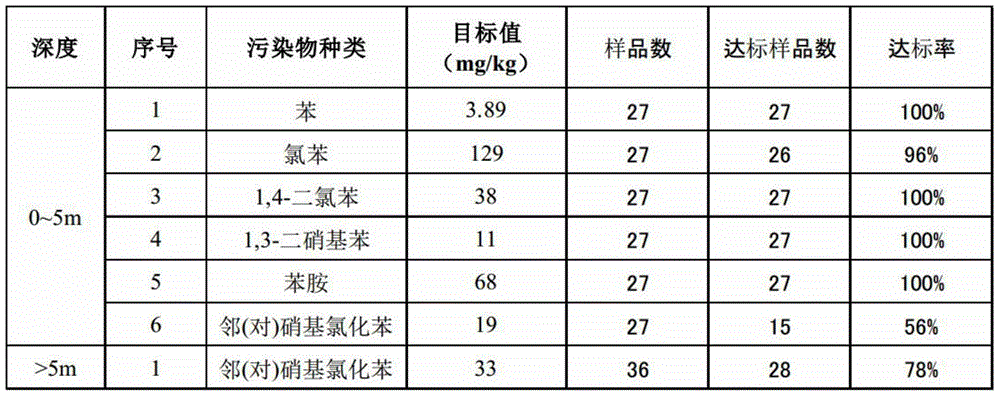

The invention discloses a method for remedying an organism contaminated field by using a bidirectional stirring injection method. The method comprises the following steps: (1) flattening the contaminated field; (2) performing shallow layer ground hardening; (3) staking out in survey; (4) locating bidirectional stirring equipment in place; (5) moving a drilling rod of the bidirectional stirring equipment; (6) performing pre-stirring drilling; (7) drilling a drill rod, injecting a medicine and stirring bidirectionally, namely, injecting the medicine through an inner tube of a conveying pipeline, injecting a mixed solution of a catalyst and a buffer agent from a pipeline between the inner tube and the outer tube of the conveying pipeline, and mixing and stirring the medicine, the catalyst, the buffer agent and soil at the bottom of the conveying pipeline; (8) lifting up the drill rod through opposite stirring; and (9) moving the drill rod to a next pile site, and repeating the step (5) to (8) until the soil in all pile sites is remedied. By adopting the method, the loss of ground mixed medicines can be reduced, the reaction velocity and the reaction time can be effectively controlled, the problem that grout spills out and turns up from the ground surface can be effectively solved, and the remediation efficiency can be improved.

Owner:SOUTHEAST UNIV +2

Method for restoring vegetation on high and steep slopes by aid of coiled plant materials

The invention discloses a method for restoring vegetation on high and steep slopes by the aid of coiled plant materials. The method includes operation steps of 1), cleaning slope surfaces; 2), constructing anchor rods; 3), hanging nets; 4), laying the coiled plant materials; 5), secondarily hanging nets; 6), fixing the nets and the coiled plant materials; 7), watering and maintaining the slope surfaces. The method has the advantages that the stability of substrates on the slope surfaces can be effectively maintained, the substrates are high in erosion resistance, construction processes are simple, the vegetation can be managed and maintained easily and conveniently in later periods, the slope surfaces can be effectively closed, and weathering and peeling of the slope surfaces can be prevented.

Owner:SICHUAN UNIV

Method for ecological restoration of high-altitude slope

The invention discloses a method for ecological restoration of a high-altitude slope. The method comprises the steps that sundries on the surface of the high-altitude slope are cleared away, wherein the sundries comprise pumice stones and capping mass, and leveling is conducted to the slope surface; an anchor rod position is marked, drilling is conducted, the top of the anchor rod is bent, and an anchoring agent is poured for fixation; a reinforcement net is paved on the slope surface and fixed on the anchor rod reserved on the slope surface; and a plant fiber blanket is paved, a geo-grid is then paved, and watering and conservation are conducted after fixation. According to the invention, rubble falling and collapse on the slope surface can be prevented; the steadiness of the slope surface structure is ensured; the plant fiber blanket is paved on the slope surface; stability of the slope is enhanced; moisture evaporation on the slope surface can be effectively reduced; the plant growth density can be rationally controlled; and vegetation coverage can be ensured, and demands for nutrients can be reduced. The method disclosed by the invention is used for the ecological restoration of the high-altitude slope; construction technologies are simple; the level of management and maintenance is reduced; consumption of manpower and materials can be greatly reduced; construction cost is reduced; and restoration effects of an ecological system are good.

Owner:云南云创数字生态科技有限公司

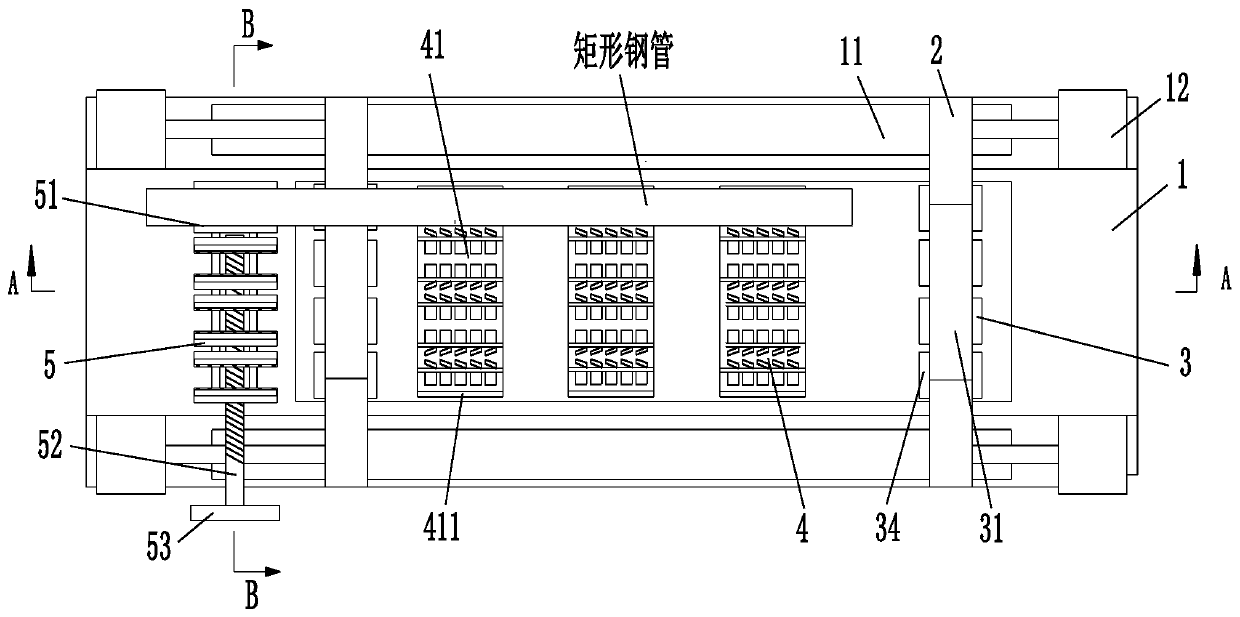

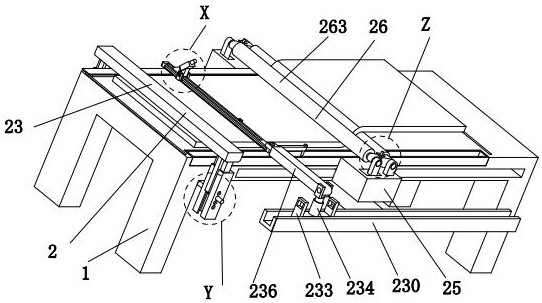

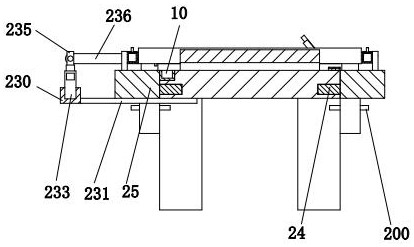

Fixing fixture for synchronous cutting of multiple rectangular steel pipes

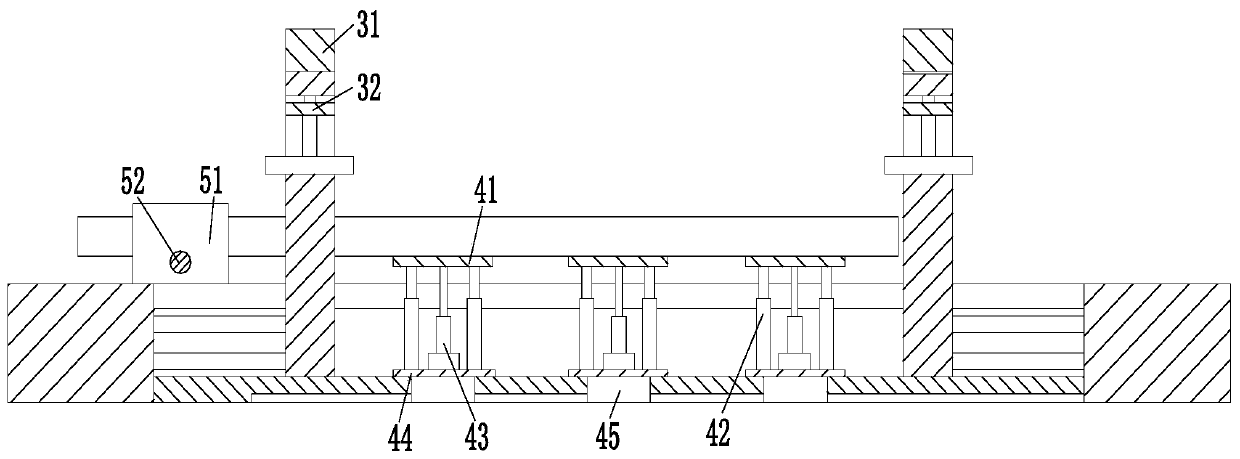

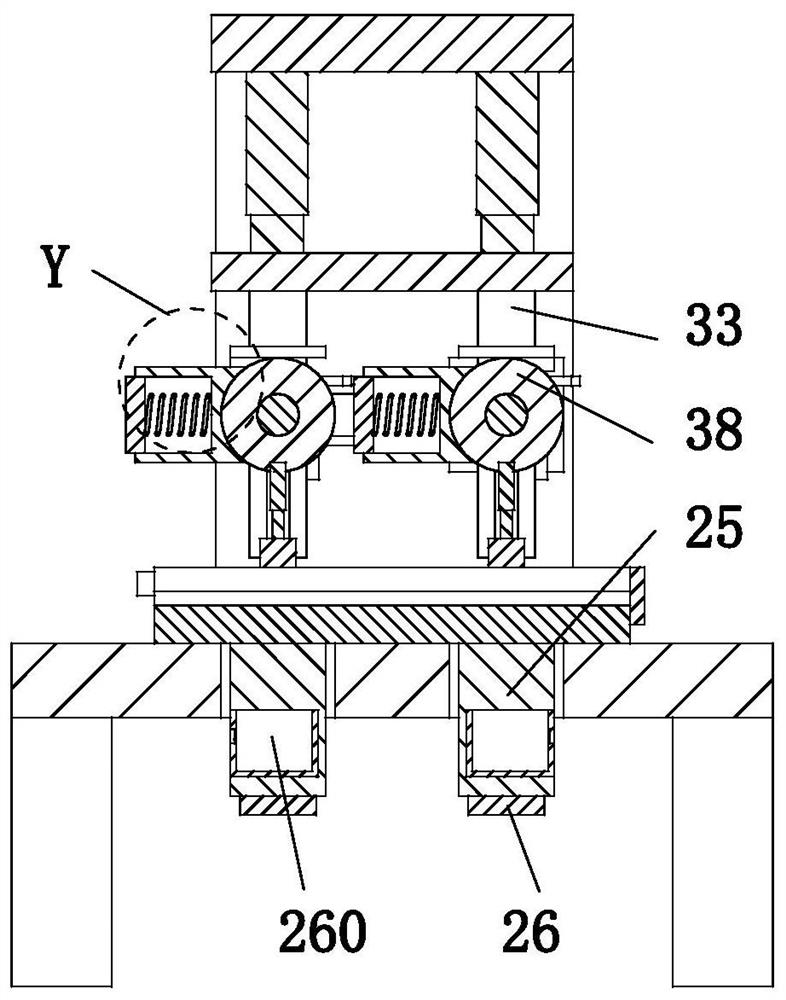

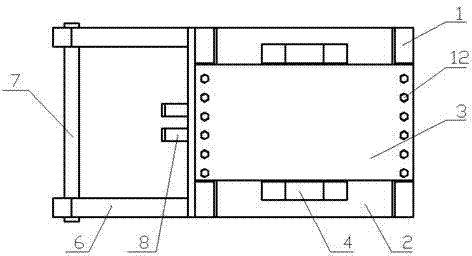

ActiveCN110605598AReduce the chance of deformationReduce the amount of horizontal movementWork clamping meansPositioning apparatusEngineeringPortal frame

The invention relates to a fixing fixture for synchronous cutting of multiple rectangular steel pipes. The fixing fixture comprises a worktable, portal frames, pressing devices, supporting devices anda clamping device; the portal frames are symmetrically arranged on the left and right sides of the worktable through a sliding mode; the pressing devices are arranged on the portal frames through a sliding mode; a rectangular through groove is formed in the middle part of the worktable; the supporting devices are arranged in the rectangular through groove in sequence from left to right; and the clamping device is arranged on the left side of the upper end surface of the worktable, and is positioned on the left side of the portal frame on the left side of the worktable. The fixing fixture cansolve such difficulties as easy deformation of cutting places of the rectangular steel pipes or even bending deformation of the whole rectangular steel pipes due to cantilever beam type cutting formedby fixation of one ends of the rectangular steel pipes by using a fixture without needing other fixing tools, easy blockage of cutters and different cutting sections in a traditional fixing fixture for rectangular steel pipe cutting.

Owner:福建泉州业德弗科技有限公司

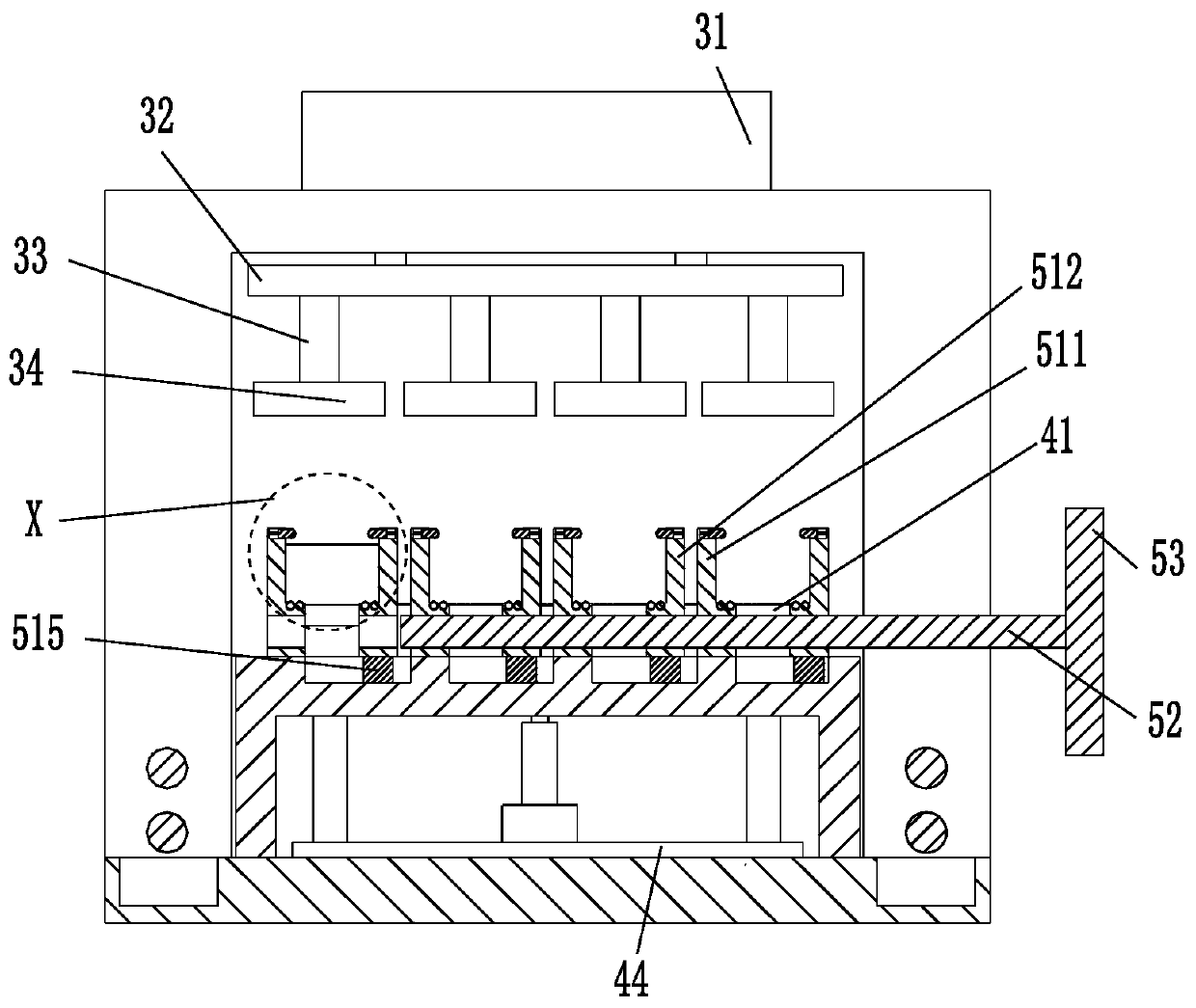

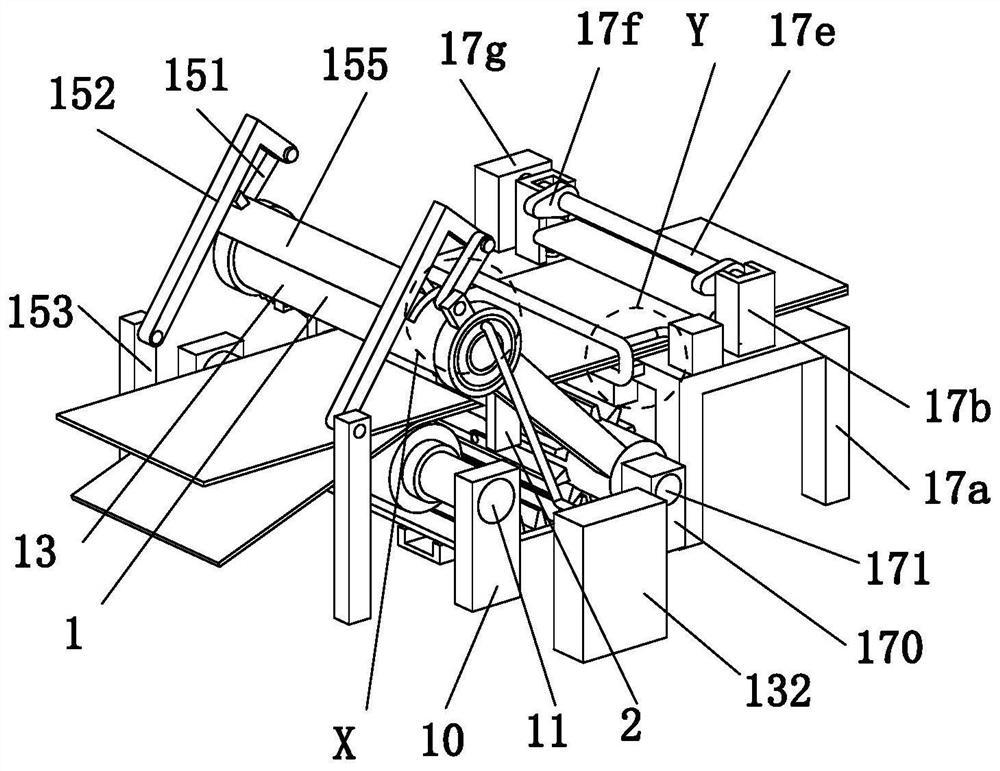

Multi-stage machining and forming equipment for curtain wall connecting piece

InactiveCN111804808AOmni-directional limit operationSimplify processing and forming stepsPerforating toolsMetal-working feeding devicesPunchingMachining

The invention relates to multi-stage machining and forming equipment for a curtain wall connecting piece. The equipment comprises a workbench, a clamping mechanism and a blanking mechanism, wherein the clamping mechanism is arranged in the middle of the upper end of the workbench, and the blanking mechanism is arranged above the clamping mechanism. The design concept of a continuous punching and cutting integrated combined structure is adopted for multi-stage machining and forming of the curtain wall connecting piece, machining and forming steps are simplified, and the machining and forming efficiency is improved; a plurality of structures with pressing effects are arranged for punching and cutting plates, so that the purpose of improving punching and cutting quality is achieved; and meanwhile, the equipment can perform omnibearing limiting operation on the plates, and a centralized storage structure is arranged for punching wastes.

Owner:浙江研基科技有限公司

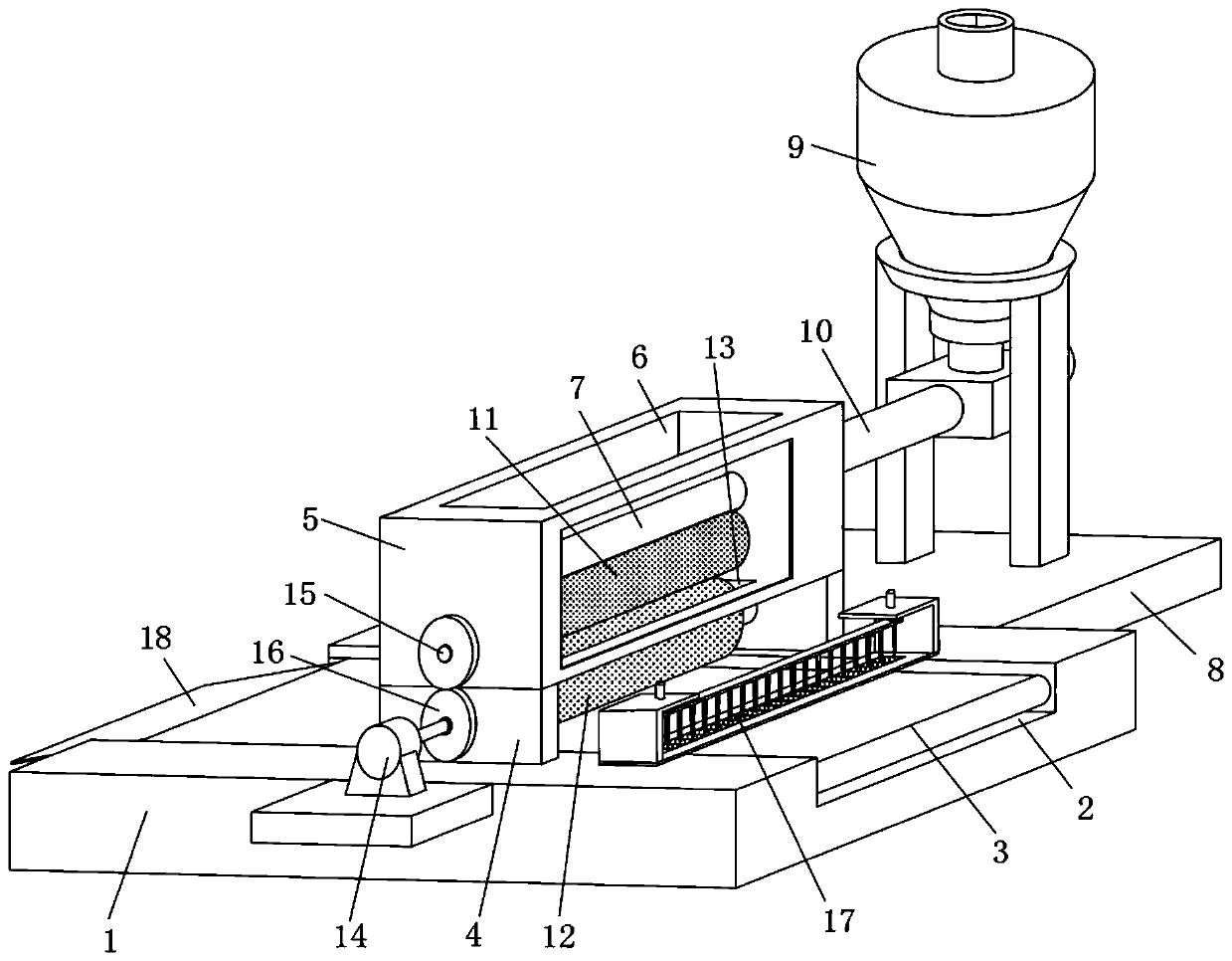

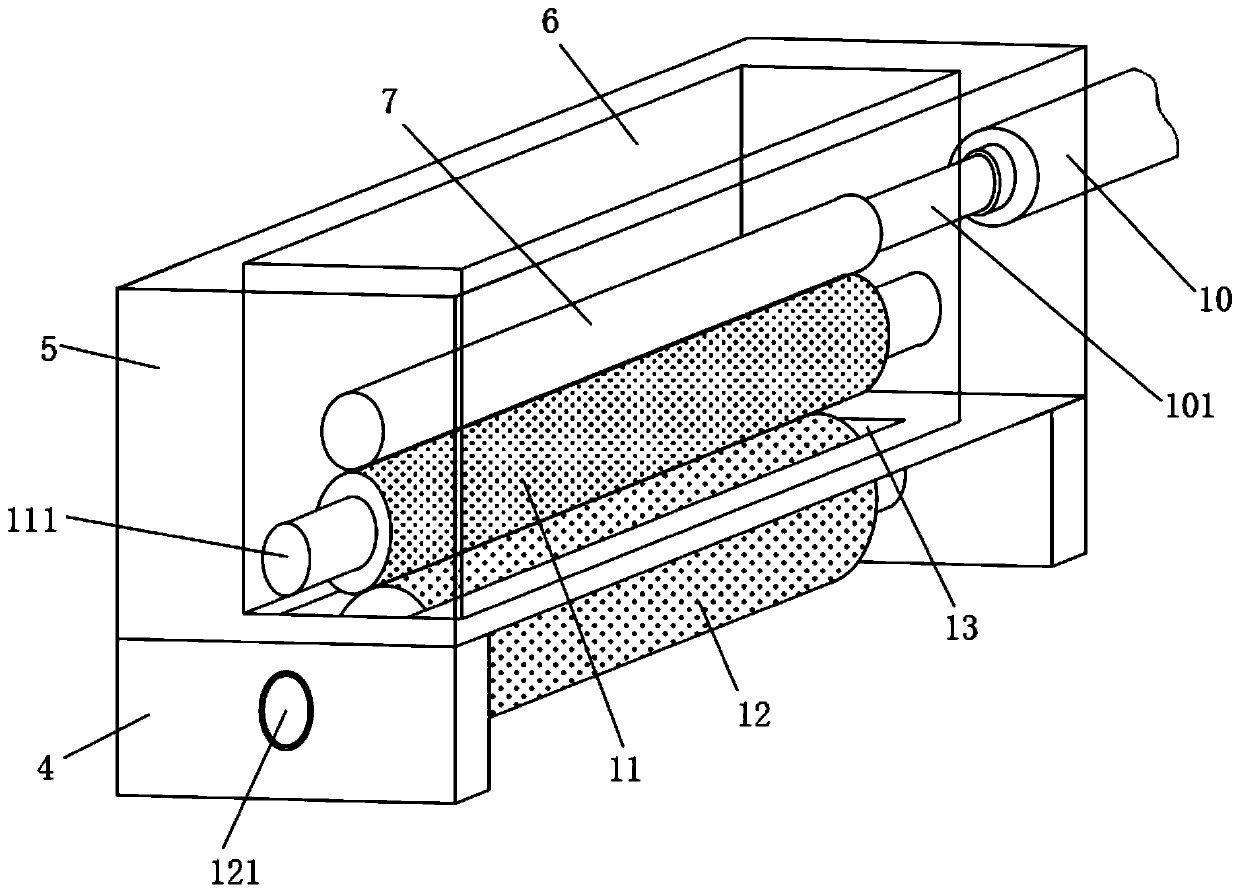

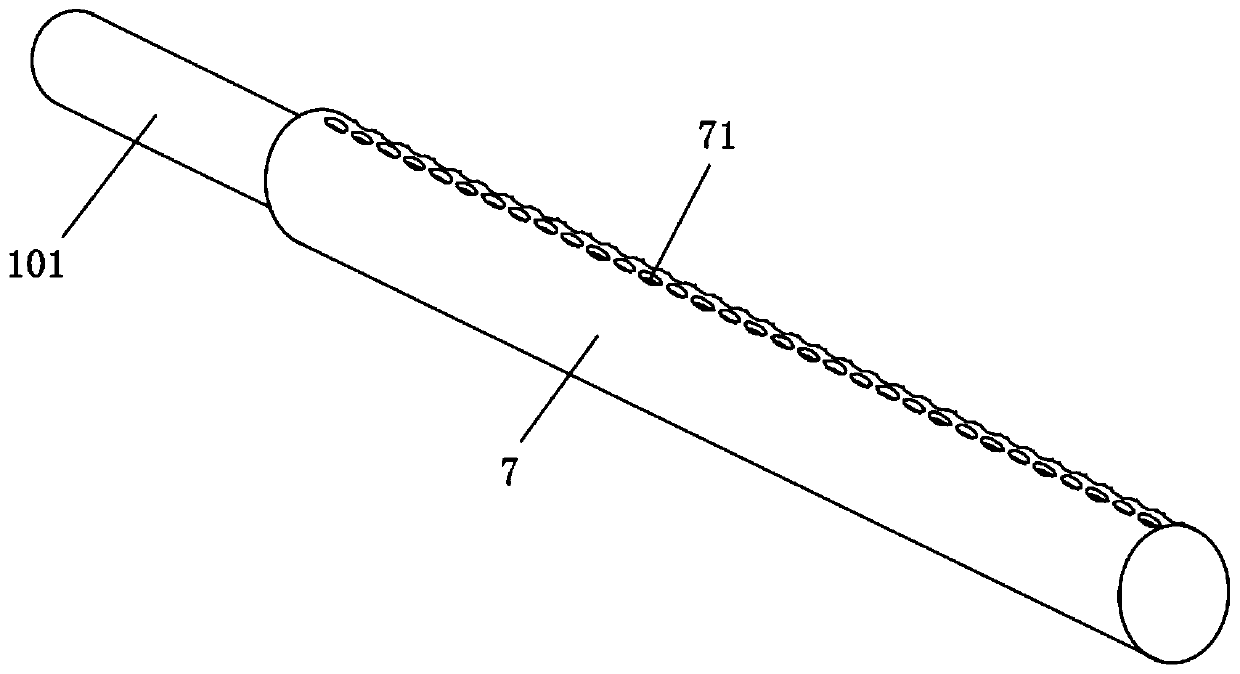

Meat product sauce-brushing device based on food processing and using method thereof

ActiveCN110803492AGood continuityImport smoothlyLoading/unloadingConveyor partsProcess engineeringFood processing

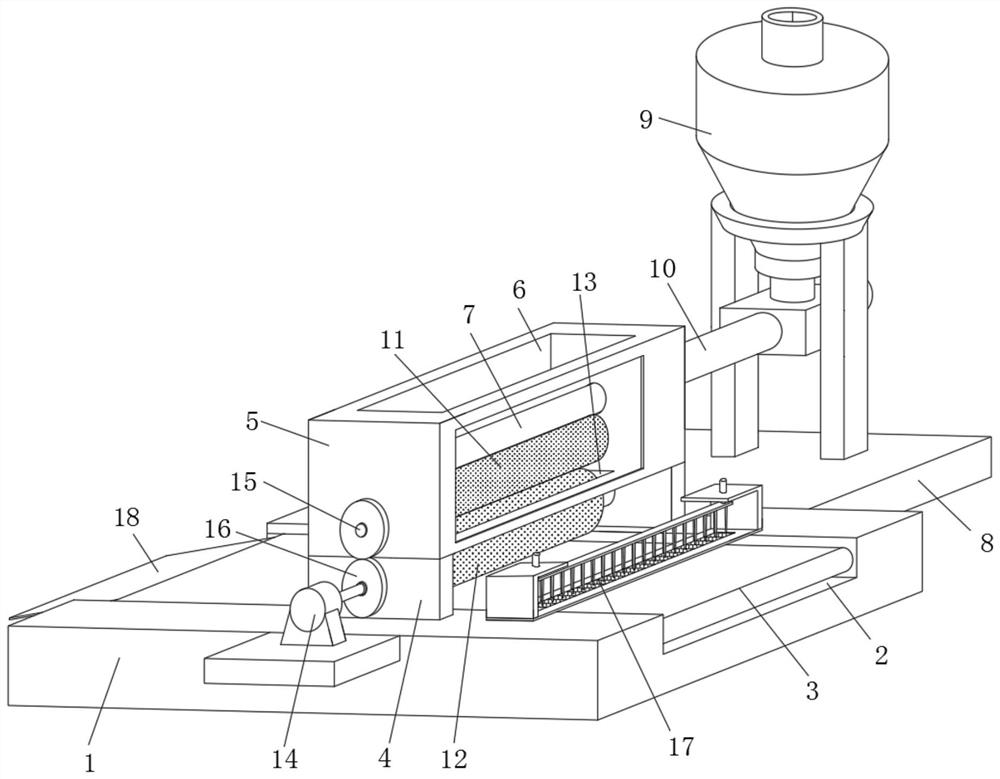

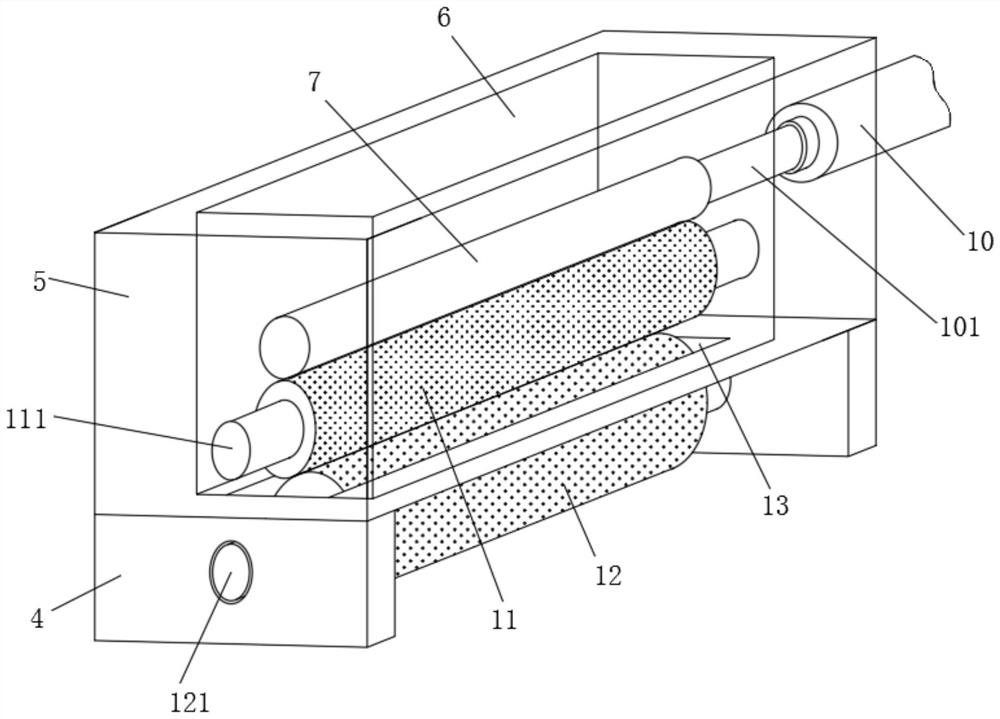

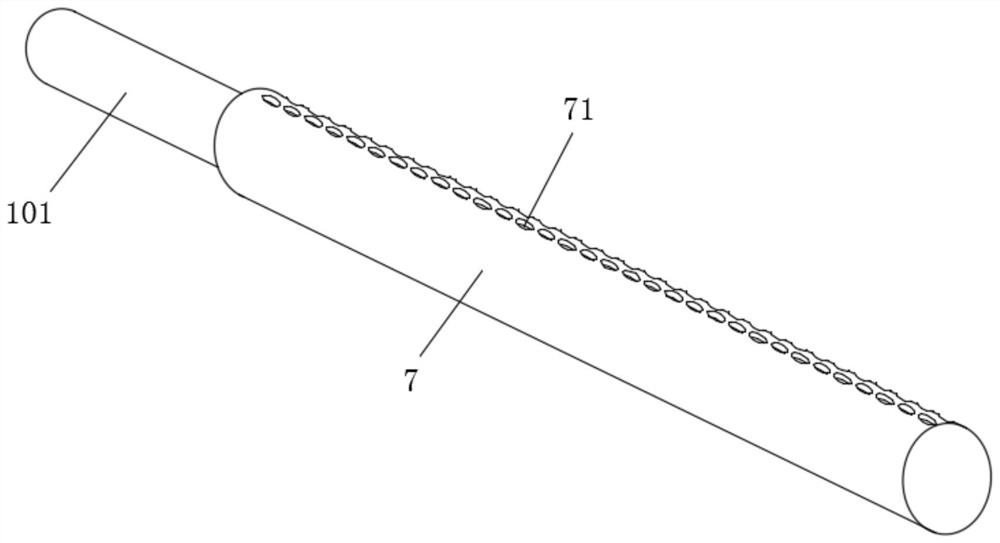

The invention discloses a meat product sauce-brushing device based on food processing and a using method thereof, and belongs to the field of food processing. According to the meat product sauce-brushing device based on food processing and the using method thereof, a sauce tank continuously guides sauce into a conveying pipe, so that the sauce is uniformly guided onto a taking roller through a plurality of leakage holes in the bottom end of the conveying pipe, the taking roller and a brushing roller are in transmission connection through a transmission mechanism, the sauce on the taking rolleris conveyed onto the brushing roller in transmission, the brushing roller uniformly smears the sauce on meat products on a conveying belt in the continuous rotating process, compared with traditionalmanual brushing or sauce brushing through a rotating common sauce brush, the sauce is smeared more continuously and more evenly, and meanwhile, the meat products are further pressed in the sauce brushing process; and a puncture device is arranged at the front end of the brushing roller to puncture the conveyed meat products to a certain extent, and thus the uniformity and permeability of subsequent sauce brushing are further effectively improved.

Owner:四川张飞牛肉有限公司

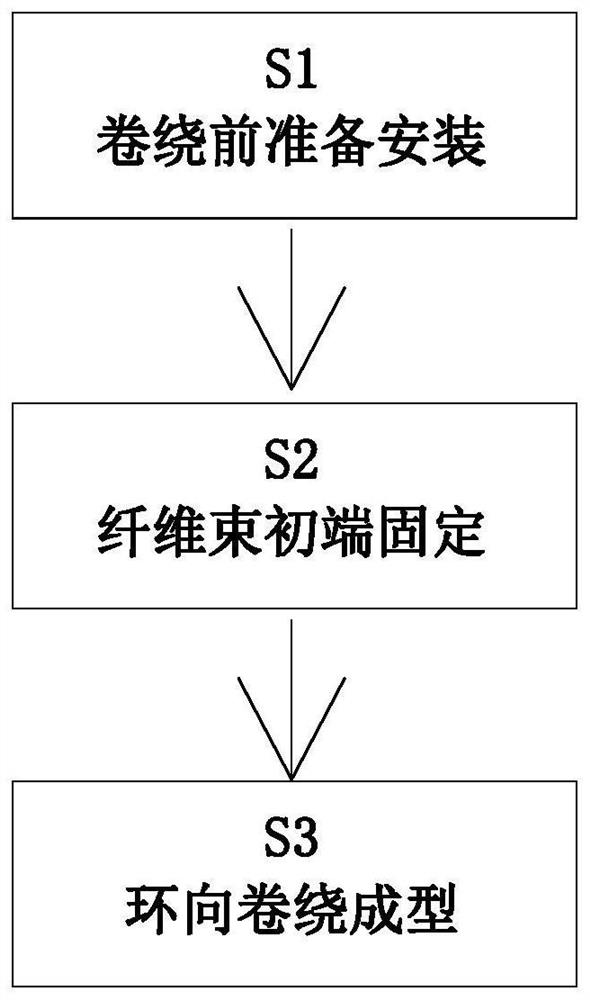

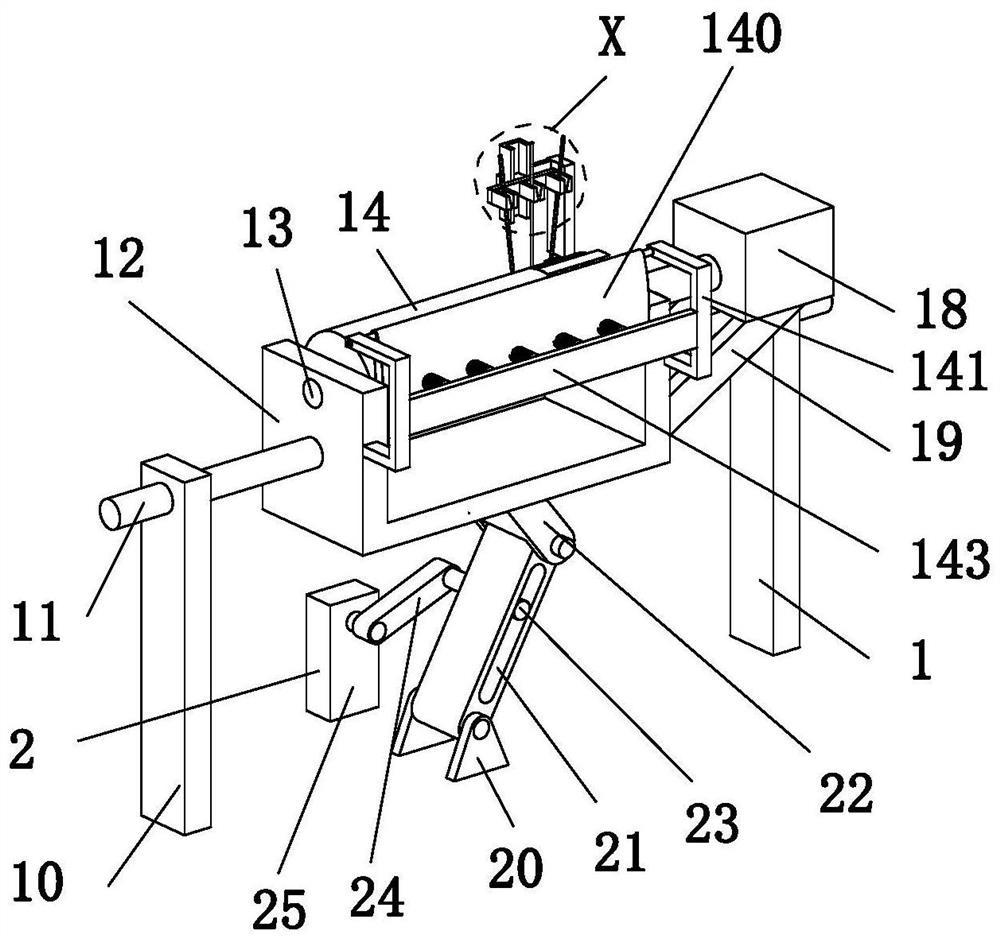

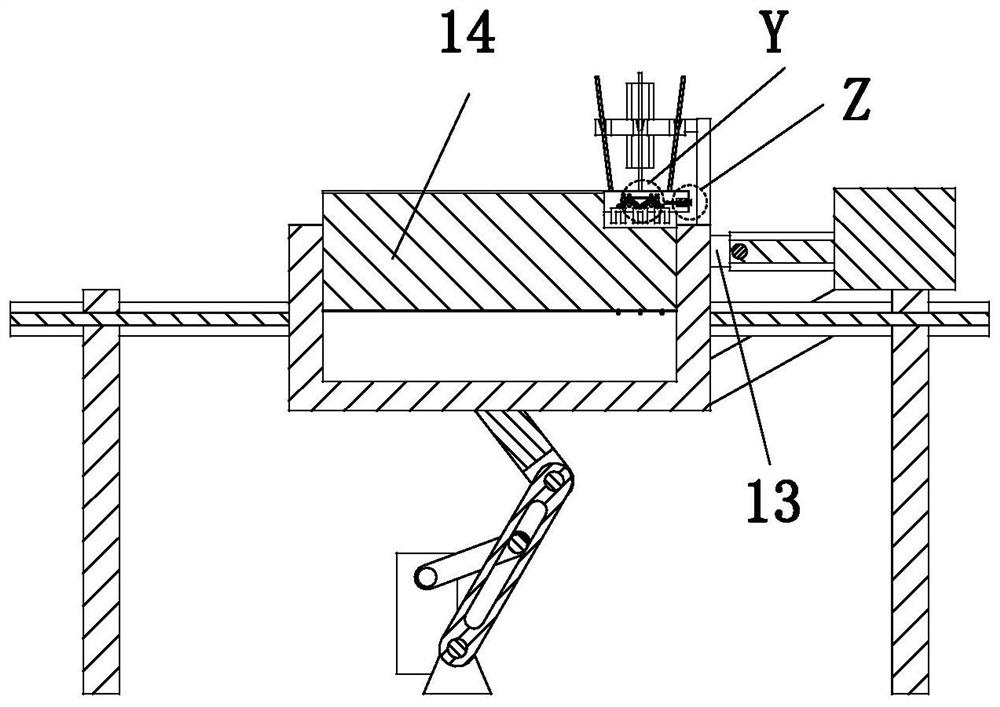

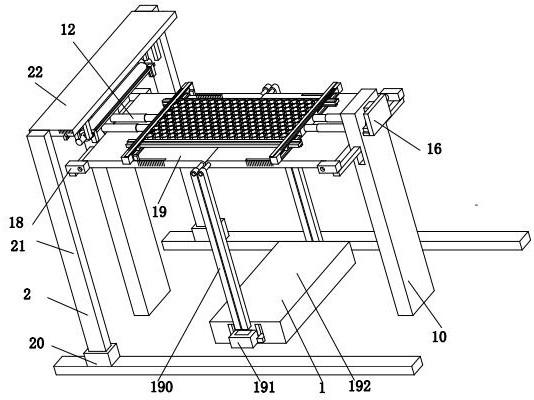

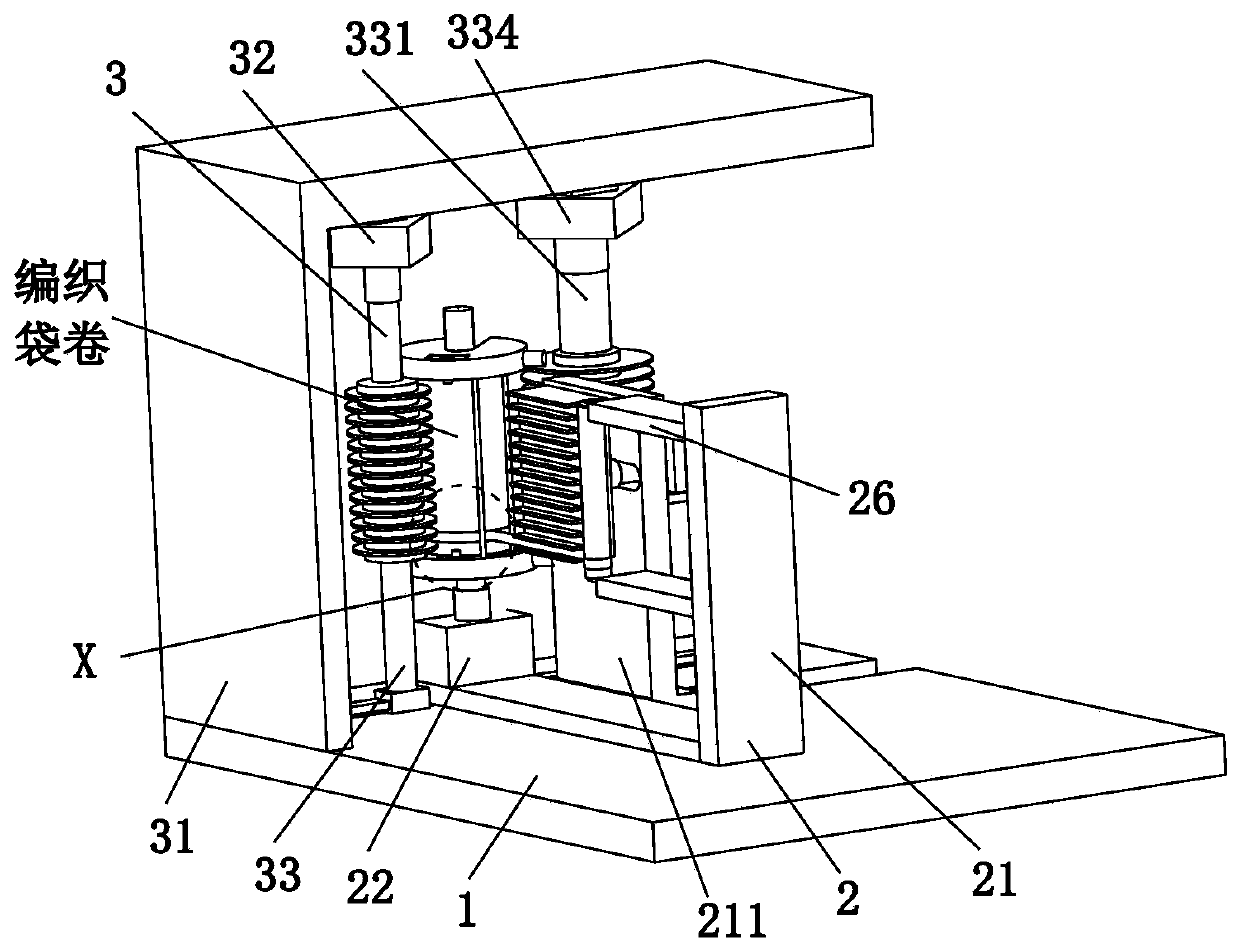

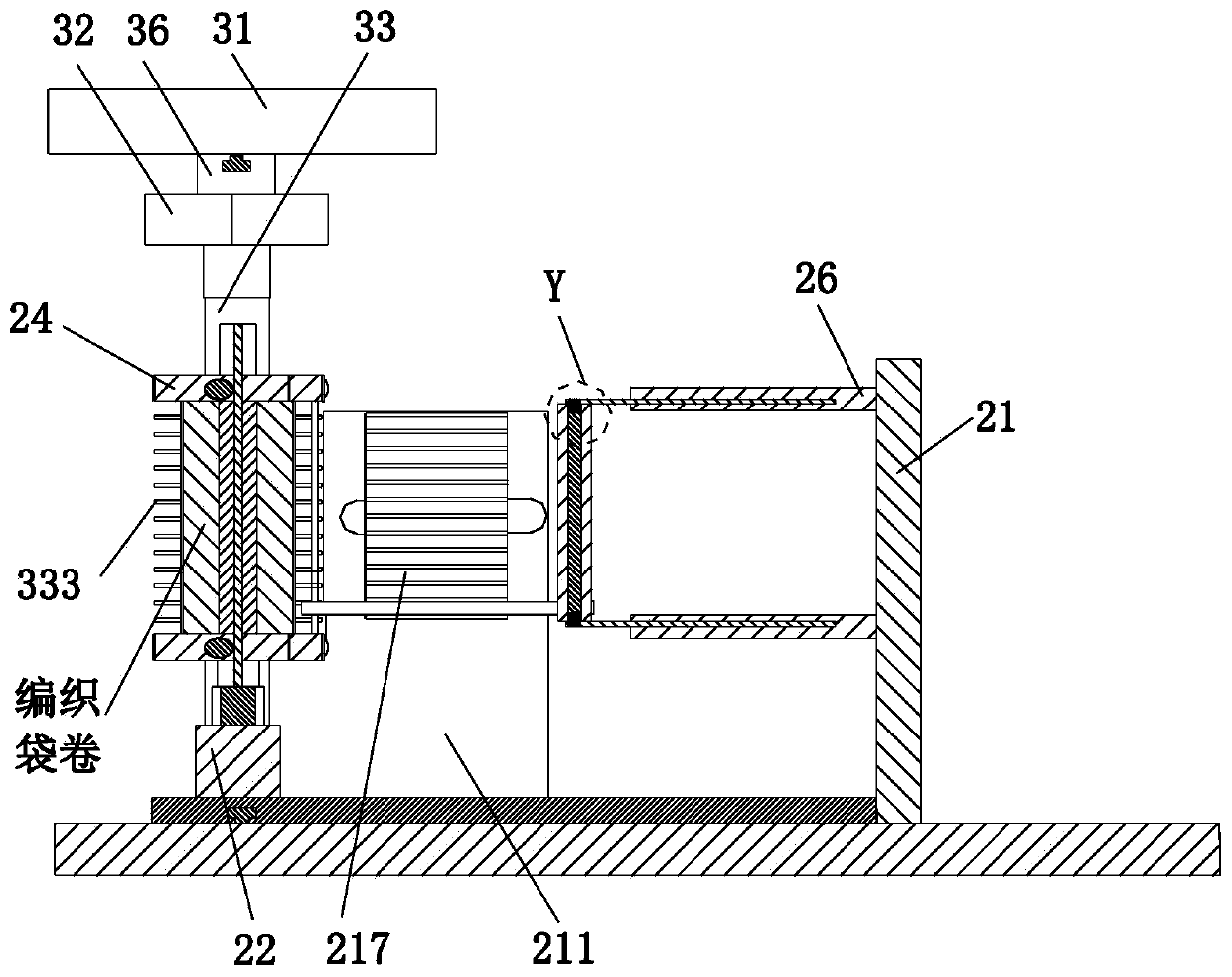

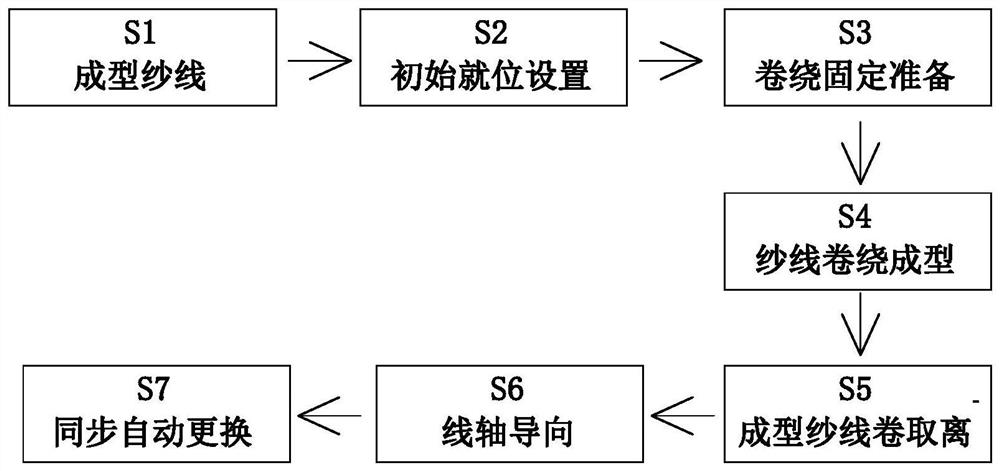

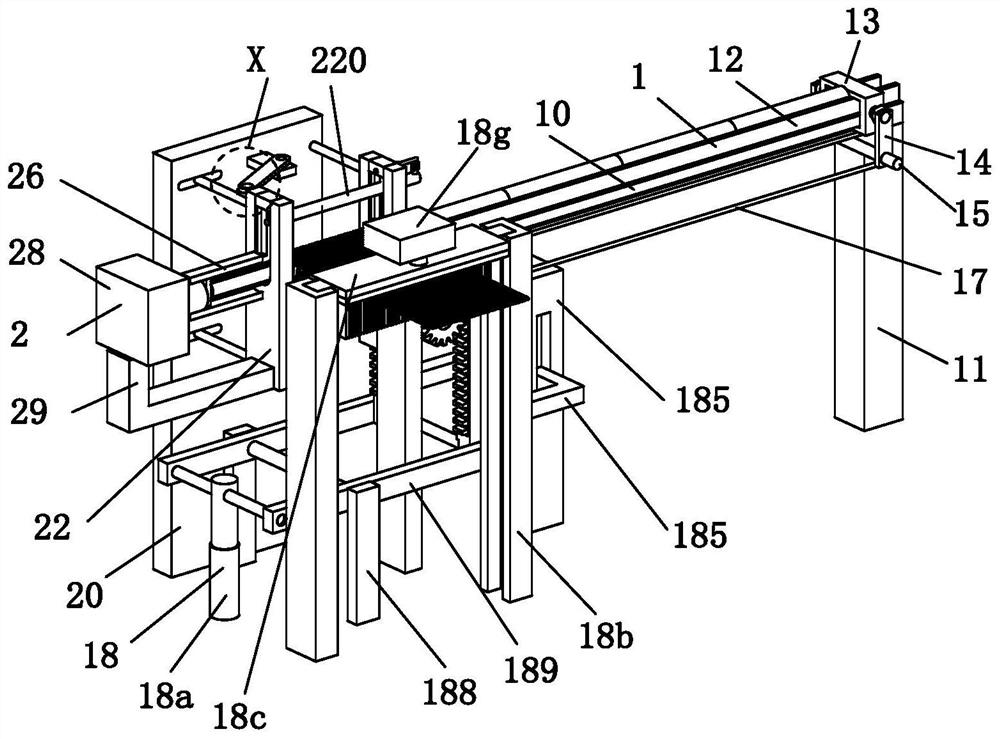

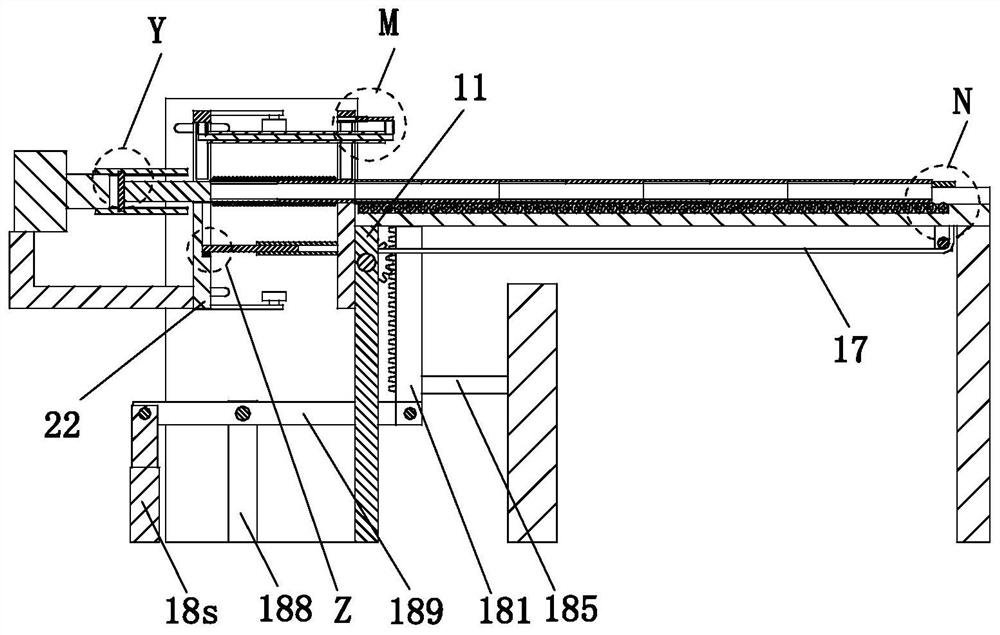

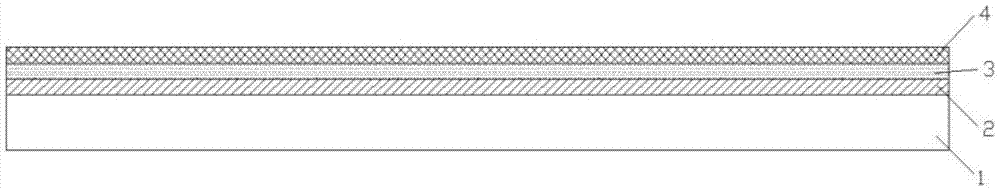

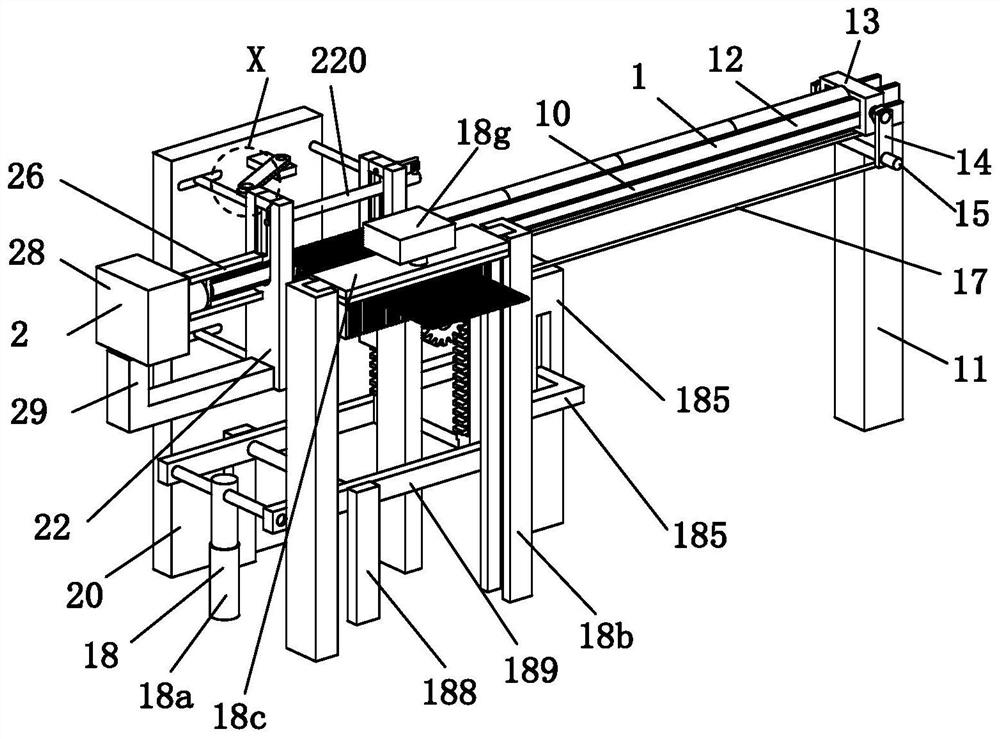

Forming production method for epoxy glass fiber reinforced plastic fiber pipe

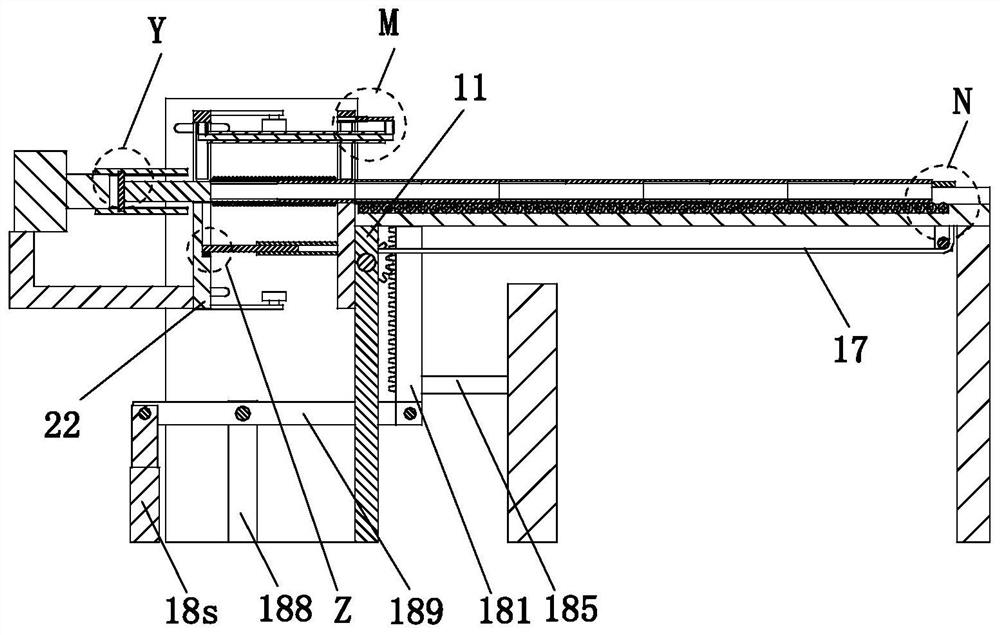

The invention relates to a forming production method for an epoxy glass fiber reinforced plastic fiber pipe. A forming production device for the epoxy glass fiber reinforced plastic fiber pipe is usedin the method. The forming production device for the epoxy glass fiber reinforced plastic fiber pipe comprises a winding mechanism and an operating mechanism, wherein the lower end of the winding mechanism is mounted on existing working ground, the operating mechanism is arranged at the lower end of the middle of the winding mechanism, and the lower end of the operating mechanism is mounted on the existing working ground. According to the method, the design concept of combining multiple fixing structures is adopted for forming production of the epoxy glass fiber reinforced plastic fiber pipe,the fixing firmness of initial winding ends of fibers can be improved according to the overall structural characteristics of the arranged fixing set, and meanwhile a structure for elastically clamping and pressing the fibers is arranged to keep the appearances of the fibers.

Owner:陶忠梅

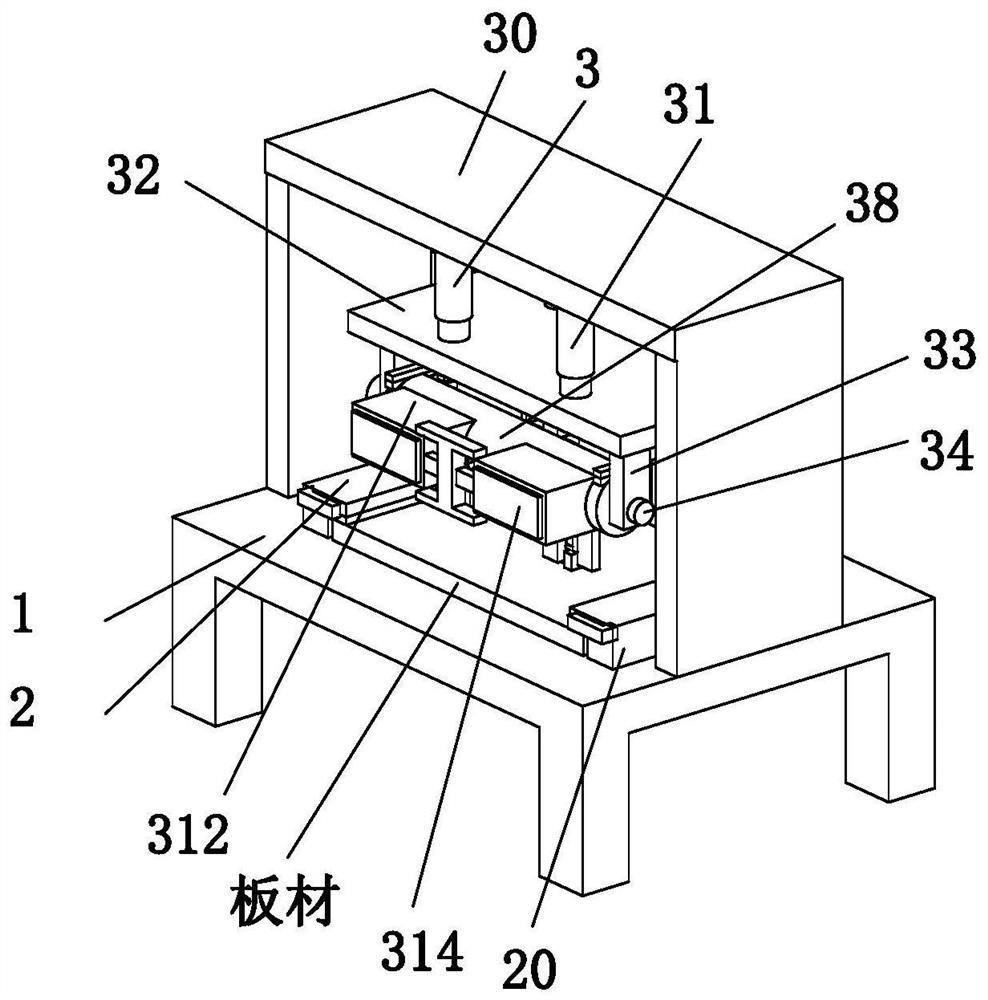

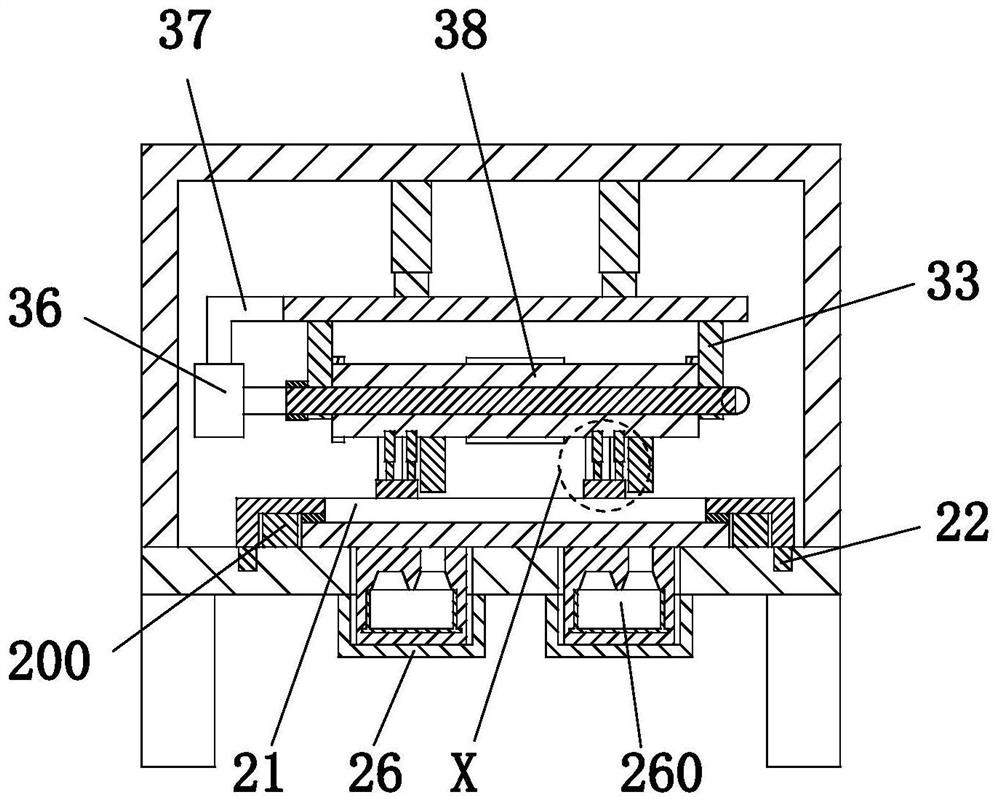

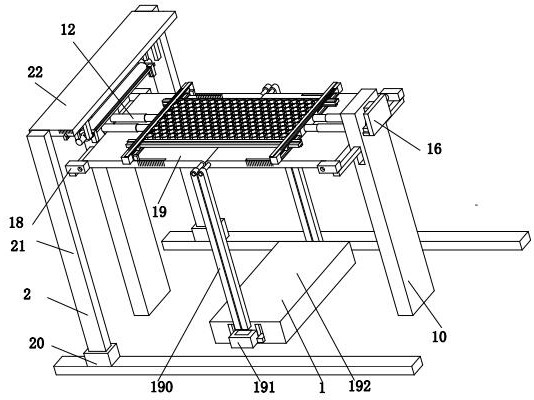

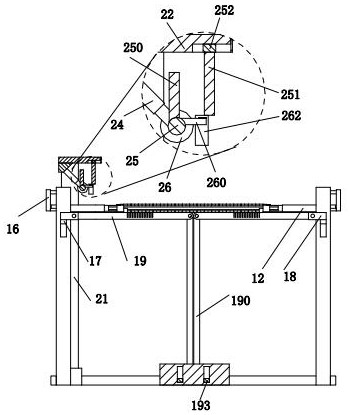

Honeycomb plate production and forming composite processing machine

ActiveCN113290945AImprove bonding tightnessImprove composite molding qualityPaper/cardboard articlesHoneycombStructural engineering

The invention relates to the field of honeycomb plate production, in particular to a honeycomb plate production and forming composite processing machine which comprises a clamping and fixing mechanism and a pressing mechanism, the clamping and fixing mechanism is arranged on the ground, and the pressing mechanism is arranged at the left end of the clamping and fixing mechanism. The clamping and fixing mechanism comprises a vertical frame, a disc, a first electric push rod, a clamping plate, a limiting block, a stop block, a connecting plate, a first electric sliding block, a lug plate, a supporting plate, a supporting rod, a connecting plate, a bottom block and a second electric sliding block. By adopting the design concept of multidirectional limiting, the whole processing machine can realize multidirectional clamping and fixing of a honeycomb core, so that the honeycomb core is prevented from shifting or deforming, the function of turning over the honeycomb core so that the honeycomb core can be subjected to double-faced composite panel treatment is also achieved, meanwhile, the arranged pressing mechanism can press a panel and the honeycomb core, then the purpose of improving the bonding compactness between the honeycomb core and the panel is achieved, and the composite forming quality of the honeycomb plate is improved.

Owner:JIANGSU HAIDEMAN BUILDING MATERIALS IND

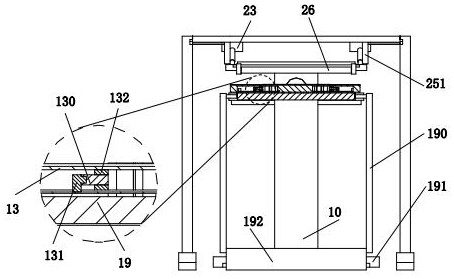

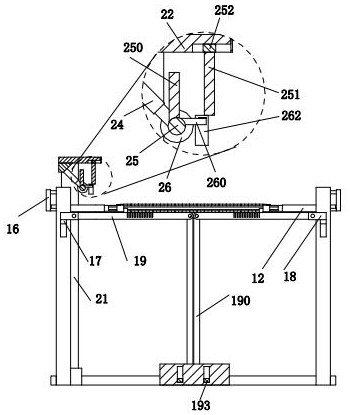

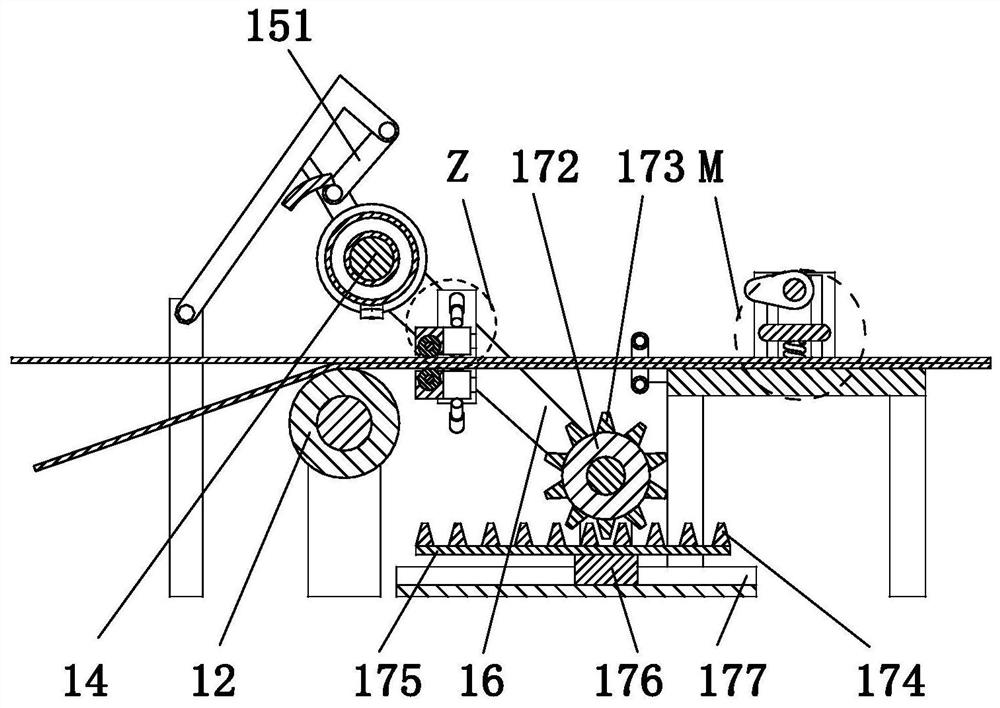

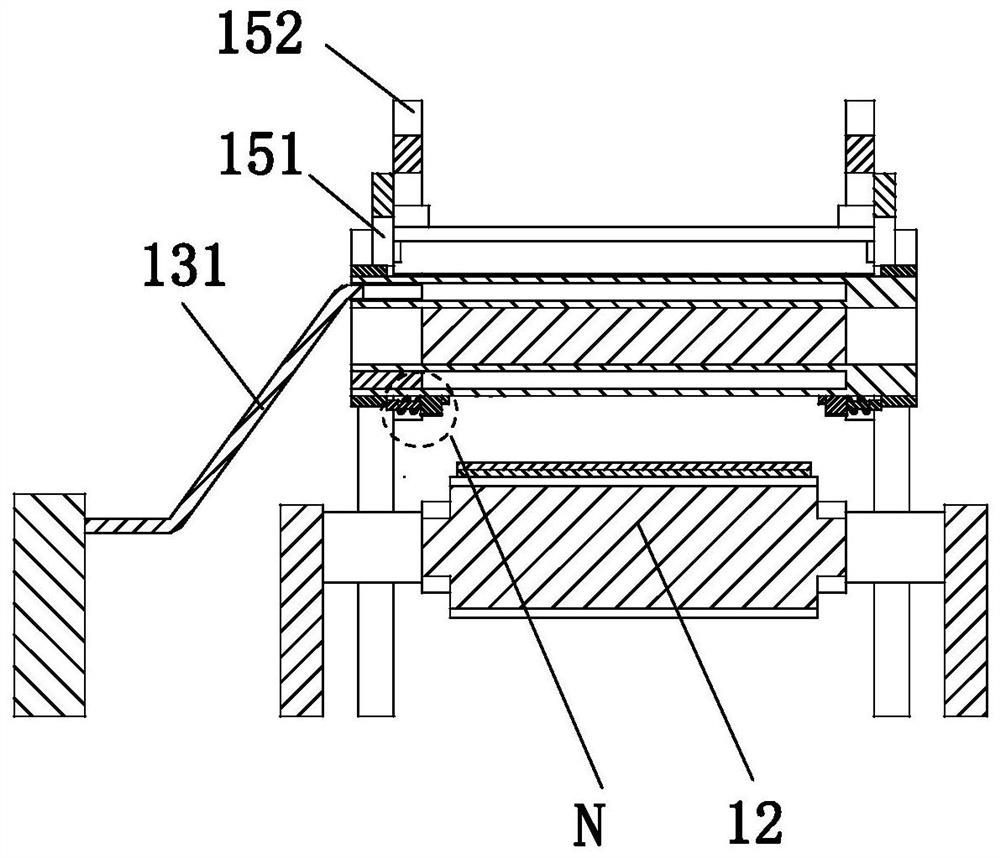

Wiredrawing processing machine for manufacturing woven bag

InactiveCN111218725AImprove molding qualityReduce repeated cutting phenomenonArtificial thread manufacturing machinesFilament manufactureMechanical engineeringIndustrial engineering

The present invention relates to a wiredrawing processing machine for manufacturing a woven bag. The wiredrawing processing machine comprises a workbench, a clamping and winding device and a cutting device, wherein the clamping and winding device is arranged at the middle of the rear end of the upper end face of the workbench in a sliding fit manner; the cutting device is arranged at the left endof the clamping and winding device; and the lower end of the cutting device is in a sliding fit with the upper end face of the workbench. According to the wiredrawing processing machine for manufacturing the woven bag, the woven bag is subjected to cutting and wiredrawing by adopting a multistage cooperative design concept, so that the device can adapt to the processing of a woven bag roll with athicker thickness, the overall utilization rate of the device is improved, meanwhile, the probability of repeated cutting of the woven bag roll for multiple times is reduced, and thus the forming quality of cutting and withdrawing is improved.

Owner:王义文

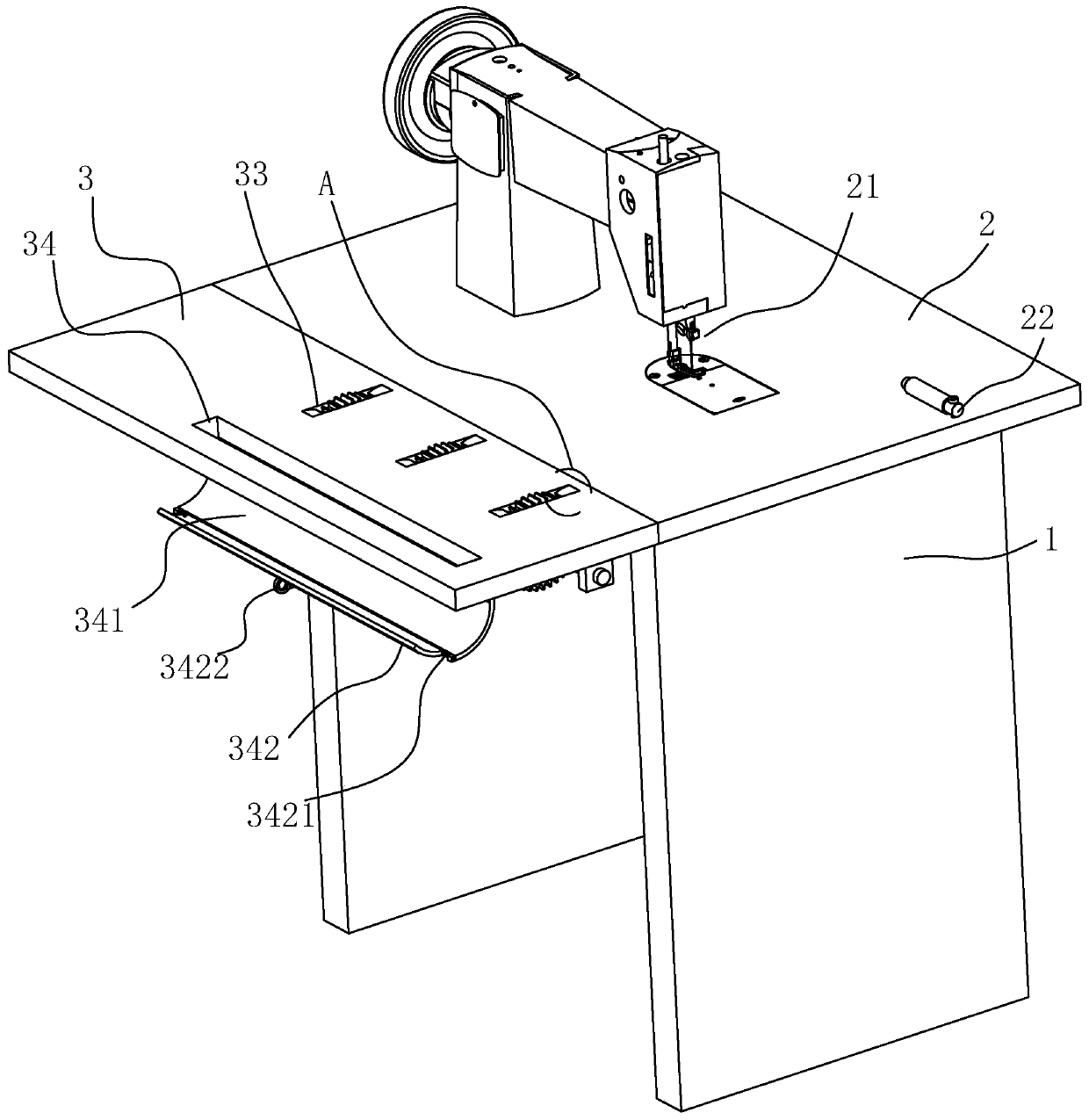

Leather product leather cutting and sewing processing technology

ActiveCN113005241APlay a smoothing roleImprove flatnessLeather clicking/perforating/clickingSkins/hides/leather/fur manufacturing apparatusProcess engineeringIndustrial engineering

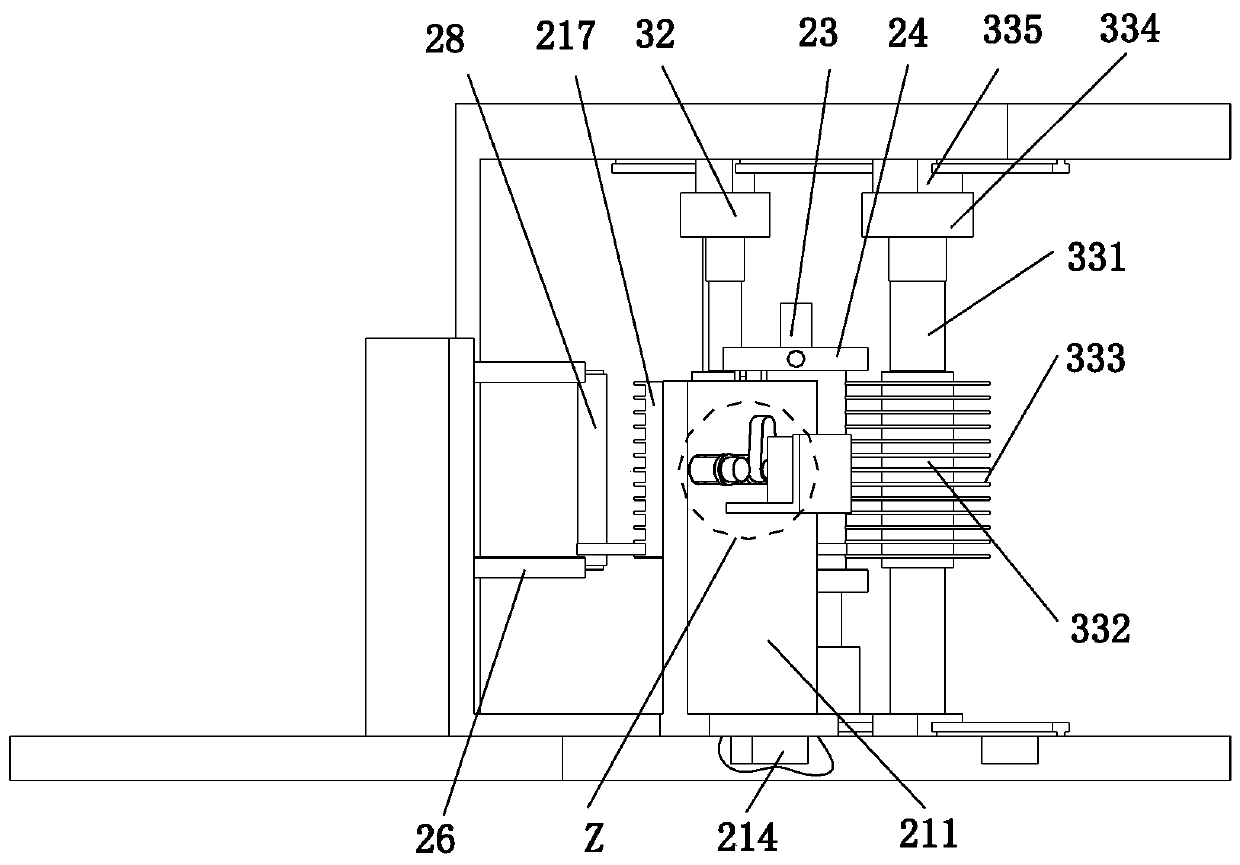

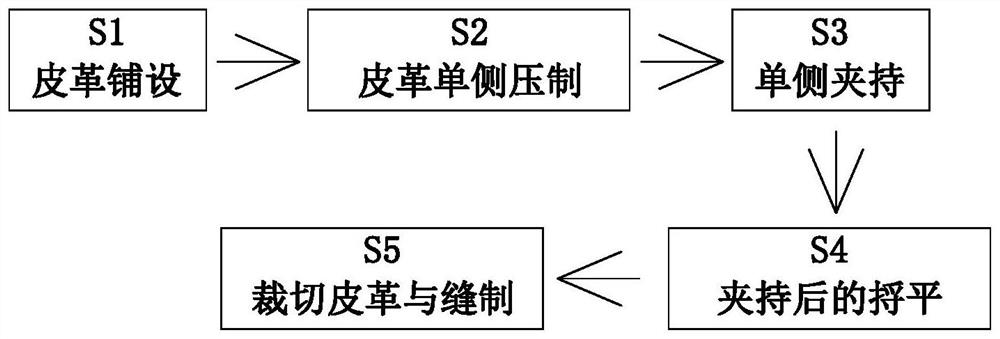

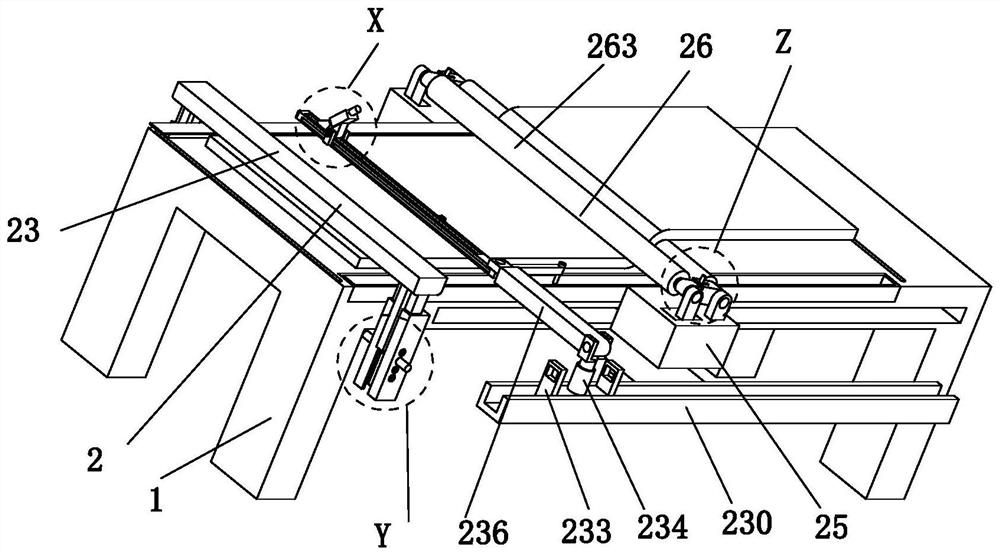

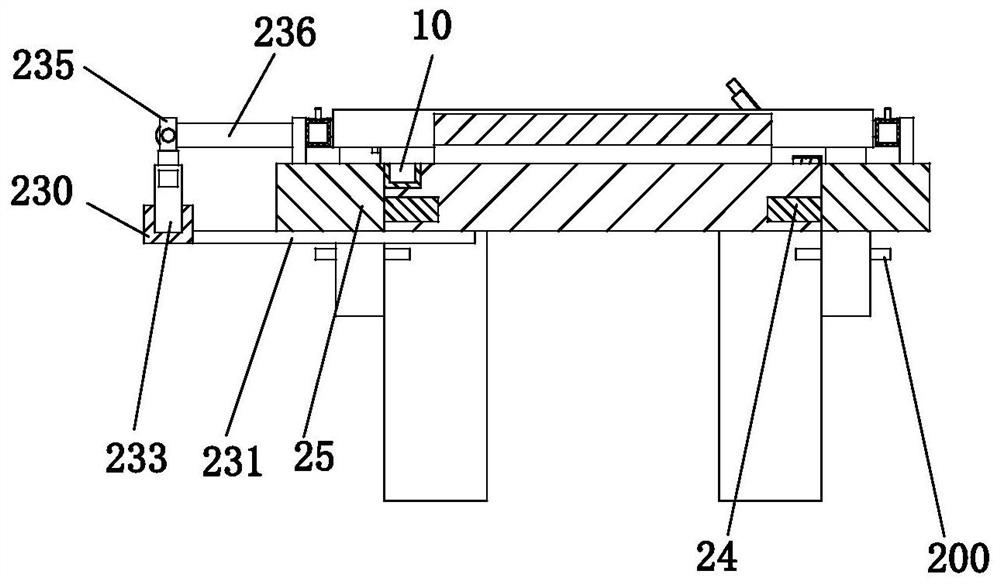

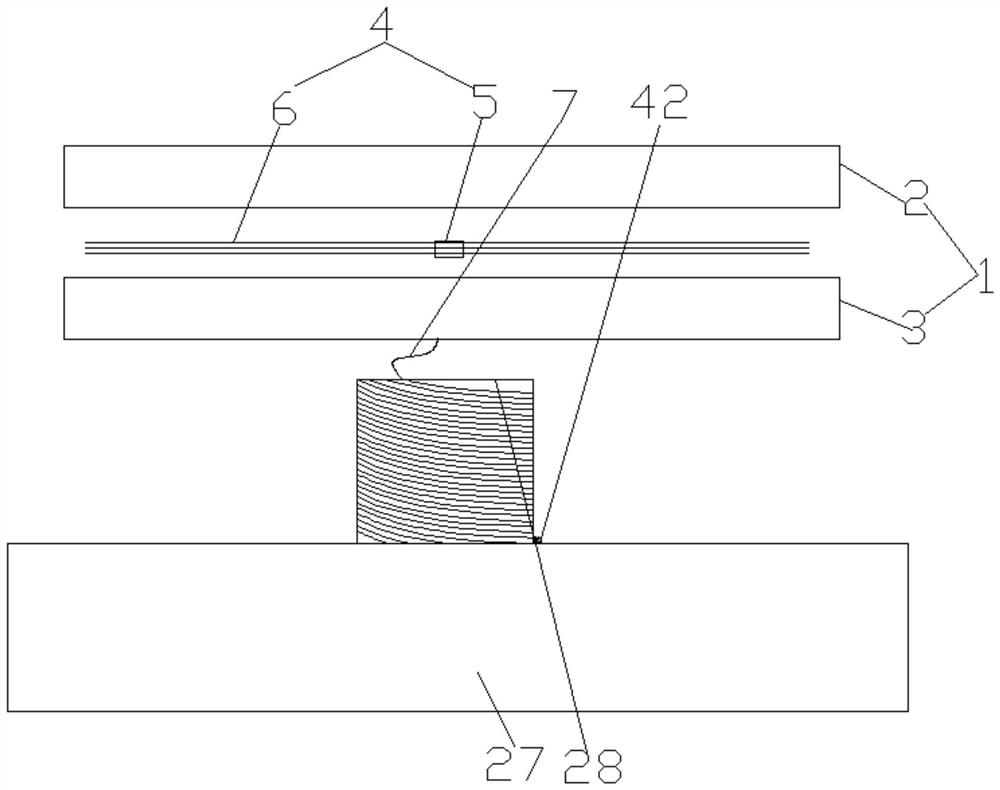

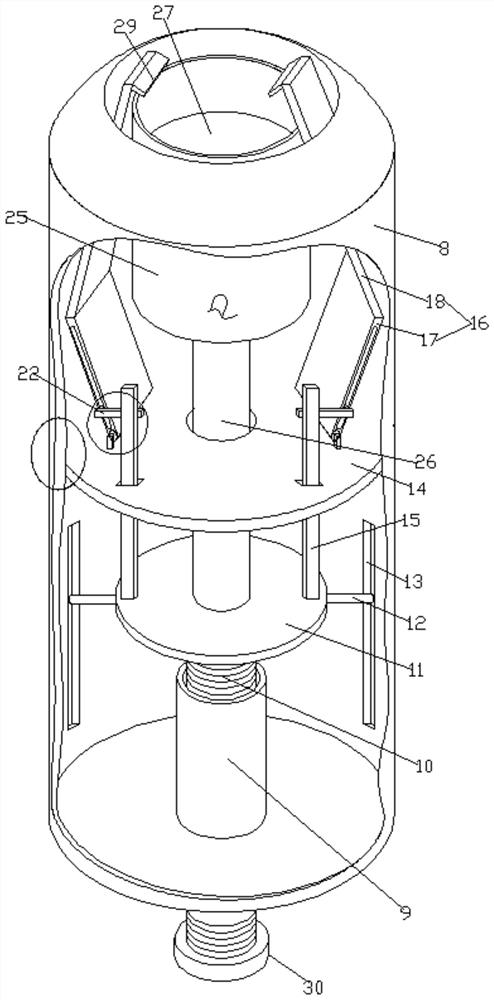

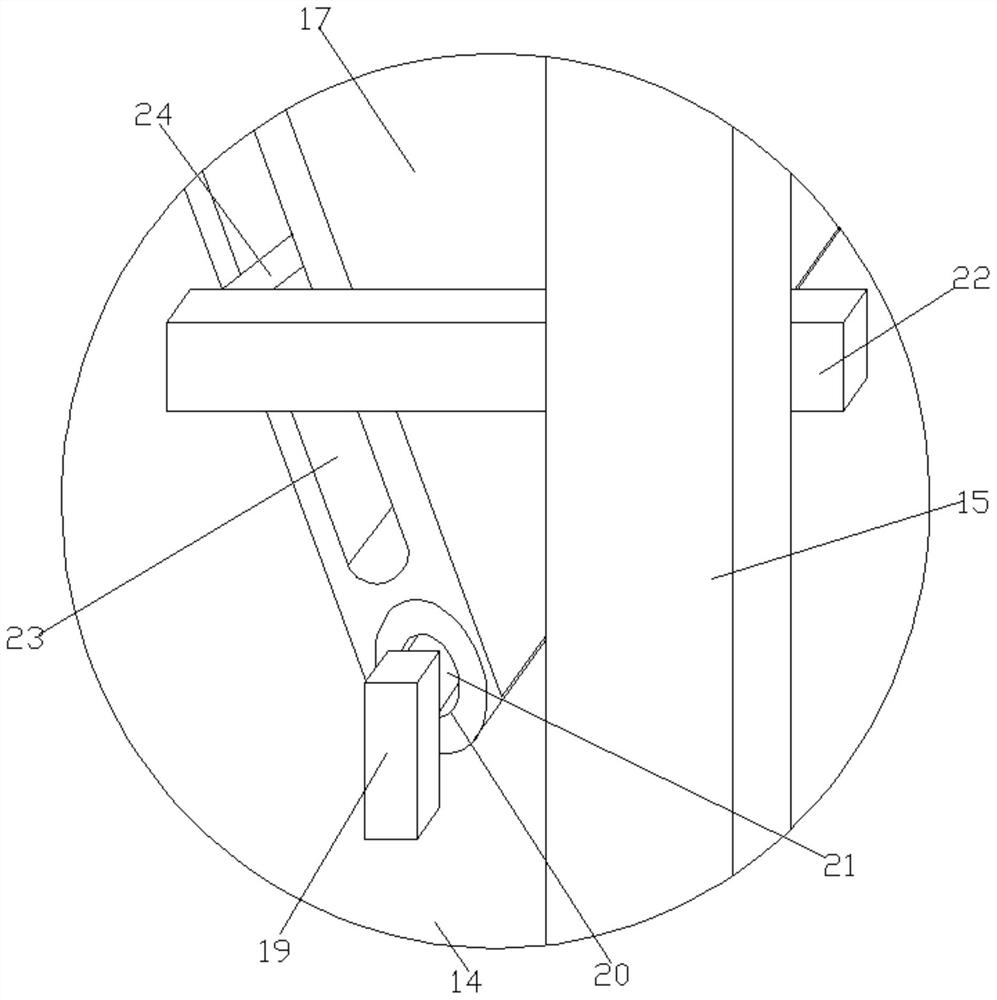

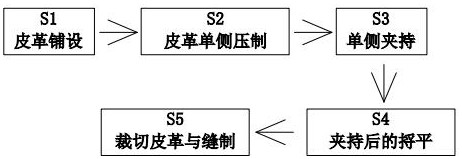

The invention relates to a leather product leather cutting and sewing processing technology which uses a leather product leather cutting and sewing processing device. The leather product leather cutting and sewing processing device comprises a working table and a clamping and fixing mechanism, the working table is installed on the existing ground, and the clamping and fixing mechanism is arranged at the upper end of the working table. According to the leather product leather cutting and sewing processing technology, the multi-adjustment design concept is adopted for leather product leather cutting and sewing processing; the arranged clamping and fixing mechanism can clamp and fix the two side ends of leather and can also play a role in smoothing the leather to keep the optimal flatness of the leather, and then the overall cutting quality of the leather is improved; meanwhile, a rolling smoothing structure is adopted so that the probability of motion clamping stagnation of the structure can be reduced by generating rolling friction; and the whole device can also realize switching between a vertical leather cutting mode and a transverse leather cutting mode, so that the adaptation degree of the device to the leather cutting requirement is greatly improved.

Owner:江苏延立汽车零部件有限公司

A non-woven fabric production thermosynthesis equipment

ActiveCN111945297BImprove adhesionHigh speedNon-woven fabricsVibration suppression adjustmentsSpinningProcess engineering

The invention relates to a heat-synthesizing equipment for producing non-woven fabrics, which includes a heat-bonding mechanism and an auxiliary pressure mechanism. The lower end of the heat-bonding mechanism is installed on the existing working ground, and the upper end of the heat-bonding mechanism is provided with an auxiliary pressure mechanism. The present invention adopts the design concept of combining multi-stage pressing structures to carry out thermal synthesis of non-woven fabrics. The auxiliary pressing mechanism and other structures with pressing effects can be used to press the thermally bonded non-woven fabrics multiple times to improve the non-woven fabrics. The purpose of the bonding degree of the woven fabric is to provide an external auxiliary heating structure to improve the bonding speed and quality of the non-woven fabric, and to provide a cooling structure to increase the solidification speed of the non-woven fabric bonding part.

Owner:惠州市新瑞无纺布有限公司

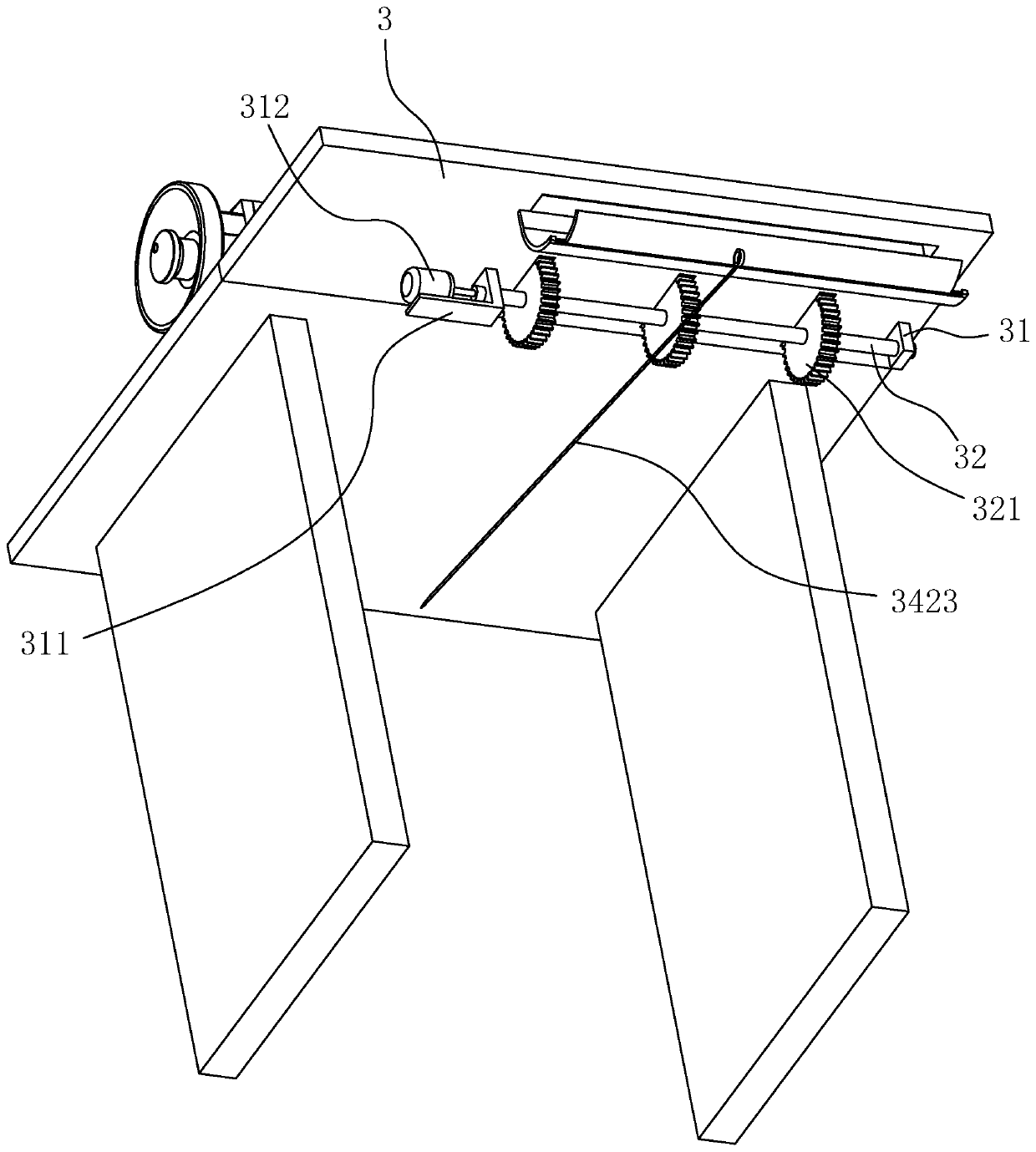

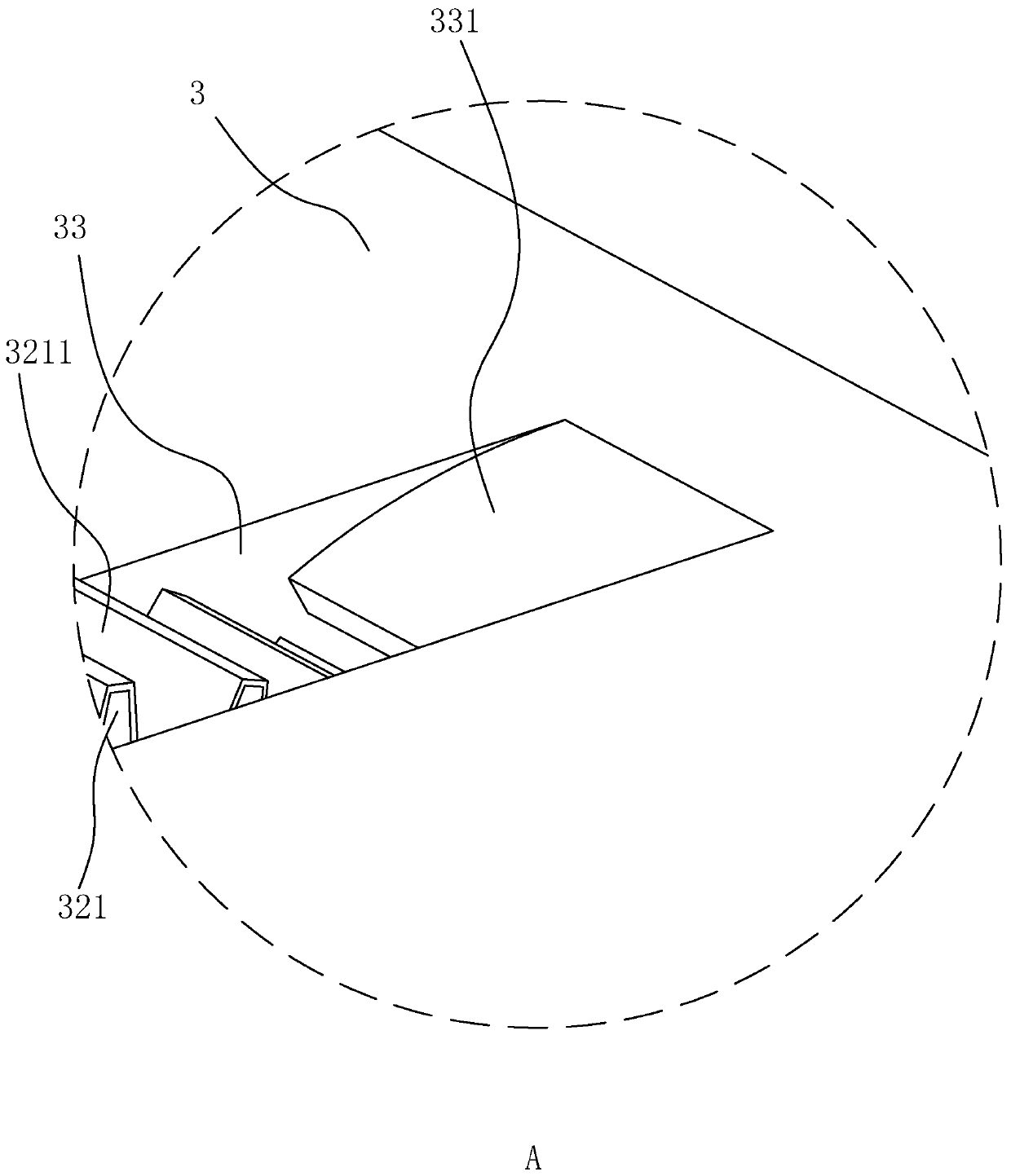

Sewing machine capable of reducing buildup

The invention discloses a sewing machine capable of reducing buildup, relates to the technical field of cloth sewing and aims to solve the technical problem that since cloth build up together needs tobe overturned to determine whether a next sewing point is correct, an operator cannot intuitively hold the whole cloth. The sewing machine according to the technical scheme is characterized in that an extension table is arranged on the side wall, far away from a sewing needle set, of a machine table; a support frame is arranged on the bottom wall of the extension table, and a rotating rod is rotatably connected to the support frame; a driving frame is arranged on the side wall, far away from the rotating rod, of the supporting frame; a driving part is arranged on the driving frame, and a driving shaft of the driving part is connected with the rotating rod; a plurality of rotating gears are arranged on the rotating rod, a plurality of rotating openings are formed in the extension table along the width direction of the extension table, the vertexes of the rotating gears are higher than the surface of the extension table, a sliding-down opening is formed in the surface of the extension table, and the rotating openings are positioned between the sliding-down opening and the machine table; whole cloth is conveniently and intuitively held by an operator, and the efficiency of sewing thewhole cloth multiple times is improved.

Owner:青岛兆明针织有限公司

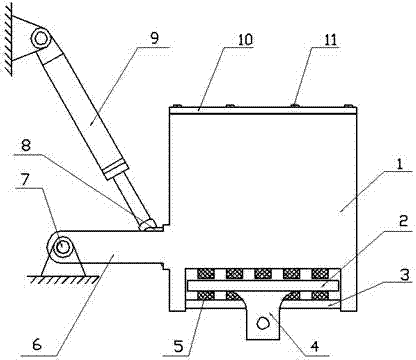

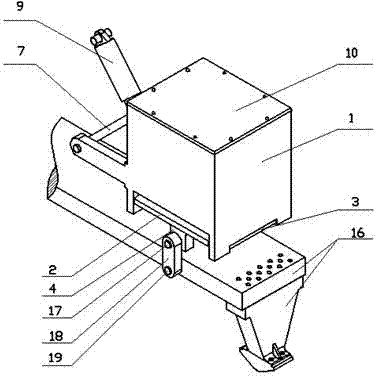

Mass adjustable counterweight for resonance crushers

InactiveCN102296523AModerate vibration shockIsolated transmissionRoads maintainenceVehicle frameRocker arm

The invention relates to a quality adjustable counterweight device for a resonant crusher, comprising a weight box and a hydraulic cylinder, characterized in that: one side of the weight box is connected with the hydraulic cylinder through lifting a lifting lug, the front of a rocker arm on the one side of the weight box is provided with a rocker arm shaft, the companding of the hydraulic cylinder allows the weight box to rotate on the rocker arm shaft through the rocker arm to complete the elevating function, the bottom of the weight box body is provided with a supporting body, the bottom ofthe supporting body is provided with two bearing lifting lugs, and a baffle plate is fixed under the weight box and traverses through between the two bearing lifting lugs to realizing the lifting andhorizontal spacing to the supporting body. The present invention has the advantages that the effect of adjustable quality of the counterweight is realized, the vibratory shock is mitigated effectively, and the transmission of the vibration to the vehicle frame is isolated effectively. The device can lift the vibration of the crushing parts without arranging the lifting device for the vibration ofthe crushing parts, so that the structure of the resonant crusher is simplified, and the operation is convenient.

Owner:WUHAN UNIV OF TECH

A compound processing machine for producing and forming honeycomb panels

ActiveCN113290945BImprove composite molding qualityRealize multi-directional clampingPaper/cardboard articlesCircular discHoneycomb

The present invention relates to the field of honeycomb panel production, in particular to a compound processing machine for producing and forming honeycomb panels, including a clamping mechanism and a pressing mechanism. The clamping mechanism is placed on the ground, and a pressing mechanism is arranged at the left end of the clamping mechanism. The fixing mechanism includes the vertical frame, the disc, the No. 1 electric push rod, the splint, the limit block, the stopper, the connecting plate, the No. 1 electric slider, the ear plate, the support plate, the support rod, the connecting plate, the bottom block and the No. 2 Electric slider, the invention adopts the design concept of multi-directional limit, the processing machine as a whole can not only realize the multi-directional clamping of the honeycomb core to avoid offset or deformation of the honeycomb core, but also has the ability to flip the honeycomb core to accept double The function of surface composite panel processing, and the pressing mechanism set at the same time can suppress the relationship between the panel and the honeycomb core, thereby achieving the purpose of improving the bonding tightness between the honeycomb core and the panel, and improving the composite molding quality of the honeycomb panel.

Owner:JIANGSU HAIDEMAN BUILDING MATERIALS IND

Vagina-implanted developing marking device for treating endometrial cancer

PendingCN114470538AClear development and accurate positioningImprove clinical treatment effectX-ray/gamma-ray/particle-irradiation therapyTunica intimaMetal sheet

The invention discloses a transvaginal endometrial cancer treatment developing marking device which comprises a pushing mechanism and a developing mechanism, the developing mechanism comprises developing cloth, the developing cloth is composed of an upper gauze piece, a lower gauze piece and a developing strip, the developing strip is located between the upper gauze piece and the lower gauze piece, and the upper gauze piece and the lower gauze piece are arranged in parallel. The developing strip is formed by weaving medical metal sheets and developing wires, a winding wire is fixedly arranged at the bottom end of the developing cloth, the pushing mechanism comprises a pipeline, the top end of the pipeline is open, the bottom of the pipeline is solid, a sleeve is fixedly arranged in the middle of the inner bottom end of the pipeline, and the inner wall of the sleeve is in an internal thread shape. The sleeve is sleeved with a screw in a threaded mode, and the top end of the screw is connected with a lifting table. The positioning developing cloth has the beneficial effects that the developing cloth is left at the uterine stump through traction of the winding wire, the designed positioning developing cloth is put into the uterine stump through the vagina, and after work is finished, the developing cloth put into the uterine stump through the vagina can be pulled out through the designed winding wire.

Owner:AFFILIATED CANCER HOSPITAL OF SHANDONG FIRST MEDICAL UNIV SHANDONG CANCER INST (SHANDONG CANCER HOSPITAL)

A kind of processing technology of leather material cutting and sewing thread

ActiveCN113005241BPlay a smoothing roleImprove flatnessLeather clicking/perforating/clickingSkins/hides/leather/fur manufacturing apparatusProcess engineeringIndustrial engineering

The invention relates to a process for processing leather trimming stitches for leather products, which uses a leather trimming stitching processing device for leather products. The leather trimming stitching processing device includes a workbench and a clamping mechanism. The workbench is installed on the existing ground, and the upper end of the workbench is provided with a clamping mechanism. The present invention adopts a multi-adjustment design concept for leather cutting and suture processing. The implementation of the clamping treatment can also smooth the leather to maintain the best flatness of the leather, thereby improving the overall cutting quality of the leather. At the same time, the rolling and smoothing structure is adopted to reduce the appearance of the structure by generating rolling friction The probability of motion jamming is reduced, and the device as a whole can also realize the conversion between the dual modes of vertically cutting leather and horizontally cutting leather, thereby greatly improving the adaptability of the device to leather cutting requirements.

Owner:江苏延立汽车零部件有限公司

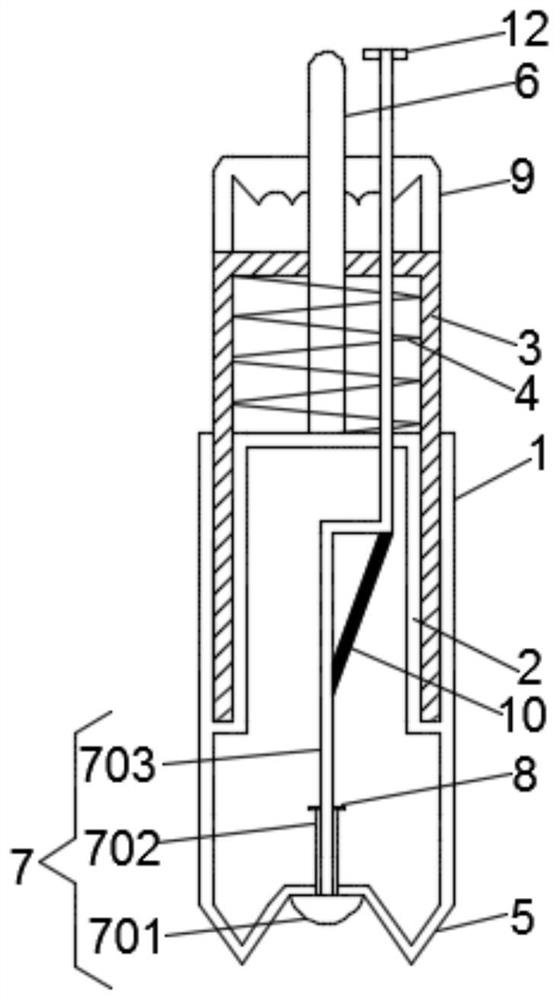

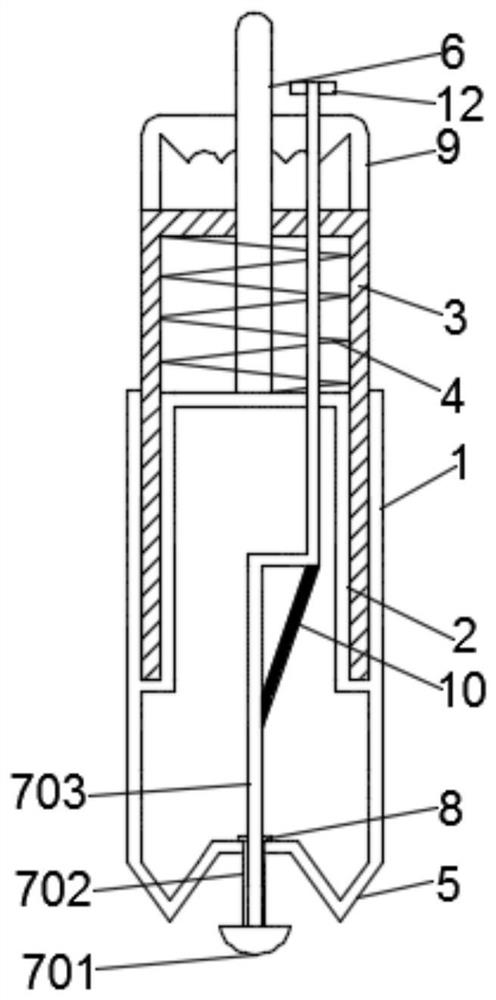

Artificial membrane rupture device for obstetrics and gynecology department

PendingCN113576629AAvoid high pressurePlay a connecting roleObstetrical instrumentsSuction devicesEngineeringApparatus instruments

The invention discloses an artificial membrane rupture device for obstetrics and gynecology department in the technical field of medical instruments, which is provided with an extending tube, an inner tube shell is fixedly connected to the inner side wall of the extending tube, a connecting cavity is formed between the extending tube and the inner tube shell, and the connecting cavity is movably connected with a first connecting tube; an extension spring is fixedly connected between the inner side of the top wall of the first connecting pipe and the outer side of the top wall of the inner pipe shell, the lower end of the extending pipe is integrally connected with a scratching edge, the scratching edge is of an annular protruding structure, a tip is formed at the protruding position, the top wall of the inner pipe shell is connected with one end of a pressing rod, and the other end of the pressing rod penetrates through the top wall of the first connecting pipe. A user stretches the stretching tube from the pudendum of a puerpera until the scratching edge is in contact with the fetal membrane, at the moment, the pressing rod is pressed to enable the scratching edge to puncture the fetal membrane. Meanwhile, the fetal membrane can be completely scratched through slight rotation, the extension spring plays a certain role in pressing the hand pressing force of the user so as to prevent the pressing force from being too large. The device can be used for quickly and safely rupturing the fetal membrane and is easy and convenient to operate.

Owner:王宇

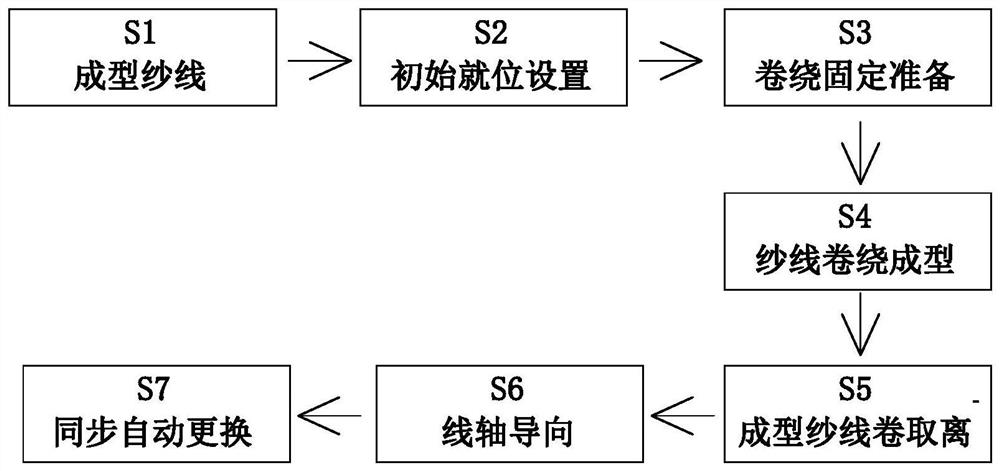

Blended yarn production process

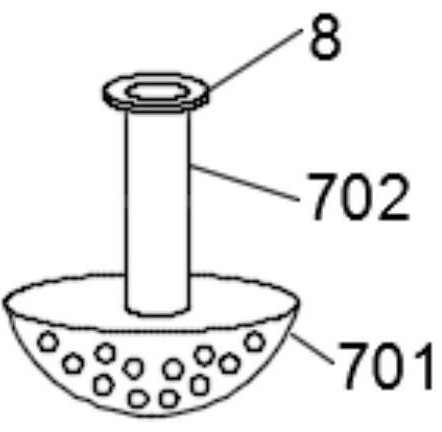

ActiveCN112813546AIncreased efficiency of form clampingRealize automatic continuous replacementYarnYarnBobbin

The invention relates to a blended yarn production process. A blended yarn production device is used, wherein the blended yarn production device comprises a replacement mechanism and a mounting mechanism; the lower end of the replacement mechanism is connected with an existing working ground; and the mounting mechanism is arranged at the left end of the replacement mechanism. Blended yarn coiling production is carried out by adopting the design concept of continuous position covering, automatic continuous replacement of a bobbin can be achieved through the arranged replacement mechanism, and then the blended yarn forming and clamping efficiency is improved on the basis that manual labor is reduced; and the bobbin can be fixed through the arranged mounting mechanism, and on the basis, the movement of the bobbin is supported and guided in each bobbin replacement process, so that the forward connection of the bobbin is ensured.

Owner:莆田市华源工贸有限公司

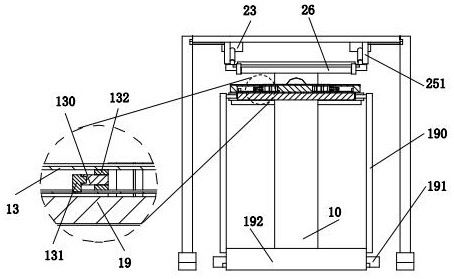

Absorption liquid storage tank for vehicle-mounted propellant waste gas treatment device

ActiveCN105151586BPlay a suppressive rolePlay anti-swing effectLarge containersGrid patternEngineering

The invention provides an absorption liquid storage tank for a vehicle-mounted propellant waste gas treatment device. An anti-swing plate and a potential energy damping device are arranged in the tank. 1. In the space formed by the horizontal anti-sway plate and the potential energy damping device floats on the liquid in the tank, the potential energy damping device can move elastically within a certain range relative to the bottom of the tank. The absorption liquid storage tank of the vehicle-mounted propellant exhaust gas treatment device of the present invention is provided with an anti-swing plate in the tank to divide the space in the tank into a grid shape, which can play a certain anti-swing effect on the liquid in the tank. The potential energy damping device floats on the liquid in the tank, and the potential energy damping device can move elastically within a certain range relative to the bottom of the tank, which can suppress the liquid to a certain extent, and the surge energy of the liquid is reduced by the potential energy Swing device absorbs, so it can play a better anti-swing effect.

Owner:北京航天凯恩新材料有限公司

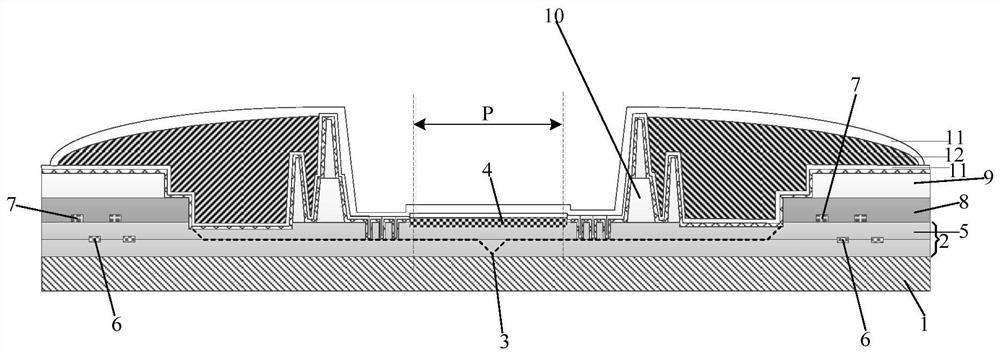

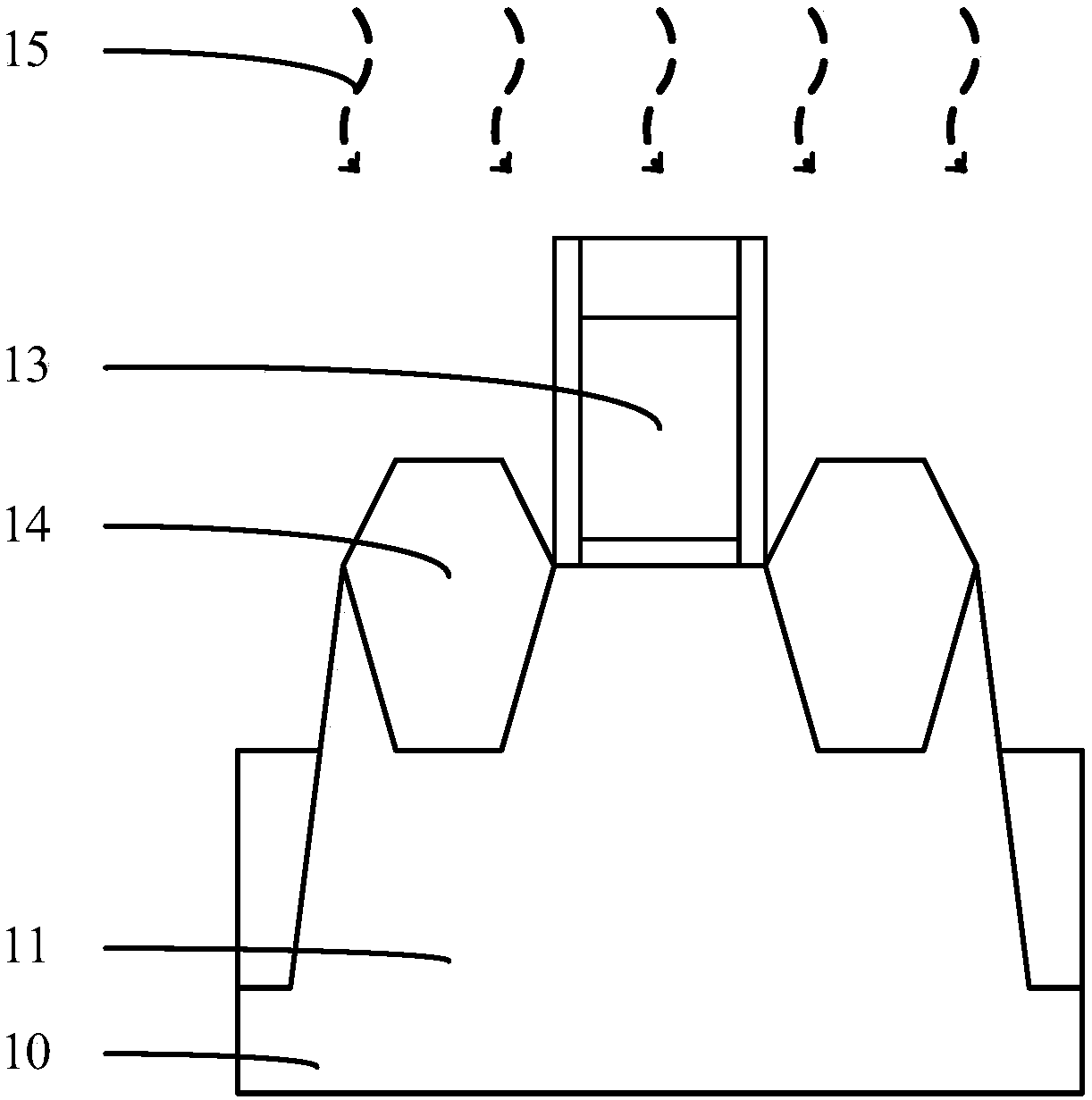

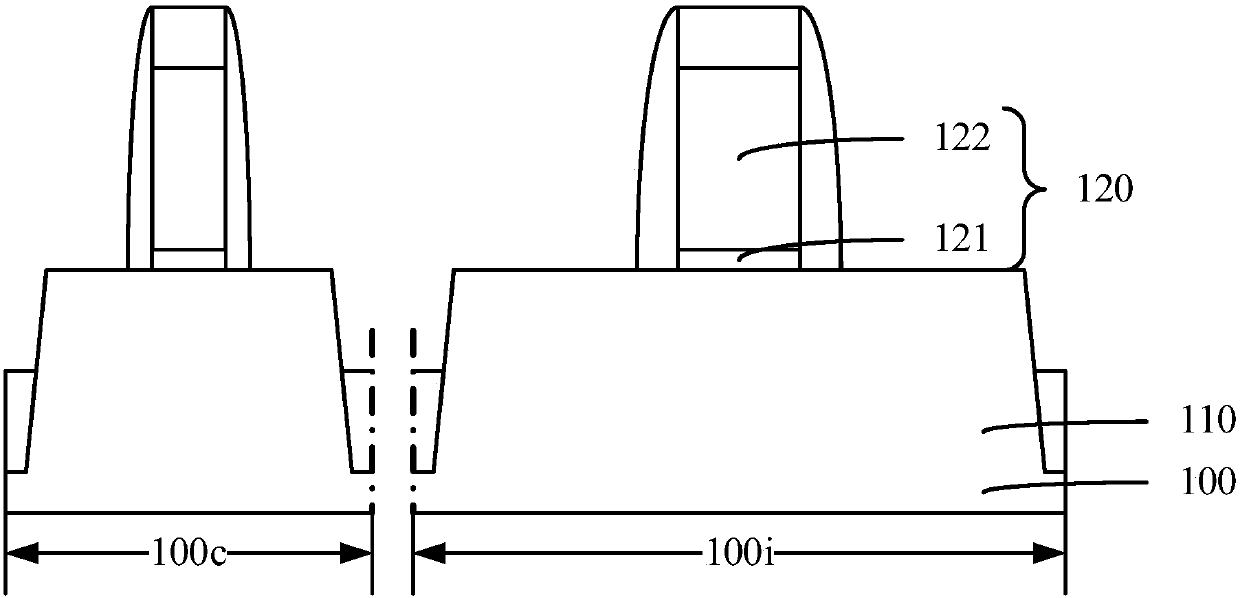

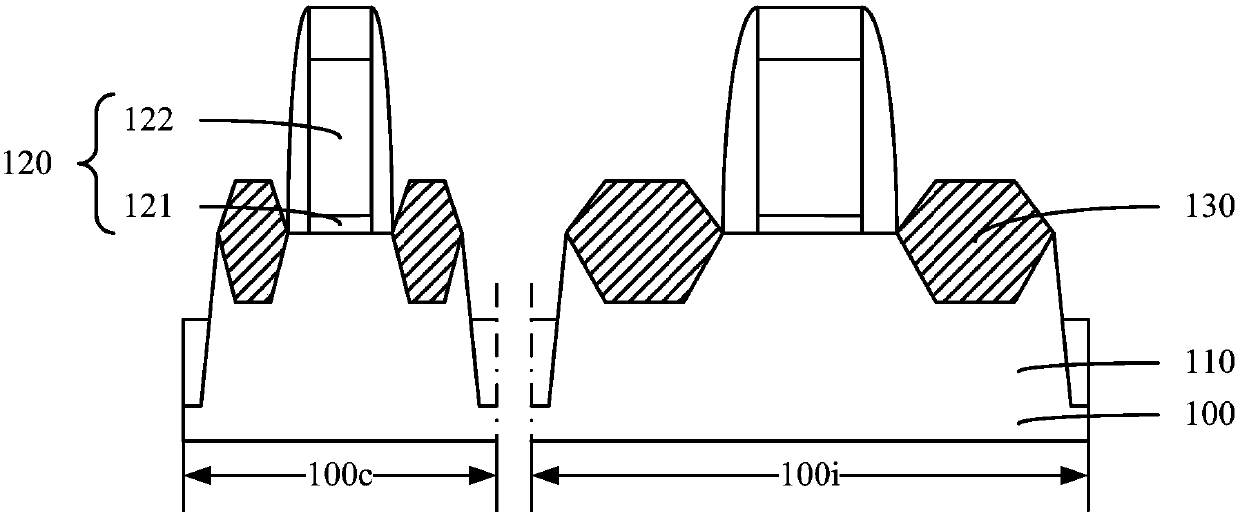

OLED display substrate and its preparation method and display device

ActiveCN110265474BAvoid damageAvoid warpingSolid-state devicesSemiconductor/solid-state device manufacturingDisplay deviceEngineering

The invention provides an OLED display substrate, a preparation method thereof, and a display device. The OLED display substrate includes a base, an inorganic layer arranged on the base and a light-emitting unit, the light-emitting unit is located on the side of the inorganic layer away from the base, the side of the base away from the inorganic layer is used for setting a camera, and the front projection area of the camera on the base is in the In the area where the light-emitting unit is located, and no light-emitting unit is retained in the orthographic projection area, the light-emitting unit includes a light-emitting structure, and in the orthographic projection area, a protective layer is provided on the side of the inorganic layer away from the substrate. The protective layer can be removed by laser cutting The light emitting structure in the area protects the inorganic layer in the area of the orthographic projection, so as to prevent the inorganic layer in the area of the orthographic projection from warping and cracking.

Owner:BOE TECH GRP CO LTD +1

A method for remediating organic pollution sites by two-way stirring and injection method

ActiveCN104624629BEliminates irritating odorsImprove the strength of the construction work surfaceContaminated soil reclamationRates reactionsDrill

The invention discloses a method for remedying an organism contaminated field by using a bidirectional stirring injection method. The method comprises the following steps: (1) flattening the contaminated field; (2) performing shallow layer ground hardening; (3) staking out in survey; (4) locating bidirectional stirring equipment in place; (5) moving a drilling rod of the bidirectional stirring equipment; (6) performing pre-stirring drilling; (7) drilling a drill rod, injecting a medicine and stirring bidirectionally, namely, injecting the medicine through an inner tube of a conveying pipeline, injecting a mixed solution of a catalyst and a buffer agent from a pipeline between the inner tube and the outer tube of the conveying pipeline, and mixing and stirring the medicine, the catalyst, the buffer agent and soil at the bottom of the conveying pipeline; (8) lifting up the drill rod through opposite stirring; and (9) moving the drill rod to a next pile site, and repeating the step (5) to (8) until the soil in all pile sites is remedied. By adopting the method, the loss of ground mixed medicines can be reduced, the reaction velocity and the reaction time can be effectively controlled, the problem that grout spills out and turns up from the ground surface can be effectively solved, and the remediation efficiency can be improved.

Owner:SOUTHEAST UNIV +2

A kind of manufacturing method of glazed tile and its product

ActiveCN104130032BIncrease high temperature viscosityAvoid dischargeTextile printerSpray Granulation

Owner:FOSHAN DONGPENG CERAMIC +2

A kind of blended yarn production process

ActiveCN112813546BIncreased efficiency of form clampingRealize automatic continuous replacementYarnYarnProcess engineering

The invention relates to a blended yarn production process, which uses a blended yarn production device. The blended yarn production device includes a replacement mechanism and an installation mechanism. The lower end of the replacement mechanism is connected to the existing working ground, and the replacement mechanism The left end is provided with an installation mechanism, the present invention adopts the design concept of continuous replenishment to produce the blended yarn into rolls, and the set replacement mechanism can realize the automatic and continuous replacement of the spool, thereby improving the forming of the blended yarn on the basis of reducing manual labor. Clamping efficiency, the installed installation mechanism can fix the spool, and on this basis, support and guide the movement of the spool during each spool replacement process, thereby ensuring the positive connection of the spool.

Owner:莆田市华源工贸有限公司

A method of using plant coils to restore vegetation on high and steep slopes

The invention discloses a method for restoring vegetation on high and steep slopes by using plant coils. The operation steps include: 1) cleaning the slope; 2) construction of anchor rods; 3) hanging nets; 4) laying plant coils; ) secondary hanging net; 6) fixed; 7) watering and maintenance. The invention can effectively maintain the stability of the slope matrix, has strong erosion resistance of the matrix, simple construction technology, convenient management and maintenance in the later stage, can effectively seal the slope surface, and prevent the slope surface from weathering and peeling off.

Owner:SICHUAN UNIV

A meat product sauce brushing device based on food processing and its application method

ActiveCN110803492BApply evenlyImprove uniformityLoading/unloadingConveyor partsProcess engineeringConveyor belt

The invention discloses a sauce brushing device for meat products based on food processing and a using method thereof, belonging to the field of food processing. The sauce is introduced into the material pipe, and the sauce is evenly introduced to the belt roller through multiple leakage holes at the bottom of the material delivery pipe, and the belt roller and the brush roller are connected by transmission mechanism, and the material on the belt roller is realized in the transmission. The sauce is transmitted to the brush roller, and the brush roller evenly smears the sauce on the meat products on the conveyor belt during the continuous rotation process. Compared with the traditional method of manually brushing or using a rotating ordinary sauce brush Brushing the sauce, the sauce of the present invention is applied more continuously and evenly, and at the same time, it also plays a role in suppressing the meat products in the process of brushing the sauce, and a puncture device is installed at the front end of the brushing roller to realize the puncturing of the conveyed meat products. A certain puncture can further effectively improve the uniformity and permeability of the subsequent sauce coating.

Owner:四川张飞牛肉有限公司

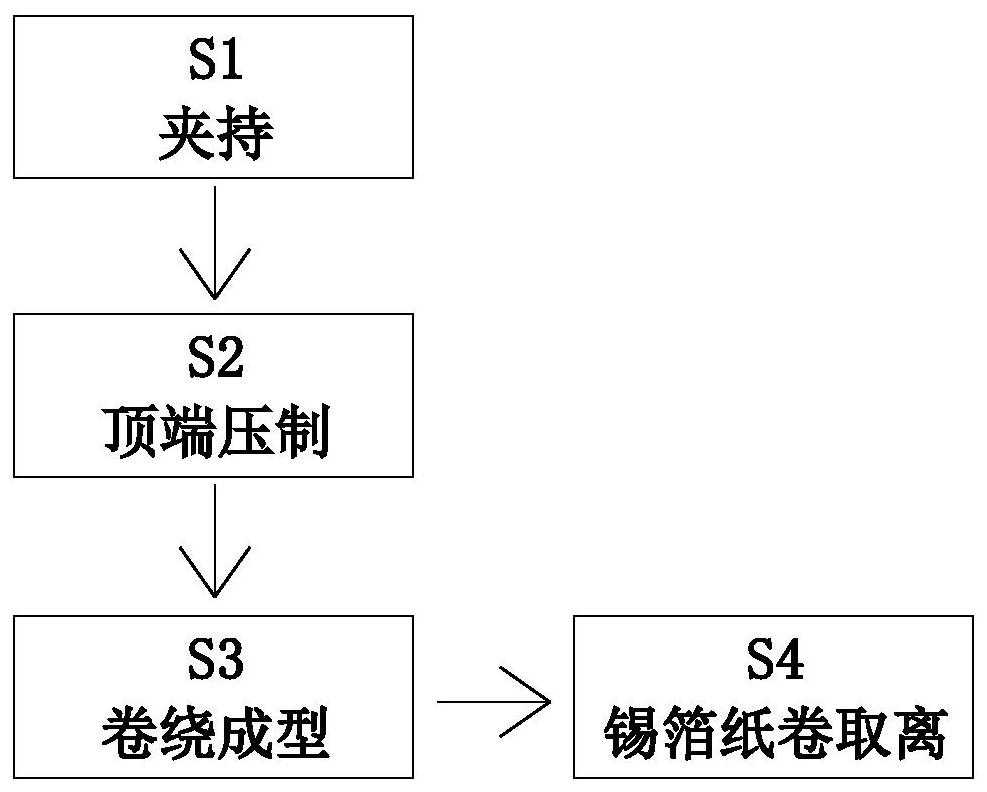

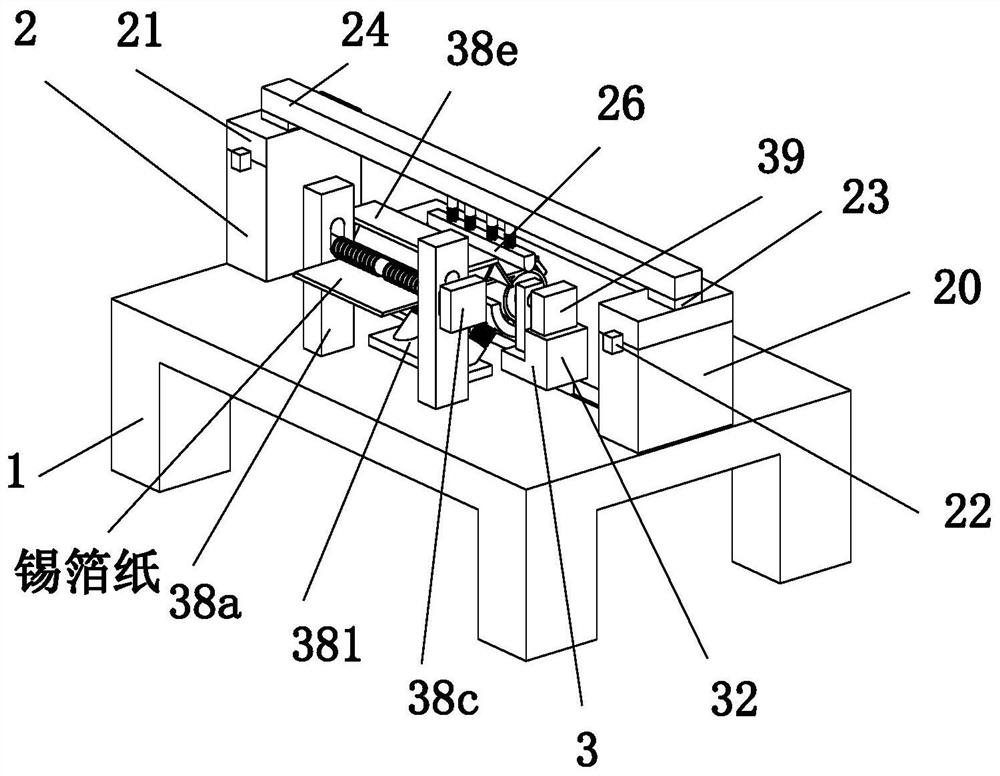

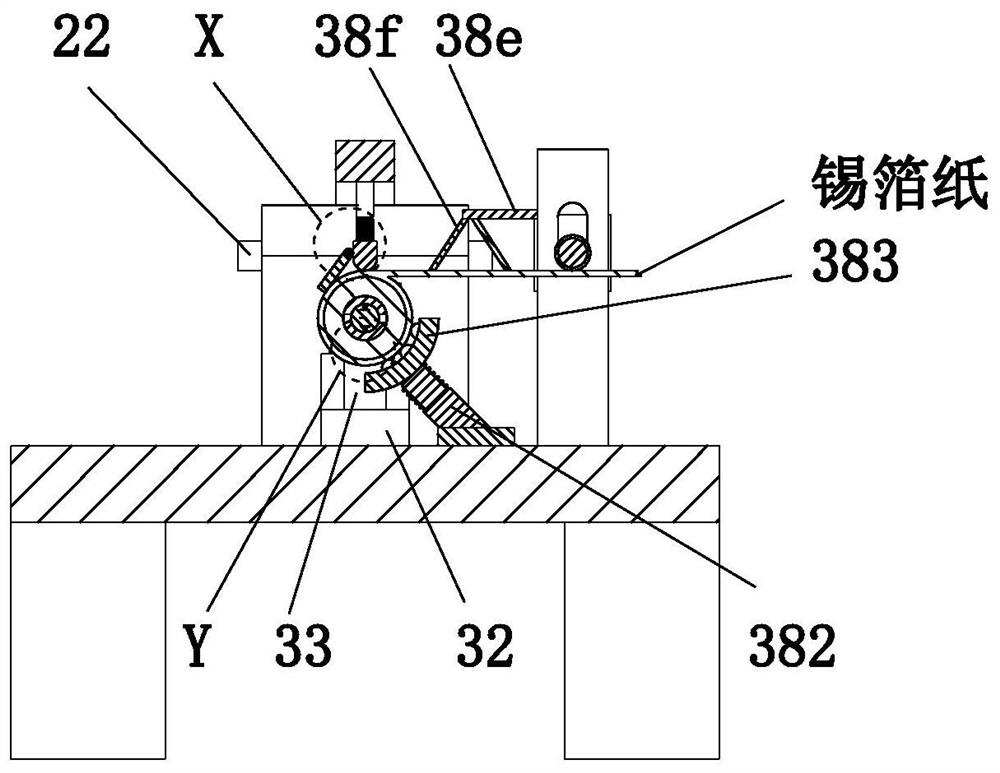

A manufacturing process for heat-resistant tinfoil rolls

The invention relates to a temperature-resistant tin foil paper roll production and manufacturing process. According to the production and manufacturing process, a temperature-resistant tin foil paperroll production and manufacturing device is adopted, the temperature-resistant tin foil paper roll production and manufacturing device comprises a workbench, a pressing mechanism and a clamping and rotating mechanism, wherein the pressing mechanism is installed in the middle of the upper end of the workbench, the clamping and rotating mechanism is arranged on the inner side of the pressing mechanism, and the lower end of the clamping and rotating mechanism is installed at the upper end of the workbench in sliding fit mode. According to the production and manufacturing process, temperature-resistant tin foil paper rolls are produced and manufactured according to the design concept of multiple adjustable pressing structures, and a plurality of structures with limiting and fixing functions are additionally arranged on the basis of the pressing mechanism with the top end pressing function, so that clinging degree between tin foil paper and a roll core and the tin foil paper is improved, the forming rate of the tin foil paper roll which is tight inside and loose outside is increased, and the clamping and rotating mechanism can be adaptively changed according to the radial size of the roll core to be clamped and fixed.

Owner:湖北夷盟包装材料有限公司

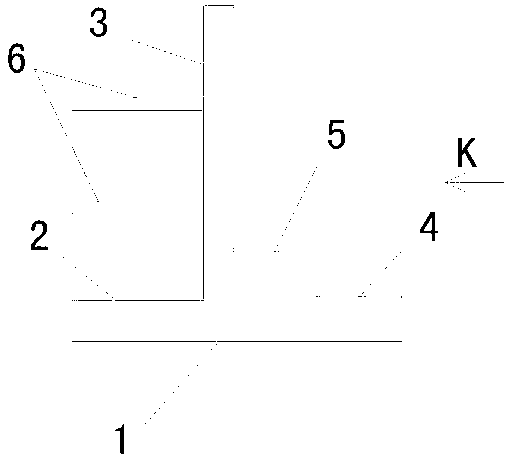

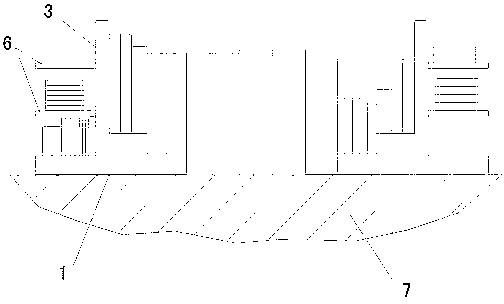

Semiconductor structure forming method

ActiveCN107785267AInhibition of stress reliefInhibition of contractionSemiconductor/solid-state device manufacturingSemiconductor devicesIonEXPOSE

A semiconductor structure forming method comprises steps: a substrate is formed; a pseudo gate structure is formed; a stress layer is formed; a source and drain doping area is formed; an interlayer dielectric layer is formed; an opening is formed, and the bottom part of the opening exposes an oxidation layer; first annealing processing is carried out to activate doped ions in the source and draindoping area; and during the first annealing processing process, the oxidation layer at the bottom part of the opening is restored. In the technical scheme of the invention, as the interlayer dielectric layer covers the stress layer, the interlayer dielectric layer can thus play a suppression role on the stress layer, the possibility of a melting phenomenon happening to the stress layer during thefirst annealing processing process can be reduced, stress release of the stress layer during the first annealing processing process is suppressed, and contraction of the stress layer during the firstannealing processing process is suppressed. The first annealing processing can activate doped ions in the source and drain doping area and can also restore the exposed oxidation layer, a heating process during the semiconductor structure forming process can thus be reduced, and the performance of the formed semiconductor structure is improved.

Owner:SEMICON MFG INT (SHANGHAI) CORP +1

A kind of polymer hydrogel fire extinguishing agent

ActiveCN108992828BImprove fire extinguishing effectPlay a suppressive roleFire extinguisherSodium bicarbonateEngineering

The invention discloses a polymer hydrogel fire extinguishing agent, which belongs to the technical field of fire safety. According to parts by weight, the present invention comprises 20-30 parts of modified chitosan liquid, 10-20 parts of starch, 10-20 parts of bacterial cellulose, 8-10 parts of sodium bicarbonate, 8-10 parts of carbomer, 10-20 parts of water, 8-10 parts of konjac mannose, 8-10 parts of pretreated aluminum nitride whiskers, 8-10 parts of phospholipids, 8-10 parts of protein powder and 8-10 parts of modified gelatin powder Stir and mix for 30-50 minutes in a mixer at a rotational speed of 600-800 r / min to obtain a polymer hydrogel fire extinguishing agent. The polymer hydrogel fire extinguishing agent provided by the invention has excellent fire extinguishing performance.

Owner:山东水击环保科技有限公司

Combined clamping type bookshelf

InactiveCN102987755ASimple structurePlay a suppressive roleBook cabinetsBook-troughsTransverse planeEngineering

Owner:DALIAN BOCON SCI & TECH

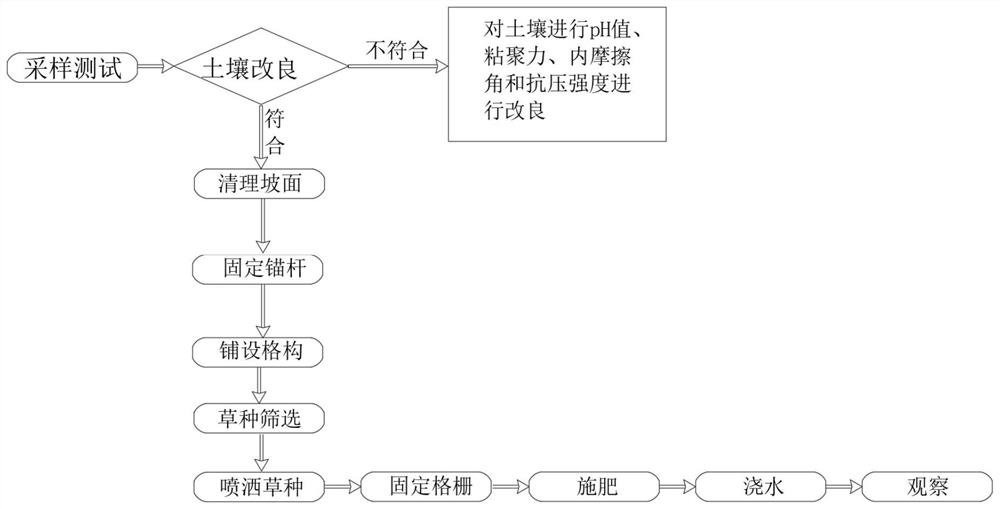

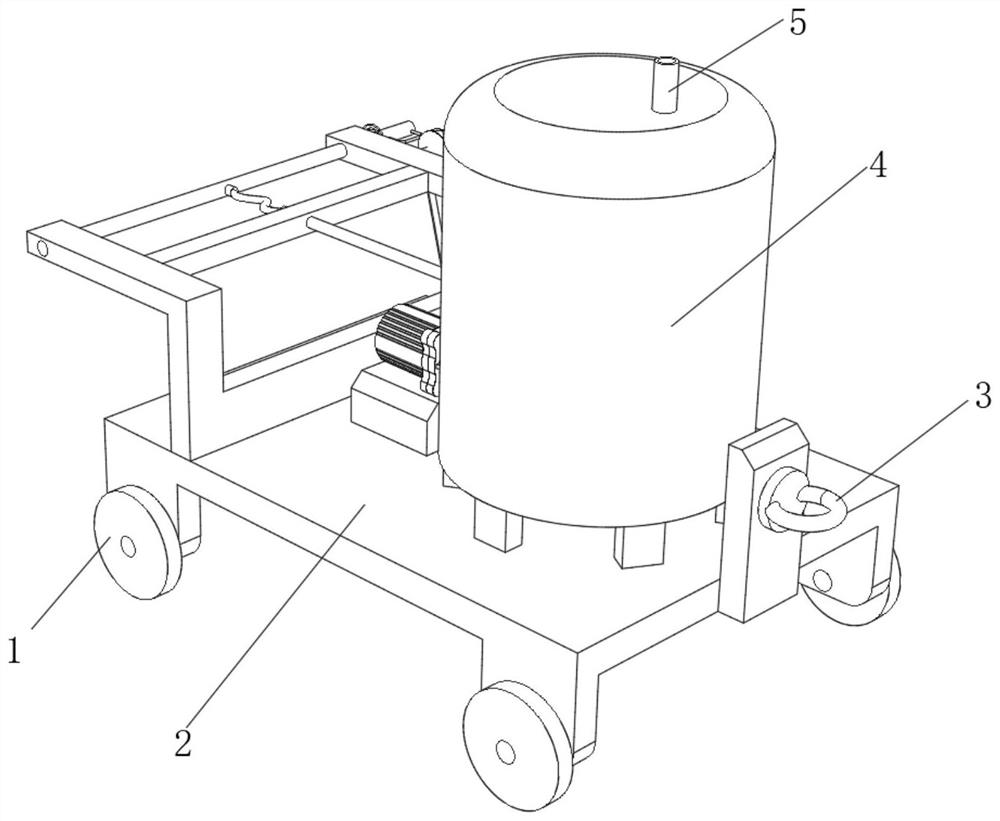

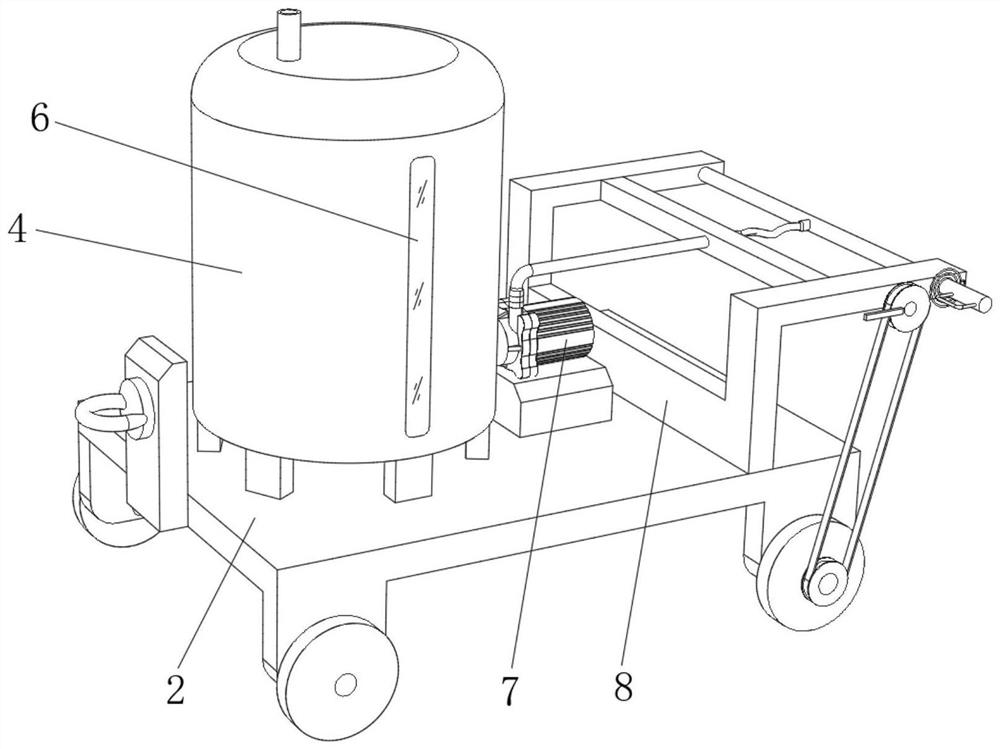

Method for promoting ecological restoration of side slope through manual intervention

PendingCN114793770APromote ecological restorationImprove cohesionGrassland seedingPlantingEnvironmental resource managementEdaphic

The invention relates to the field of ecological restoration, and discloses a method for promoting slope ecological restoration through manual intervention, which comprises the following steps: S1, sampling and testing: sampling slope soil by using a sampling device, carrying out flowerpot experiment on the slope soil, and carrying out pH value test, compressive strength test, cohesive force test and internal friction angle test, S2, improving soil, and after the test is completed, carrying out artificial intervention on the slope soil to promote slope ecological restoration. The results of the pH value, the compressive strength, the cohesive force and the internal friction angle of the slope soil are obtained and calculated, and whether planting standards are met or not is detected. According to the method, the integrity of soil can be improved, the solid-phase bonding force among particles can be greatly improved, the cohesive force of the soil is improved, the internal friction angle is increased, the mechanical property of the soil is improved, the planting effect of the soil is improved, the slope can be conveniently fastened, soil loss is prevented, and the stability of the slope is improved; and the planting effect of the slope surface can be further improved.

Owner:STATE GRID FUJIAN ELECTRIC POWER RES INST +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com