A meat product sauce brushing device based on food processing and its application method

A technology for food processing and meat products, which is applied in the field of sauce brushing devices for meat products based on food processing, which can solve the problems of low operation efficiency, inability to brush sauce, missed brushing, etc., and achieve the goal of achieving continuity, improving uniformity and permeability Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

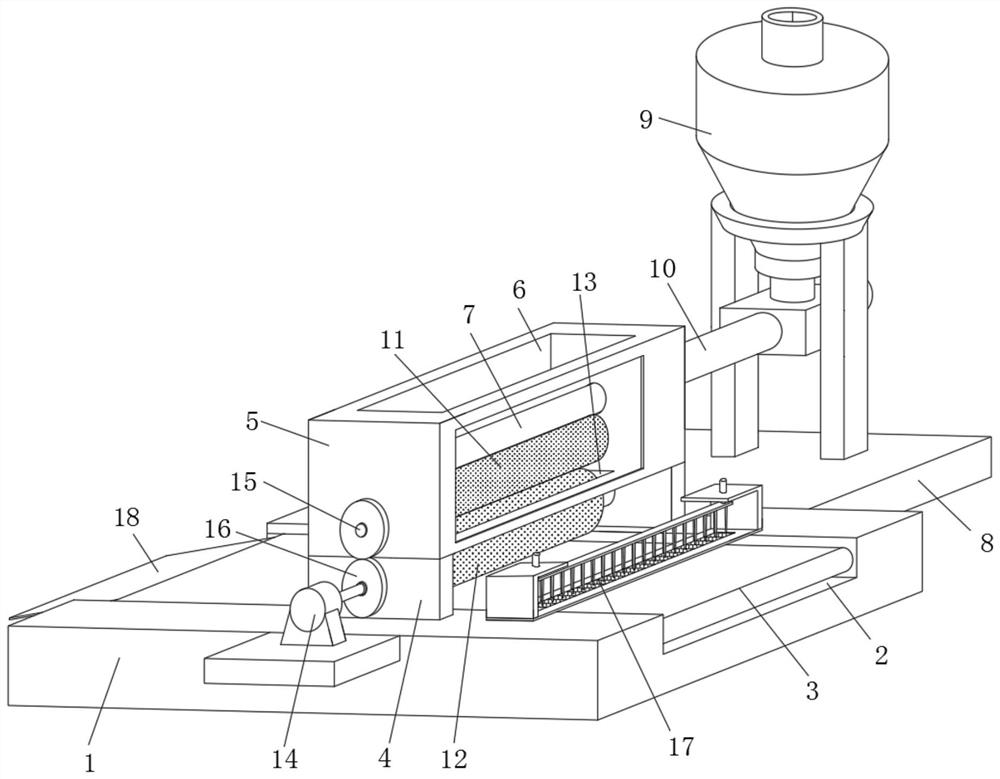

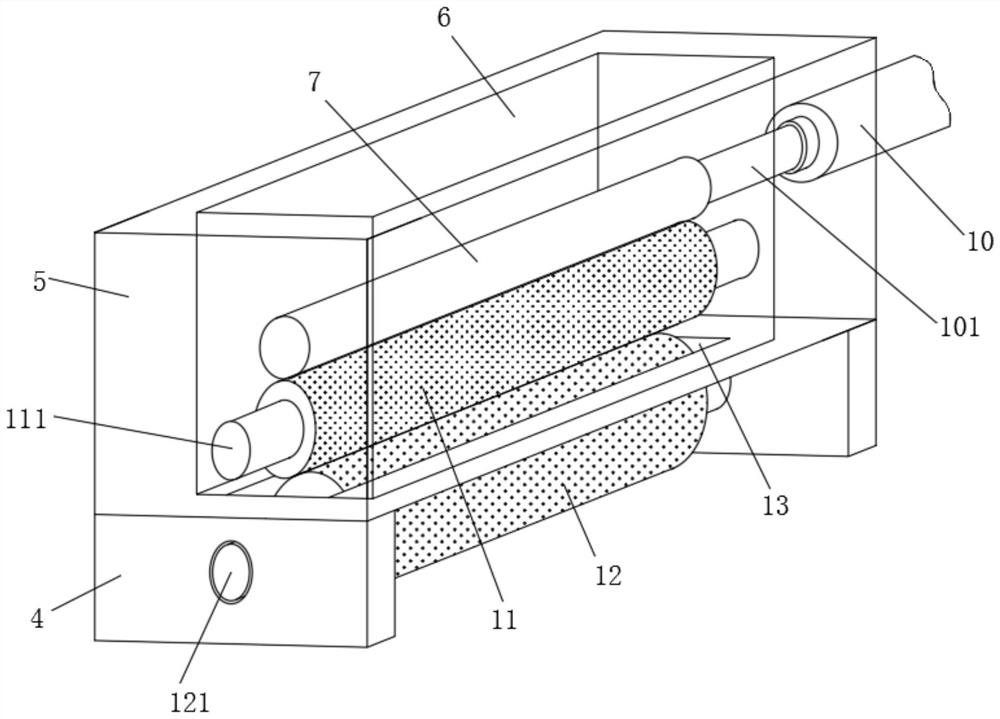

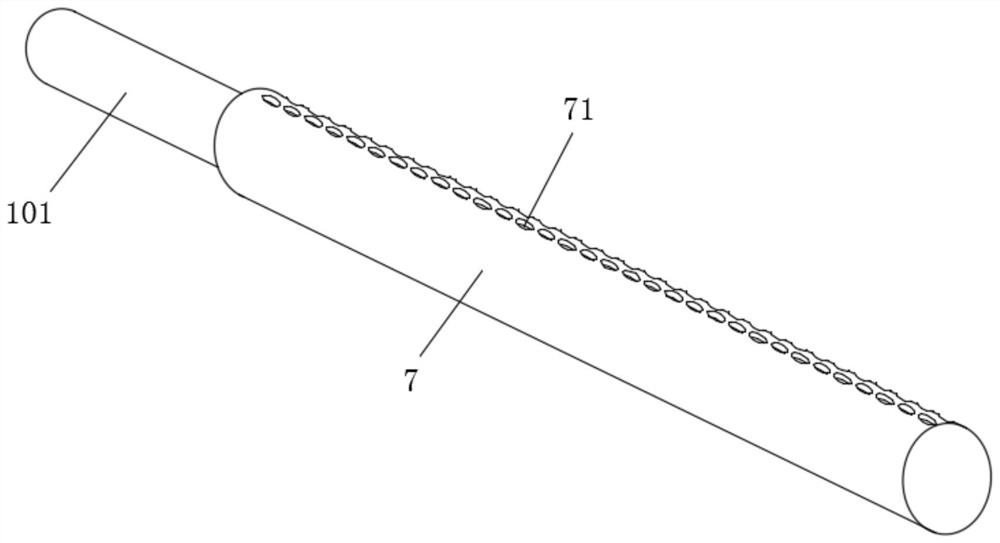

[0044] See Figure 1-3 A food-processed meat product brush sauce device, including the transfer station 1 and the brush sauce bin 5 fixed to the upper end of the transport table 1 and the sauce can 9 fixed to the upper end of the transport table 1, the transport station 1 A transport chamber 2 is provided in the upper end, and a conveying strip 3 is mounted in the conveying chamber 2, the conveyor belt 3 is used to transmit the meat products of the sauce, and both sides of the lower end of the brush box 5 are fixed through the support plate 4 in the conveying table 1. On both sides of the upper end, the inside of the brush sauce tank 5 is provided with an operation chamber 6, and the operation chamber 6 is fixed to the side wall of the upper end is fixedly mounted with a pumping tube 7 in which the sauce can 9 is connected, and the sauce introduction in the sauce can 9 is introduced. Subsequent brush sauce operation is performed within the pump 7.

[0045] On one side of the transm...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com