Patents

Literature

33results about How to "Realize reverse drive" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Vibrator of beam type linear ultrasonic motor using bending vibration modes

ActiveCN101626203AImprove mechanical output capabilityImprove performancePiezoelectric/electrostriction/magnetostriction machinesEngineeringControl theory

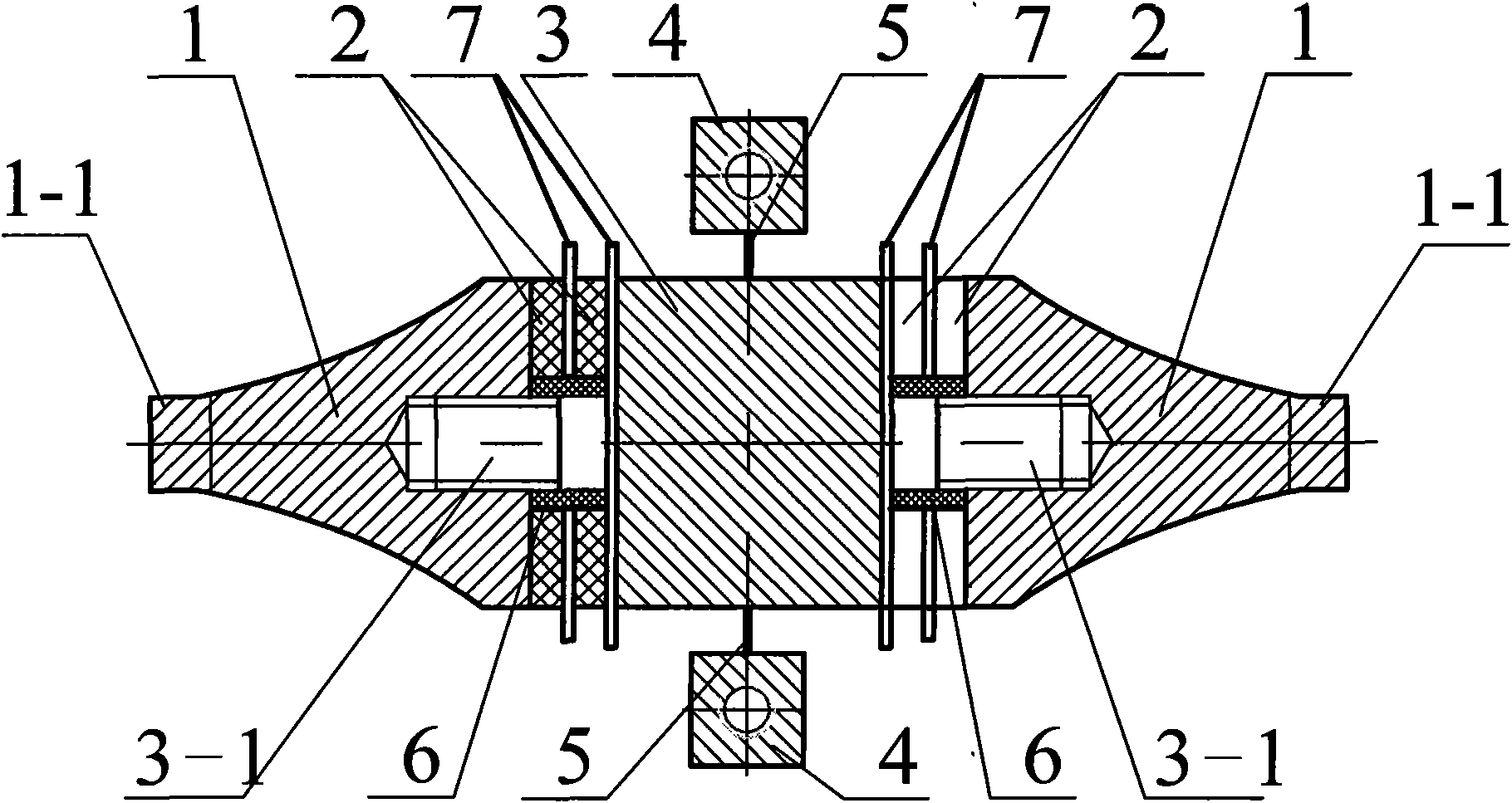

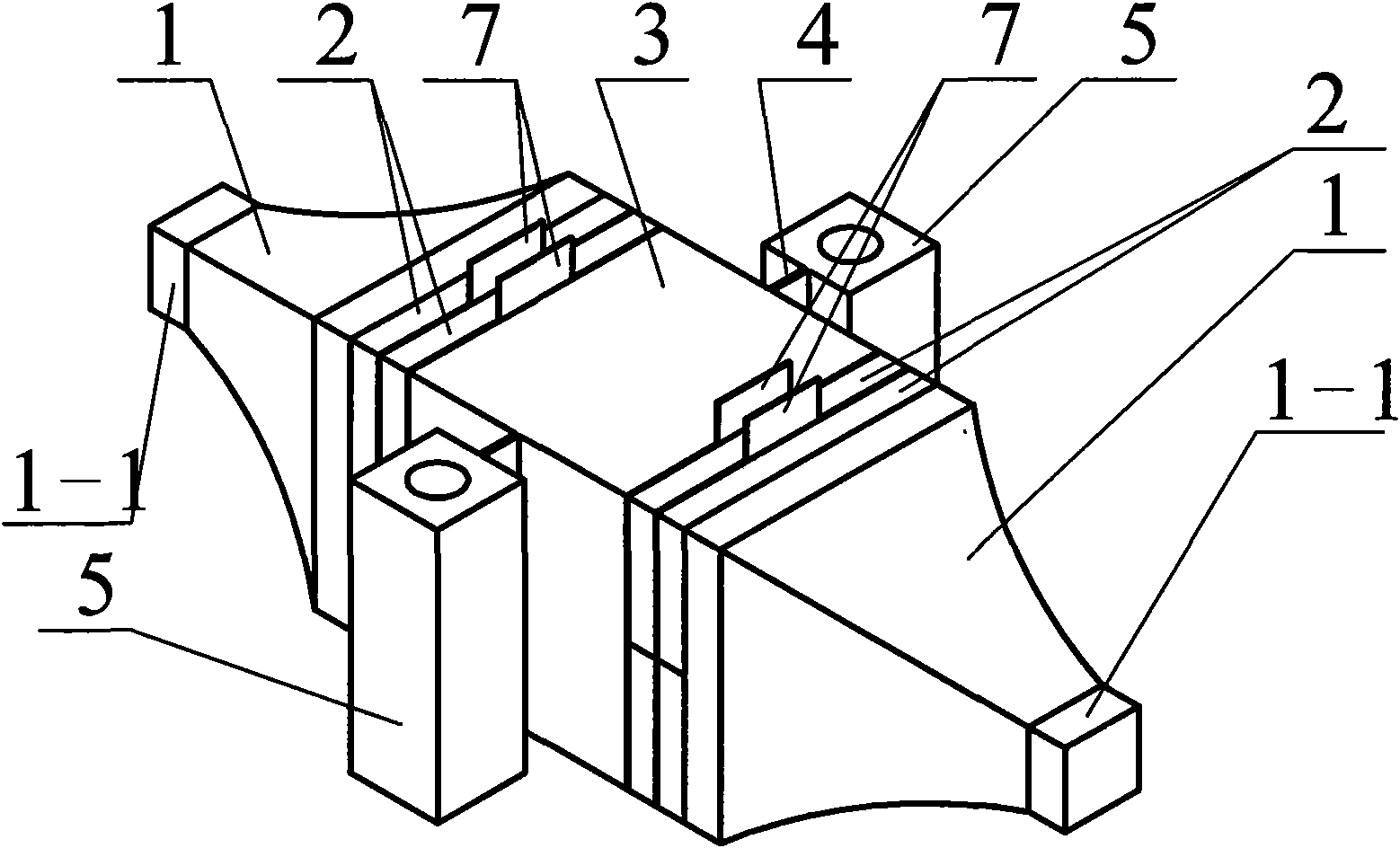

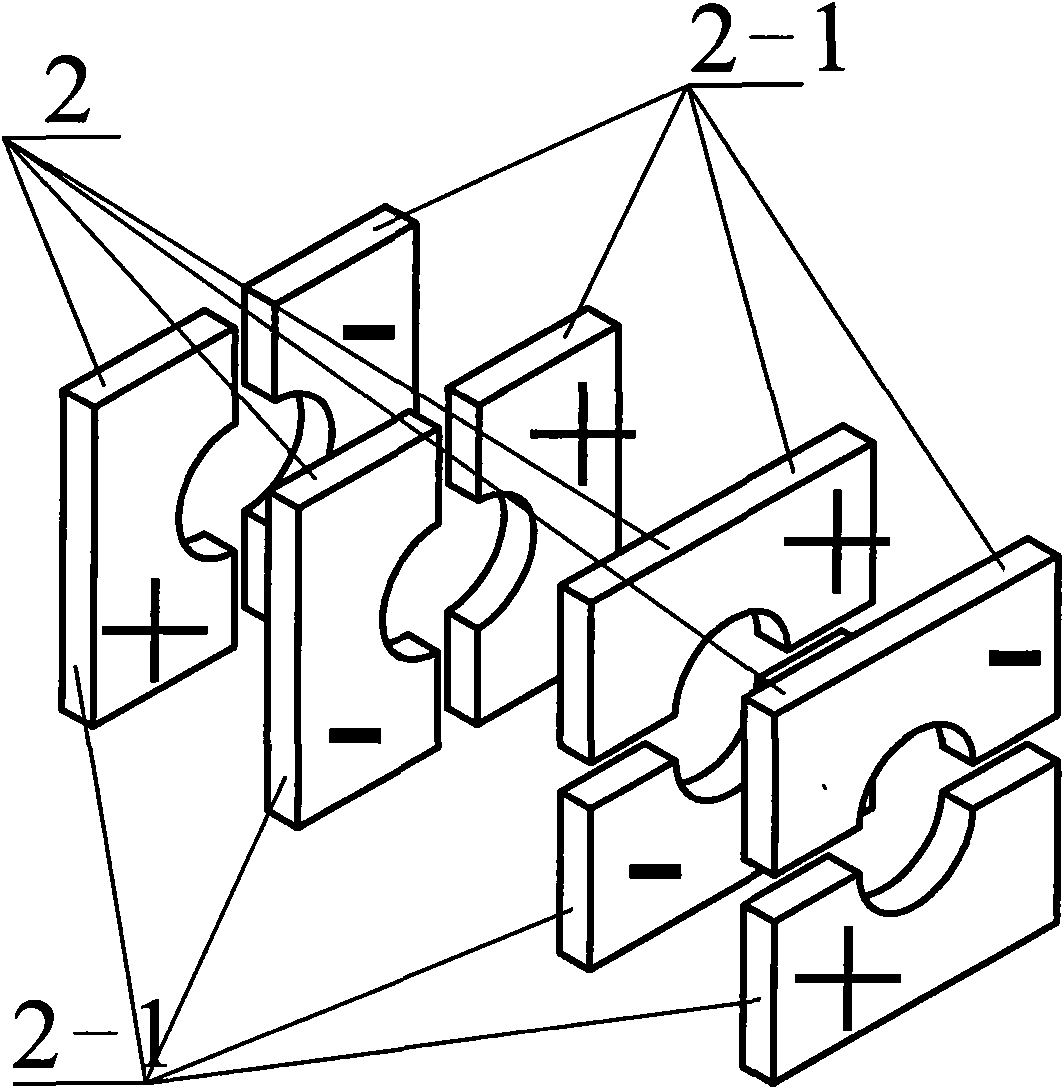

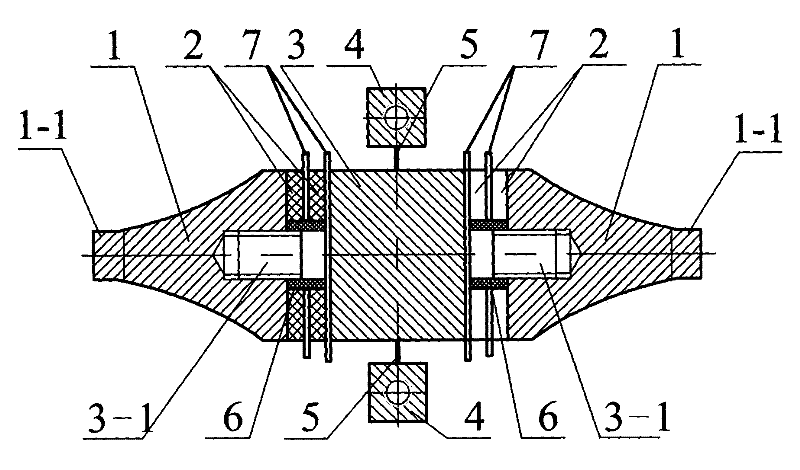

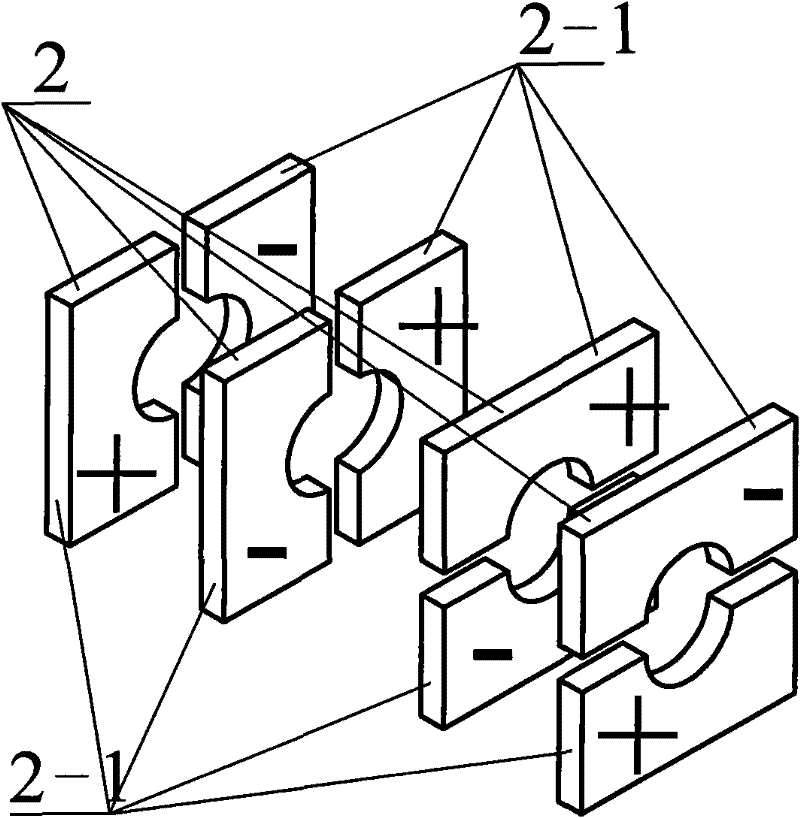

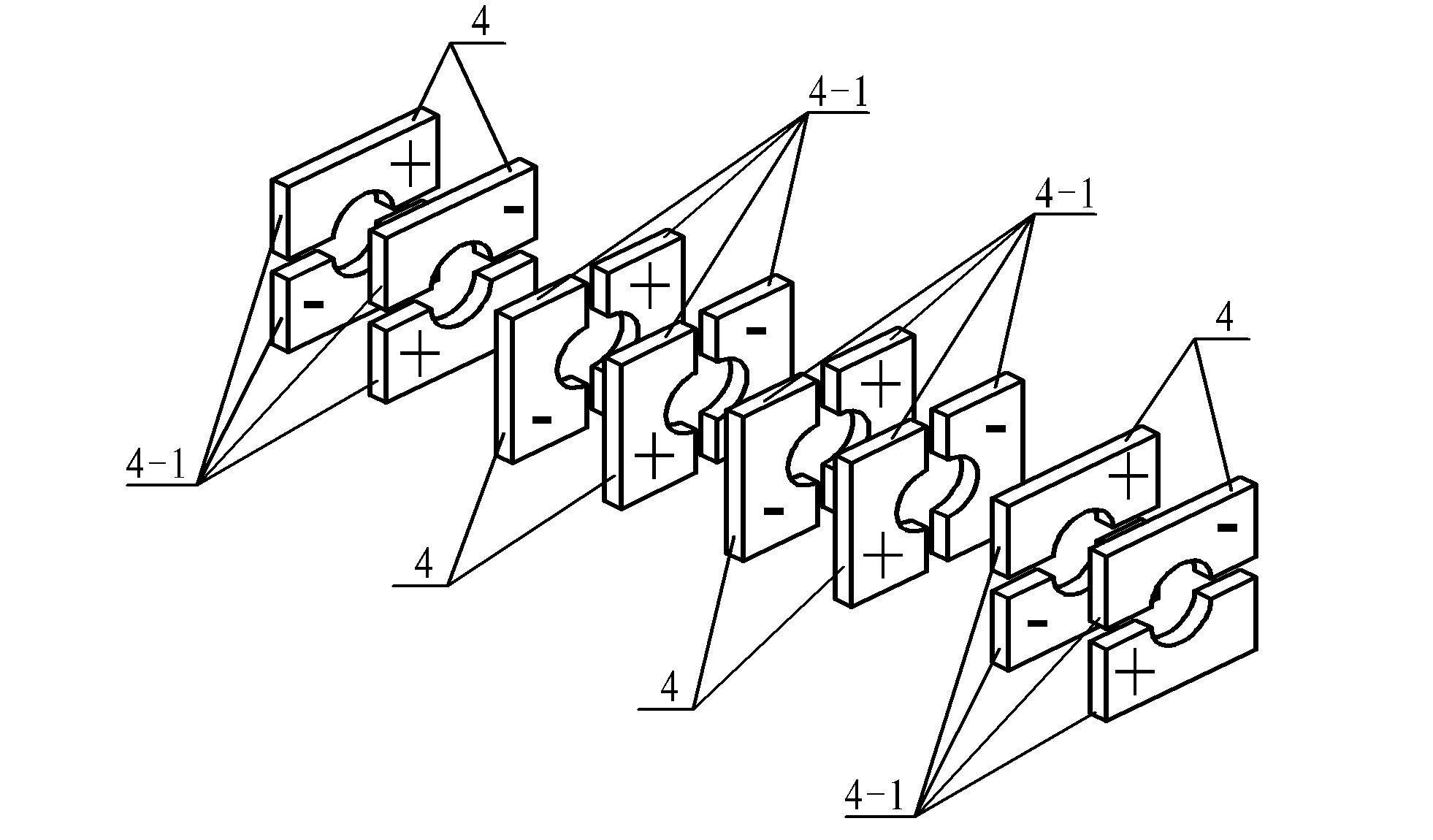

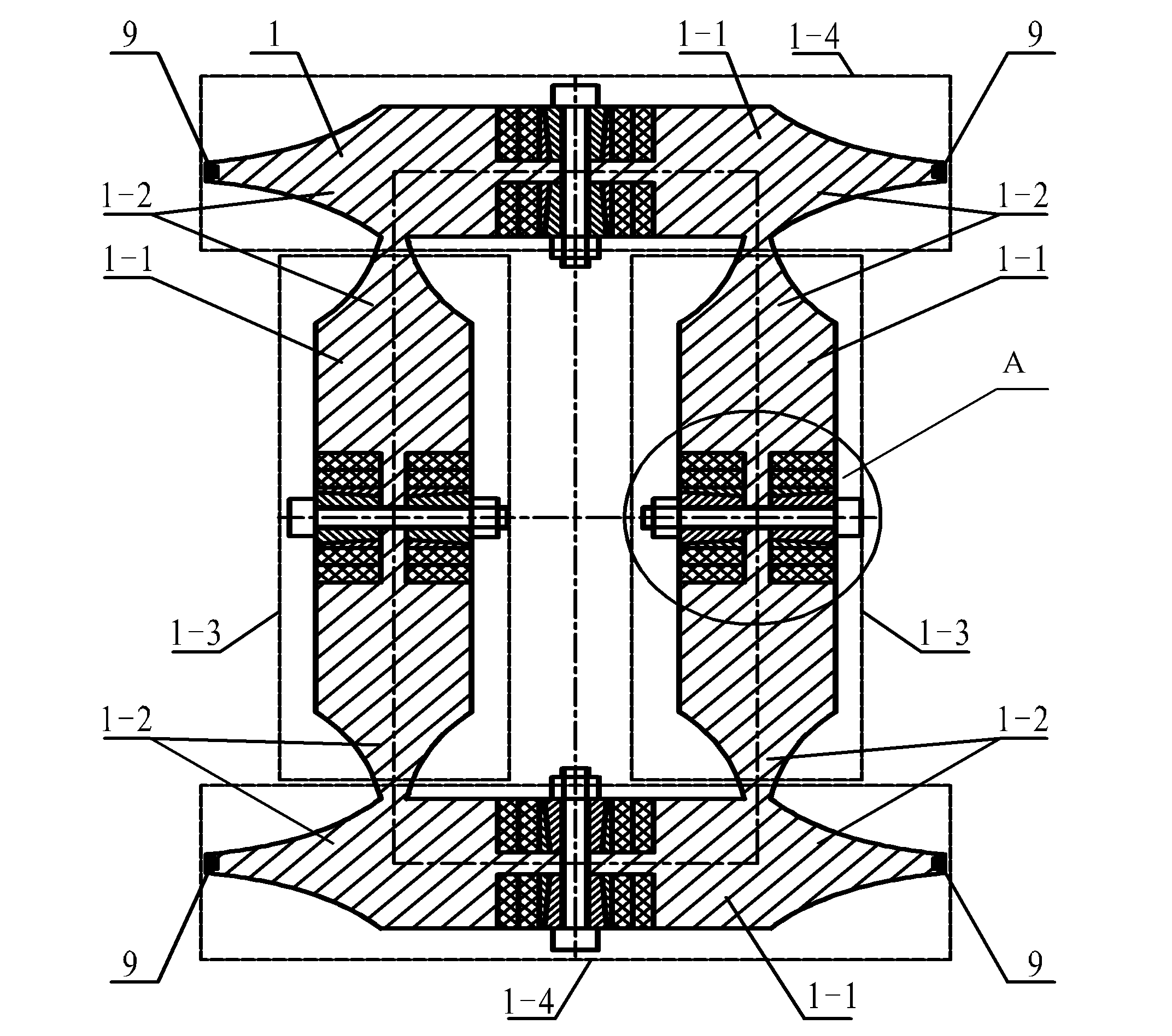

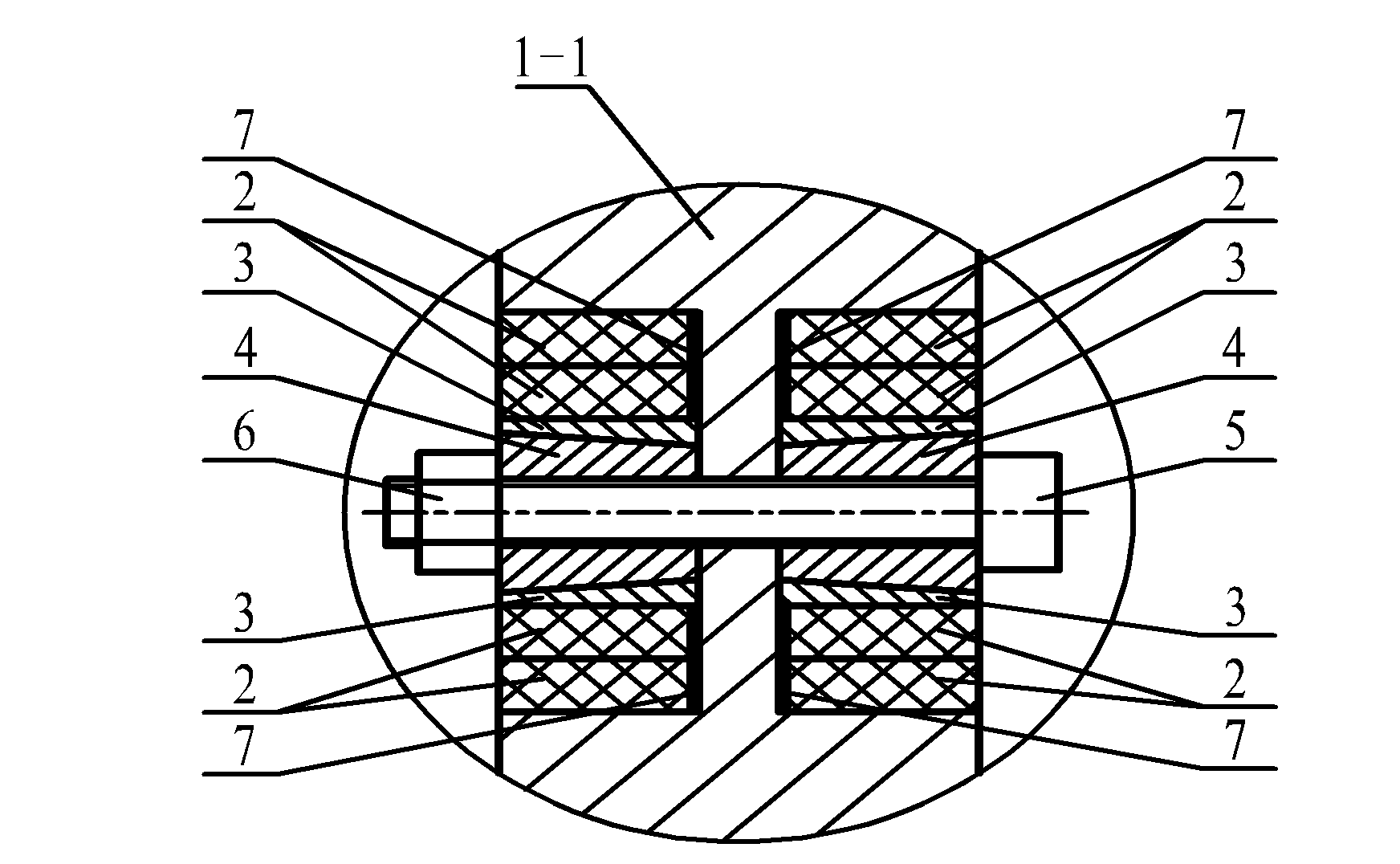

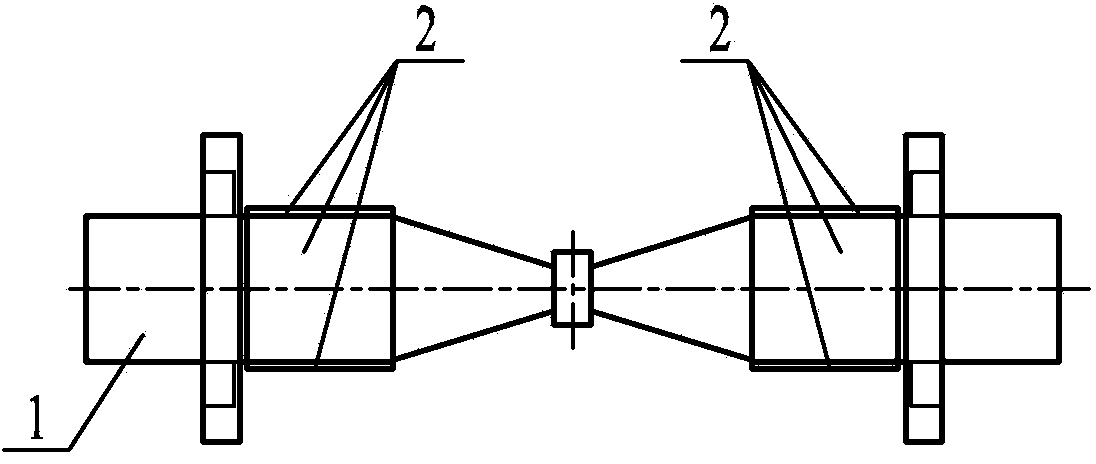

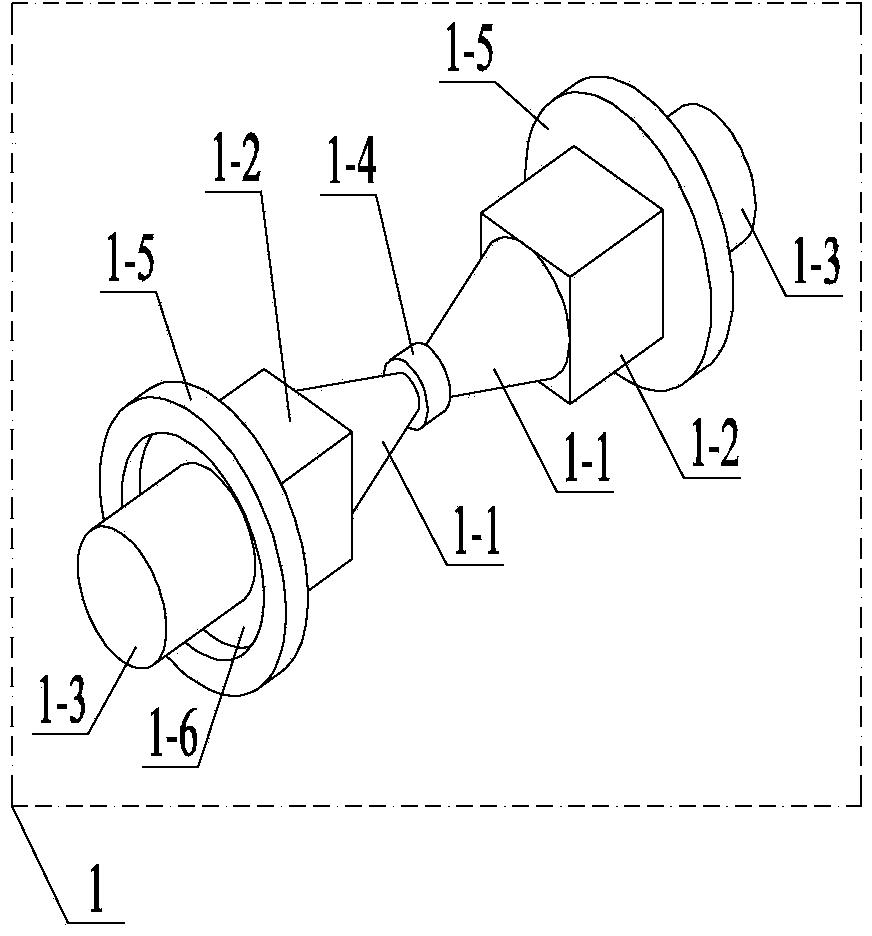

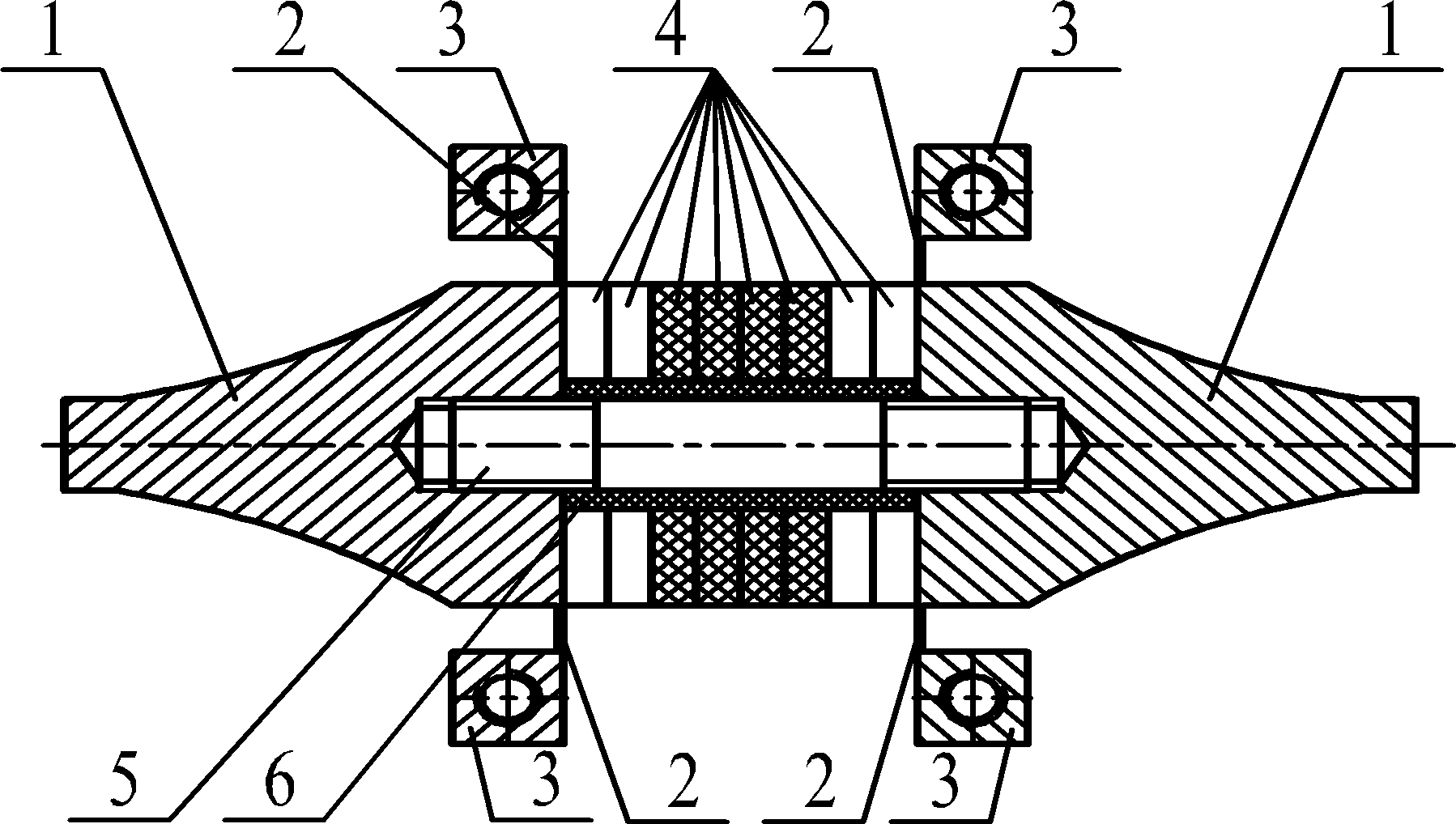

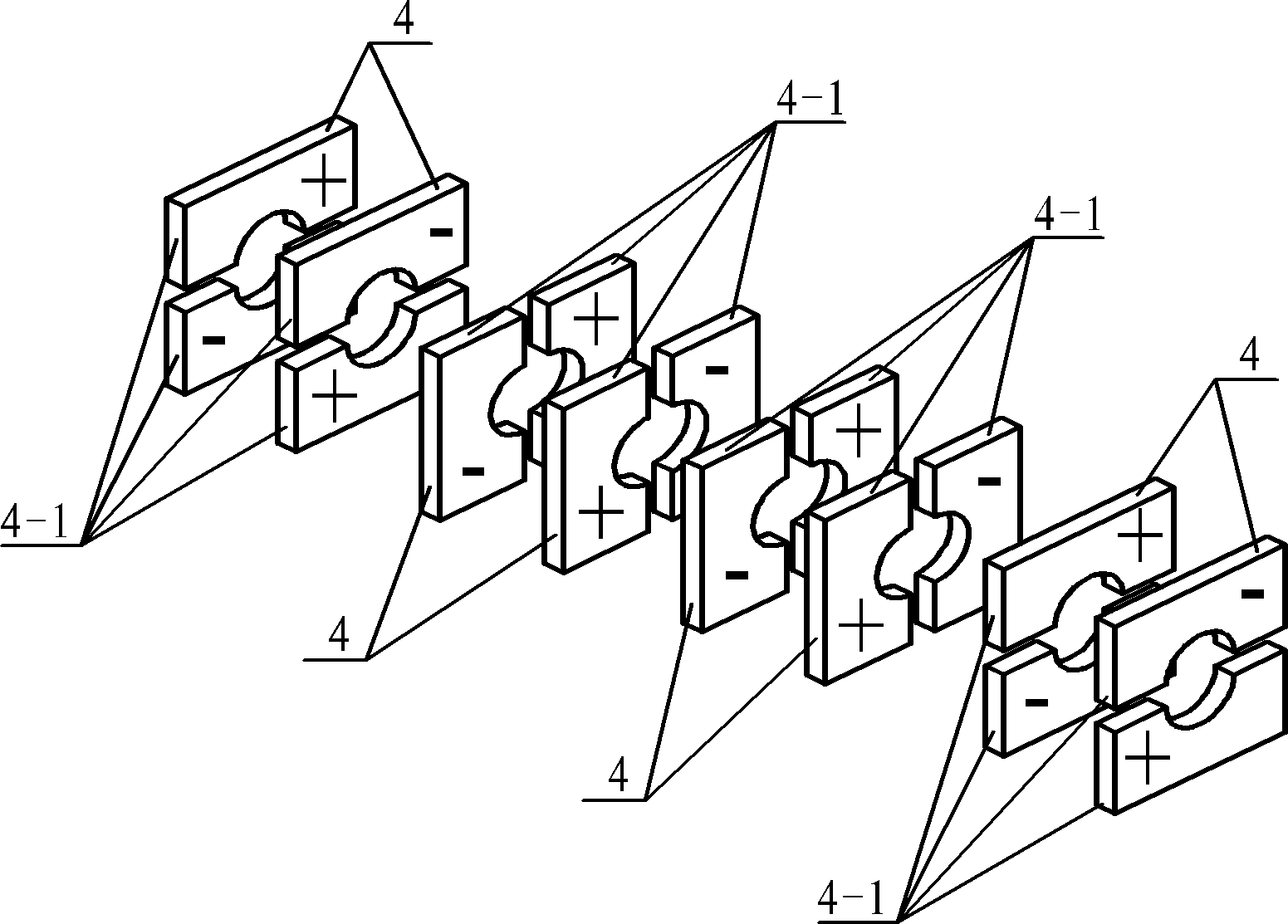

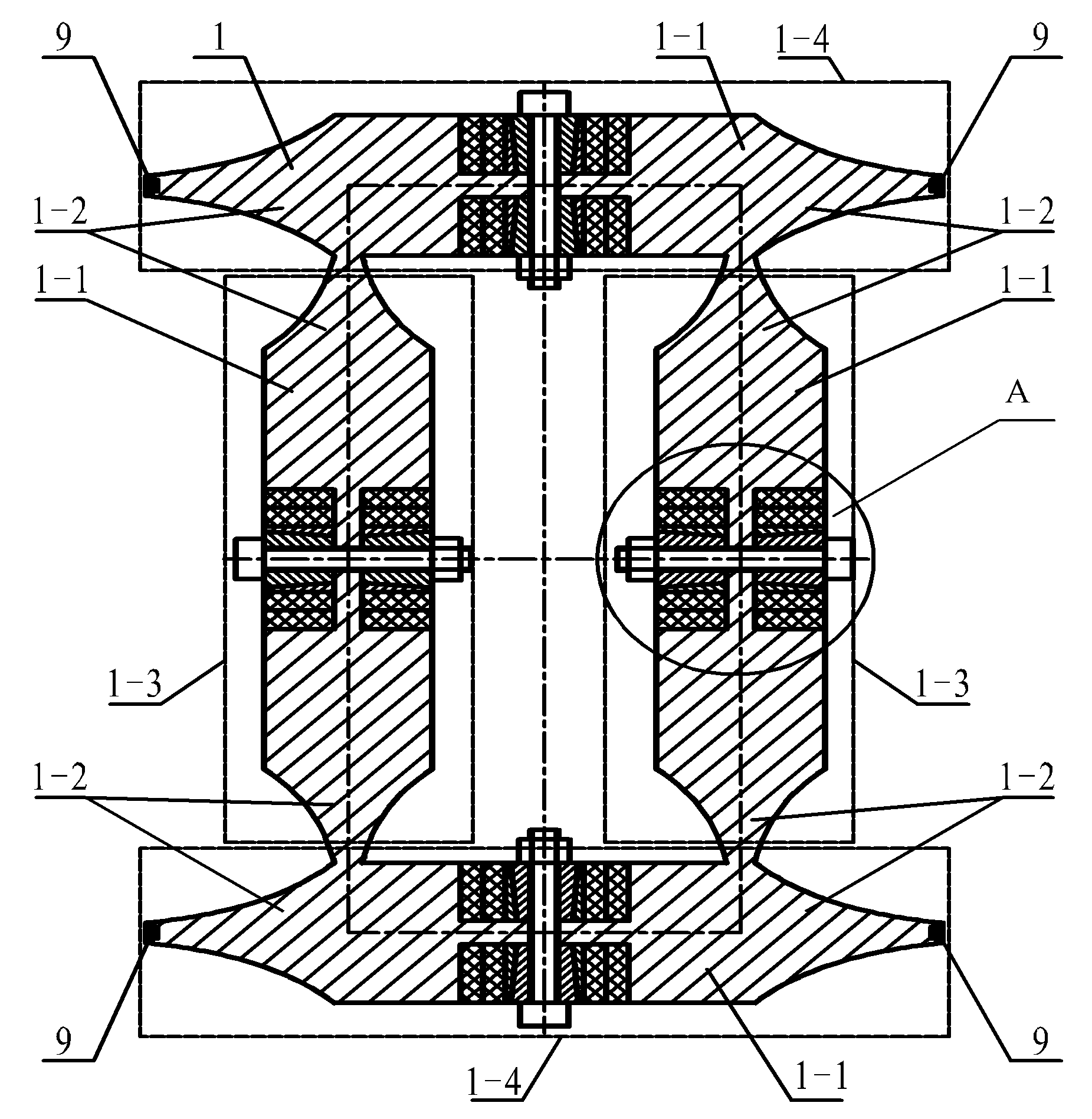

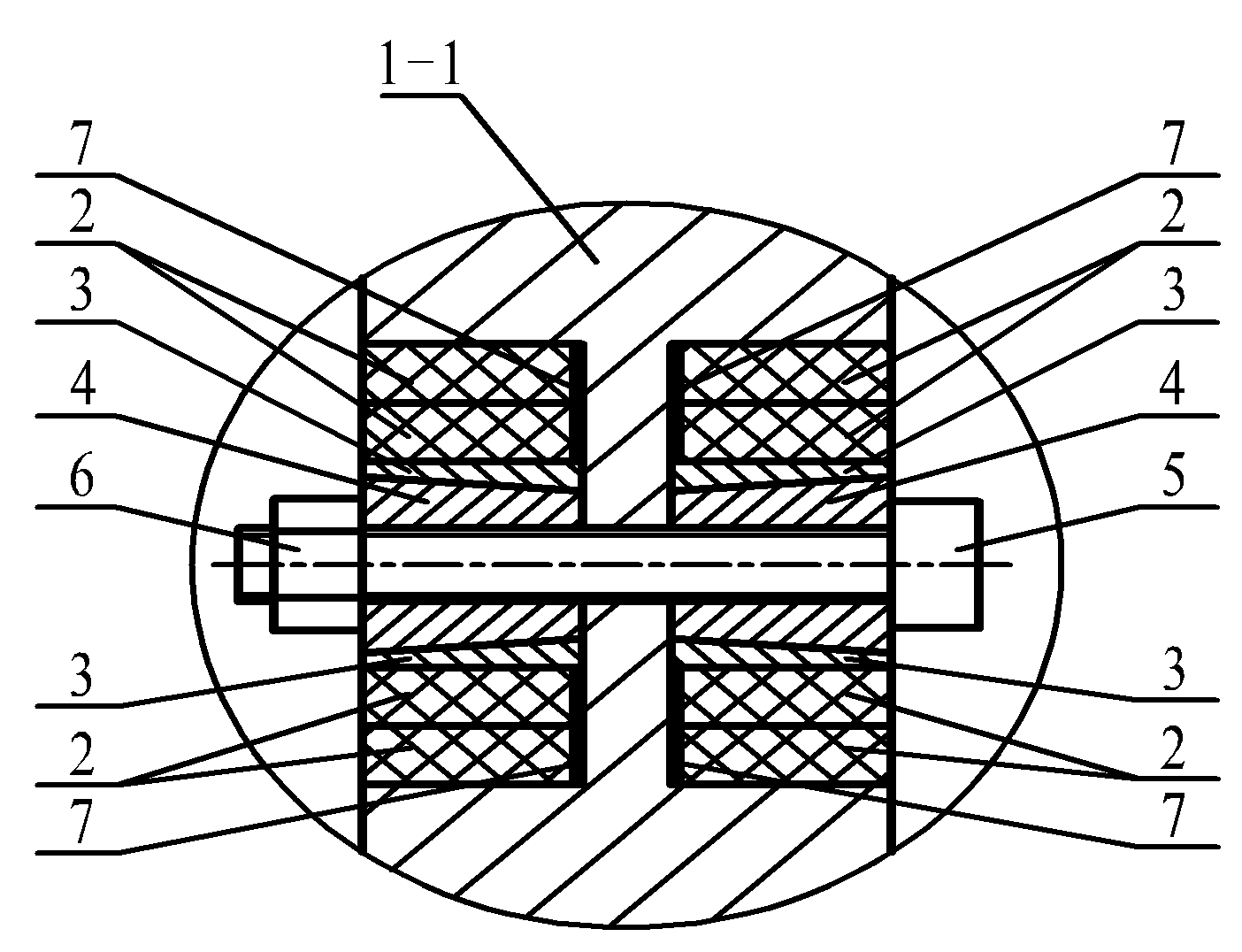

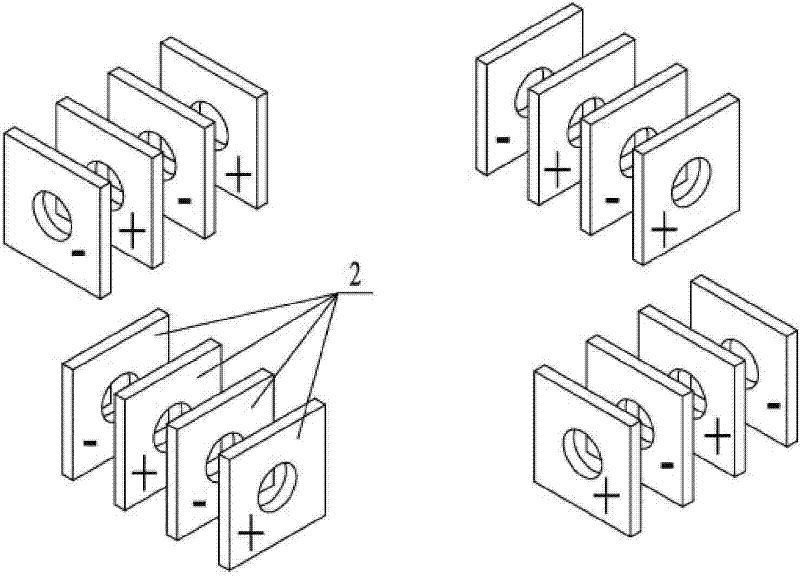

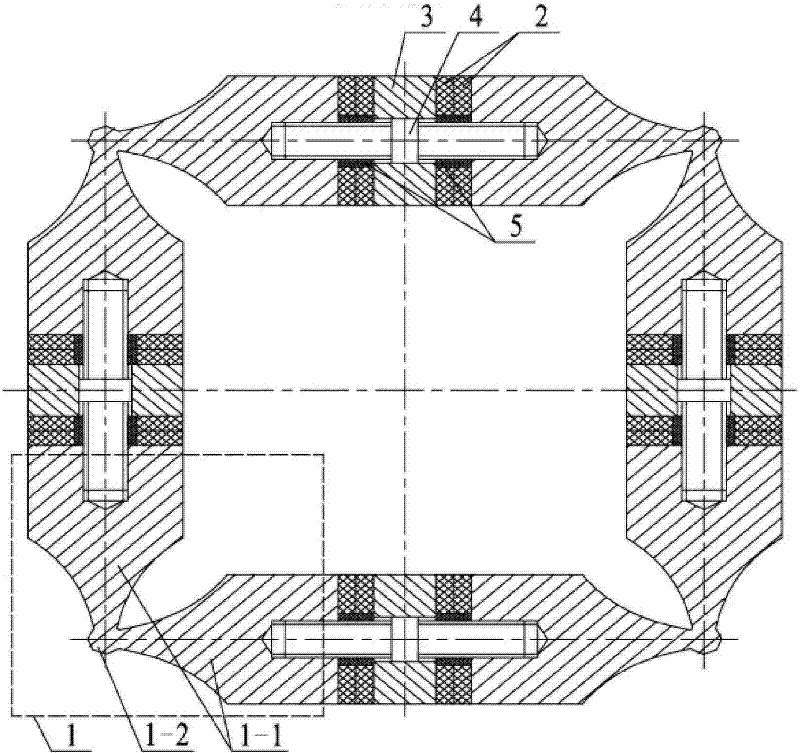

A vibrator of a beam type linear ultrasonic motor using bending vibration modes belongs to the technical field of piezoelectric ultrasonic motors and is used for the piezoelectric ultrasonic motors. The vibrator solves the problem that the mechanical output capabilities of the ultrasonic motors are restricted because of low tensile strength and low electromechanical coupling efficiency of ceramic materials in the prior art. The vibrator comprises two driving pads, two end covers, two insulating sleeves, two pairs of piezoelectric ceramics with polarization directions being thickness directions, a flange, two thin-walled beams and mounting bases; wherein, studs extend out from the end faces of the flange along the axis of the flange; each stud is sleeved with a pair of piezoelectric ceramics; an end cover is screwed at the overhanging end of each stud; the tail end of each end cover is provided with a driving pad; each piezoelectric ceramic is composed of two symmetrical half piezoelectric ceramics which are combined after being split; the polarization directions of the two half piezoelectric ceramics are opposite; the splitting lines of the two pairs of piezoelectric ceramics at both sides of the flange are vertical to each other; the polarization directions of the piezoelectric ceramics in each pair are opposite.

Owner:HARBIN INST OF TECH

Vibrator of beam type linear ultrasonic motor using bending vibration modes

ActiveCN101626203BImprove mechanical output capabilityImprove performancePiezoelectric/electrostriction/magnetostriction machinesElectric machineryEngineering

A vibrator of a beam type linear ultrasonic motor using bending vibration modes belongs to the technical field of piezoelectric ultrasonic motors and is used for the piezoelectric ultrasonic motors. The vibrator solves the problem that the mechanical output capabilities of the ultrasonic motors are restricted because of low tensile strength and low electromechanical coupling efficiency of ceramicmaterials in the prior art. The vibrator comprises two driving pads, two end covers, two insulating sleeves, two pairs of piezoelectric ceramics with polarization directions being thickness directions, a flange, two thin-walled beams and mounting bases; wherein, studs extend out from the end faces of the flange along the axis of the flange; each stud is sleeved with a pair of piezoelectric ceramics; an end cover is screwed at the overhanging end of each stud; the tail end of each end cover is provided with a driving pad; each piezoelectric ceramic is composed of two symmetrical half piezoelectric ceramics which are combined after being split; the polarization directions of the two half piezoelectric ceramics are opposite; the splitting lines of the two pairs of piezoelectric ceramics at both sides of the flange are vertical to each other; the polarization directions of the piezoelectric ceramics in each pair are opposite.

Owner:HARBIN INST OF TECH

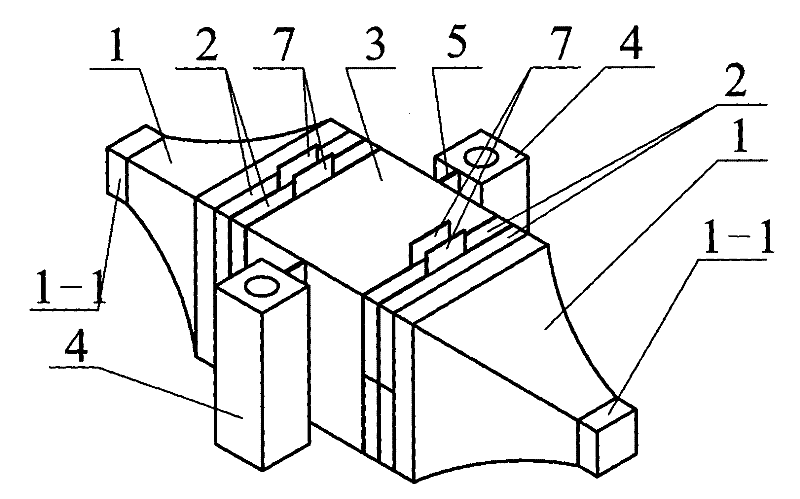

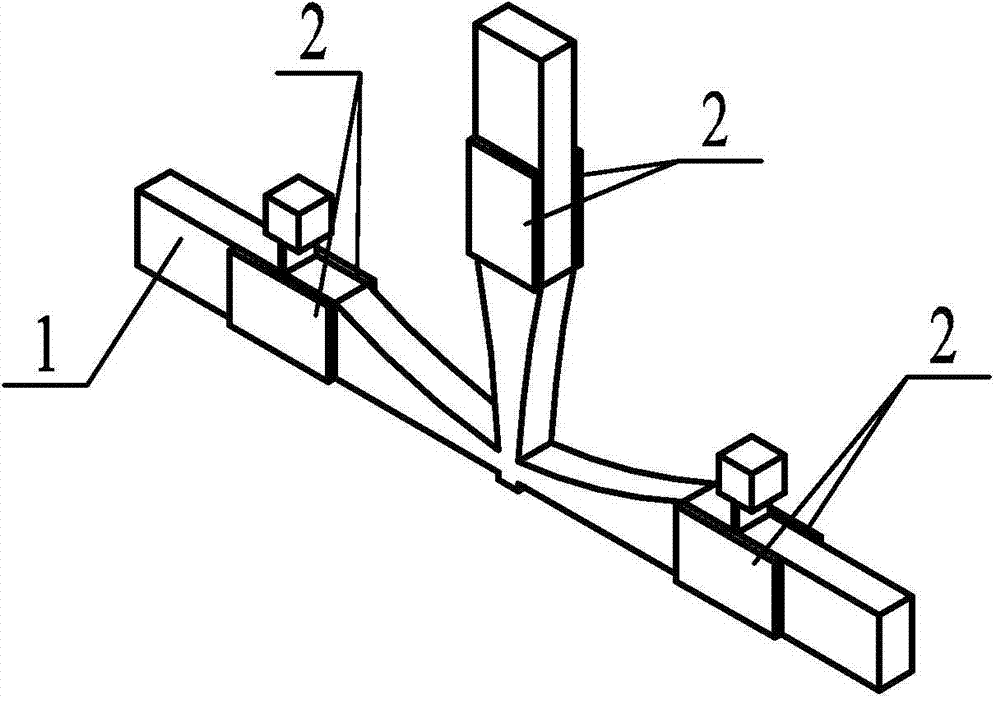

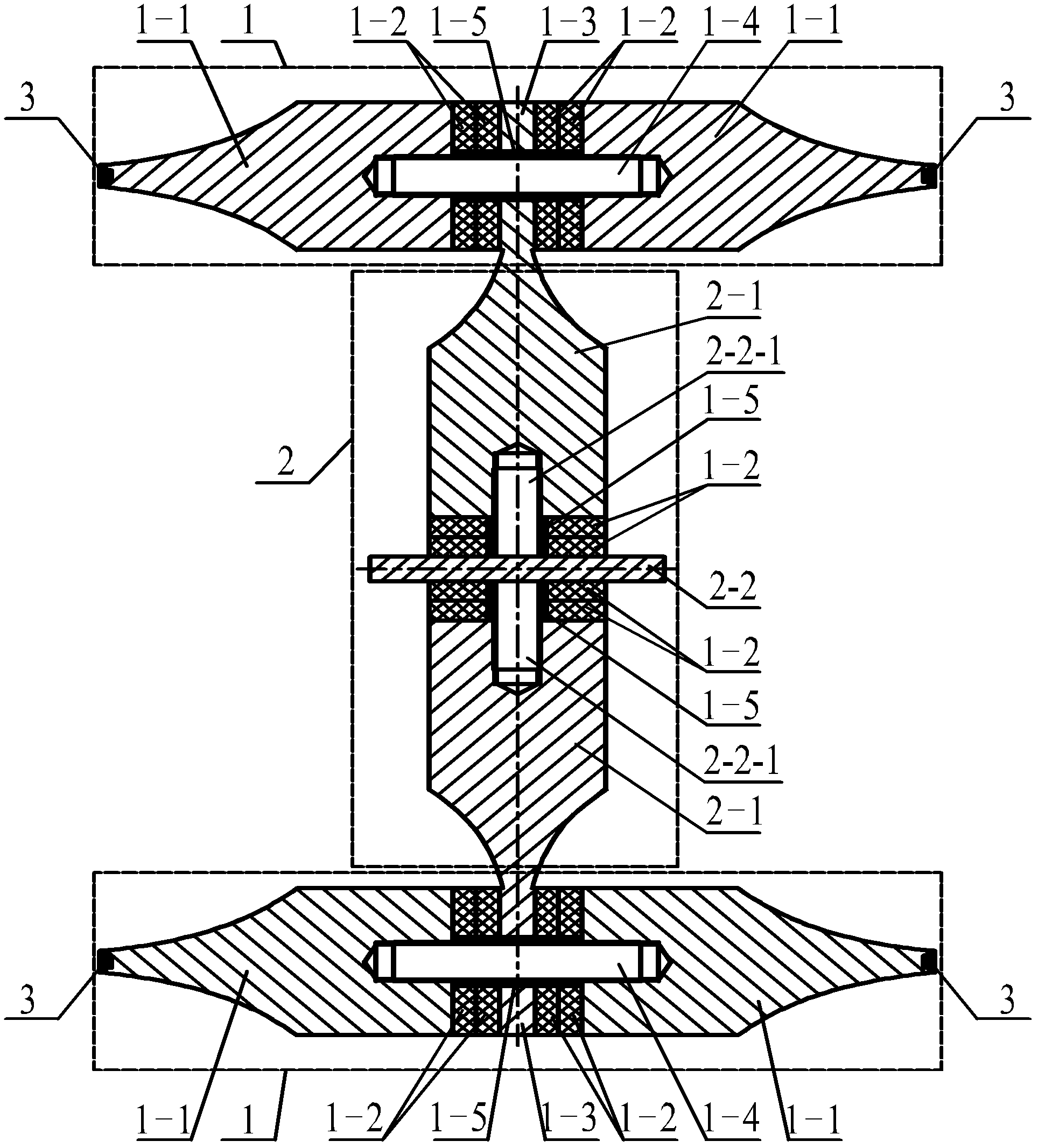

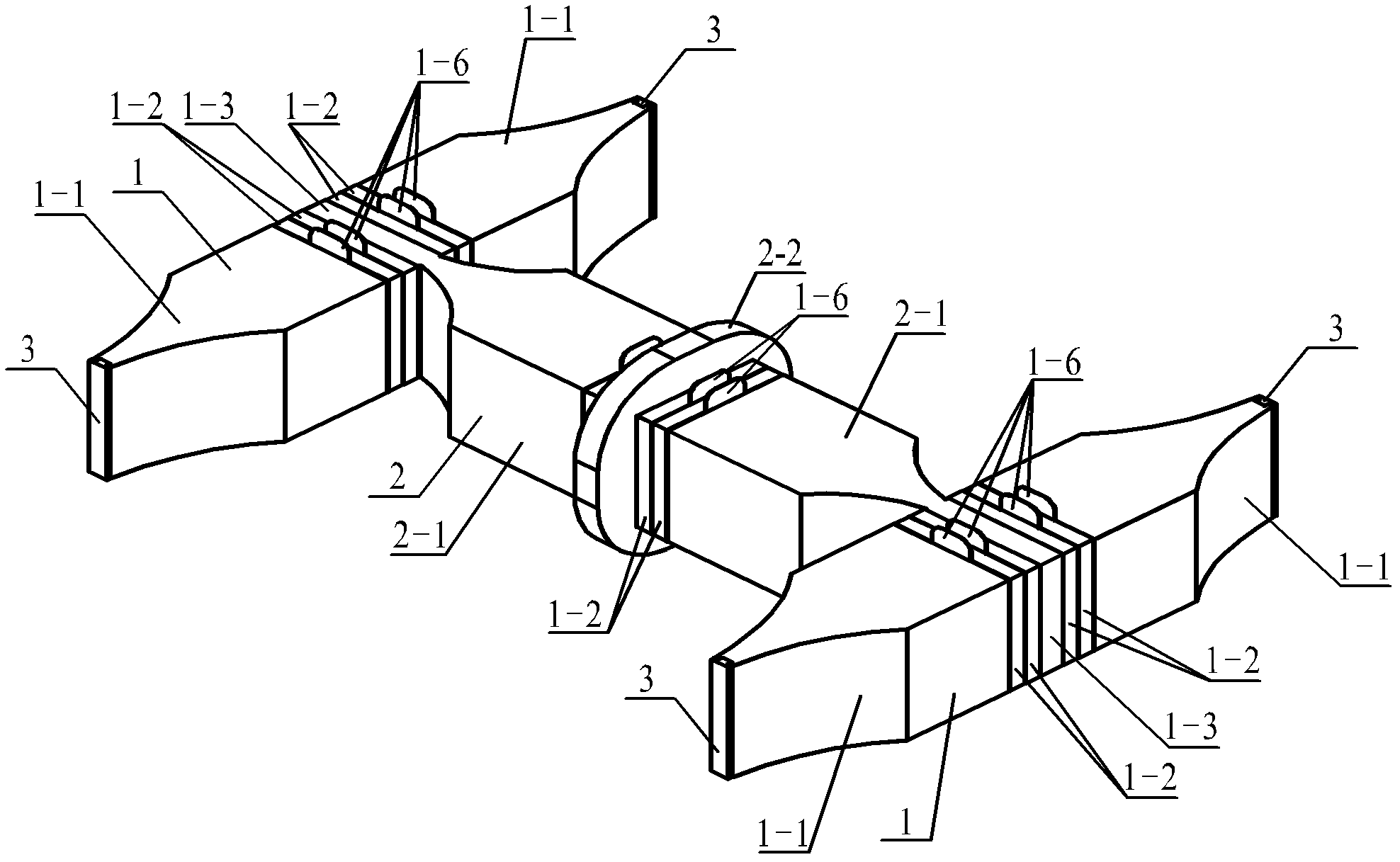

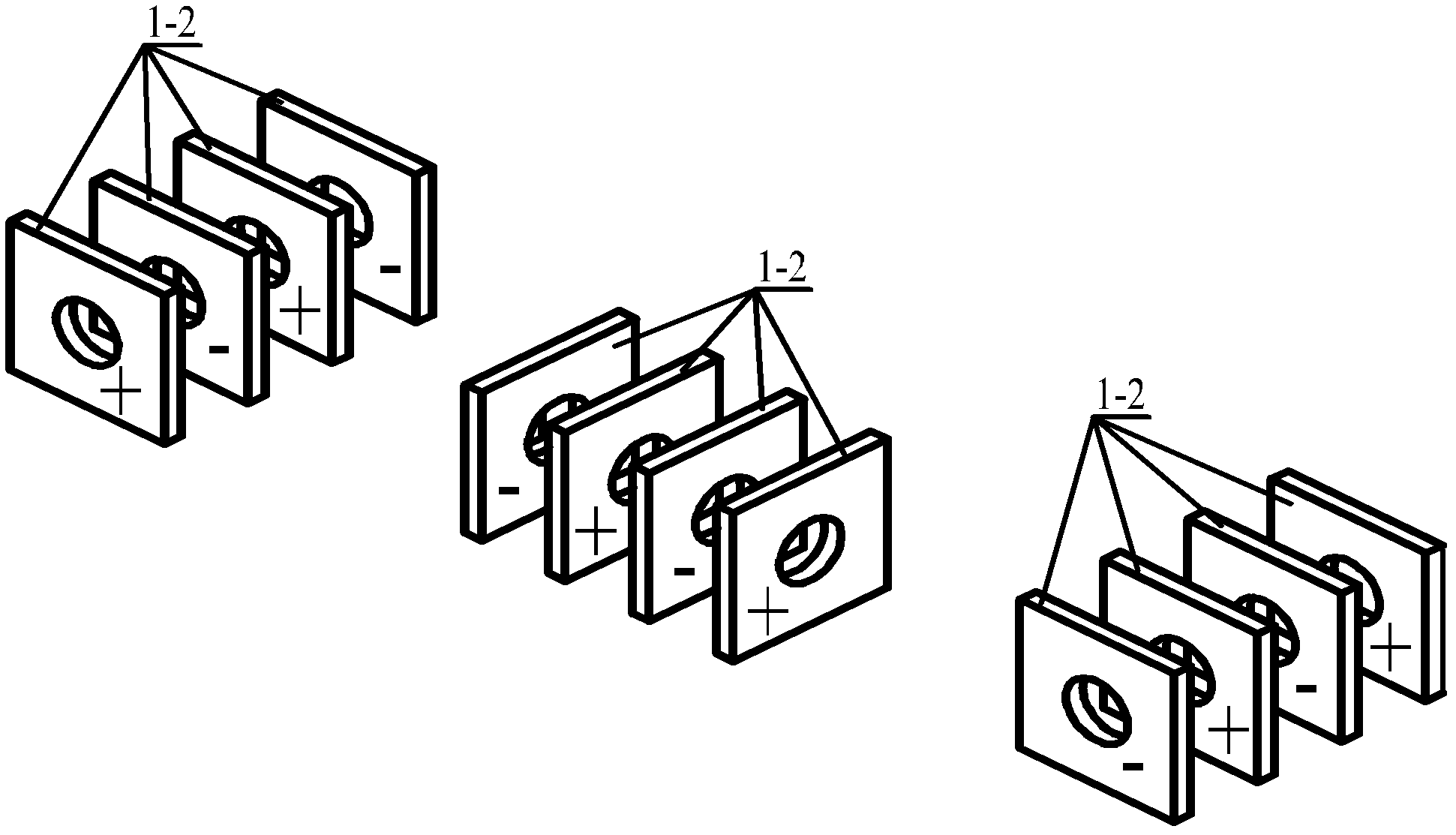

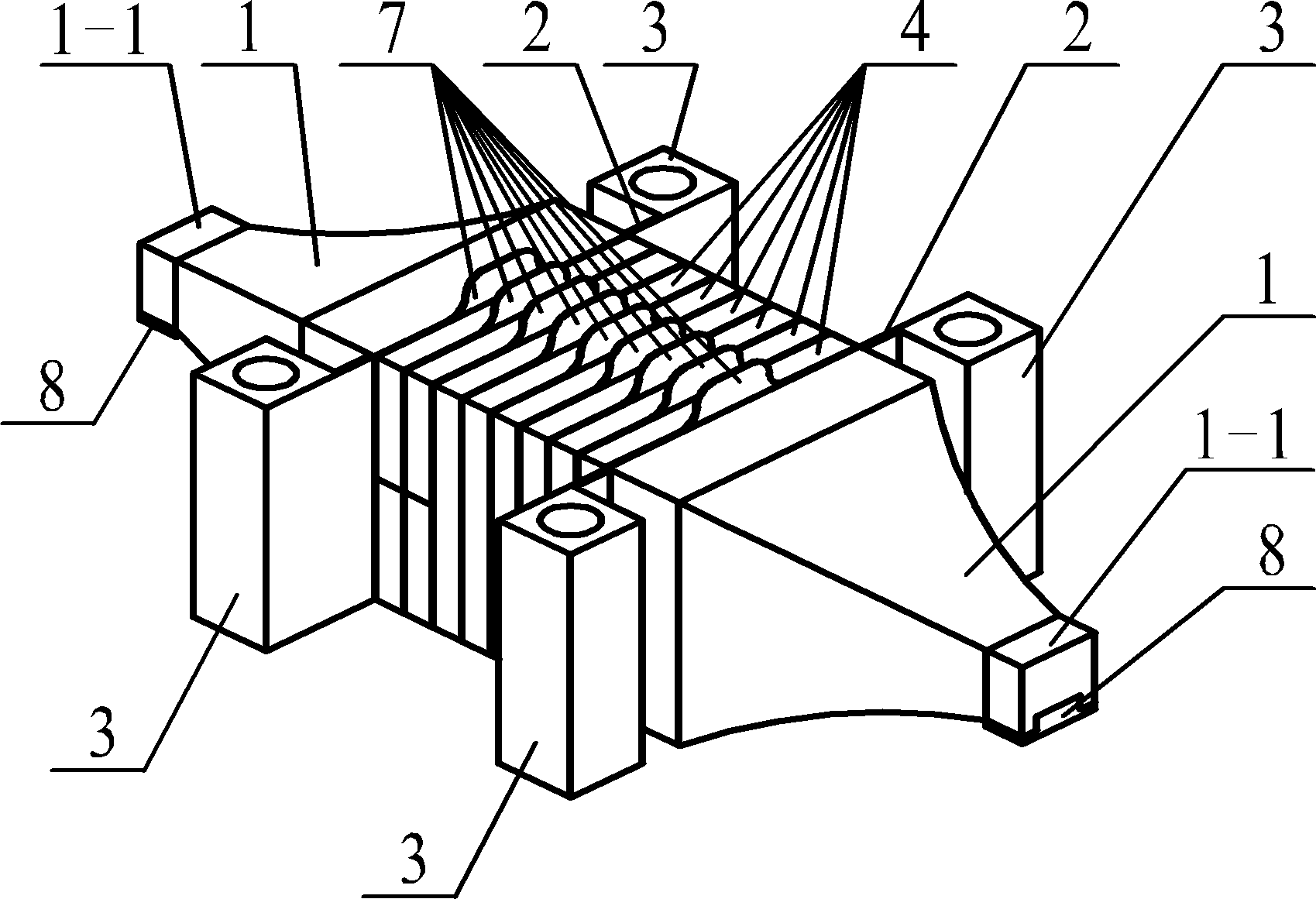

Composite flexural vibration sandwich type double-foot linear ultrasonic motor vibrator

ActiveCN102361413AIncrease flexibilityAchieve macro motion outputPiezoelectric/electrostriction/magnetostriction machinesAcousticsSandwich type

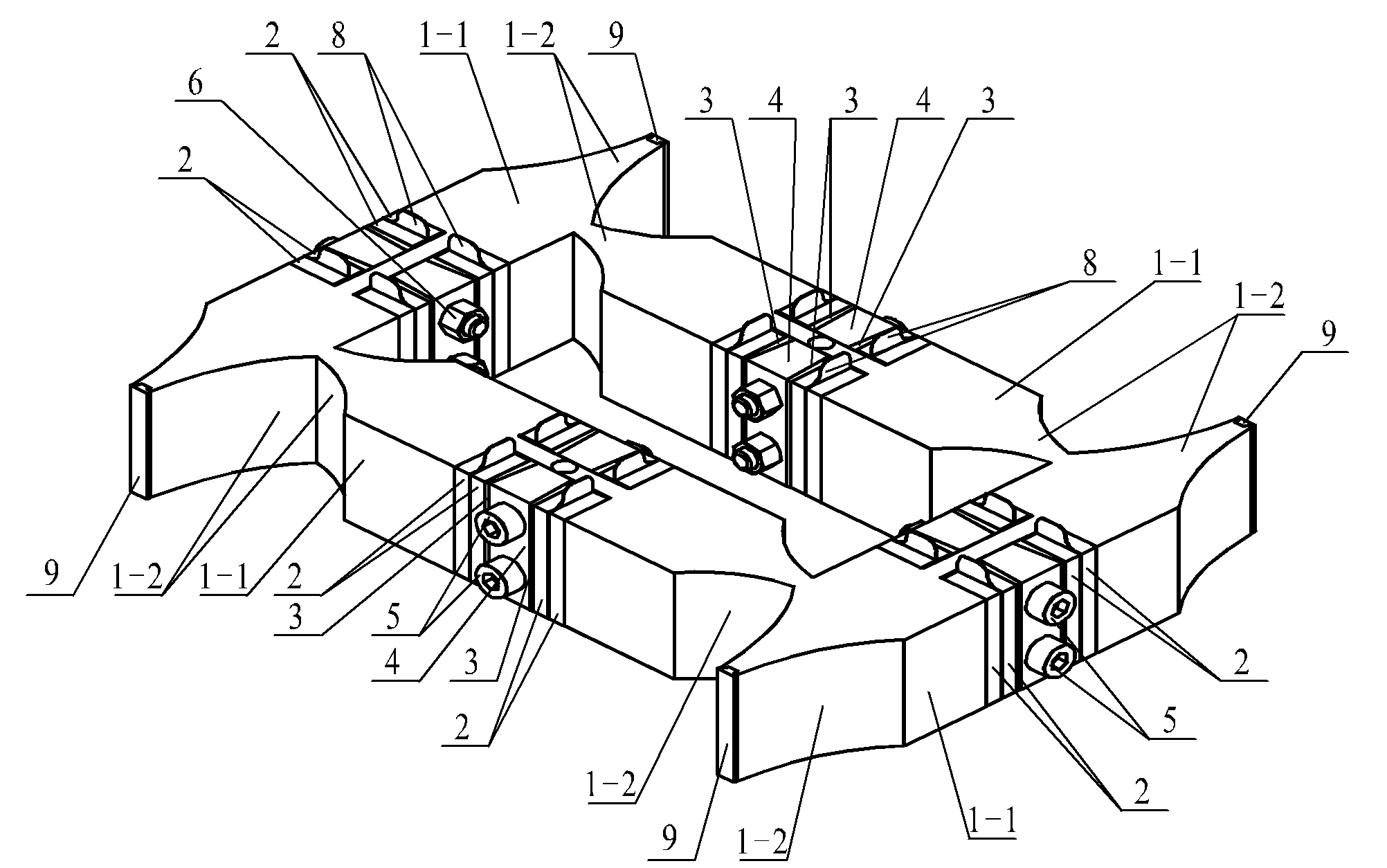

The invention discloses a composite flexural vibration sandwich type double-foot linear ultrasonic motor vibrator, and belongs to the technical field of piezoelectric ultrasonic motors. The vibrator solves the problem that the output thrust of a motor is affected by inconsistent vibration properties of two driving feet of the conventional flexural vibration modal beam type linear ultrasonic motor vibrator. Eight flexural vibration piezoelectric ceramic chips are sleeved on a stud of the vibrator, two end covers are respectively screwed at two ends of the stud to compact the eight flexural vibration piezoelectric ceramic chips, an electrode plate is respectively arranged between the adjacent flexural vibration piezoelectric ceramic chips and between the contact faces of the flexural vibration piezoelectric ceramic chip and the big end face of the end cover, insulating bushes are arranged between the contact faces of all the flexural vibration piezoelectric ceramic chips and the stud and between the contact faces of all the electrode plates and the stud, two thin-wall beams are symmetrically arranged at two sides of the big end face of each end cover, a mounting seat is fixed at the outer side of each thin-wall beam, a driving foot is arranged on the small end face of each end cover, and the driving feet are blocks, the sections of which are in the same shape as the small end faces. The vibrator is suitable for an ultrasonic motor.

Owner:HARBIN INST OF TECH

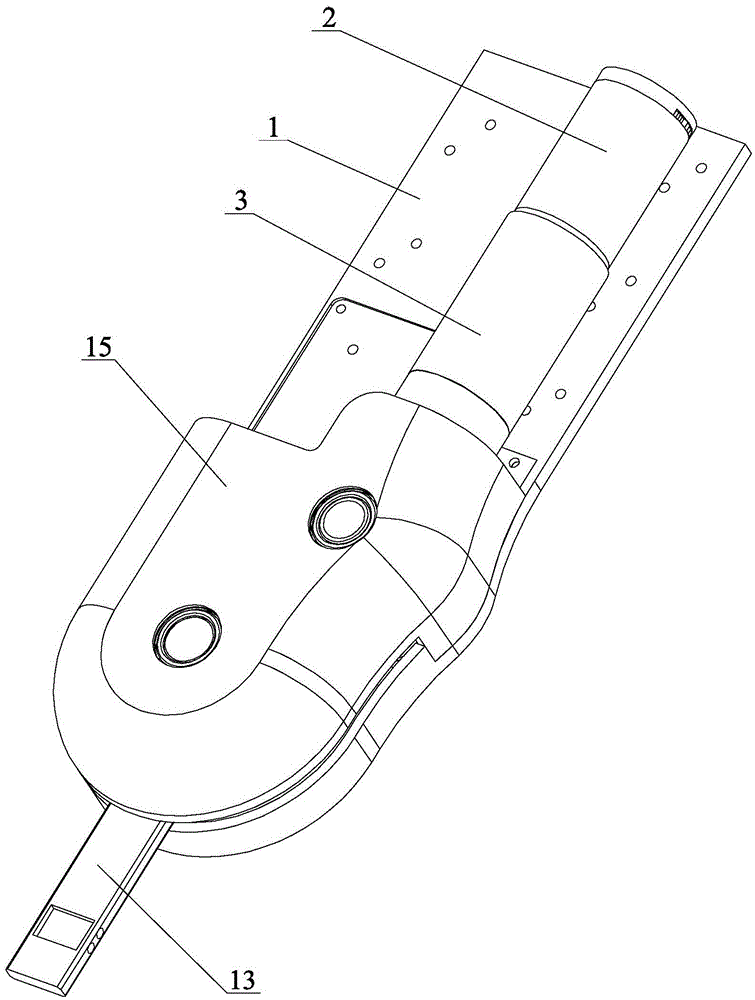

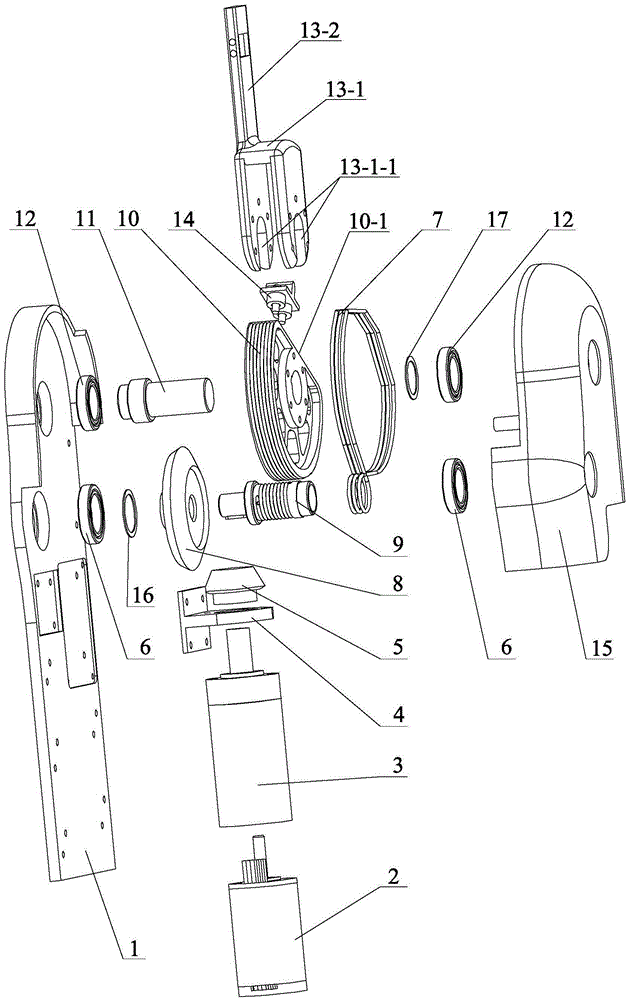

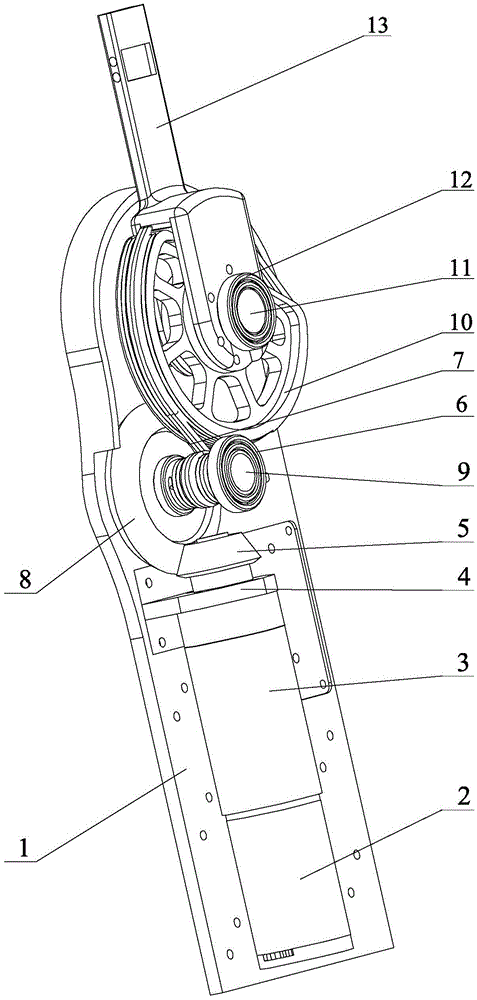

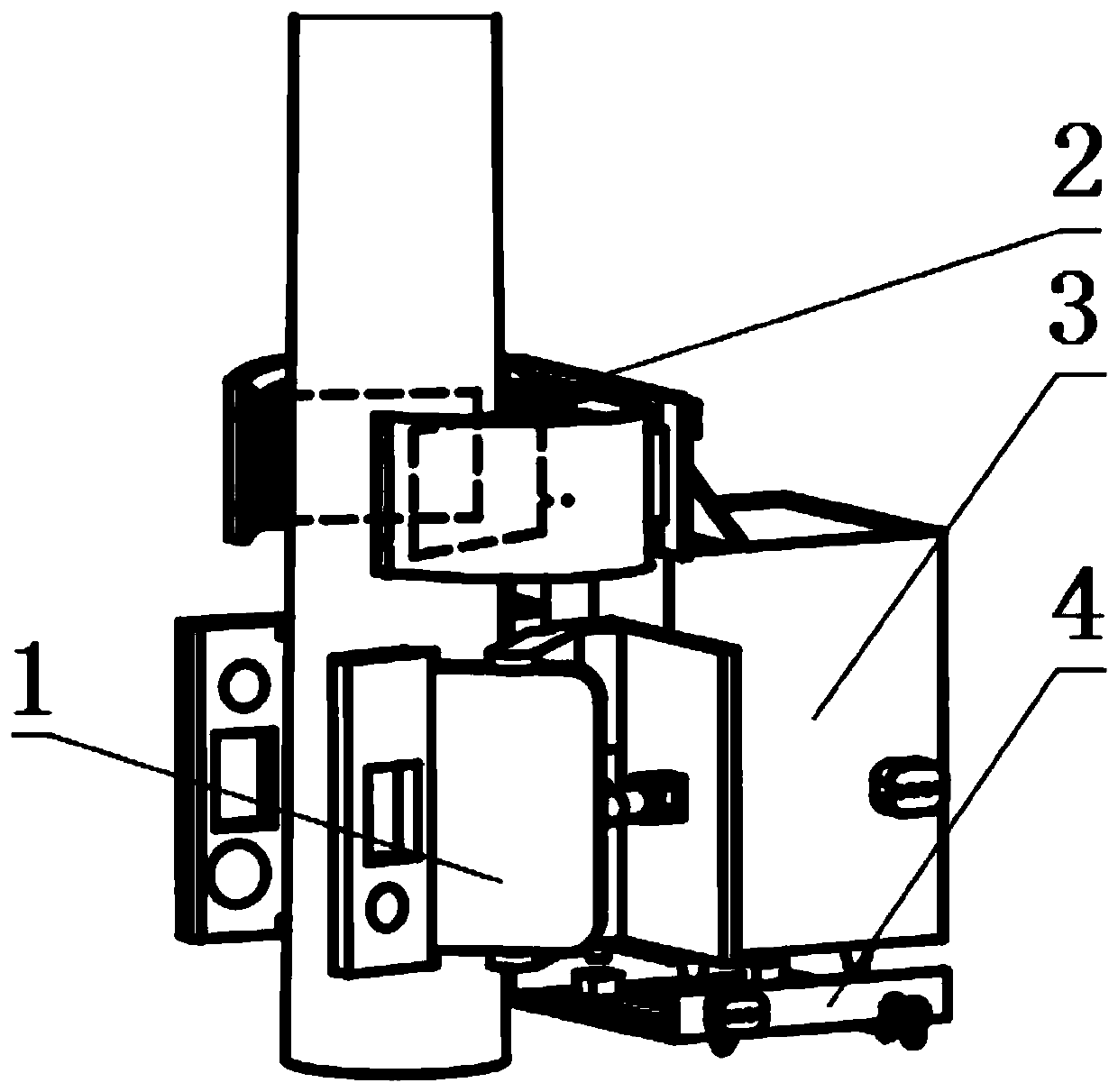

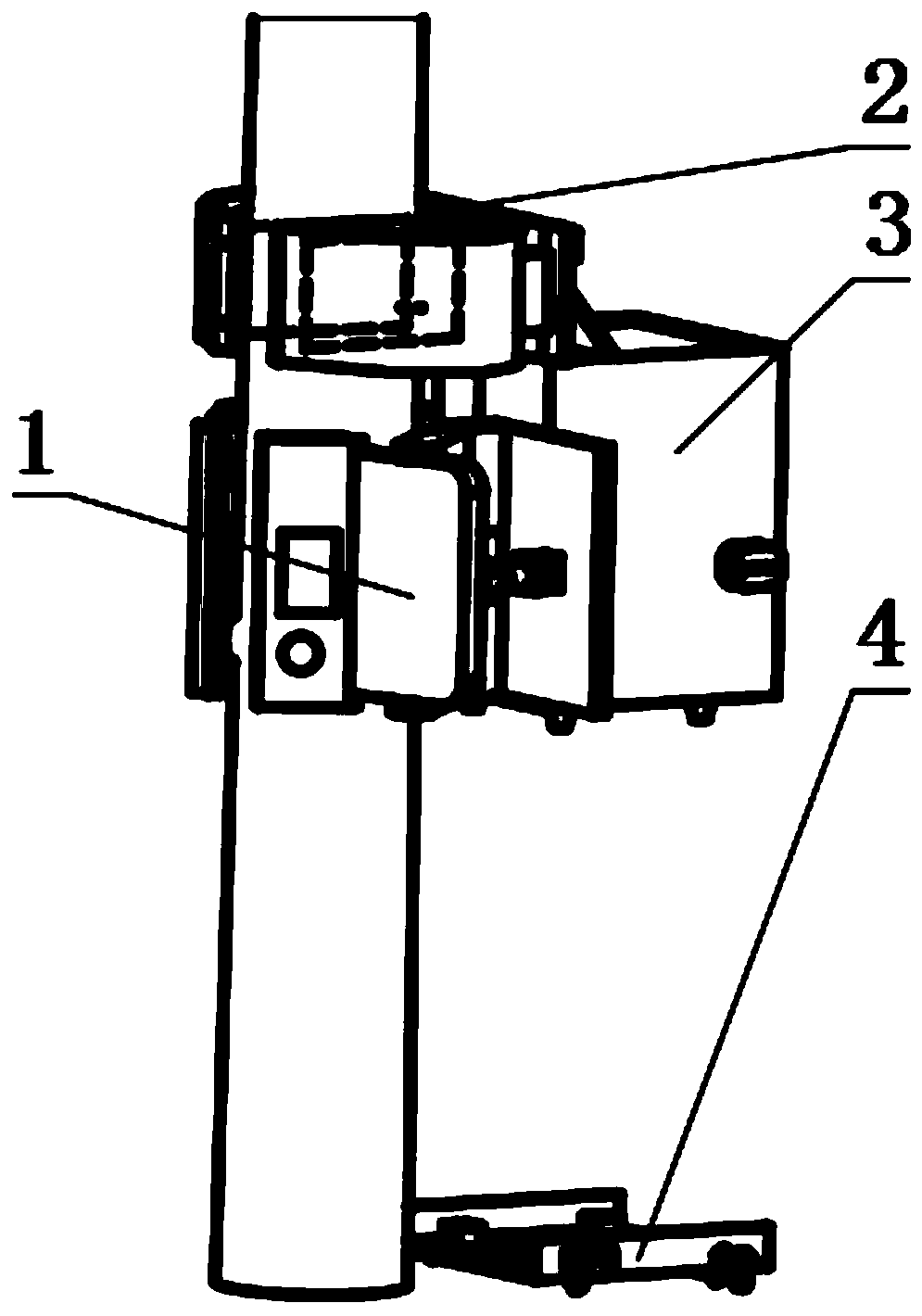

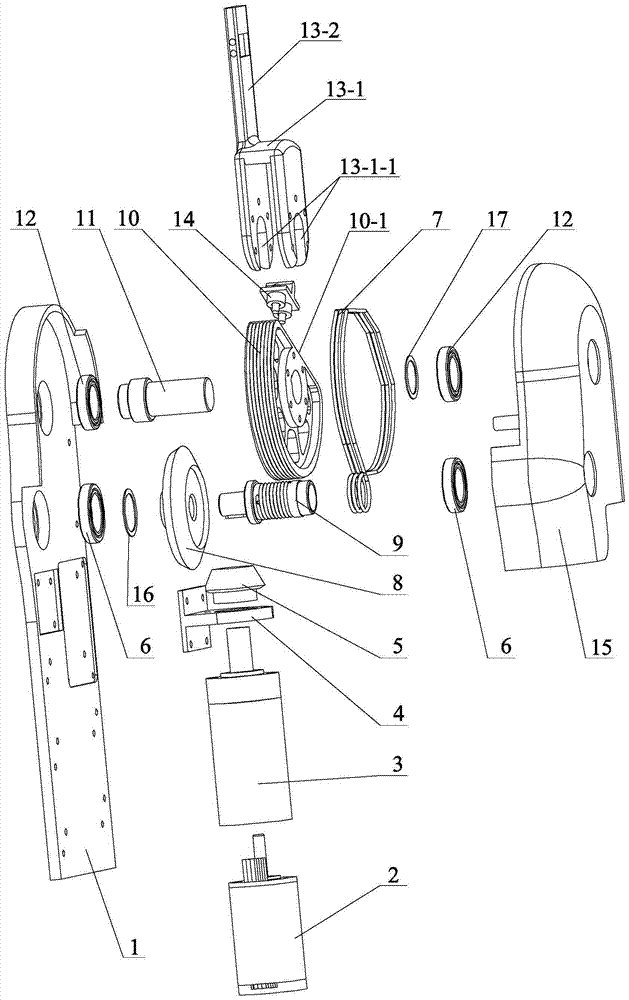

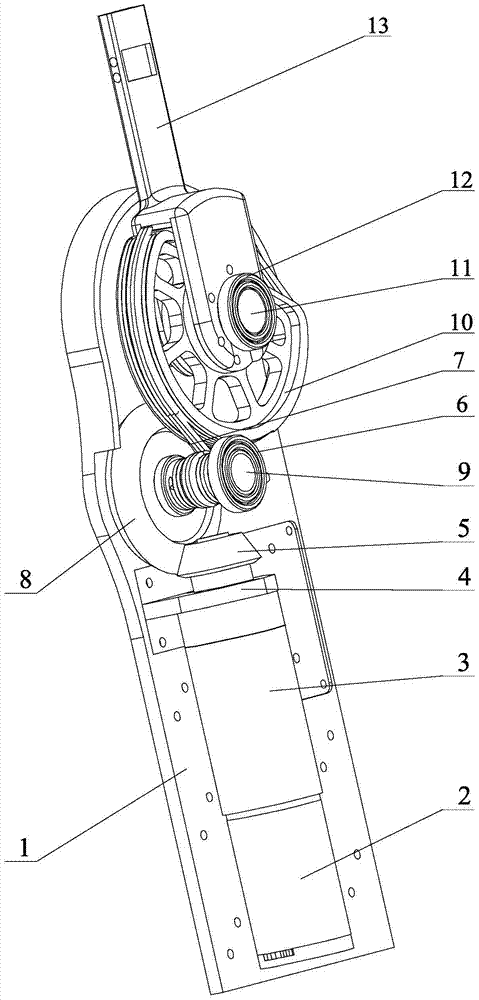

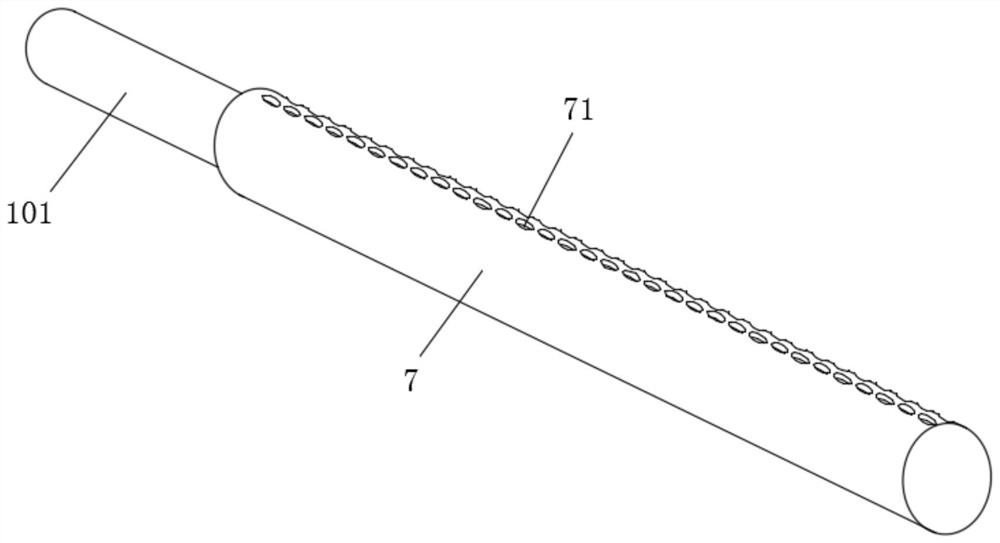

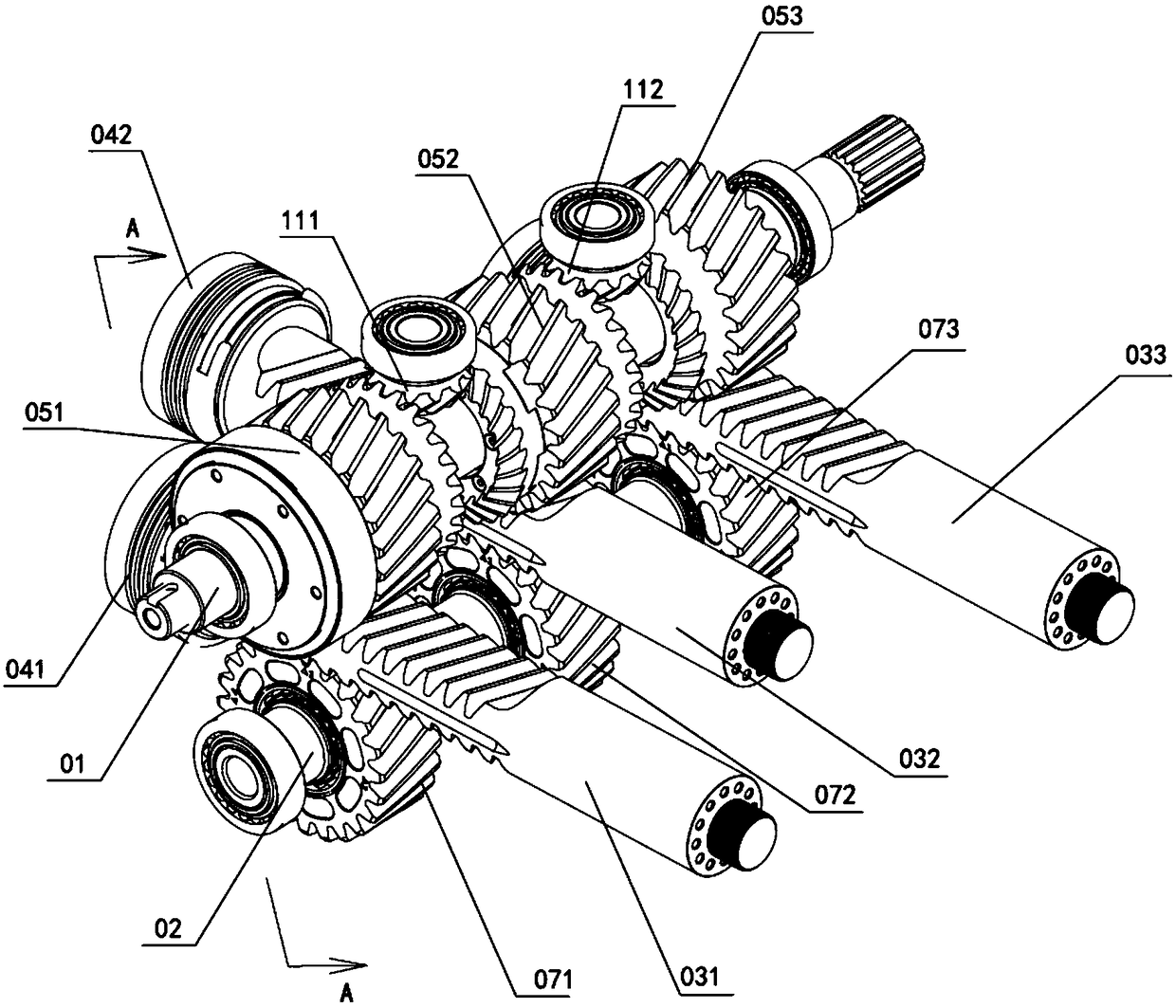

Serial flexible driving joint having steel wire transmission function

The invention relates to a robot driving joint, in particular to a serial flexible driving joint having a steel wire transmission function. A reversing bevel pinion is in key connection with an output shaft of a planetary reducer, a reversing big bevel gear is meshed with the reversing bevel pinion and is in key connection with a small rope wheel, one end of a transmission steel wire rope winds around the small rope wheel, the other end of the transmission steel wire rope winds around a big rope wheel, then winds around the small rope wheel and is fixed on the small rope wheel, the big rope wheel is in key connection with a big rope wheel shaft, a rope pre-tightening device is located above a plane, the rope pre-tightening device and one end of a plane of the big rope wheel are arranged in an inverted U-shaped groove of an inverted U-shaped shifting fork, a joint driving assembly is arranged on one end surface of one side of a supporting bottom plate, an external supporting casing is buckled on the supporting bottom plate, an output rod is exposed out of the supporting bottom plate and the external supporting casing, two small rope wheel supporting bearings and two big rope wheel shaft supporting bearings are supported on the corresponding supporting bottom plate and the corresponding external supporting casing respectively. The flexible driving joint is applied to a joint part of a robot.

Owner:HARBIN INST OF TECH

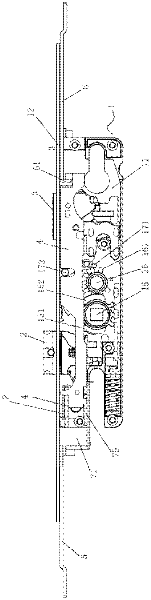

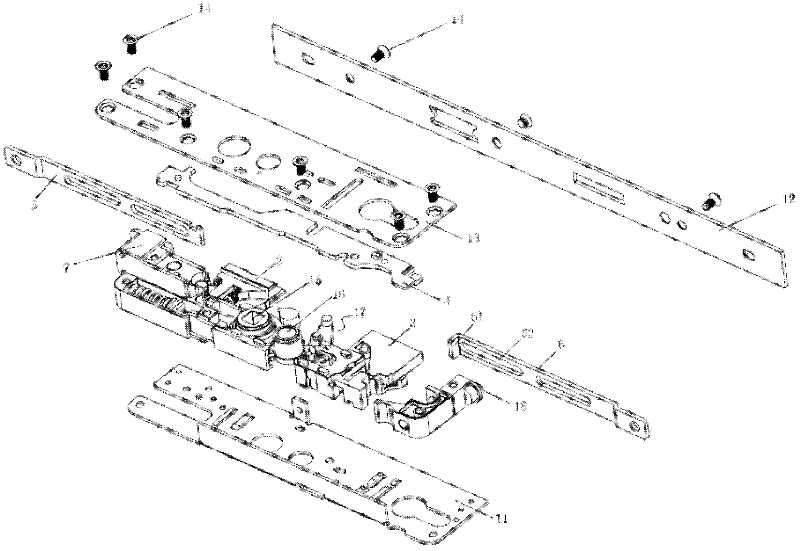

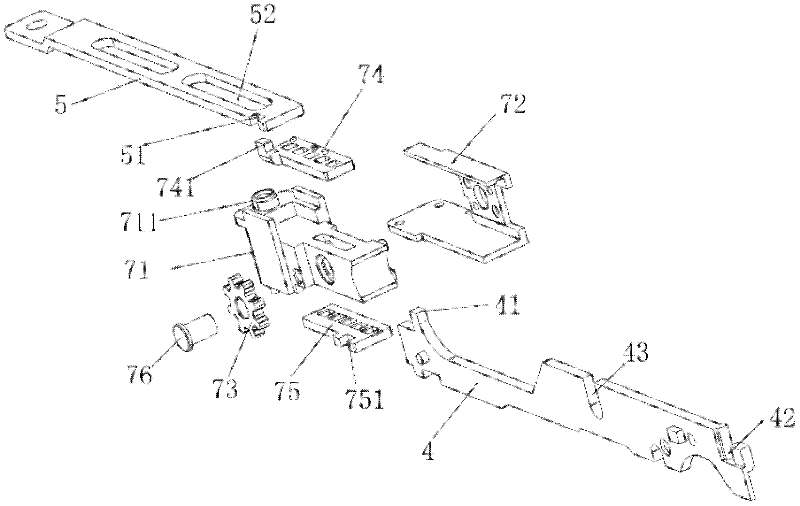

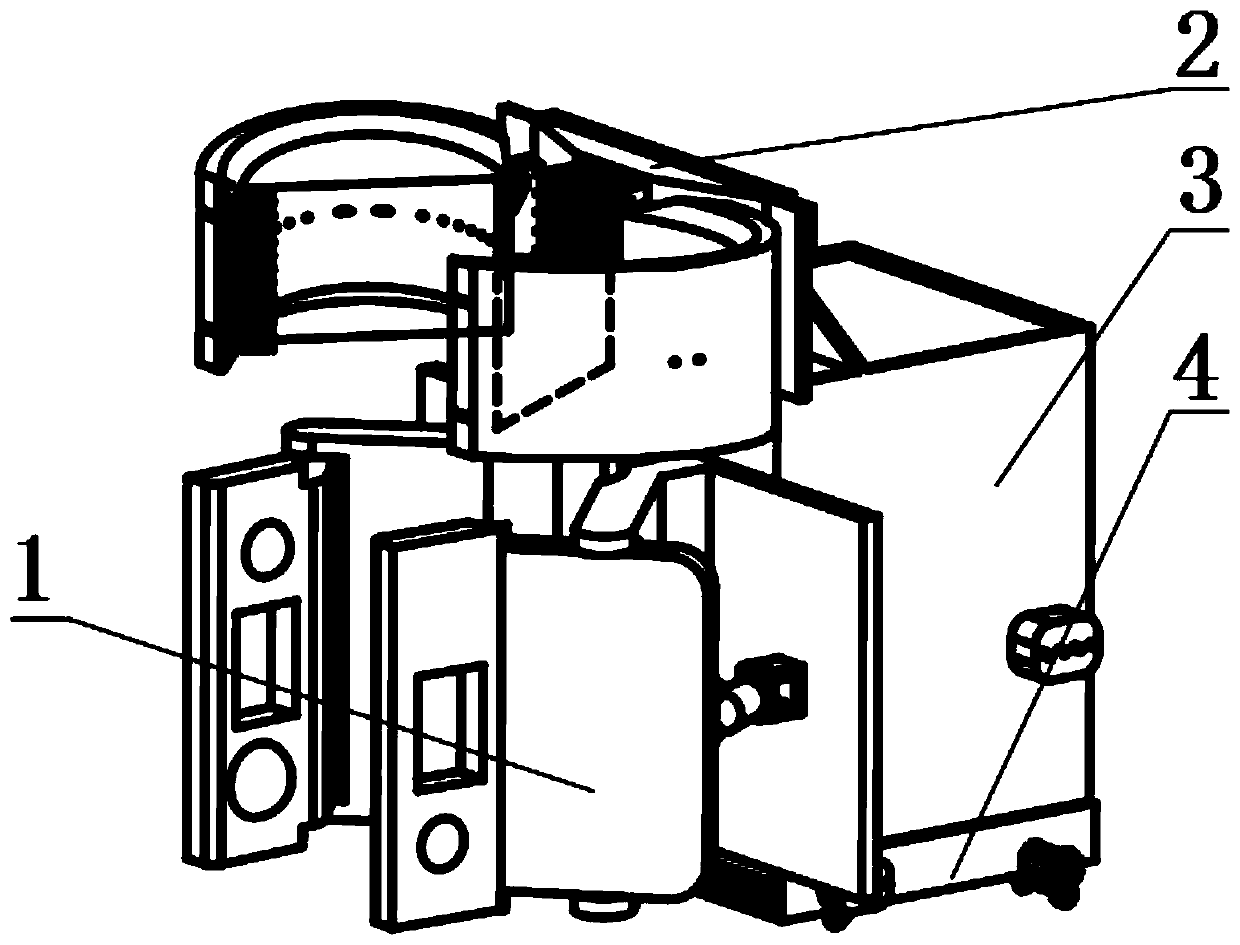

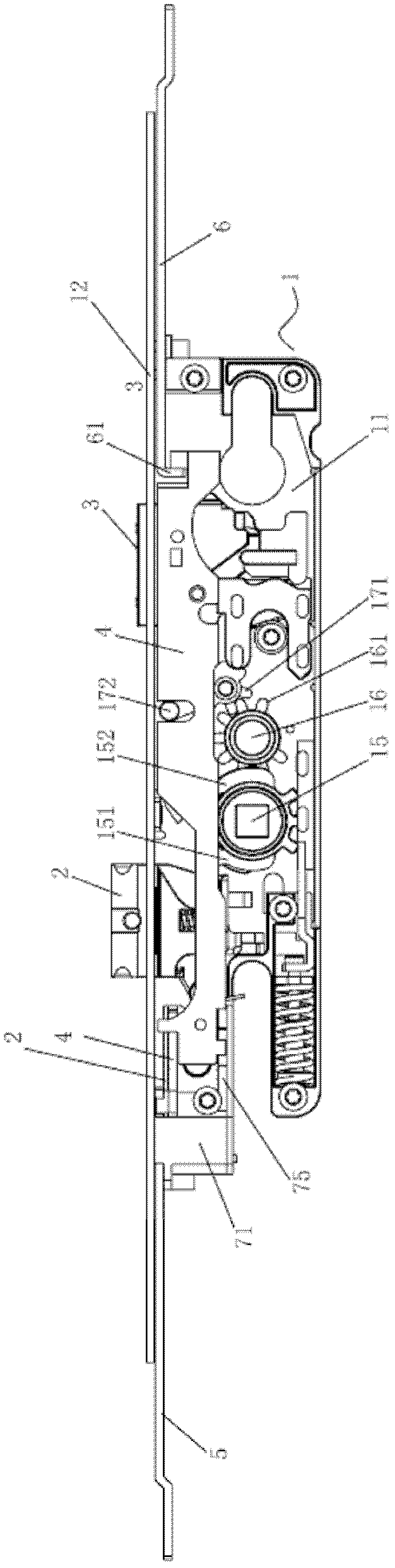

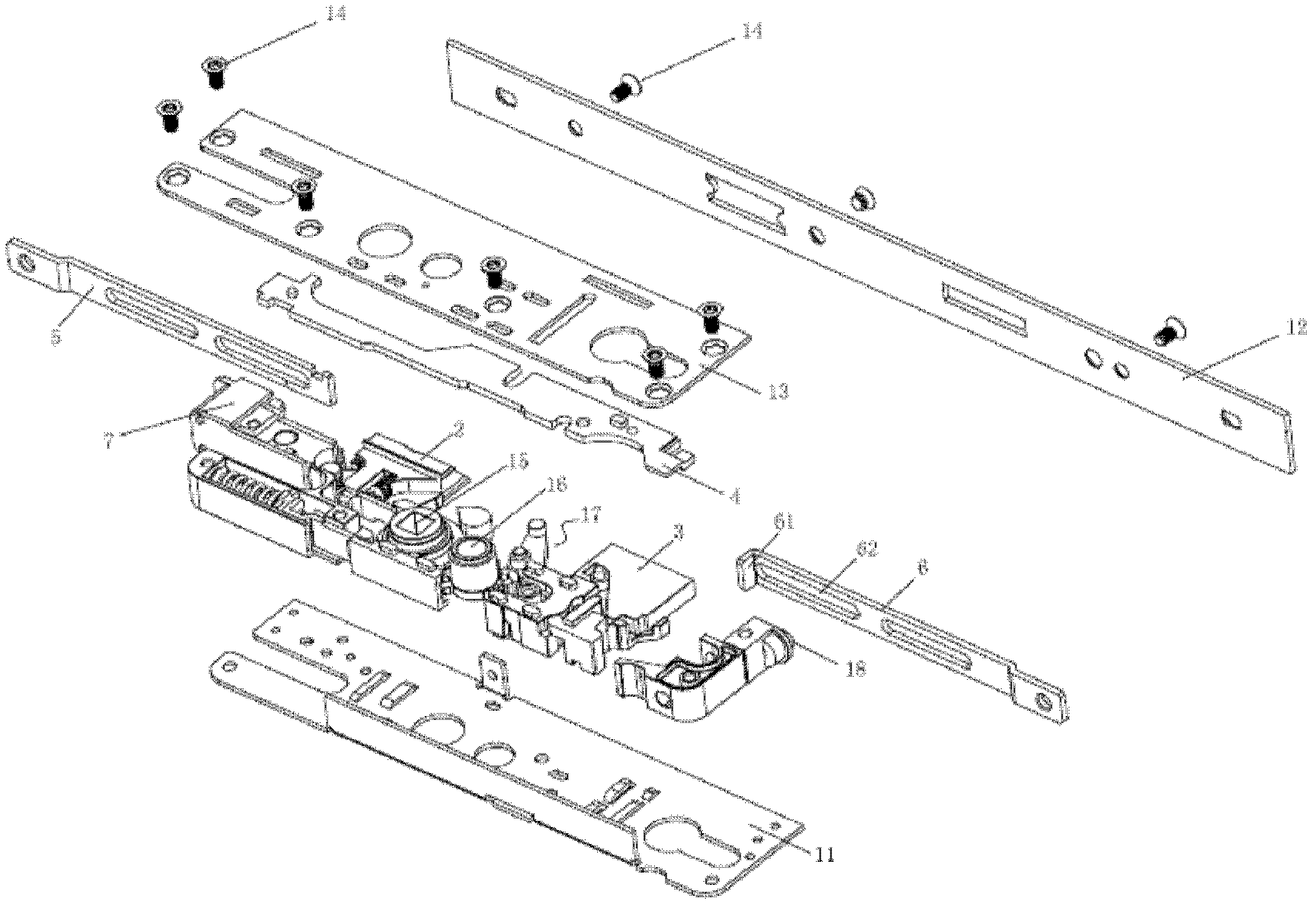

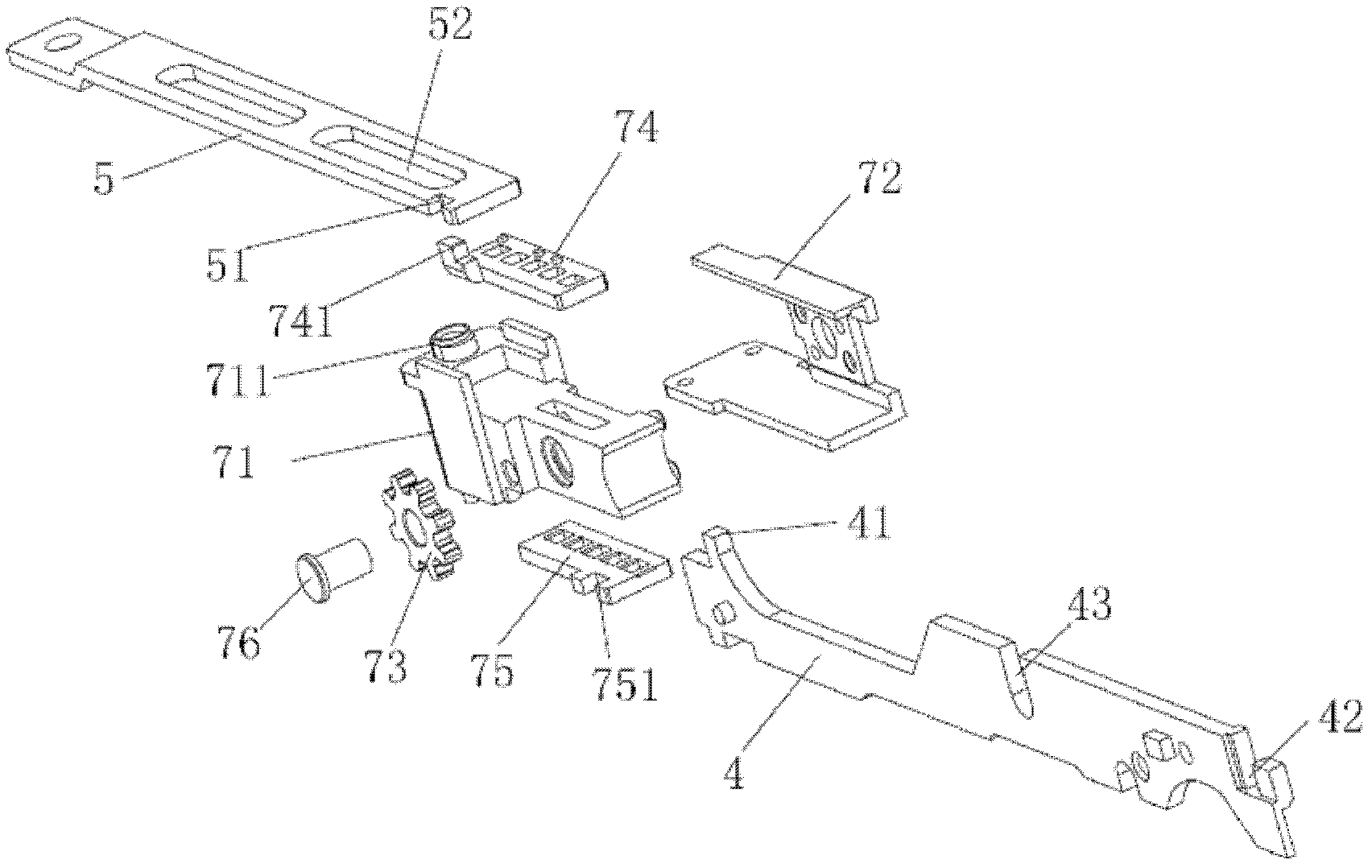

Reversible lock body

The invention relates to a reversible lock body comprising a lock body shell which is internally equipped with a containing cavity, and an inclined tongue and a square tongue which stretch out from one side of the lock body shell, wherein an unlocking shifting block capable of being driven by a key is arranged in the containing cavity; a rotary shifting block for driving the inclined tongue is arranged by means of being connected with the unlocking shifting block; a driving deflector rod is further arranged by means of being connected with the unlocking shifting block; a transmission bar which does a linear movement with the swinging of the driving deflector rod is arranged by means of being connected with the driving deflector rod; and one end of the transmission bar is connected with a first locking bar, and the other end of the transmission bar is connected with a second locking bar through a reversing gear assembly capable of changing the transmission direction of the transmissionbar. According to the reversible lock body, no extra reserving structure is added, and simultaneously, reverse driving of the first locking bar and the second locking bar is realized so that a door lock is locked in a vertical direction. Therefore, the cost is saved, and the reversible lock body is more convenient and fast to install and maintain and is a mechanical lock body with compact structure and good practicability.

Owner:CMECH (GUANGZHOU) INDUSTRIAL LTD

Street lamp cleaning device

PendingCN110813809AAchieve cleaningReduce volumeCleaning using toolsCleaning using liquidsEngineeringSmall footprint

Owner:CHANGAN UNIV

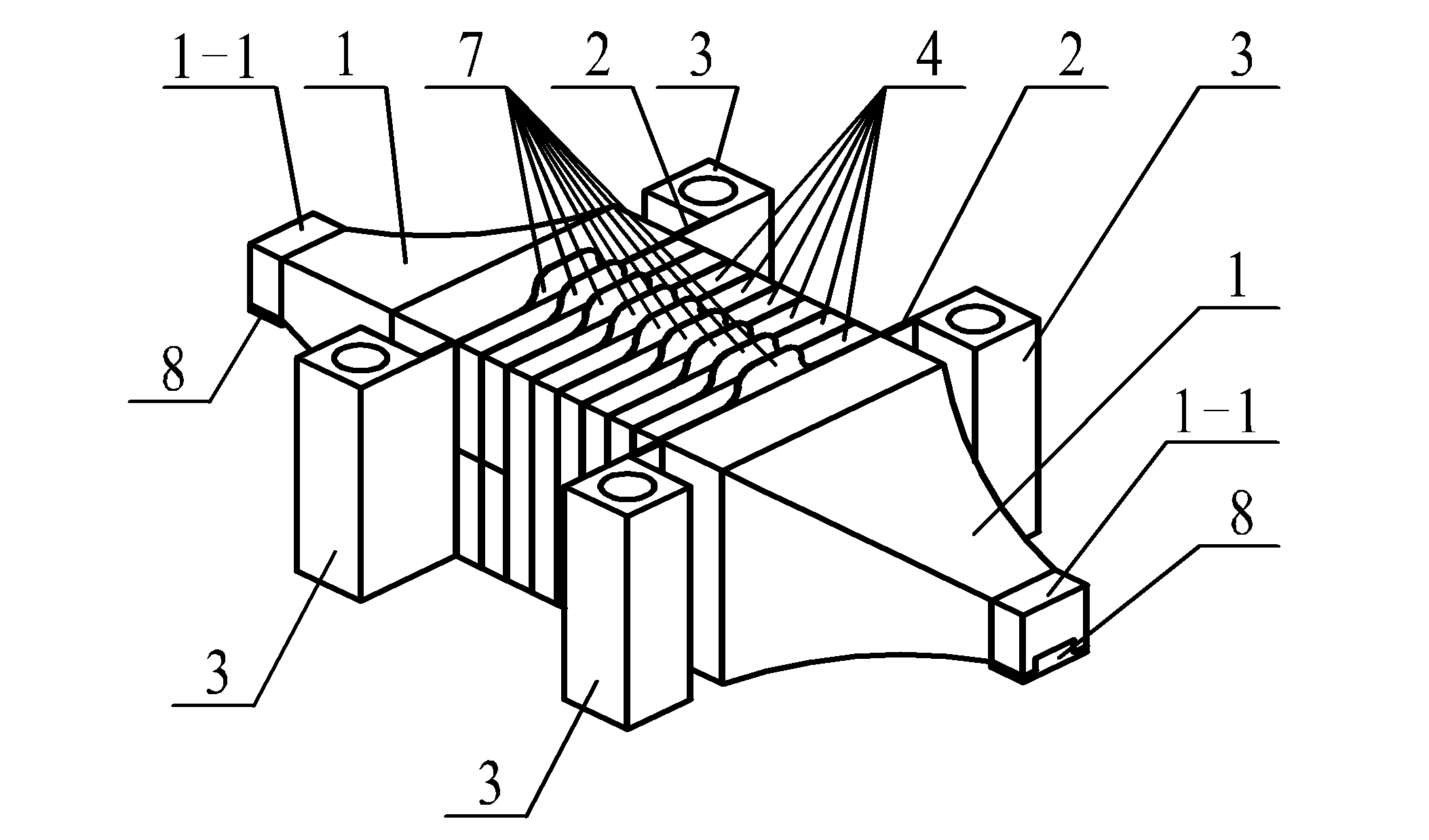

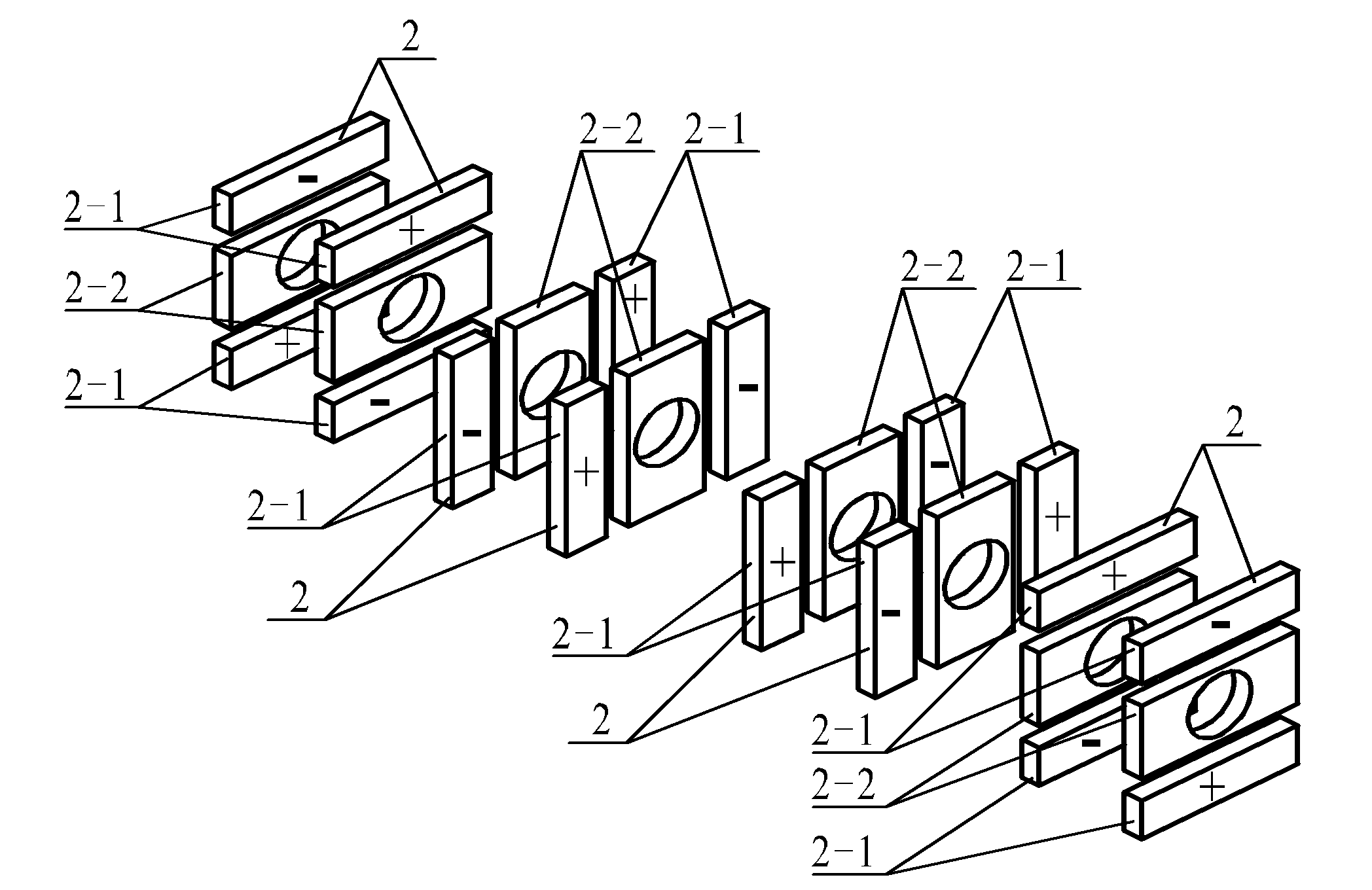

Partition excitation type composite bending vibration linear ultrasonic motor oscillator

InactiveCN102437780AIncrease flexibilityImproved electrical coupling efficiencyPiezoelectric/electrostriction/magnetostriction machinesElectricityScrew thread

The invention provides a partition excitation type composite bending vibration linear ultrasonic motor oscillator, belonging to the piezoelectric ultrasonic motor technology field. Problems that drive foot vibration characteristics of a present bending vibration modal girder type linear ultrasonic motor oscillator are inconsistent, and cutting combination arrangement of bending vibration piezoelectric ceramic sheets is not reasonable are solved. A center of a large end plane of an end cap is provided with a blind hole with internal screw thread. A flange is provided with two studs, each stud is in joint connection with two pairs of bending vibration piezoelectric ceramic sheets, and an end part of a stud is matched with the blind hole through screwing. An electrode slice is provided between adjacent bending vibration piezoelectric ceramic sheets and between a bending vibration piezoelectric ceramic sheet and a contact surface of the flange. The studs are provided with insulation sleeves. Two side surfaces of the flange are provided with two thin walled beams. Outboard of each of the thin walled beams is provided with an installation seat. A small end plane of the end cap is provided with a drive foot. Each bending vibration piezoelectric ceramic sheet is split into two no-bore rectangular piezoelectric ceramic sheets with a same size at two ends and a center hole rectangular piezoelectric ceramic sheet in the middle. The invention is applied to an ultrasonic motor oscillator.

Owner:HARBIN INST OF TECH

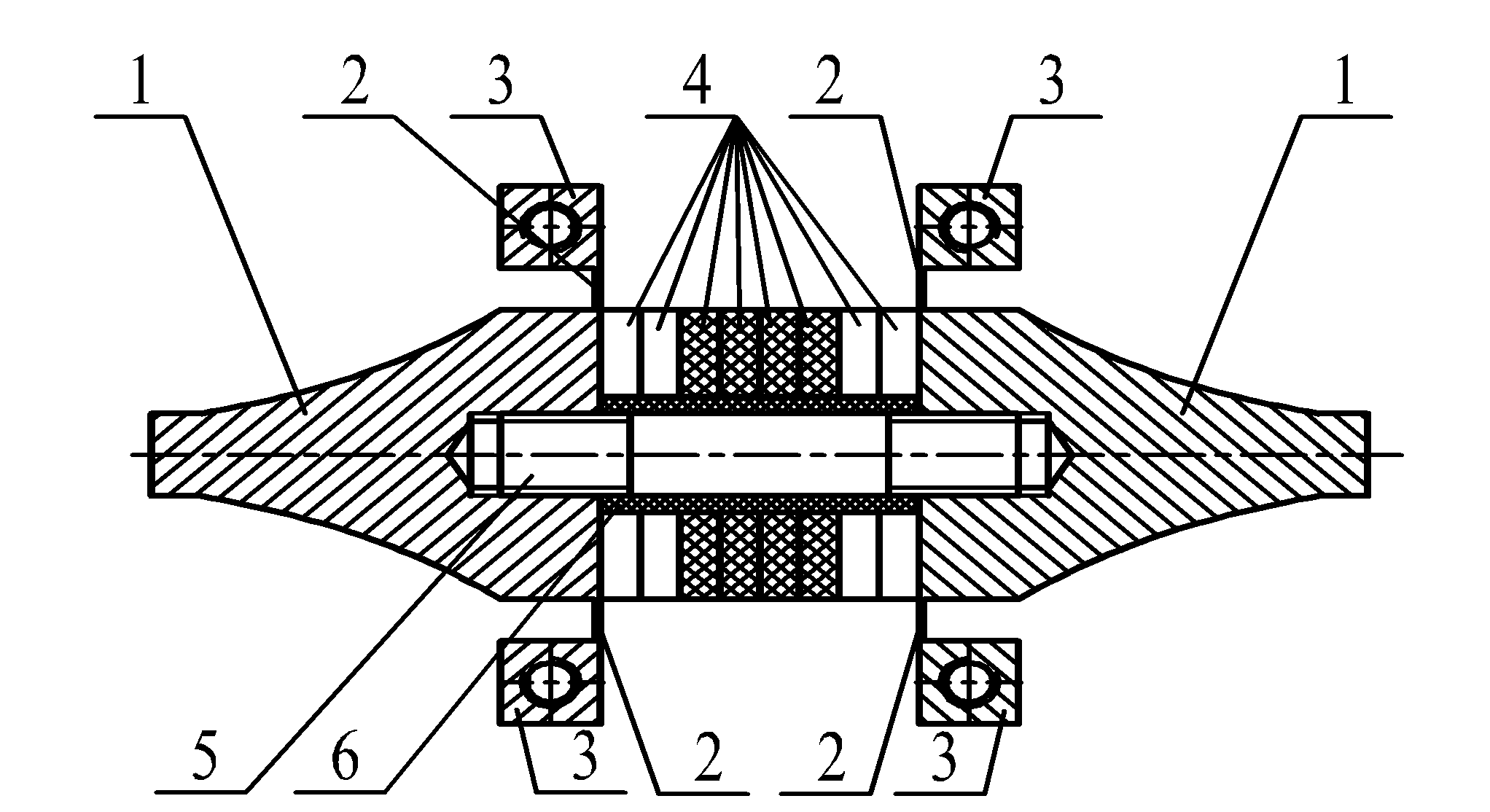

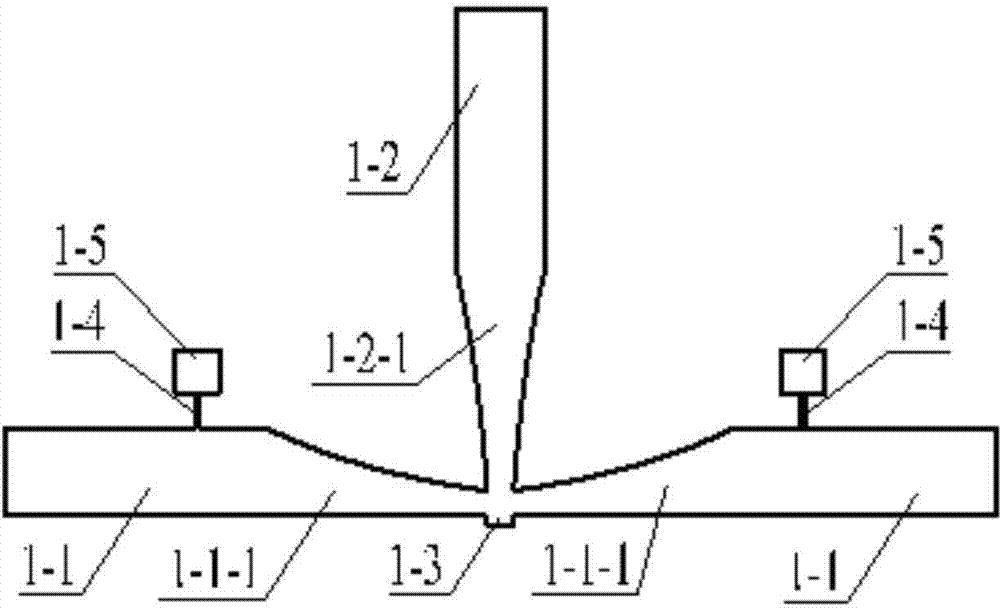

Patch type longitudinal vibration composite single-foot piezoelectric ultrasonic motor oscillator

InactiveCN103795290ALow machining accuracy requirementsSimple structurePiezoelectric/electrostriction/magnetostriction machinesLongitudinal vibrationPatch type

The invention provides a patch type longitudinal vibration composite single-foot piezoelectric ultrasonic motor oscillator, and relates to the technical field of ultrasonic motors. The patch type longitudinal vibration composite single-foot piezoelectric ultrasonic motor oscillator aims to resolve the problems that an existing T-shaped linear ultrasonic motor oscillator is complex to machine and assemble and achieves microminiaturization difficultly. The tail end of each horizontal beam is provided with a horizontal amplitude-change pole, the tail end of a vertical beam is provided with a vertical amplitude-change pole, the horizontal amplitude-change poles and the vertical amplitude-change pole are blocks, the size of the section of each block is gradually reduced, a driving foot is fixedly connected with the small ends of the two horizontal amplitude-change poles and the small end of the vertical amplitude-change pole, the two horizontal beams and the vertical beam are arranged in a T shape, the side surfaces of the two horizontal beams are respectively provided with a thin wall beam, and the outer side of each thin wall beam is provided with a flange. The upper surface of each horizontal beam, the lower surface of each horizontal beam, the upper surface of the vertical beam and the lower surface of the vertical beam are respectively provided with a piezoelectric ceramic piece, all the piezoelectric ceramic pieces are polarized in the direction of thickness, the piezoelectric ceramic piece on the upper surface of the vertical beam and the piezoelectric ceramic piece on the lower surface of the vertical beam are opposite in polarizing direction, and the piezoelectric ceramic piece on the upper surface of each horizontal beam and the piezoelectric ceramic piece on the lower surface of the corresponding horizontal beam are opposite in polarizing direction. The patch type longitudinal vibration composite single-foot piezoelectric ultrasonic motor oscillator can be used for ultrasonic motors.

Owner:HARBIN INST OF TECH

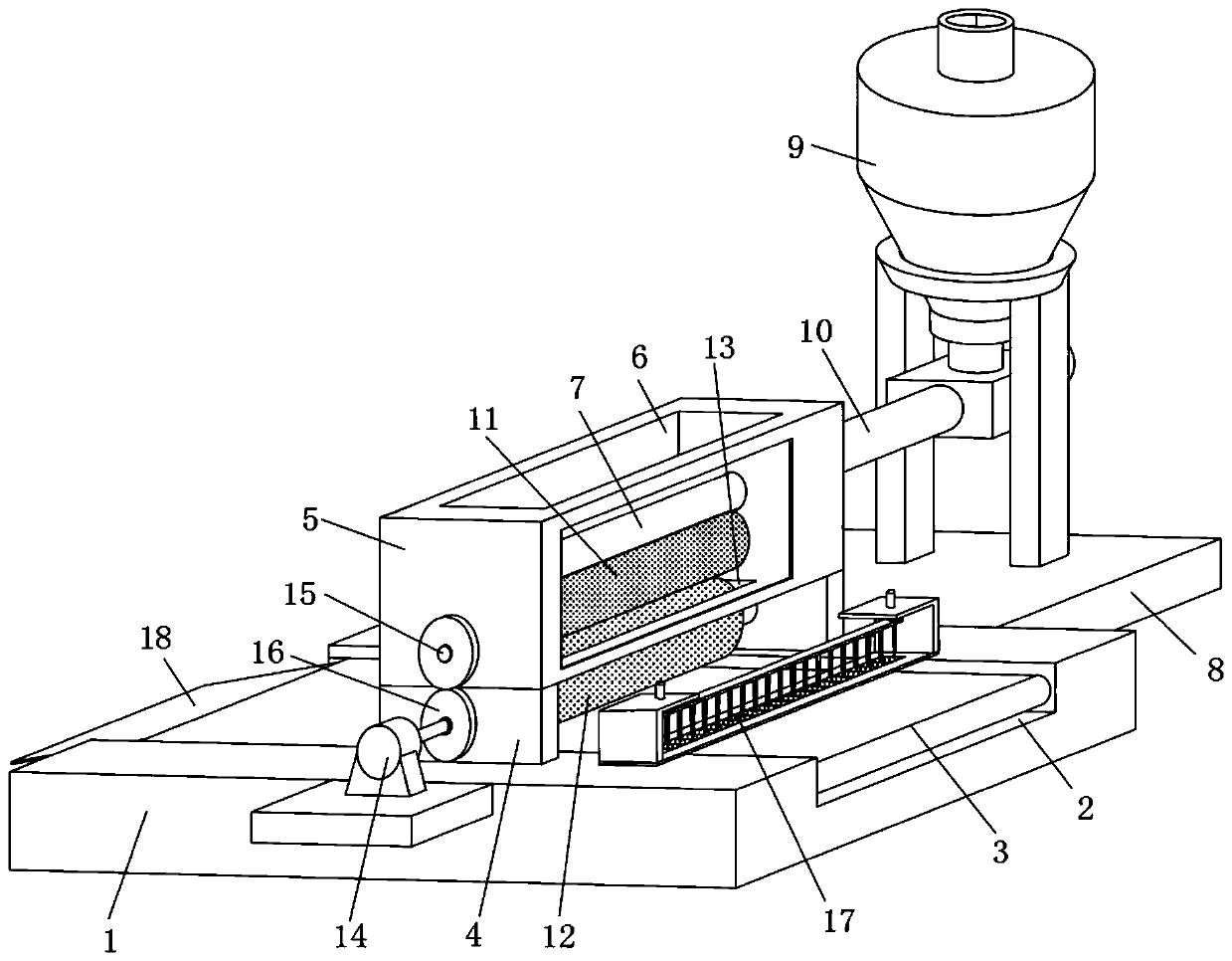

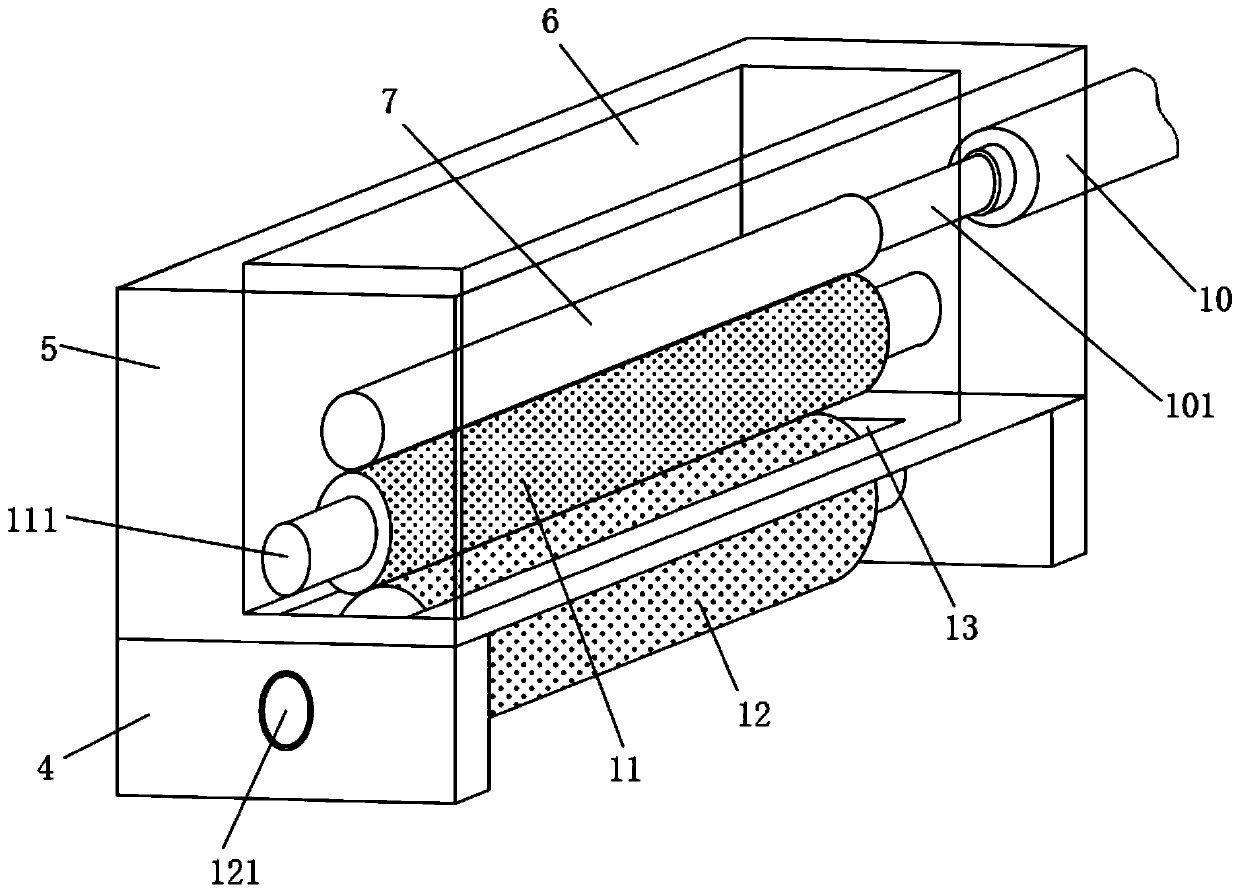

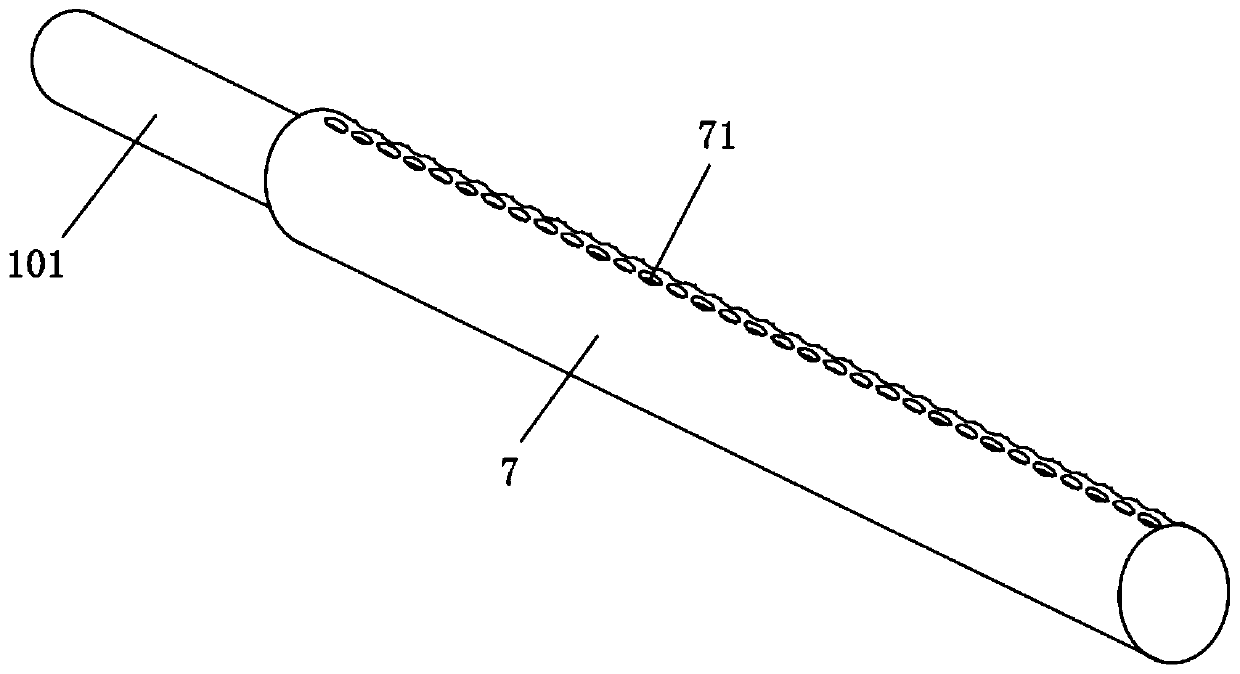

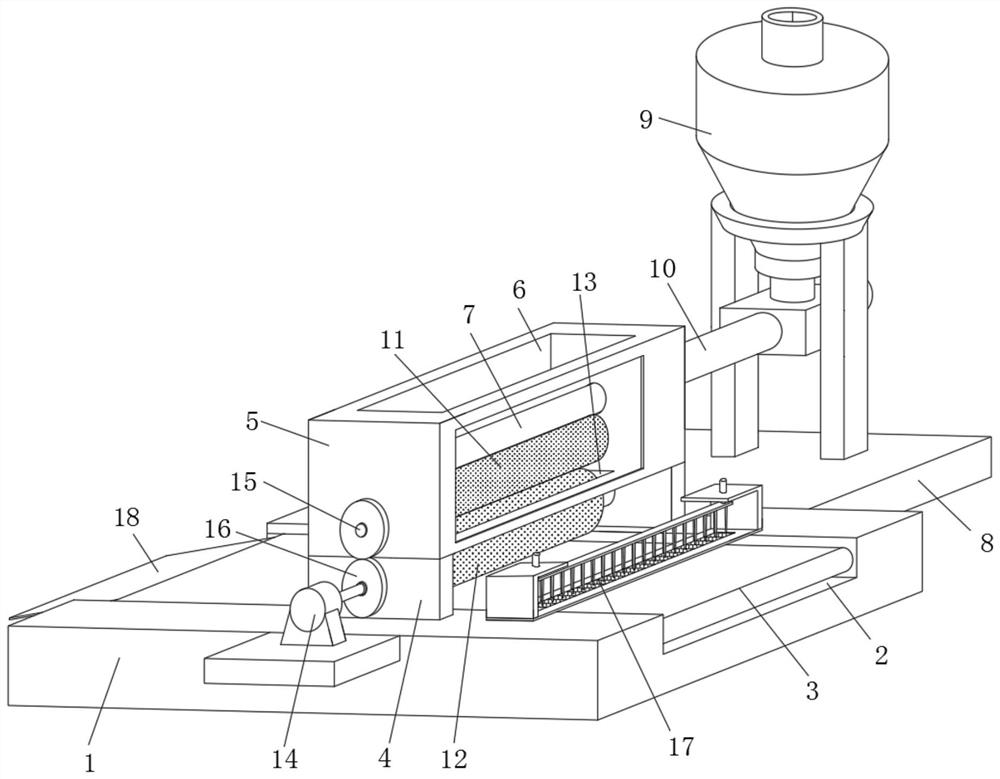

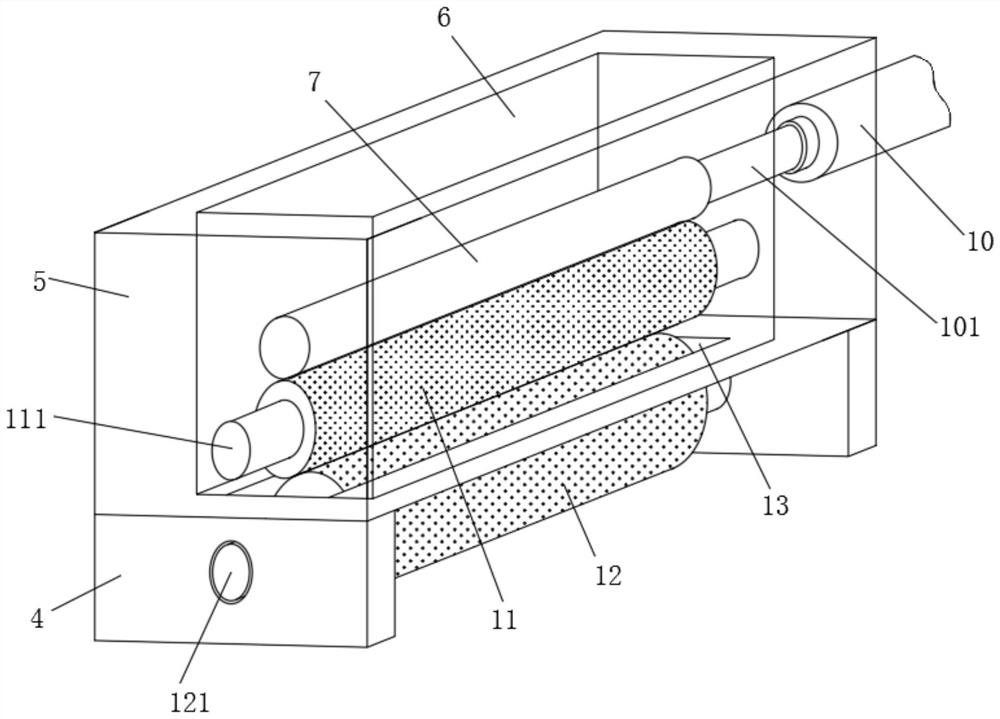

Meat product sauce-brushing device based on food processing and using method thereof

ActiveCN110803492AGood continuityImport smoothlyLoading/unloadingConveyor partsProcess engineeringFood processing

The invention discloses a meat product sauce-brushing device based on food processing and a using method thereof, and belongs to the field of food processing. According to the meat product sauce-brushing device based on food processing and the using method thereof, a sauce tank continuously guides sauce into a conveying pipe, so that the sauce is uniformly guided onto a taking roller through a plurality of leakage holes in the bottom end of the conveying pipe, the taking roller and a brushing roller are in transmission connection through a transmission mechanism, the sauce on the taking rolleris conveyed onto the brushing roller in transmission, the brushing roller uniformly smears the sauce on meat products on a conveying belt in the continuous rotating process, compared with traditionalmanual brushing or sauce brushing through a rotating common sauce brush, the sauce is smeared more continuously and more evenly, and meanwhile, the meat products are further pressed in the sauce brushing process; and a puncture device is arranged at the front end of the brushing roller to puncture the conveyed meat products to a certain extent, and thus the uniformity and permeability of subsequent sauce brushing are further effectively improved.

Owner:四川张飞牛肉有限公司

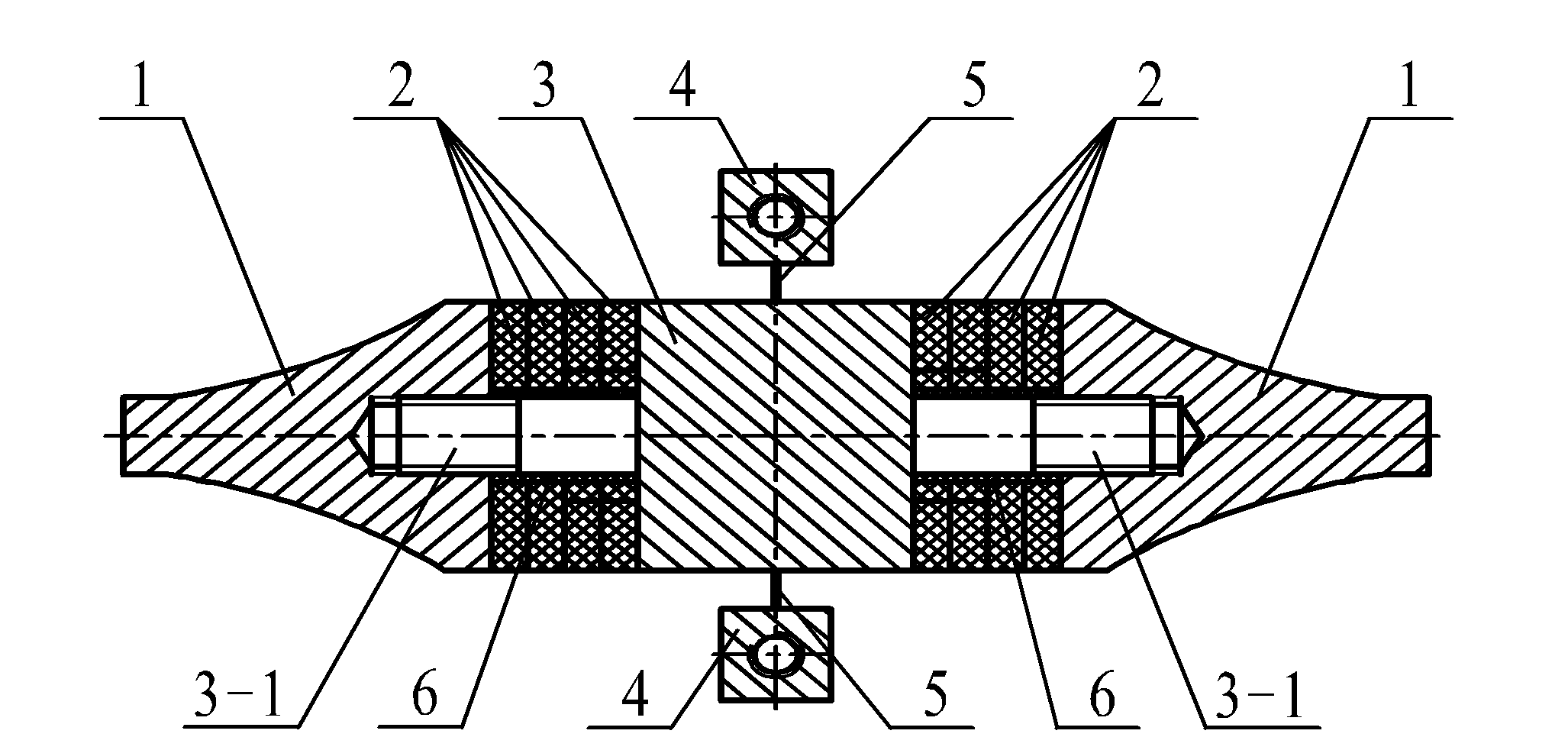

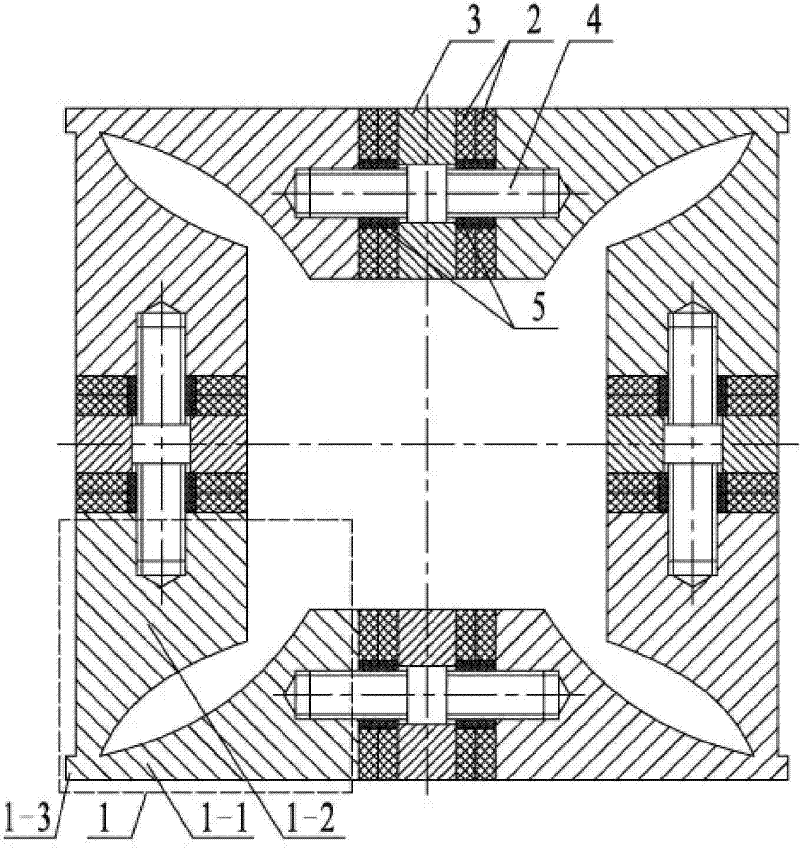

Wedge-shaped pre-tightened sandwich type rectangular four-pin linear ultrasonic motor vibrator

InactiveCN102437779ASimple structureAvoid internal stressPiezoelectric/electrostriction/magnetostriction machinesEngineeringLongitudinal vibration

A wedge-shaped pre-tightened sandwich type rectangular four-pin linear ultrasonic motor vibrator, belonging to the technical field of piezoelectric ultrasonic motor, which solves the problem in the current rectangular four-pin linear ultrasonic motor vibrator that has complex structure and high requirement on the processing and assembling precision, wherein two horizontal combined beams and two longitudinal combined beams form a rectangular frame; the central positions of the inside face and the outside face of the column beam of each combined beam are respectively opened with a rectangular chute; the central position of each rectangular chute is provided with a pre-pressing block; a pair of longitudinal vibration piezoelectric ceramic chips is installed between two side faces of the pre-pressing block and the side wall of the rectangular chute; a wedge-shaped block is formed between each pair of longitudinal vibration piezoelectric ceramic chips and the pre-pressing block; the contact surface between the wedge-shaped block and the bottom part of the rectangular chute is a big end face of the wedge-shaped block; two pre-pressing blocks on the same combined beam are cooperatively connected with a pre-tightening nut via a pre-tightening screw, and then the longitudinal vibration piezoelectric ceramic chips are pre-tightened. The invention is suitable for manufacturing the ultrasonic motor vibrator.

Owner:HARBIN INST OF TECH

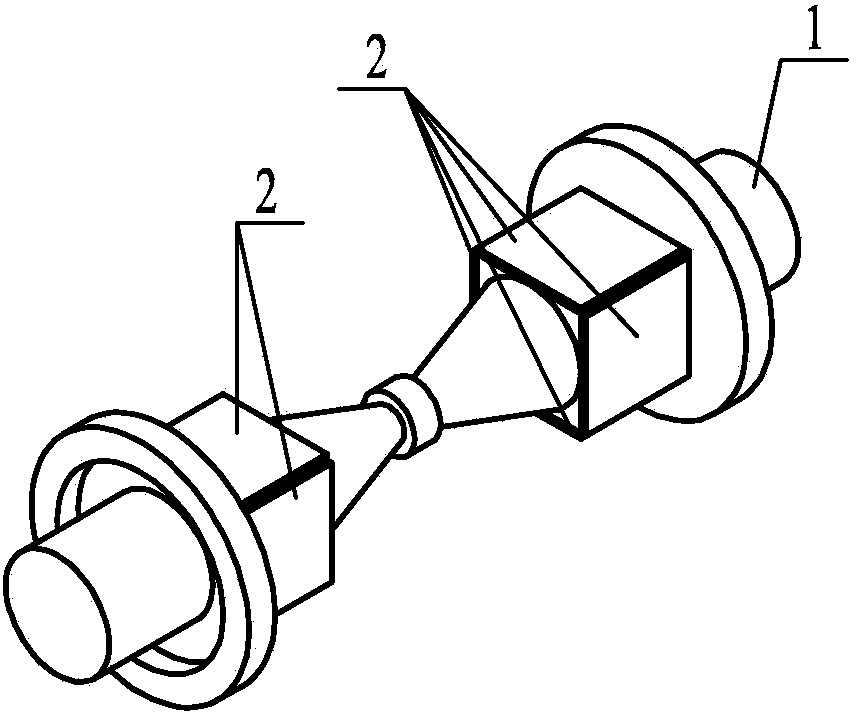

Paster bent vibration composite single-foot piezoelectric supersonic motor vibrator

InactiveCN103746599AExcited bending vibrationAchieve macro motion outputPiezoelectric/electrostriction/magnetostriction machinesEngineeringFlange

A paster bent vibration composite single-foot piezoelectric supersonic motor vibrator belongs to the technical field of piezoelectric supersonic motors and aims to solve the problem that the integration is unfavorably realized due to a complex system as the existing supersonic motor vibrator adopts a dual-driving feet structure and is assisted with two sets of rotors and a guide rail system for realizing driving. The paster bent vibration composite single-foot piezoelectric supersonic motor vibrator comprises two variable amplitude rods, two middle beams, two rear end covers, a driving foot, two flanges and eight piezoelectric ceramic pieces; each variable amplitude rod is a block body gradually thinned from the head end to the tail end; each middle beam is a cuboid with a square section; head ends of the two variable amplitude rods are connected with the head ends of the two middle beams; the tail ends of the two variable amplitude rods are connected by the driving foot; a rear end cover is arranged at the tail end surface of each middle beam; a flange is arranged outside each rear end cover; one piezoelectric ceramic piece is arranged on each side surface of each middle beam; the piezoelectric ceramic pieces are polarized along the thickness direction; the mutually parallel four piezoelectric ceramic pieces are same in the polarization direction. The paster bent vibration composite single-foot piezoelectric supersonic motor vibrator is suitable for the piezoelectric supersonic motor needing integration.

Owner:HARBIN INST OF TECH

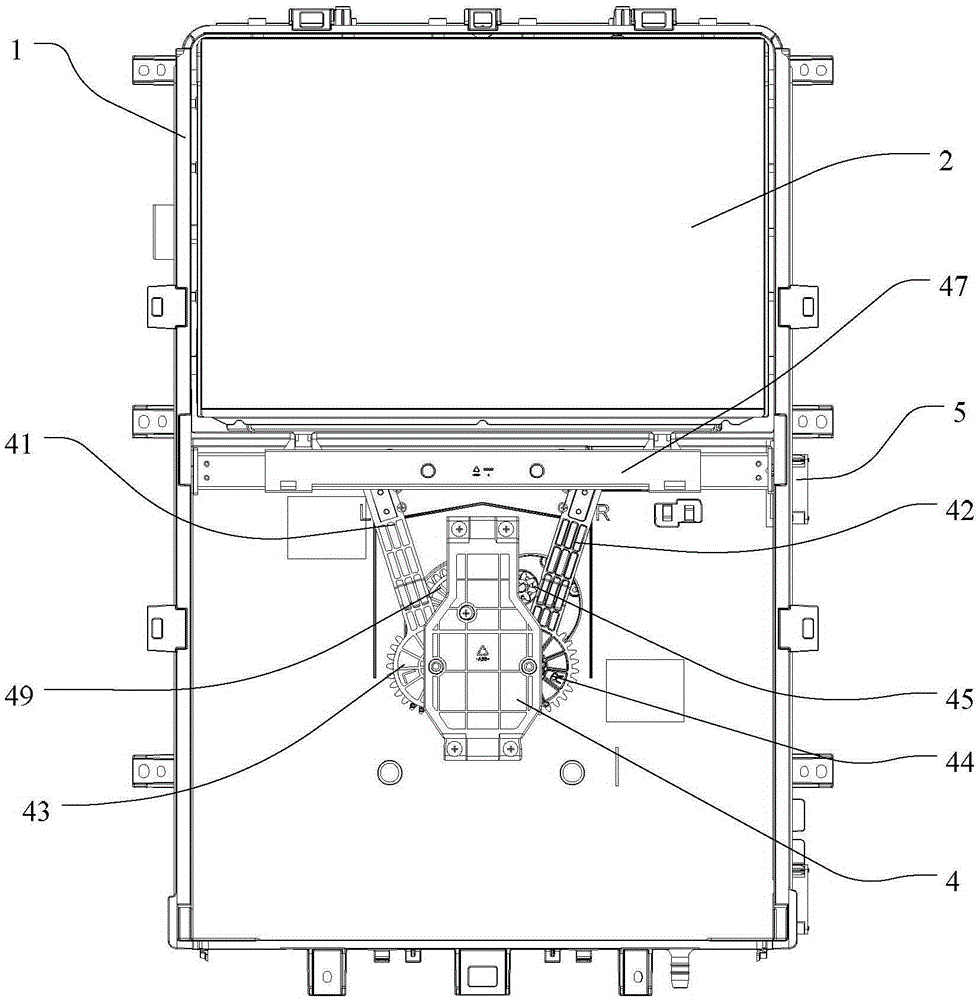

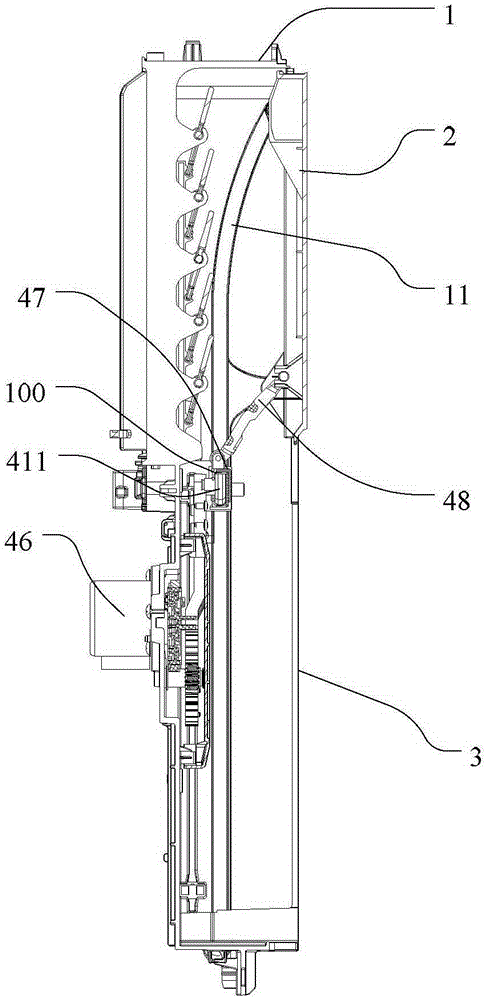

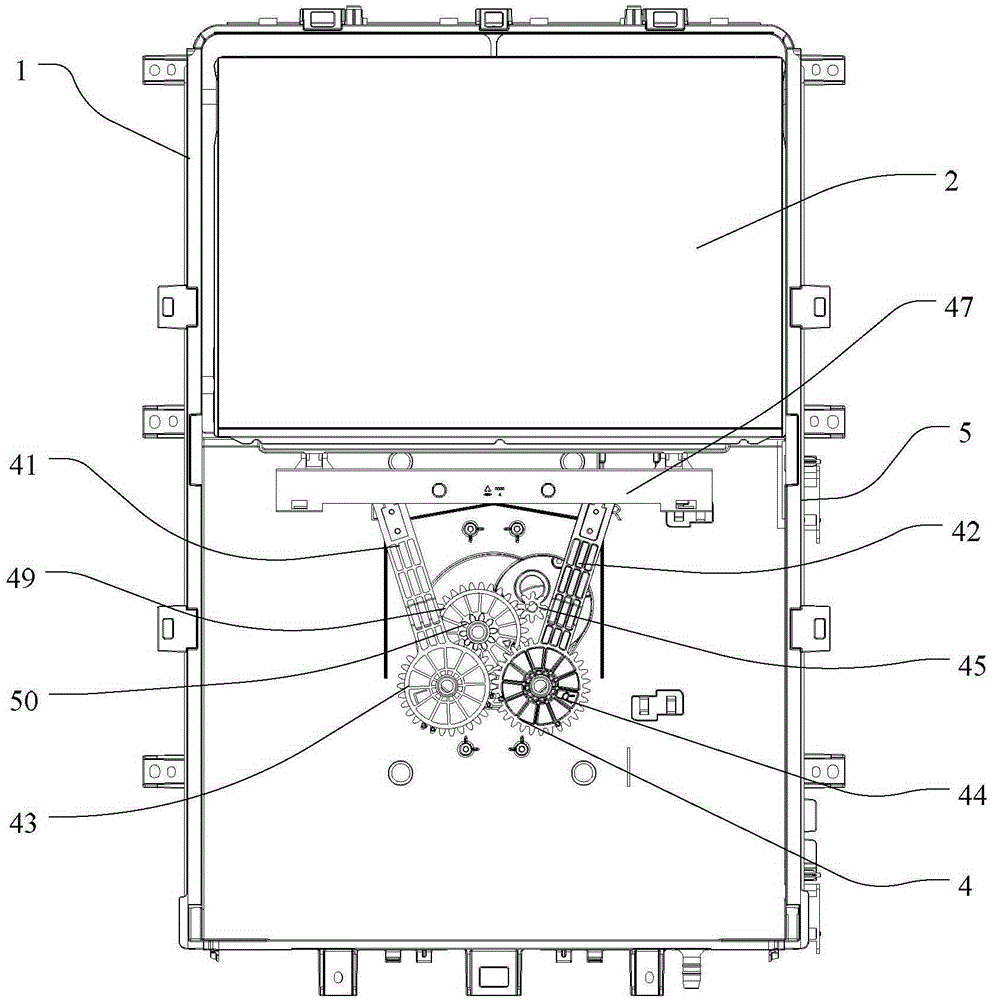

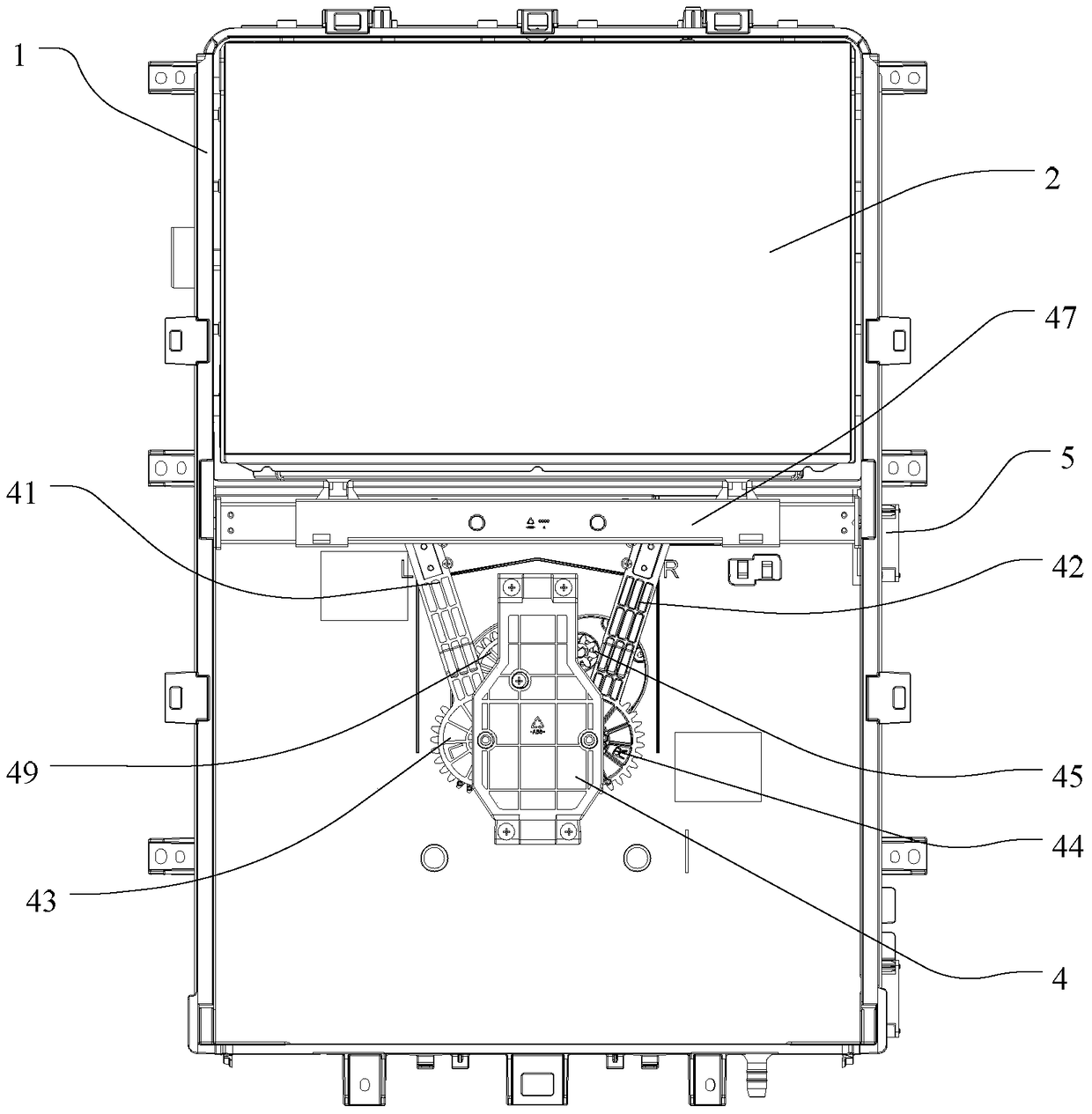

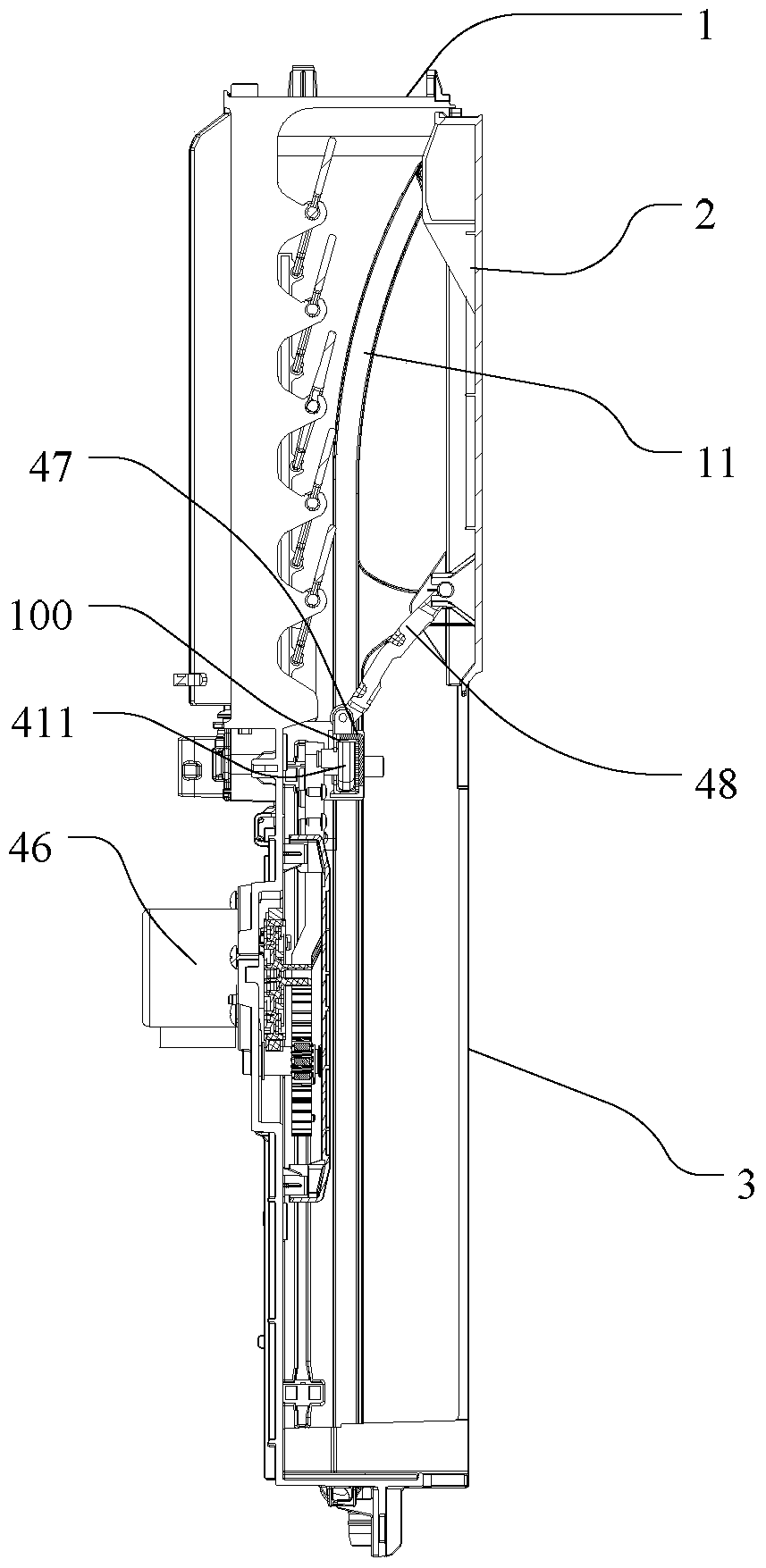

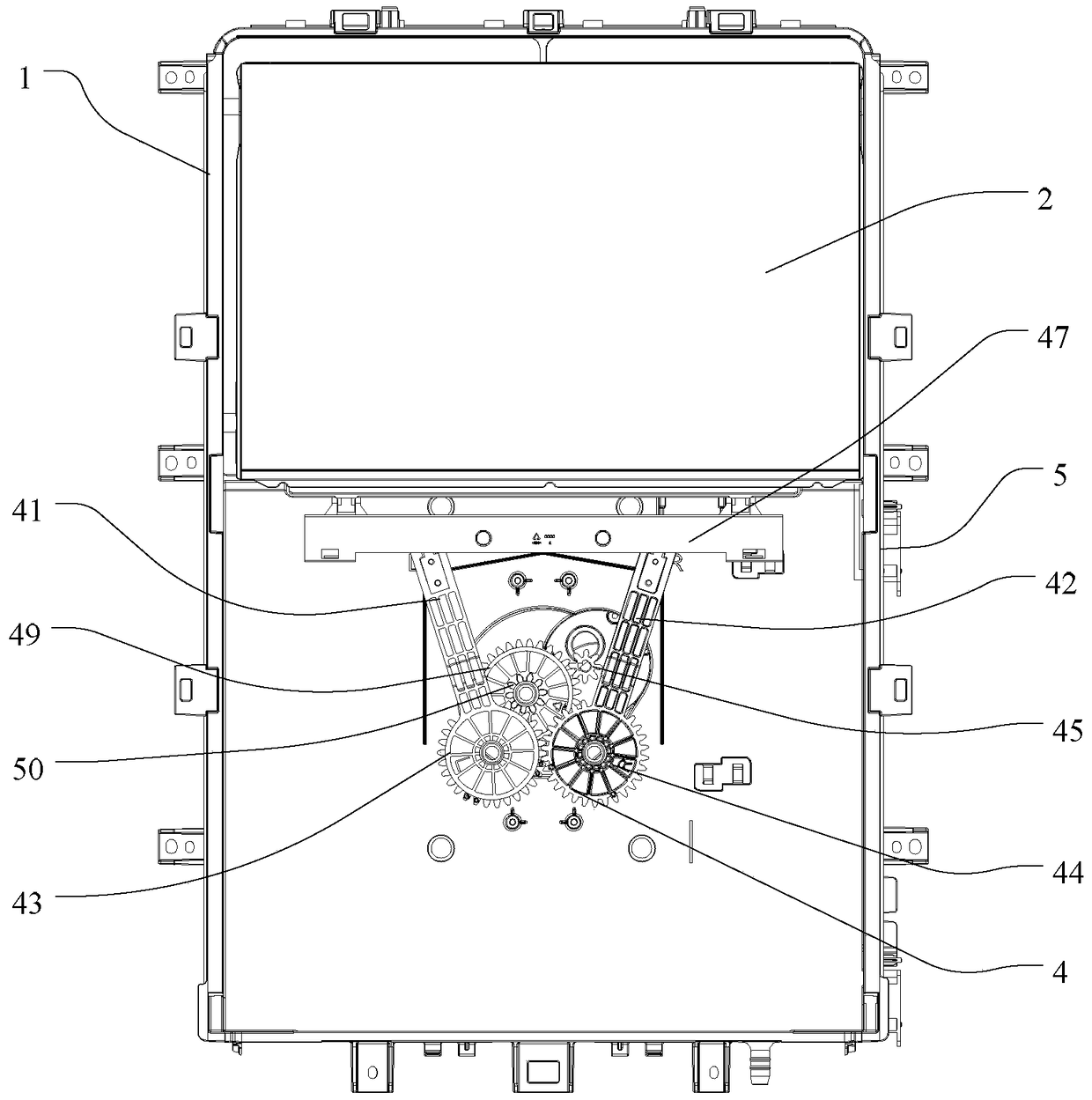

Sliding door drive device and air conditioning device

The invention relates to a sliding door drive device used for driving a sliding door to vertically move. The sliding door drive device comprises a first oscillating bar, a second oscillating bar and a driving wheel. The first oscillating bar and the second oscillating bar are symmetrically arranged. A first driven gear and a second driven gear engaged with the first driven gear are arranged at the lower end of the first oscillating bar and the lower end of the second oscillating bar respectively. The second end of the first oscillating bar and the second end of the second oscillating bar are connected with the sliding door. The driving gear is connected with a power mechanism to drive the first driven gear and the second driven gear to synchronously rotate. In the sliding door drive device, due to the fact that the driven gears for driving the oscillating bars are in gear transmission with the driving gear, the driving gear can be driven by the driven gears for reverse transmission under the action that external force is artificially exerted on the driven gears. When the sliding door drive device cannot be started normally, the sliding door can be manually pushed downwards to the inner side of an air conditioning device, and therefore a lower panel is demounted down, and the air conditioning device is maintained.

Owner:GREE ELECTRIC APPLIANCES INC

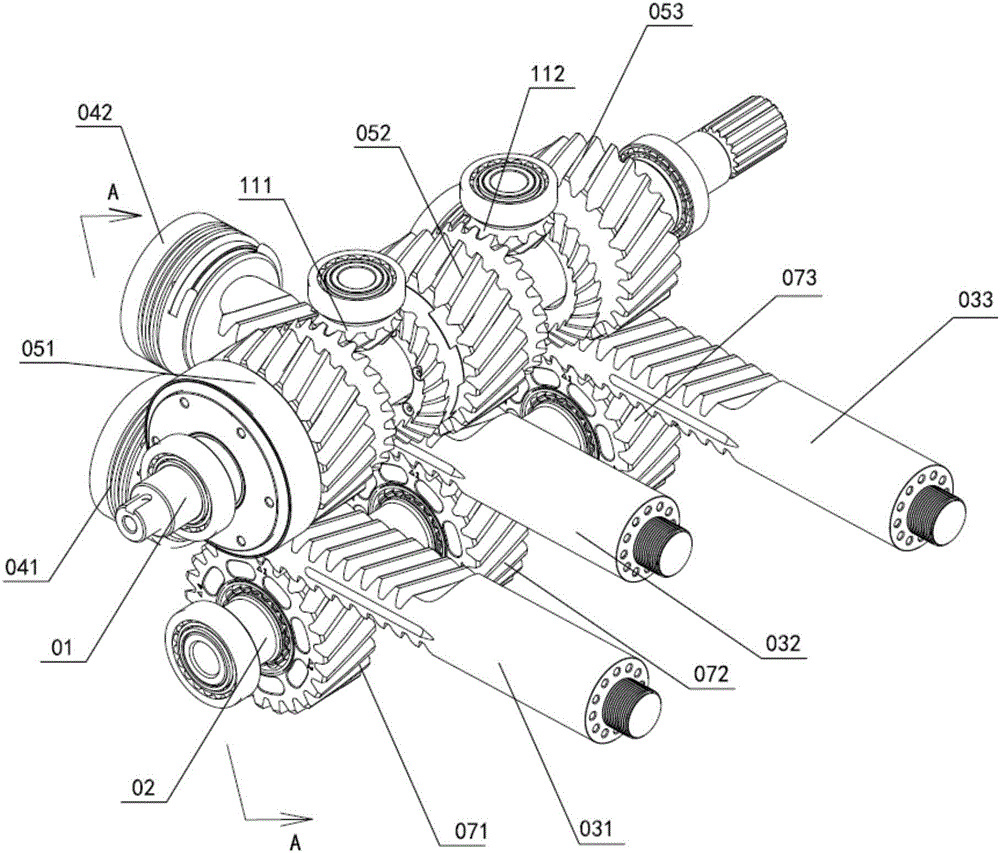

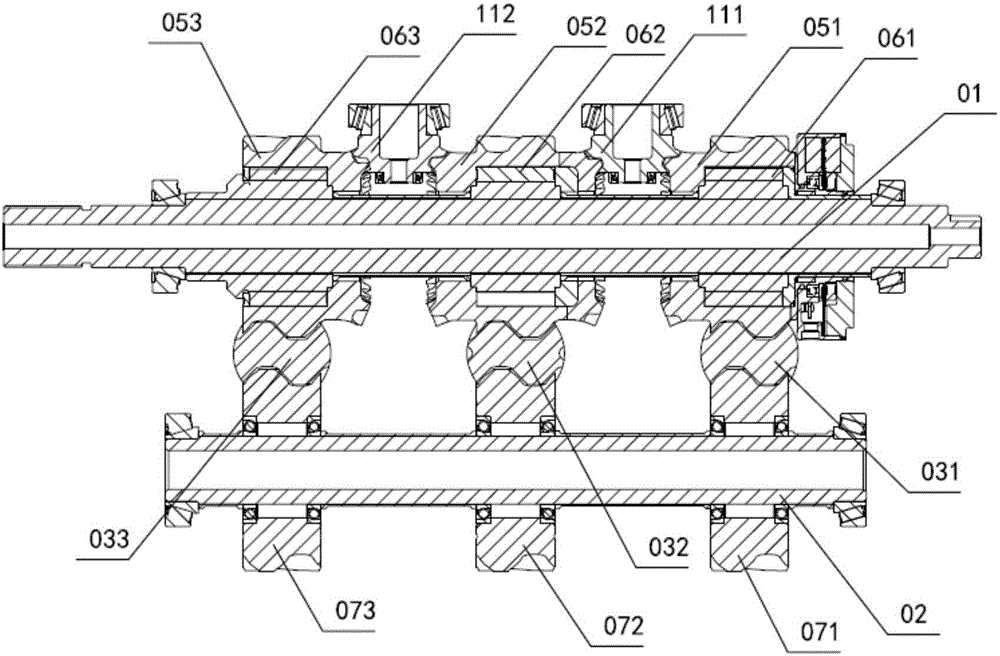

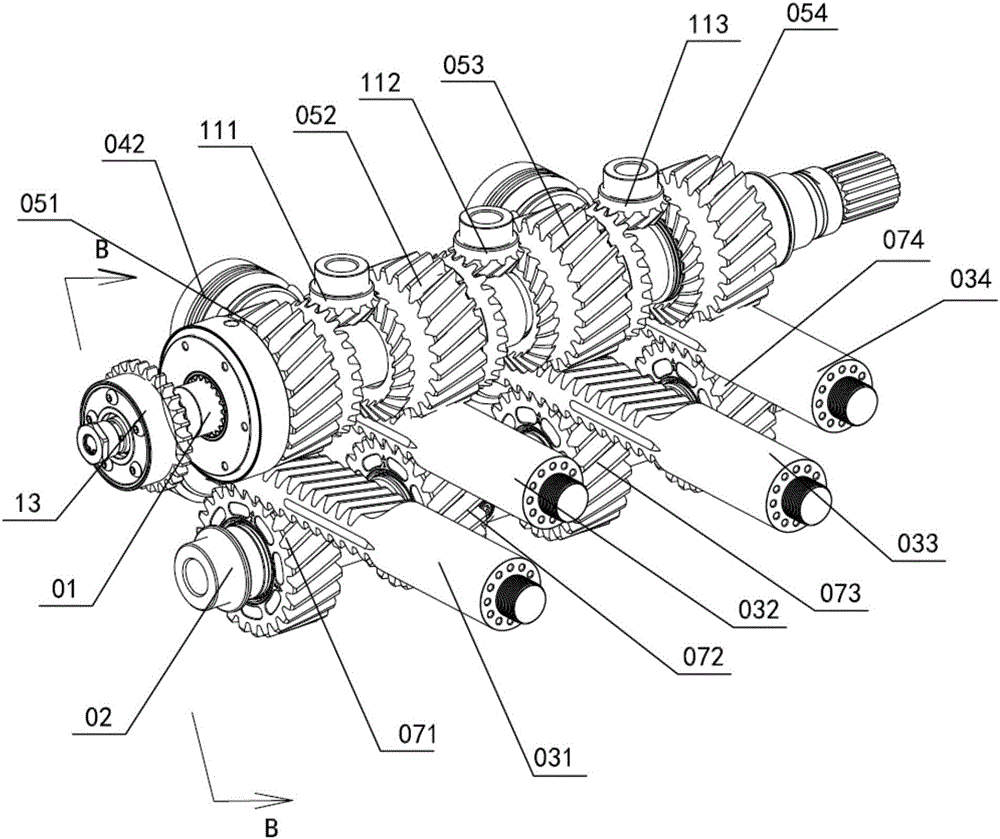

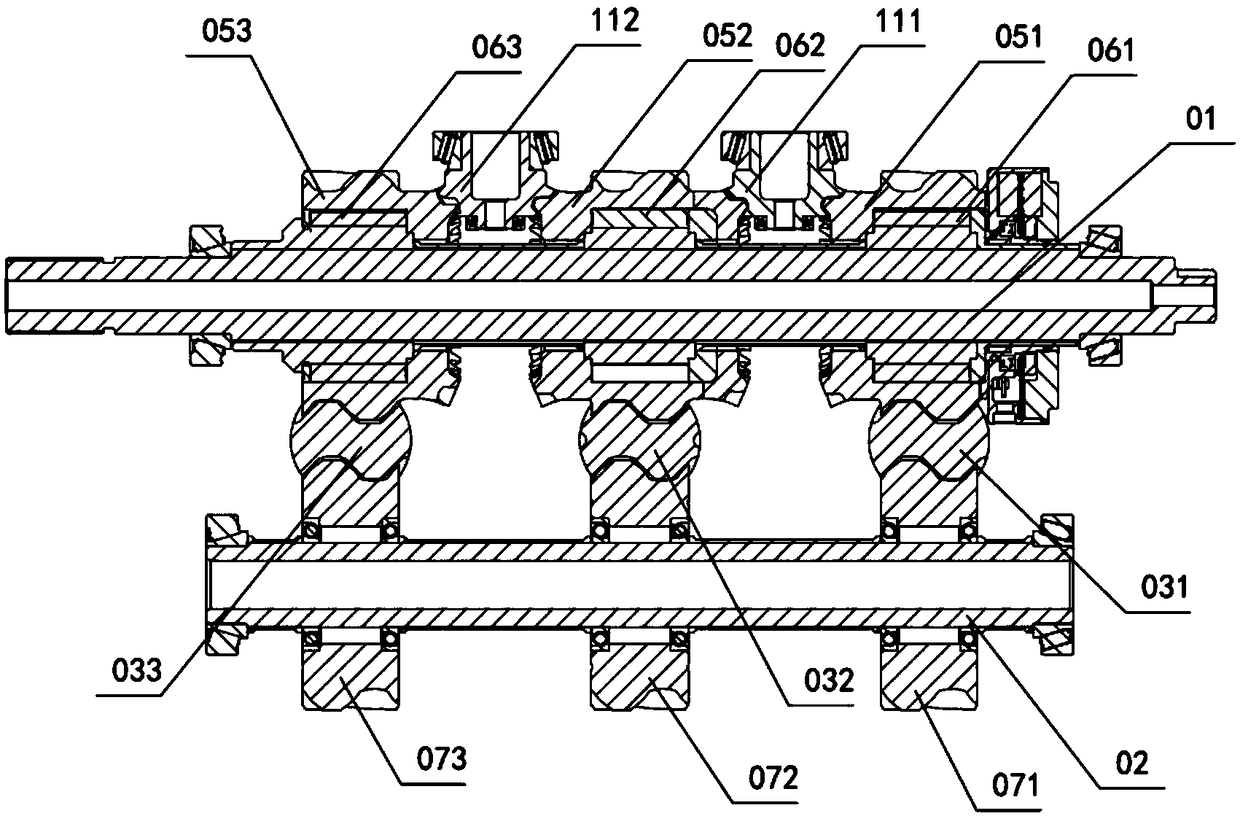

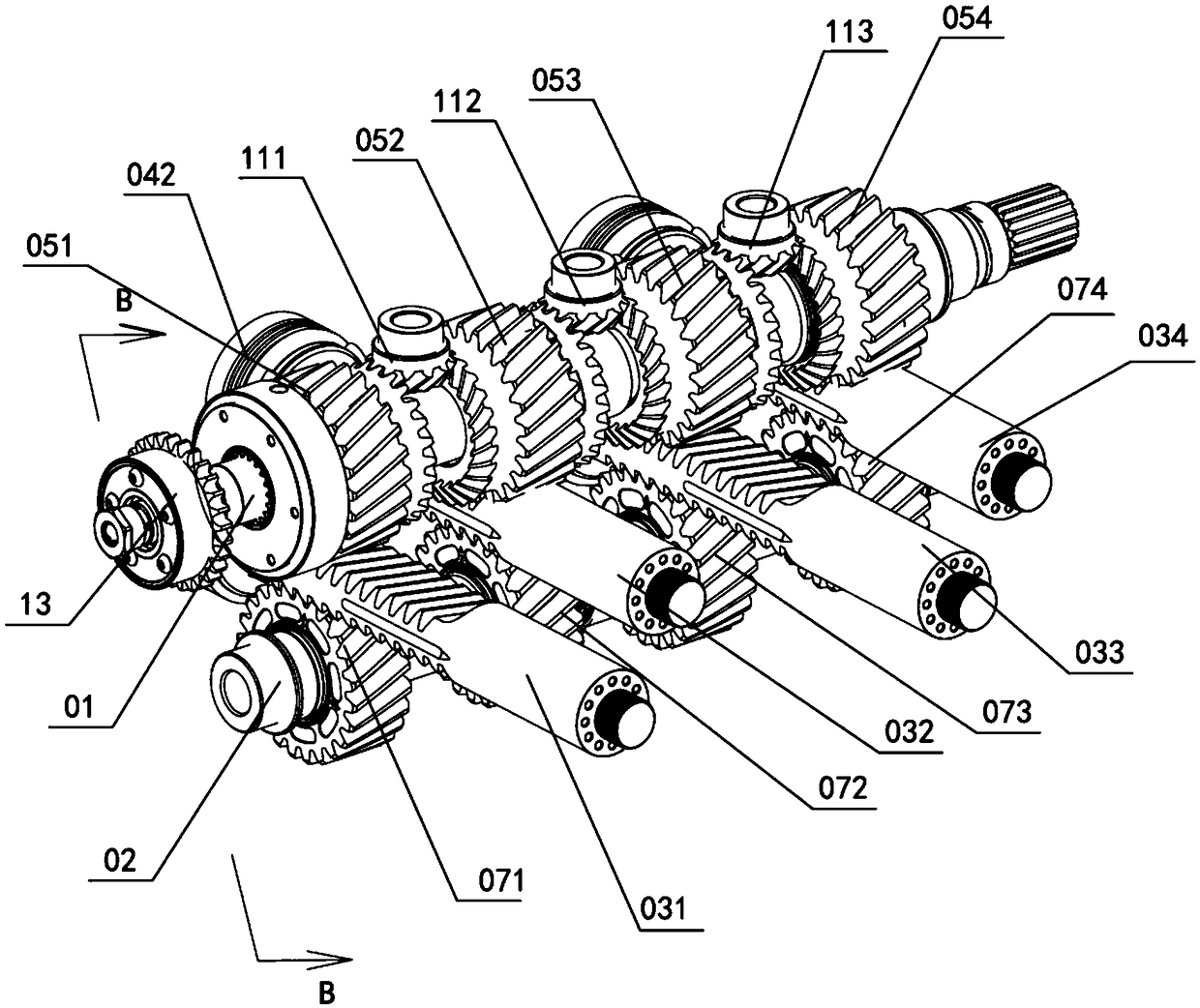

Series connection non-crankshaft engine transmission mechanism and engine with series connection non-crankshaft engine transmission mechanism

The invention discloses a series connection non-crankshaft engine transmission mechanism which comprises a power shaft and an auxiliary shaft. At least two air cylinder piston rods are arranged between the power shaft and the auxiliary shaft. Air cylinder pistons are arranged at the end heads of the same ends of the air cylinder piston rods correspondingly. One side of each air cylinder piston rod is engaged with a main gear which is arranged on the power shaft in a sleeving manner through a one-way clutch. The combining directions of the one-way clutches are the same. The other side of each air cylinder piston rod is rotationally connected with the auxiliary shaft through a guiding mechanism. Every two adjacent two main gears are in transmission connection through a reverse transmission mechanism. When one air cylinder piston rod acts, the corresponding main gear rotates, and when the combining directions of the one-way clutches are the same, the main gears corresponding to the power shaft enable the power shaft to rotate to output power through the corresponding one-way clutches. Meanwhile, transmission and reversing of power needed by the stroke of the corresponding air cylinder piston rods are achieved by every adjacent two main gears through the corresponding reverse transmission mechanisms. The transmission mechanism belongs to a free piston type, and therefore a variable compression ratio function is achieved.

Owner:朱晓明

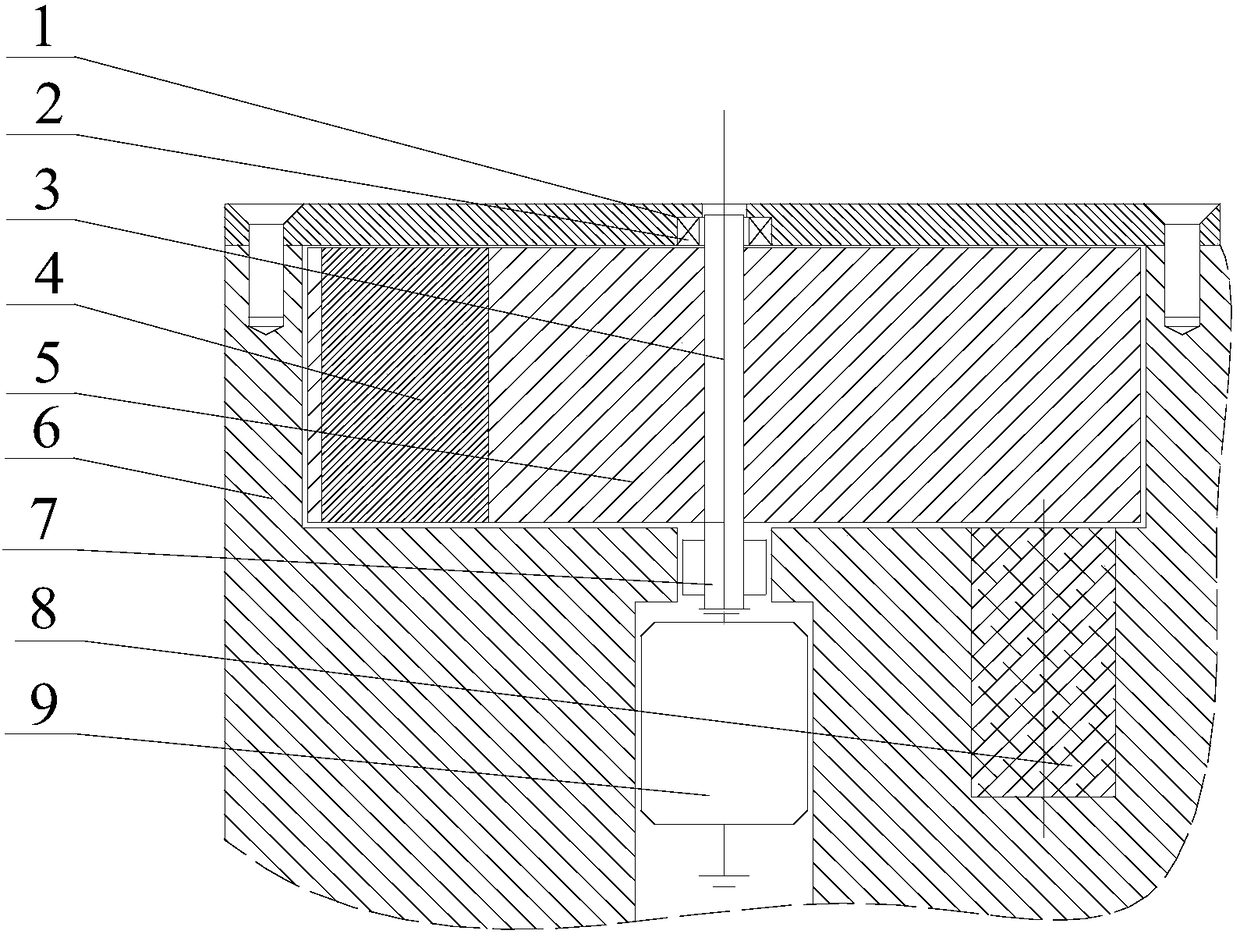

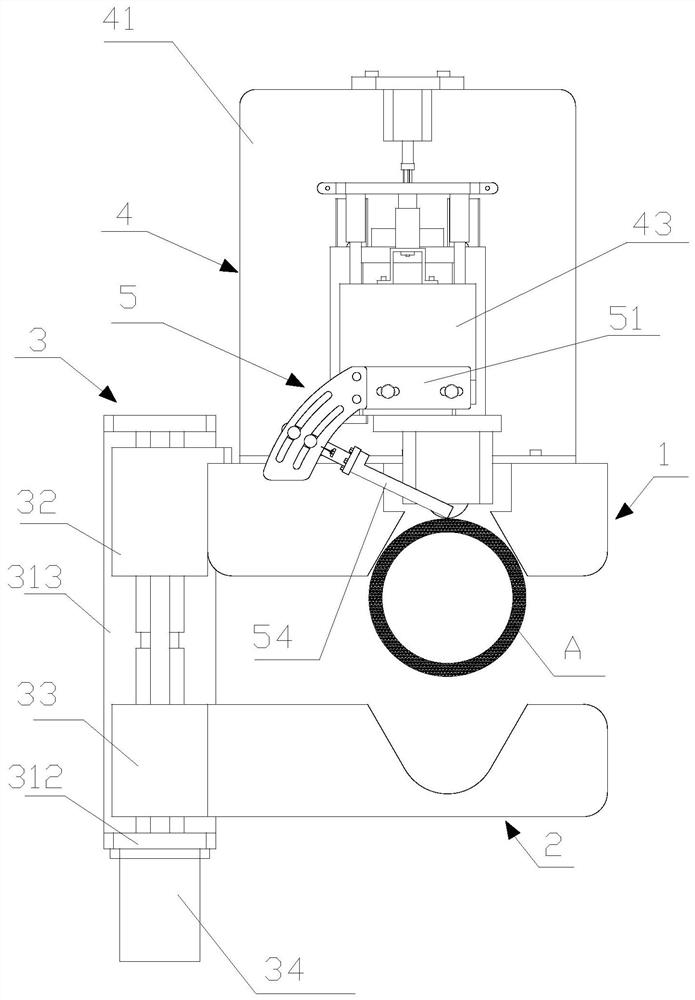

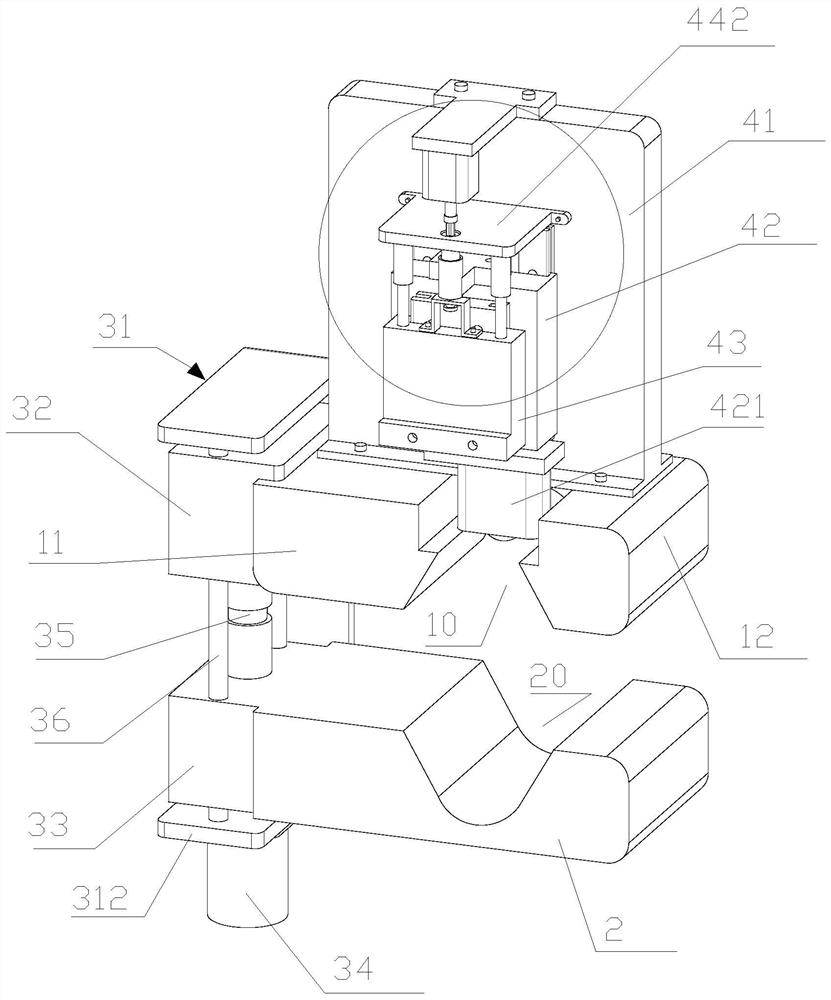

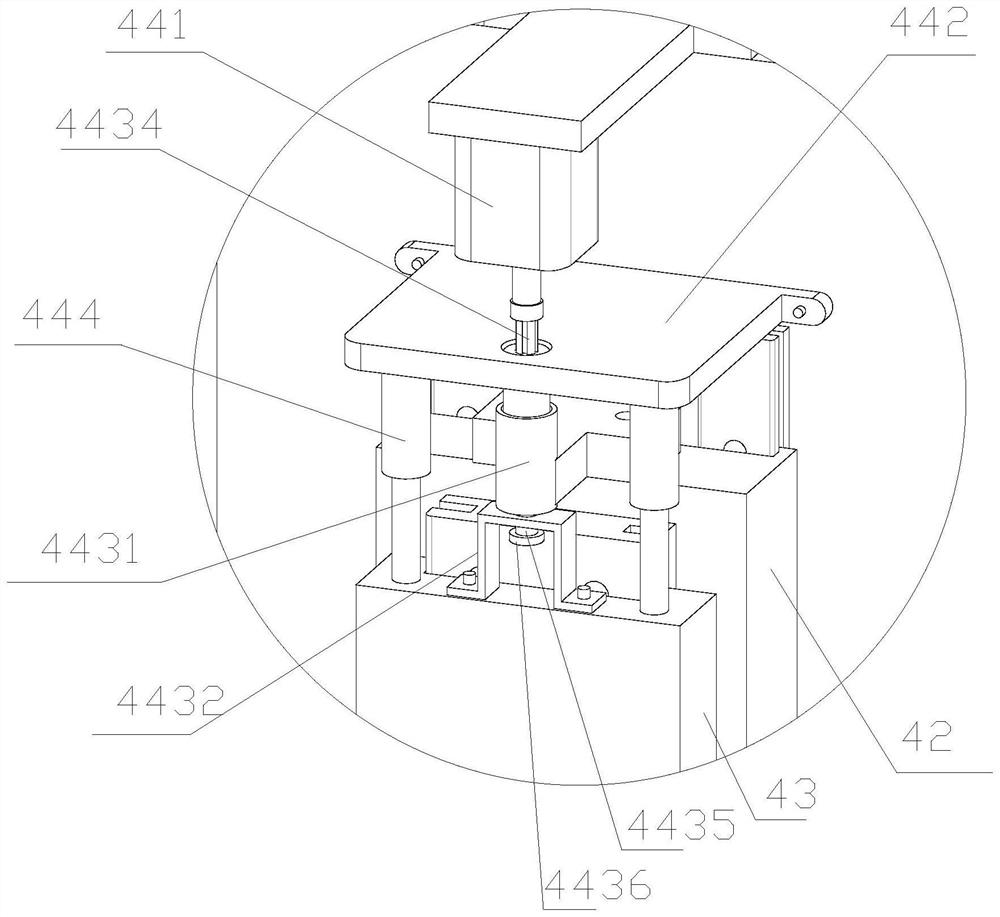

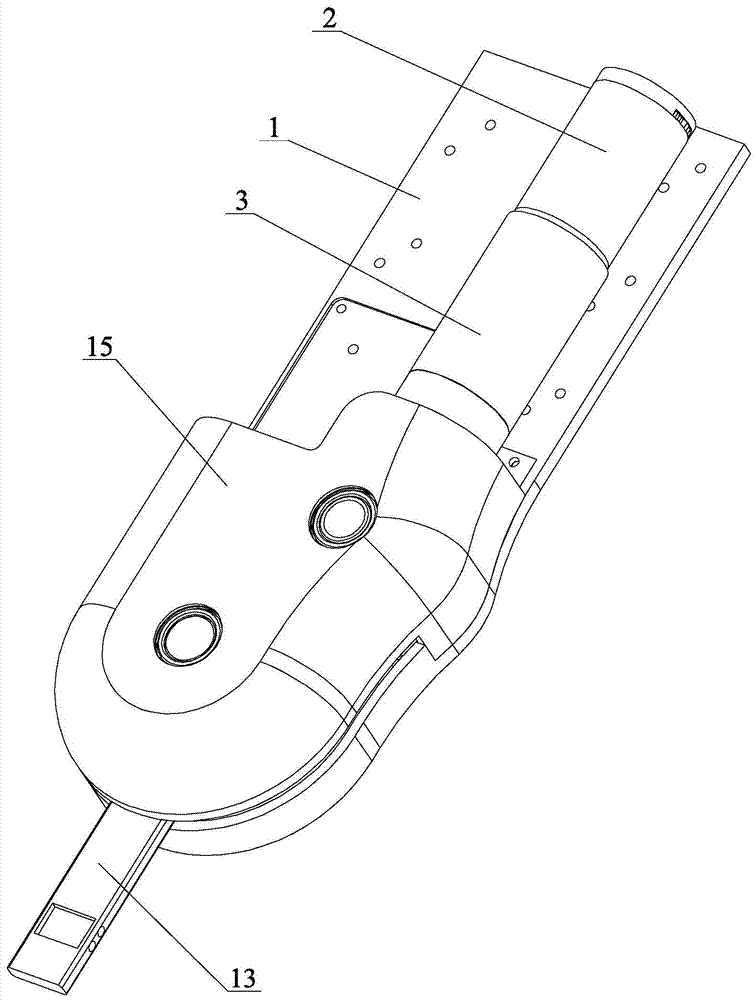

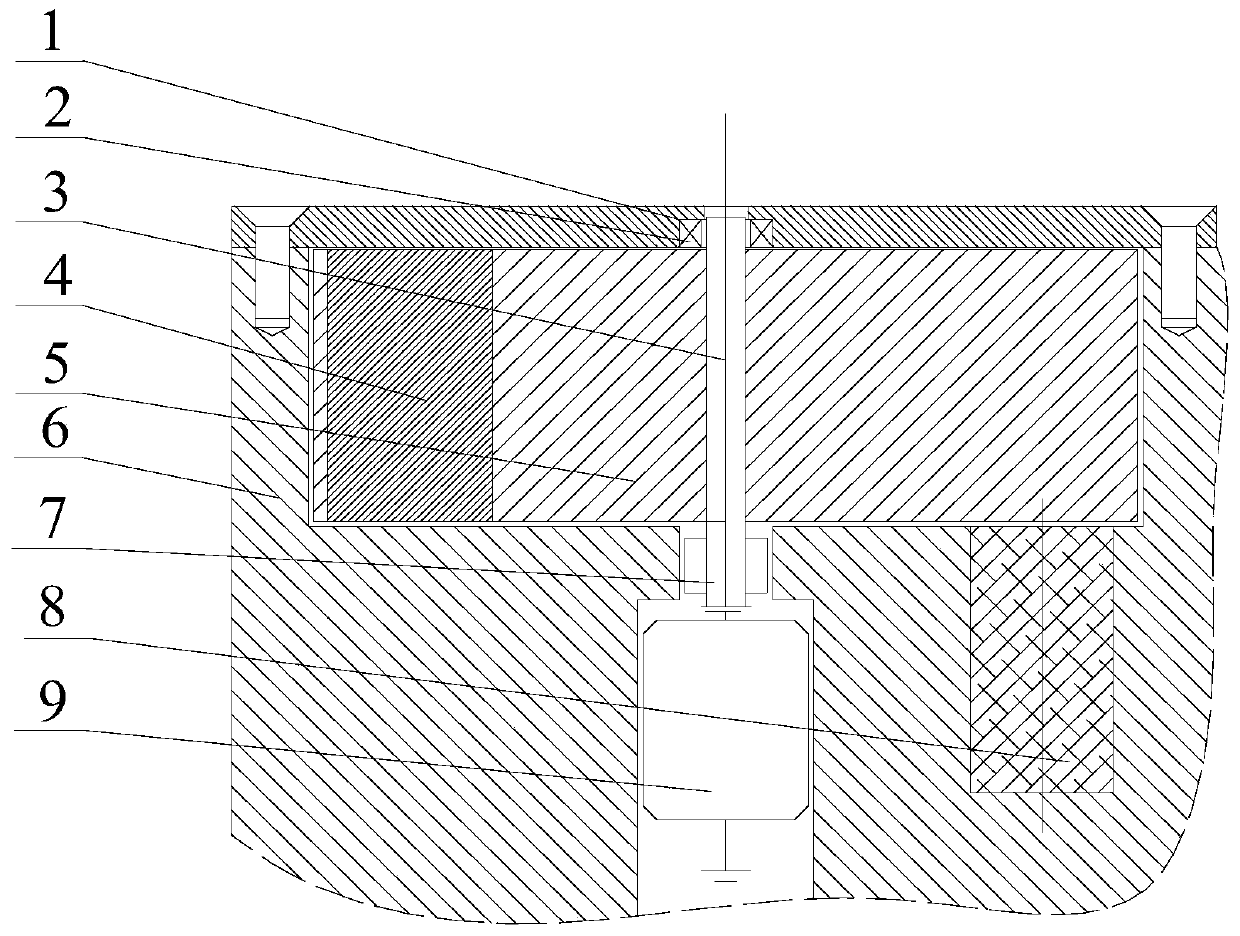

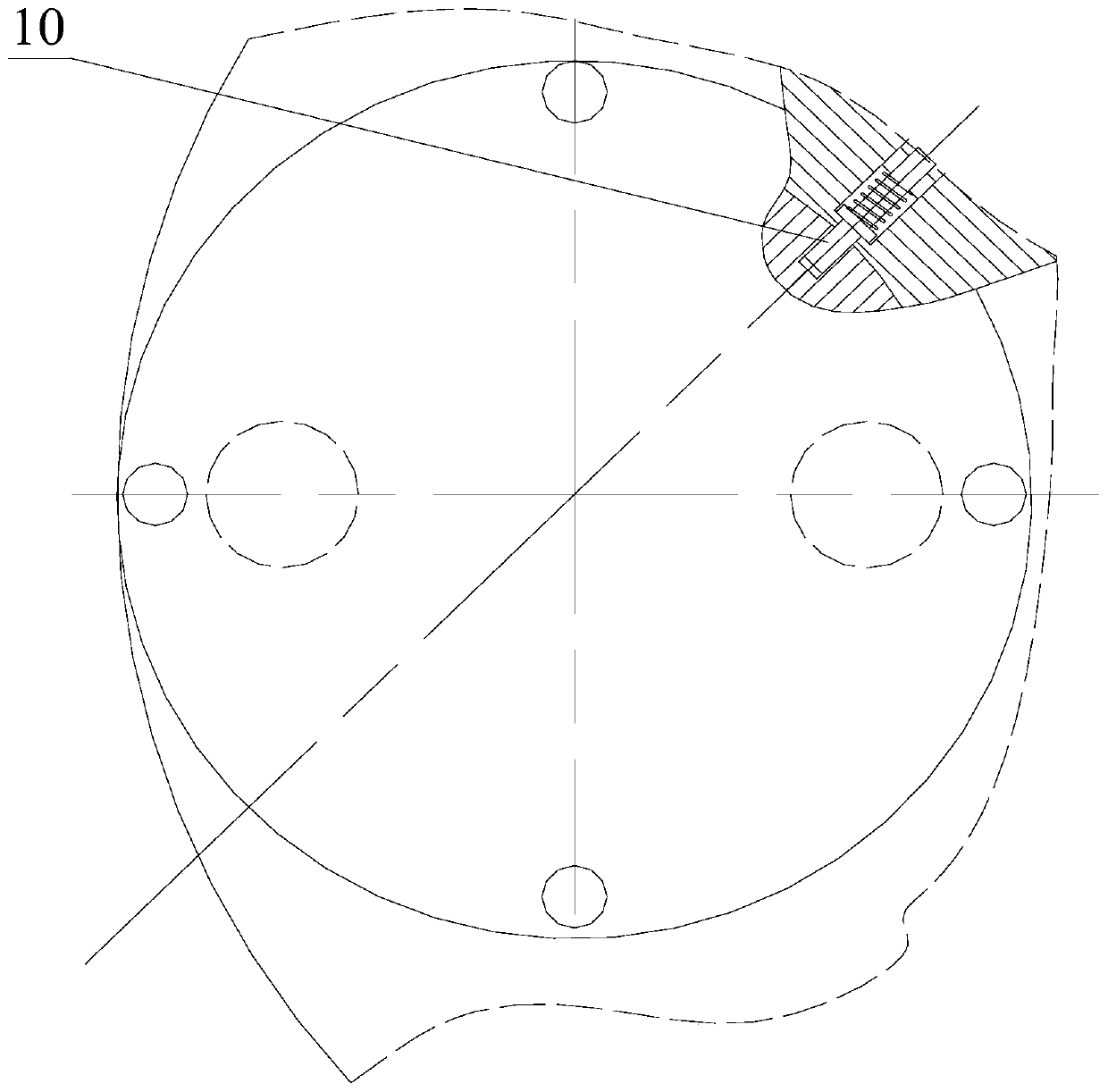

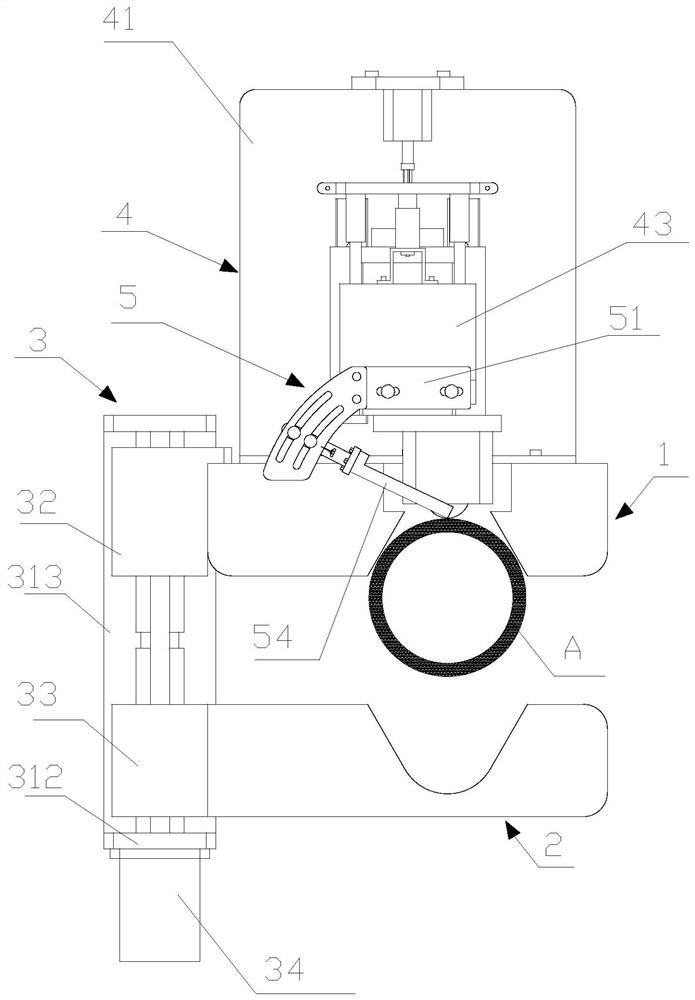

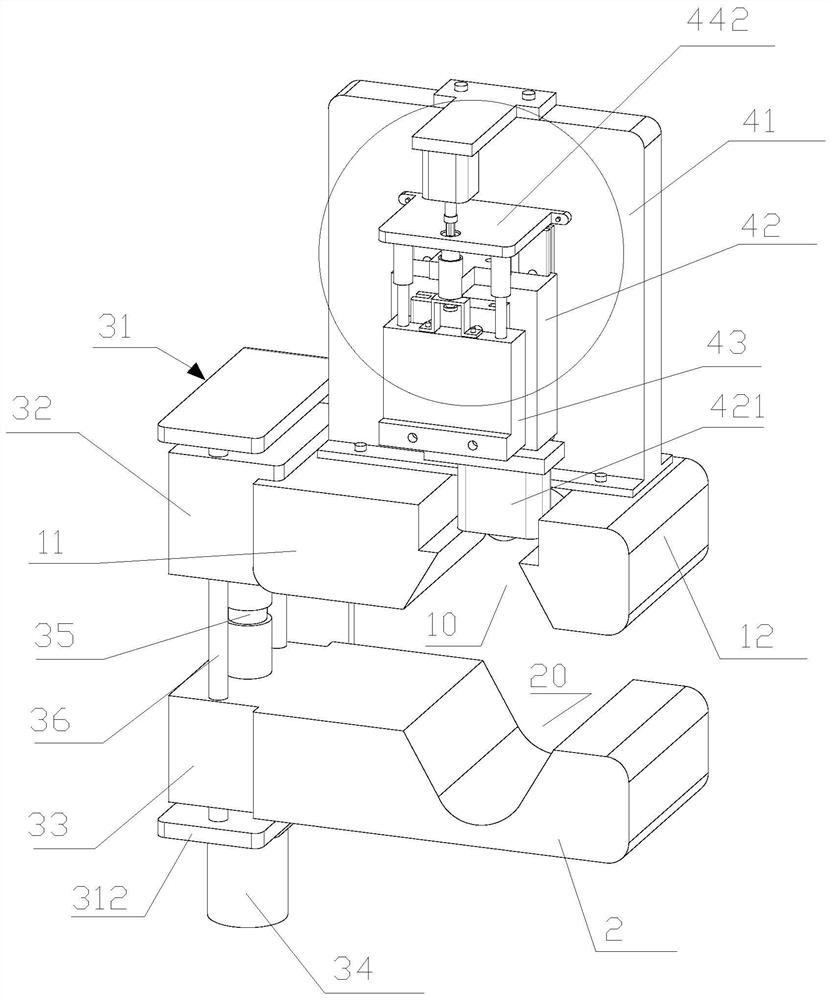

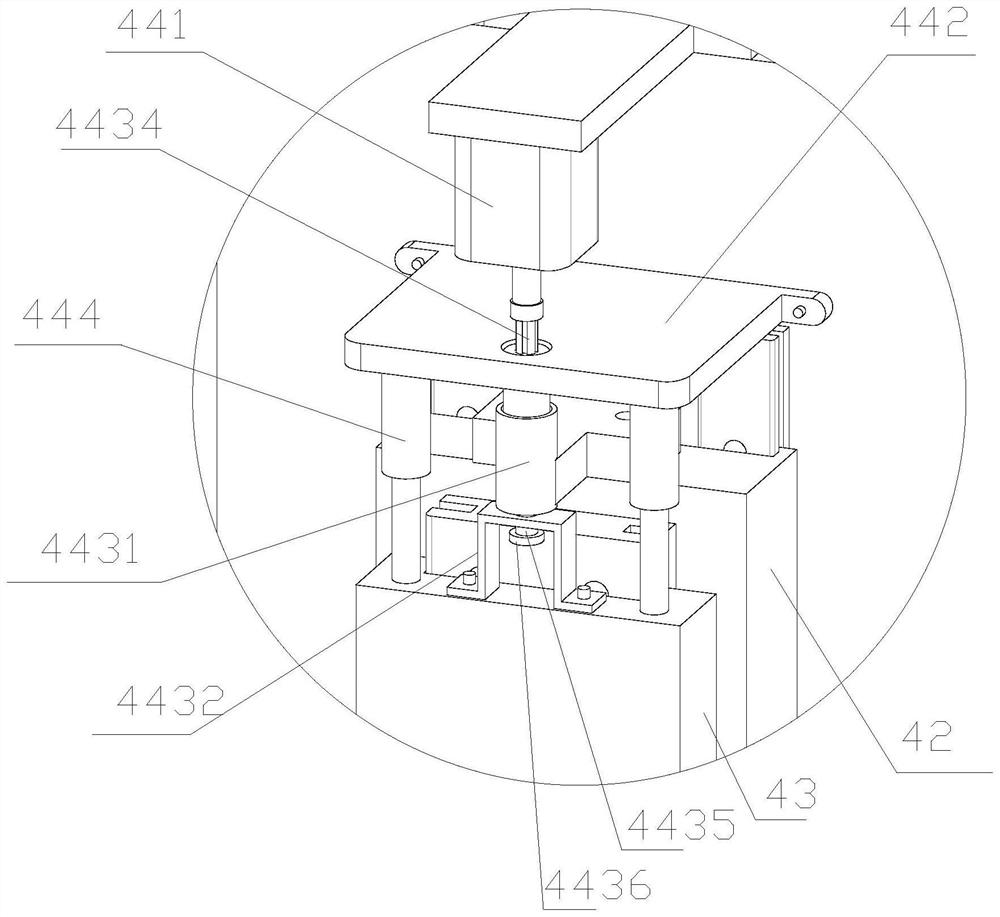

Isolation mechanism

ActiveCN108087152ARealize reverse driveUniform driving forceMachine part testingRocket engine plantsEnd stagesEngineering

Owner:GUIZHOU AEROSPACE ELECTRONICS TECH

Cable stripping device with adjustable cutting angle, and cable stripping method thereof

InactiveCN112787200AAchieve regulationGuaranteed normal movementLine/current collector detailsApparatus for removing/armouring cablesEngineeringElectrical and Electronics engineering

The invention relates to a cable stripping device with an adjustable cutting angle. A cutter used by the device comprises a mounting part, a fixed connecting part and a cutter handle connecting part; the fixed connecting part is arranged on the mounting part, the cutter handle connecting part is in sliding fit with the fixed connecting part, and the sliding track of the cutter handle connecting part on the fixed connecting part is an arc-shaped track with the cutter point position of the stripping cutter connected with the cutter handle connecting part as the circle center. When the connecting position and direction of the cutter handle connecting part and the fixed connecting part are adjusted, the position of the stripping cutter can be adjusted, but the cutter point position of the stripping cutter is ensured to be unchanged, namely the angle between the stripping cutter and the cable is adjusted, and the stripping cutting starting position is not changed, so that the cable can be effectively stripped according to different stripping angle requirements.

Owner:杭州冉思睿智科技有限责任公司 +2

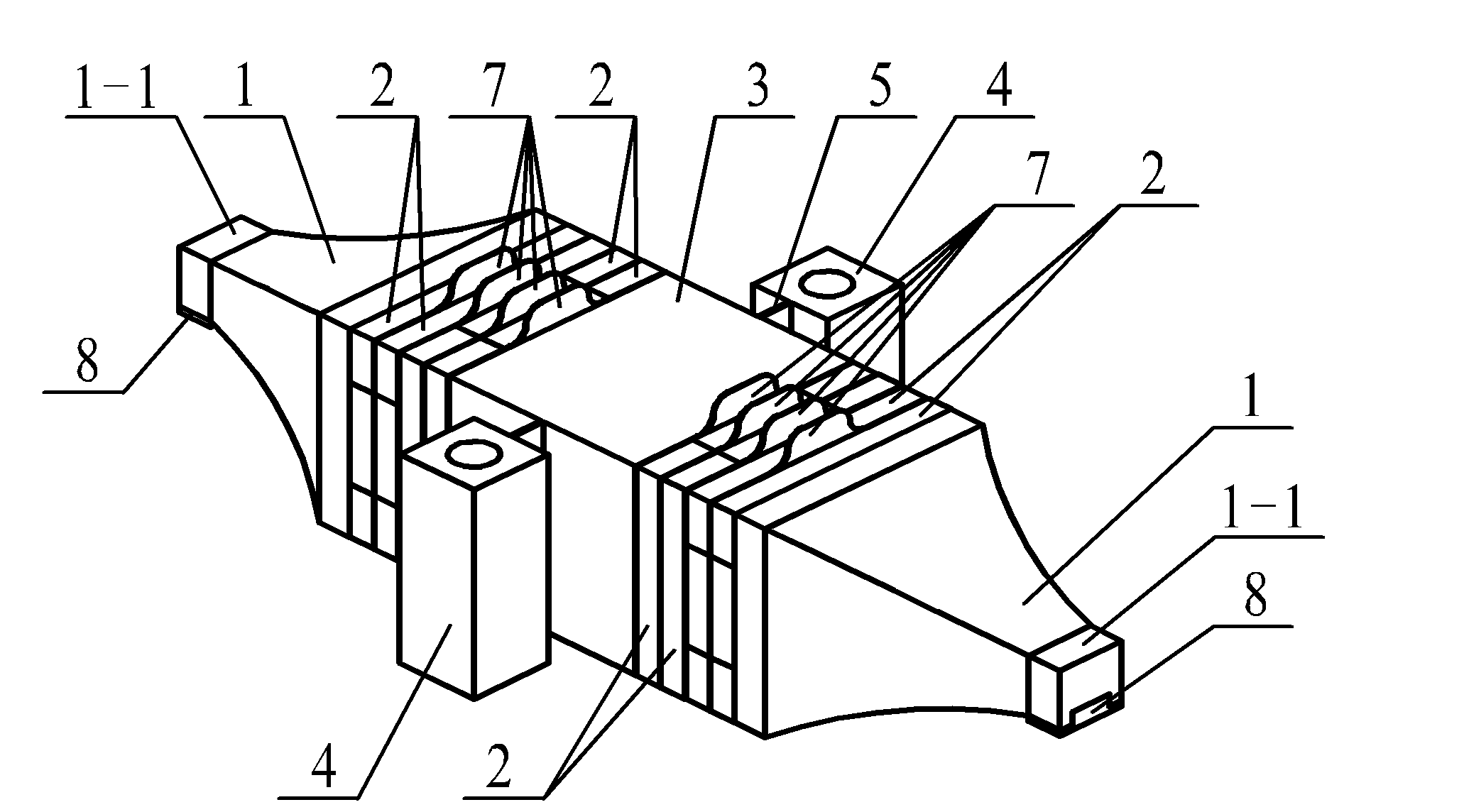

Sandwich I-shaped four-footed linear ultrasonic motor vibrator

ActiveCN102437782BAchieve macro motion outputIncrease amplitudePiezoelectric/electrostriction/magnetostriction machinesElectricityTransformer

Owner:HARBIN INST OF TECH

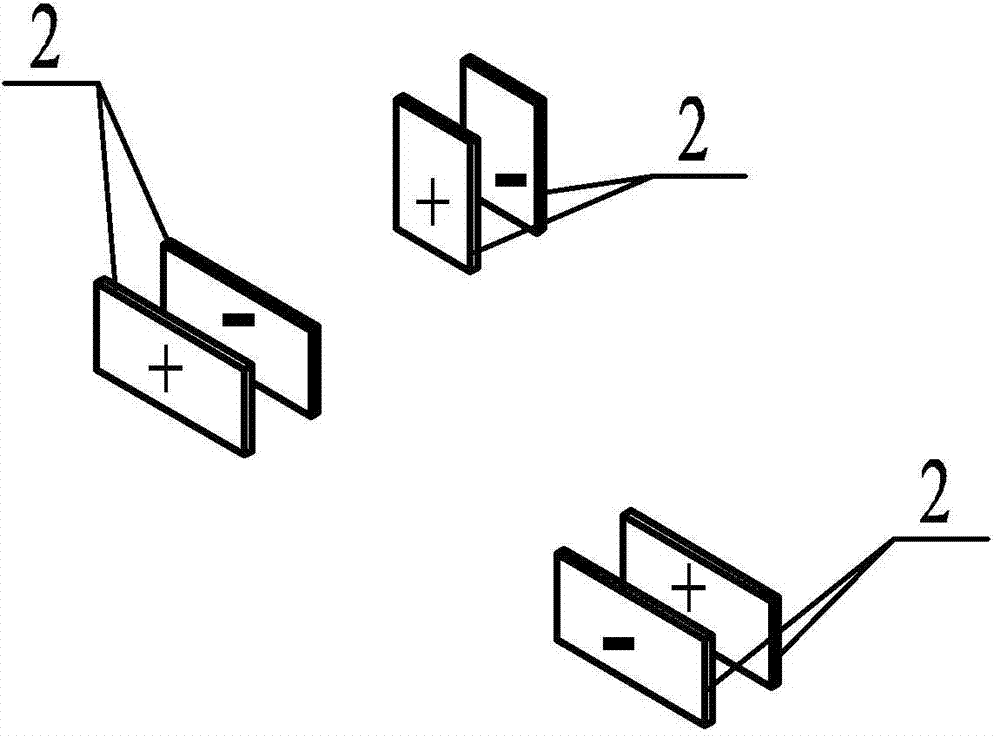

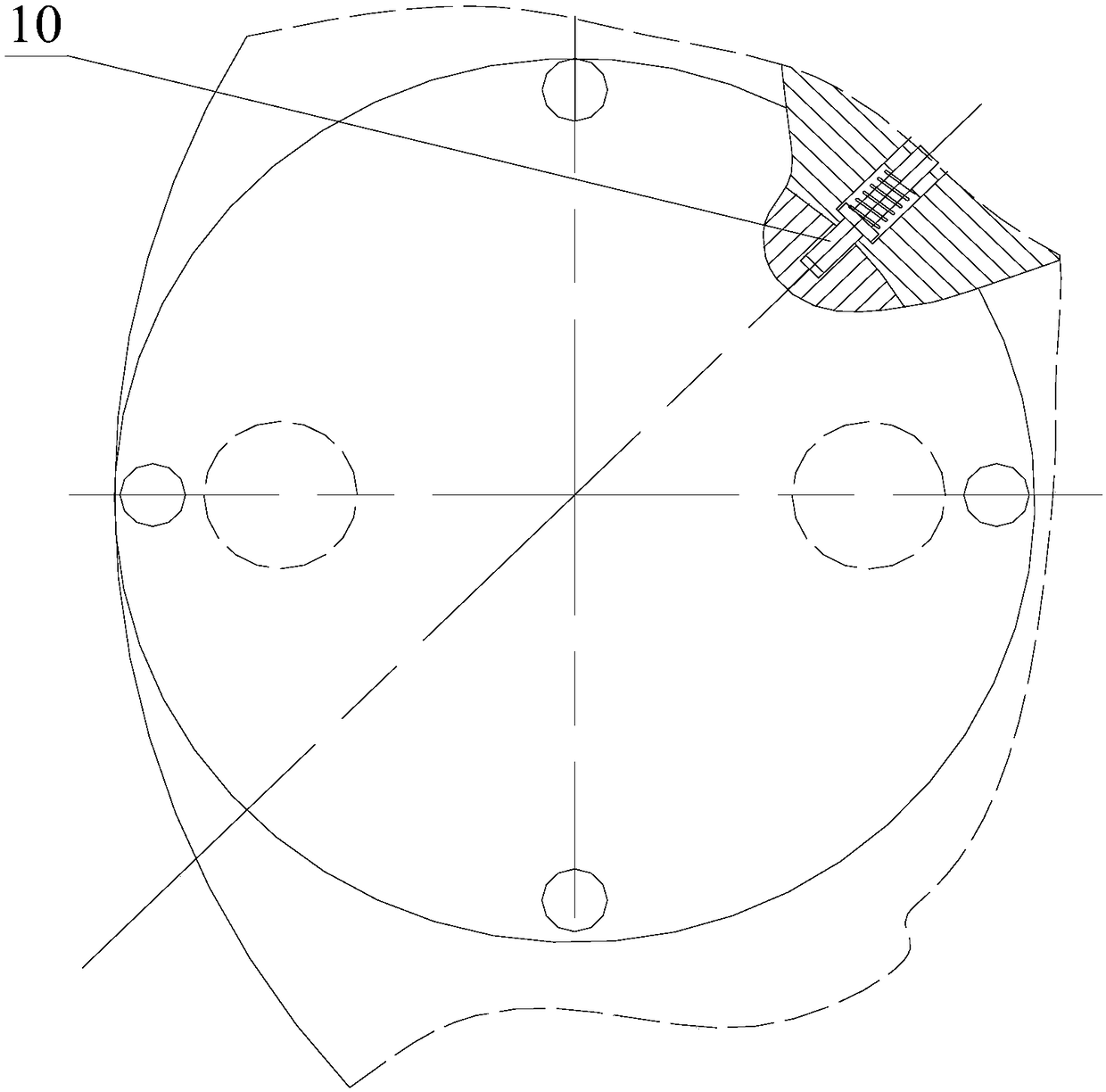

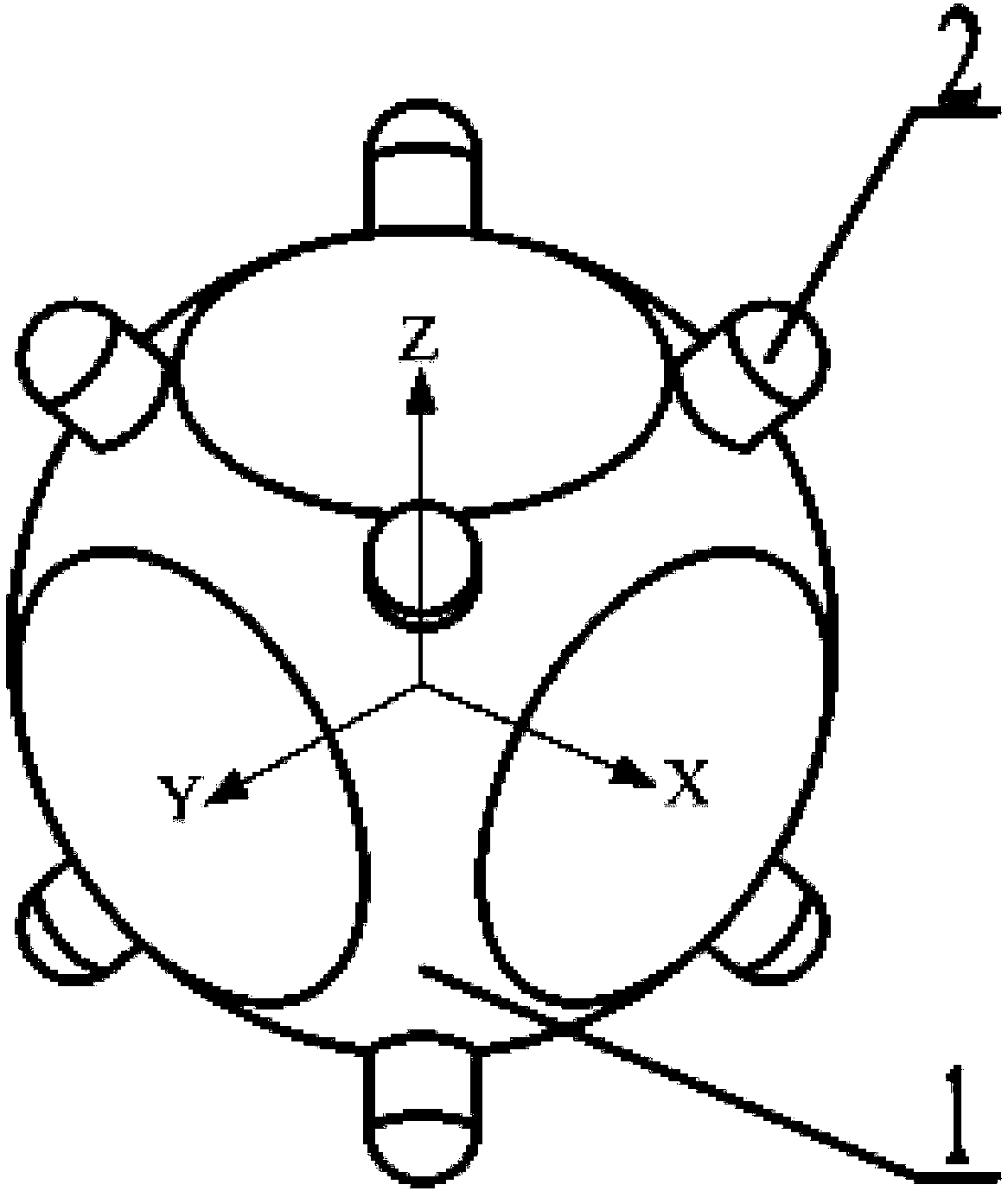

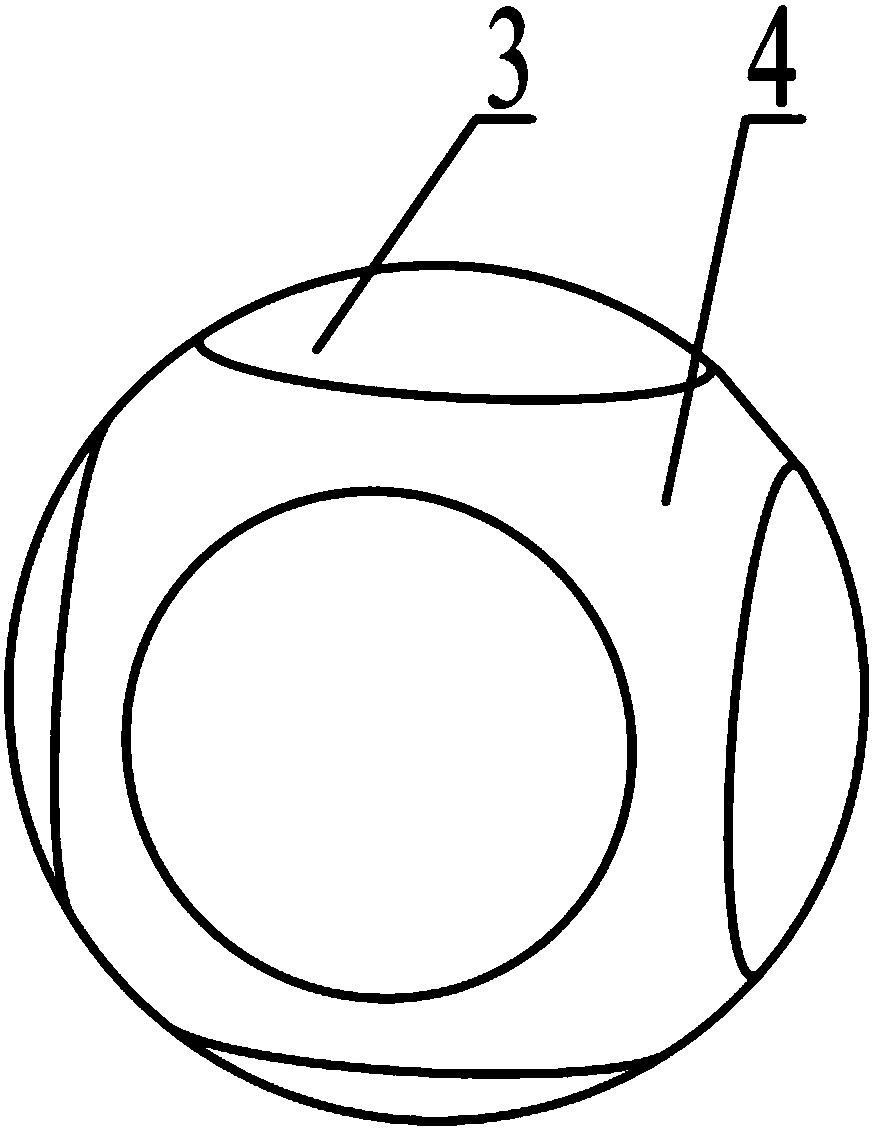

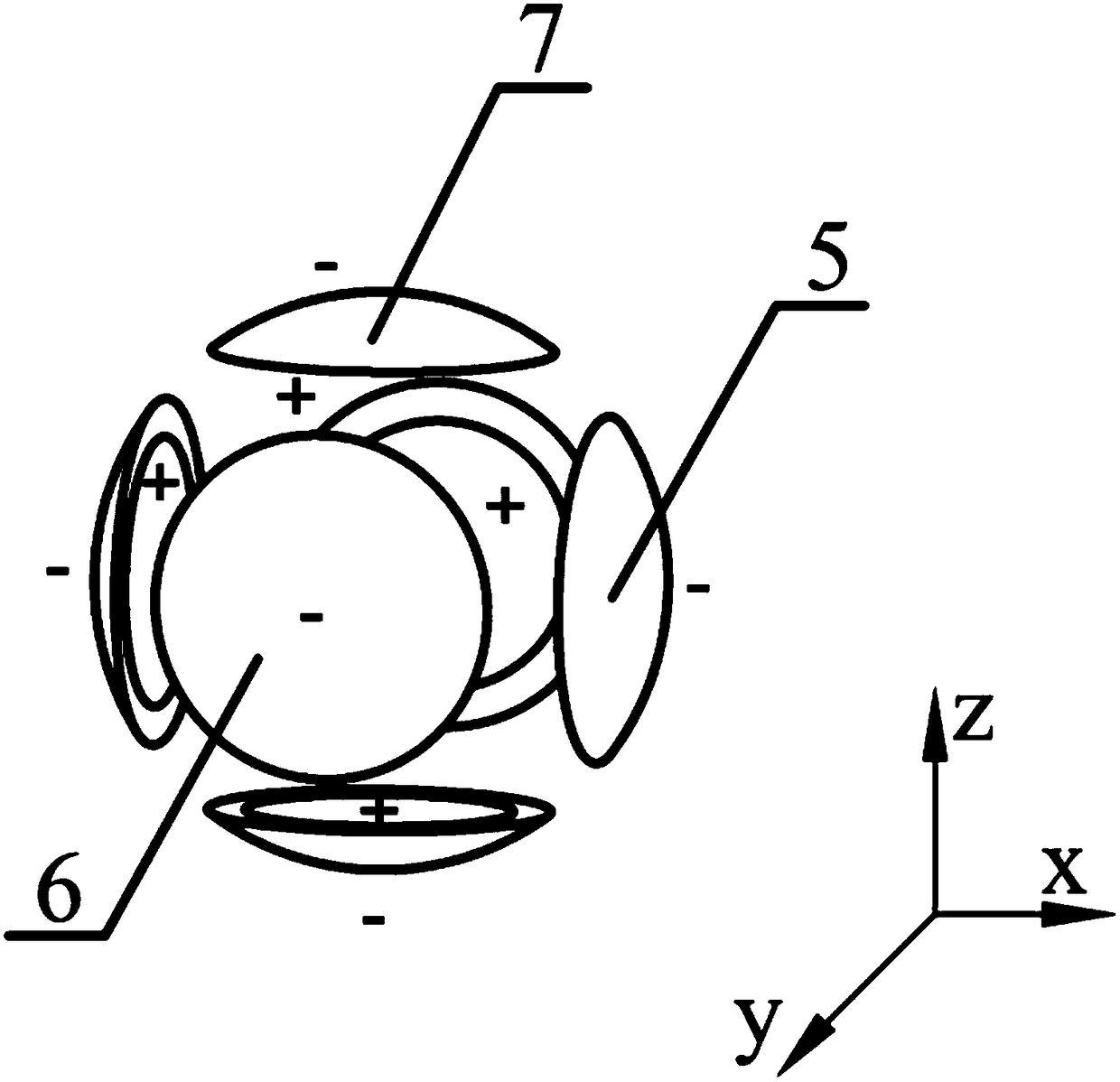

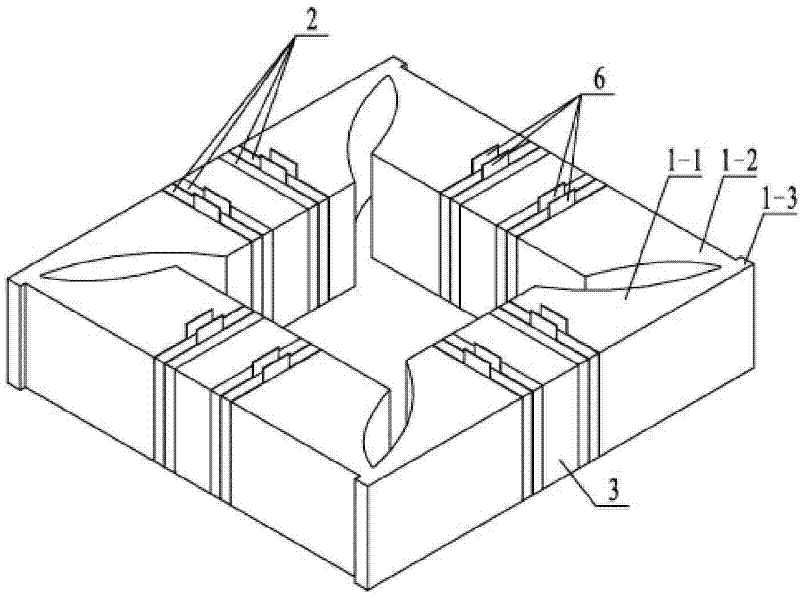

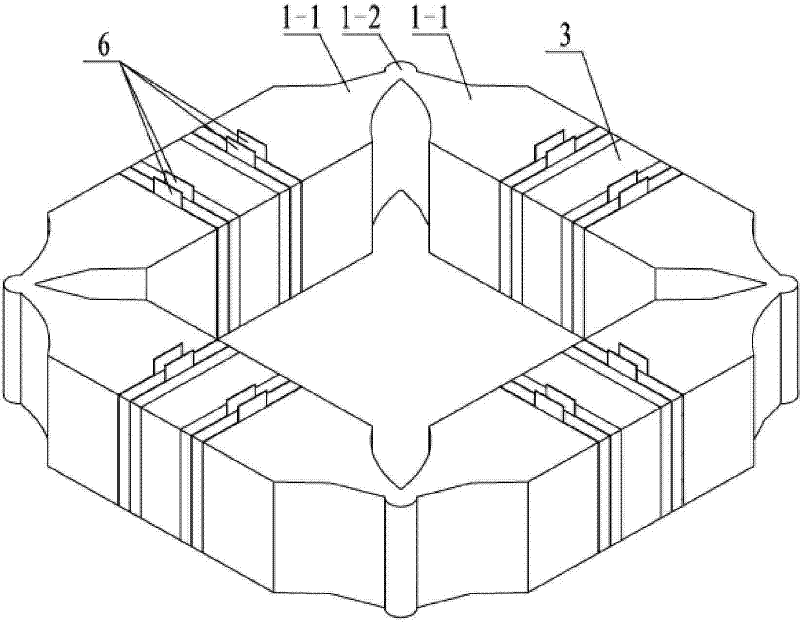

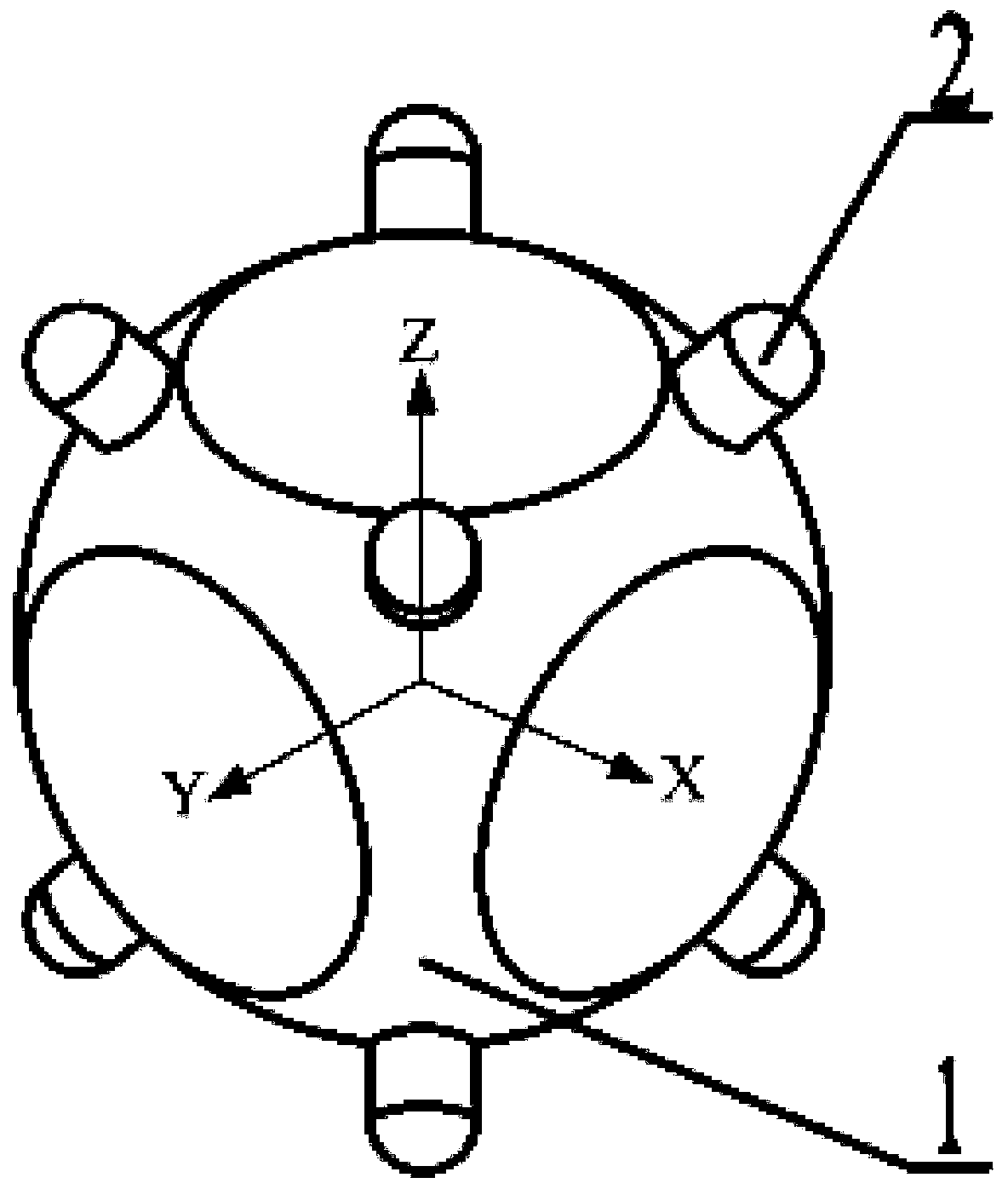

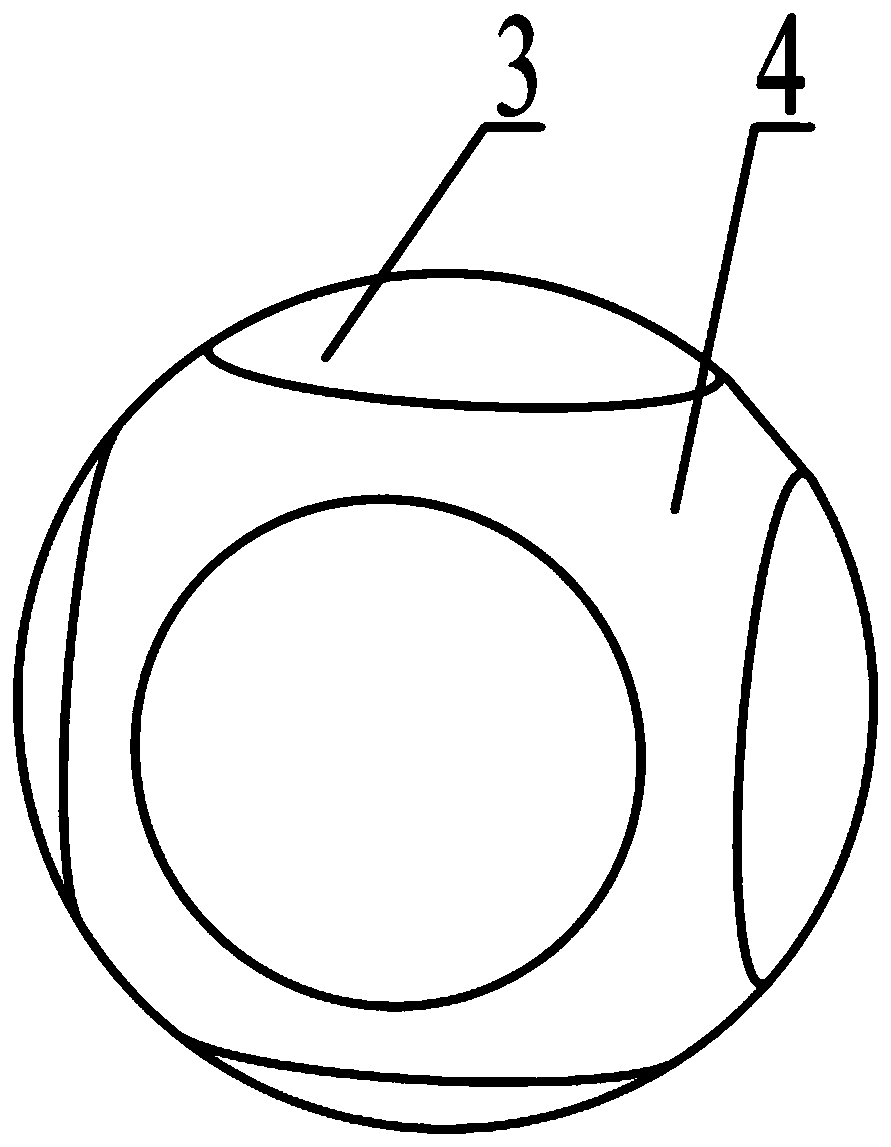

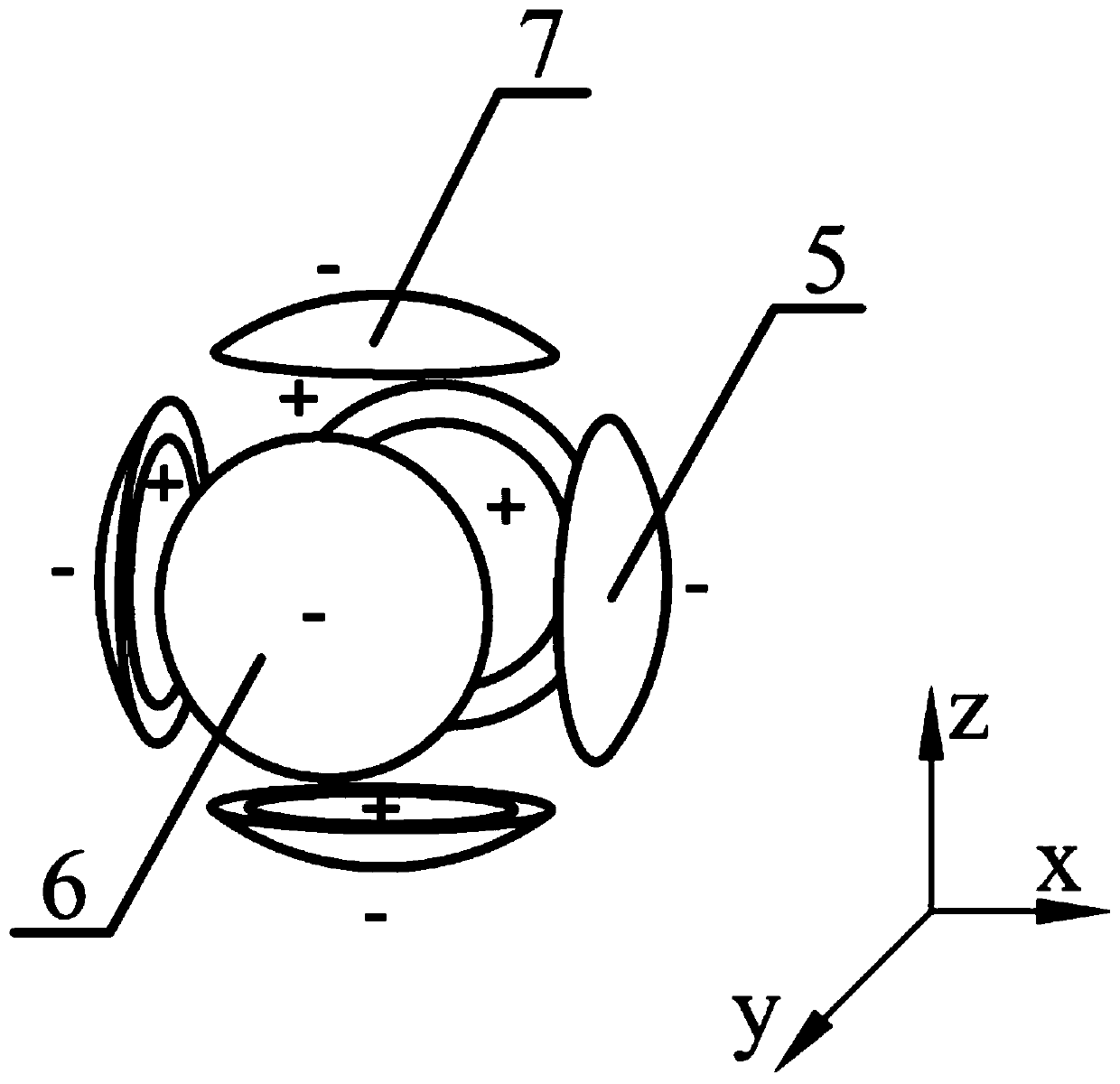

Three-degree-of-freedom spherical stator base body of ultrasonic motor stator and excitation method of stator base body

ActiveCN108377107ARealize reverse driveCompact structurePiezoelectric/electrostriction/magnetostriction machinesPhase differenceThree degrees of freedom

The invention relates to a three-degree-of-freedom spherical stator base body of an ultrasonic motor and an excitation method of the stator base body and belongs to the piezoelectric ultrasonic motortechnical field. The present invention aims to solve the problems of few driving feet, insufficient driving capability, complicated structure, large size and difficulty in achieving miniaturization ofan existing multi-degree-of-freedom rotation type ultrasonic motor. A pair of x-axis electrode sub-region, a pair of y-axis electrode sub-region and a pair of z-axis electrode sub-region are symmetrically distributed along the x-axis direction, y-axis direction, and z-axis direction of the surface of a piezoelectric ceramic spherical shell respectively; a blank area among all the electrode sub-regions is a non-electrode area; the polarization directions of each pair of electrode sub-regions are the same; the electrode sub-regions are polarized along the radial thickness of the spherical shell; eight driving feet are uniformly arranged on the non-electrode area; spatial distance difference between the eight driving feet and all the electrode sub-regions is 45 degrees; and a spatial phase angle between the axis of each driving foot and an xoy plane is 45 degrees. The three-degree-of-freedom spherical stator base body is used for making a multi-degree-of-freedom ultrasonic motor.

Owner:HARBIN INST OF TECH

Composite flexural vibration sandwich type double-foot linear ultrasonic motor vibrator

ActiveCN102361413BIncrease flexibilityAchieve macro motion outputPiezoelectric/electrostriction/magnetostriction machinesAcousticsSandwich type

The invention discloses a composite flexural vibration sandwich type double-foot linear ultrasonic motor vibrator, and belongs to the technical field of piezoelectric ultrasonic motors. The vibrator solves the problem that the output thrust of a motor is affected by inconsistent vibration properties of two driving feet of the conventional flexural vibration modal beam type linear ultrasonic motor vibrator. Eight flexural vibration piezoelectric ceramic chips are sleeved on a stud of the vibrator, two end covers are respectively screwed at two ends of the stud to compact the eight flexural vibration piezoelectric ceramic chips, an electrode plate is respectively arranged between the adjacent flexural vibration piezoelectric ceramic chips and between the contact faces of the flexural vibration piezoelectric ceramic chip and the big end face of the end cover, insulating bushes are arranged between the contact faces of all the flexural vibration piezoelectric ceramic chips and the stud and between the contact faces of all the electrode plates and the stud, two thin-wall beams are symmetrically arranged at two sides of the big end face of each end cover, a mounting seat is fixed at the outer side of each thin-wall beam, a driving foot is arranged on the small end face of each end cover, and the driving feet are blocks, the sections of which are in the same shape as the small end faces. The vibrator is suitable for an ultrasonic motor.

Owner:HARBIN INST OF TECH

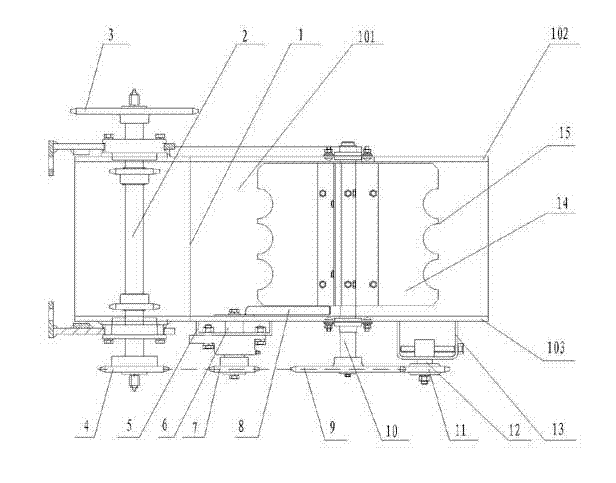

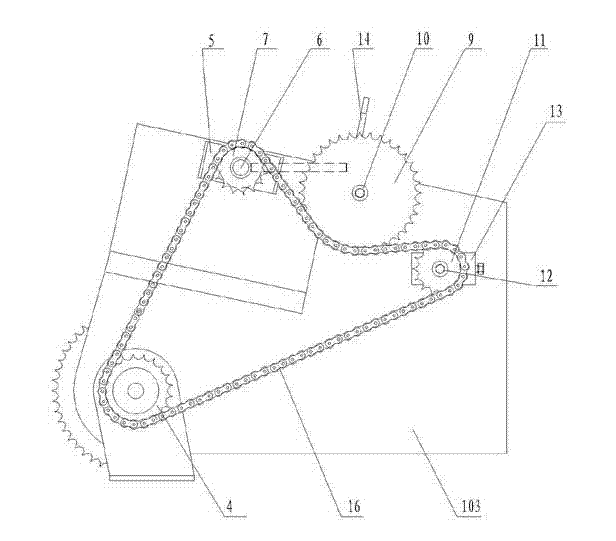

Impurity removal device of corncob lift conveyer of corn harvester

InactiveCN103168565ARealize co-direction transmissionRealize reverse driveHarvestersDrive shaftEngineering

The invention relates to an impurity removal device of a corncob lift conveyer of a corn harvester. An intermediate shaft is arranged at the outer back of the upper side of a second frid through a mounting rack, the intermediate shaft stretches into a shaft end at the inner side of the second frid to fix a lifting lever, and an intermediate chain wheel is arranged on the other shaft end of the second frid. A rotating shaft is assembled at the outer front of the upper side of the second frid through a tensioning support, a tensioning chain wheel is arranged at a shaft end of the rotating shaft, and the intermediate chain wheel, the tensioning chain wheel and a power take-off chain wheel at a shaft end of a driving shaft are meshed with a closed transmission chain. An impurity removal shaft is arranged on a first frid and the second frid, and poking plates with poking teeth are fixed on the impurity removal shaft, a power input chain wheel is arranged at a shaft end of the impurity removal shaft, and the power input chain wheel is meshed with the transmission chain in an outer mode. Straw and other impurities horizontally stacked at an inlet end of the corncob lift conveyer are poked to the lifting direction of the lift conveyer by the lifting lever of the intermediate shaft and then sent to a lifting part to convey the straw and other impurities out by the poking plates of the impurity removal shaft. The impurity removal device of the corncob lift conveyer of the corn harvester is reasonable in structure, simple to manufacture and reliable to use.

Owner:RONGCHENG HAISHAN MECHANICAL MFG

A steel wire transmission series flexible drive joint

Owner:HARBIN INST OF TECH

an isolation mechanism

ActiveCN108087152BRealize reverse driveUniform driving forceMachine part testingRocket engine plantsElectric machineryStructural engineering

Owner:GUIZHOU AEROSPACE ELECTRONICS TECH CO LTD

Sandwich-type rectangular quadruped linear ultrasonic motor vibrator with wedge preload

InactiveCN102437779BSimple structureAvoid internal stressPiezoelectric/electrostriction/magnetostriction machinesEngineeringLongitudinal vibration

A wedge-shaped pre-tightened sandwich type rectangular four-pin linear ultrasonic motor vibrator, belonging to the technical field of piezoelectric ultrasonic motor, which solves the problem in the current rectangular four-pin linear ultrasonic motor vibrator that has complex structure and high requirement on the processing and assembling precision, wherein two horizontal combined beams and two longitudinal combined beams form a rectangular frame; the central positions of the inside face and the outside face of the column beam of each combined beam are respectively opened with a rectangular chute; the central position of each rectangular chute is provided with a pre-pressing block; a pair of longitudinal vibration piezoelectric ceramic chips is installed between two side faces of the pre-pressing block and the side wall of the rectangular chute; a wedge-shaped block is formed between each pair of longitudinal vibration piezoelectric ceramic chips and the pre-pressing block; the contact surface between the wedge-shaped block and the bottom part of the rectangular chute is a big end face of the wedge-shaped block; two pre-pressing blocks on the same combined beam are cooperatively connected with a pre-tightening nut via a pre-tightening screw, and then the longitudinal vibration piezoelectric ceramic chips are pre-tightened. The invention is suitable for manufacturing the ultrasonic motor vibrator.

Owner:HARBIN INST OF TECH

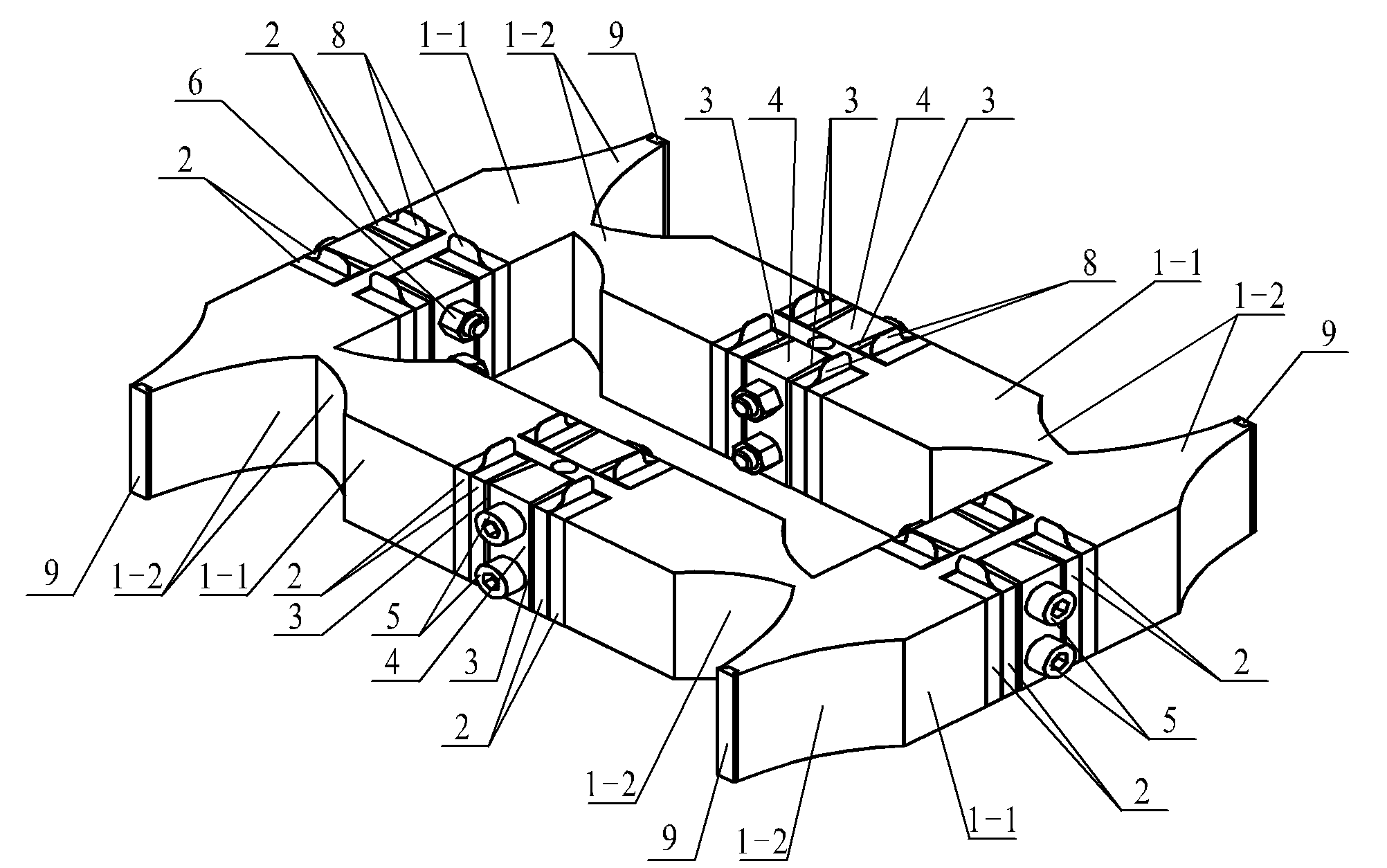

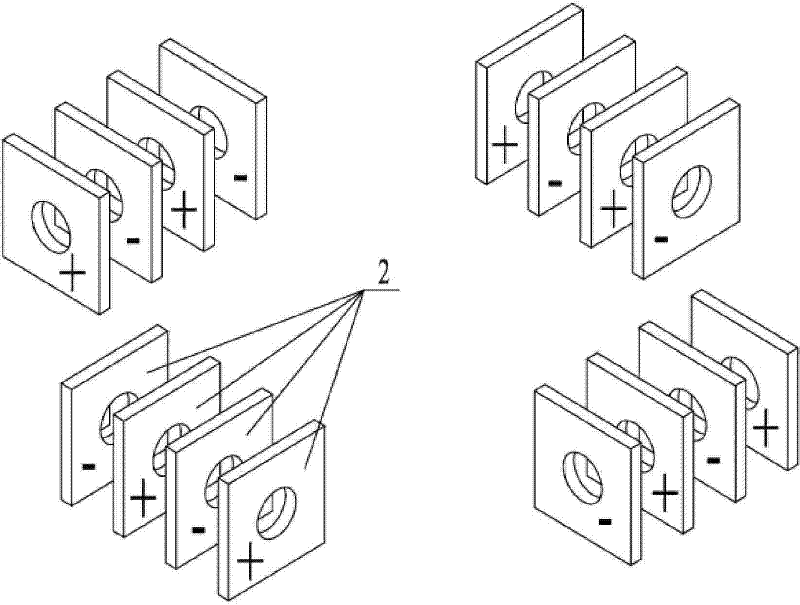

Rectangular four-pin linear ultrasonic motor vibrator

ActiveCN101626205BSimple structureFlexible designPiezoelectric/electrostriction/magnetostriction machinesControl theoryUltrasonic motor

The invention relates to a rectangular four-pin linear ultrasonic motor vibrator, which relates to ultrasonic motor vibrators and solves the problem of limited output capability of the prior ultrasonic motor stator. The rectangular four-pin linear ultrasonic motor vibrator consists of four front end covers, eight pairs of piezoelectric ceramic plates, four flanges, four preloaded double-screw bolts, insulation bushes and electrode slices, wherein each front end cover comprises a horizontal horn, a vertical horn and a driving pin which is of a rectangle, the horizontal horn and the vertical horn are arranged in an orthogonal way, and the horizontal horn, the vertical horn and the driving pins are integrated pieces; big end faces of two adjacent horizontal horns are fixedly connected with the flanges via the preloaded double-screw bolts; a pair of piezoelectric ceramic plates is sleeved on a double-screw bolt arranged between the flanges and each horizontal horn, big end faces of two adjacent vertical horns are fixedly connected with the flanges via the preloaded double-screw bolts, and a pair of piezoelectric ceramic plates are sleeved on a double-screw bolt arranged between the flanges and each vertical horn. The invention can be applied to the field of ultrasonic motor manufacture.

Owner:HARBIN INST OF TECH

A meat product sauce brushing device based on food processing and its application method

ActiveCN110803492BApply evenlyImprove uniformityLoading/unloadingConveyor partsProcess engineeringConveyor belt

The invention discloses a sauce brushing device for meat products based on food processing and a using method thereof, belonging to the field of food processing. The sauce is introduced into the material pipe, and the sauce is evenly introduced to the belt roller through multiple leakage holes at the bottom of the material delivery pipe, and the belt roller and the brush roller are connected by transmission mechanism, and the material on the belt roller is realized in the transmission. The sauce is transmitted to the brush roller, and the brush roller evenly smears the sauce on the meat products on the conveyor belt during the continuous rotation process. Compared with the traditional method of manually brushing or using a rotating ordinary sauce brush Brushing the sauce, the sauce of the present invention is applied more continuously and evenly, and at the same time, it also plays a role in suppressing the meat products in the process of brushing the sauce, and a puncture device is installed at the front end of the brushing roller to realize the puncturing of the conveyed meat products. A certain puncture can further effectively improve the uniformity and permeability of the subsequent sauce coating.

Owner:四川张飞牛肉有限公司

A sliding door driving device and an air conditioning device

The invention relates to a sliding door drive device used for driving a sliding door to vertically move. The sliding door drive device comprises a first oscillating bar, a second oscillating bar and a driving wheel. The first oscillating bar and the second oscillating bar are symmetrically arranged. A first driven gear and a second driven gear engaged with the first driven gear are arranged at the lower end of the first oscillating bar and the lower end of the second oscillating bar respectively. The second end of the first oscillating bar and the second end of the second oscillating bar are connected with the sliding door. The driving gear is connected with a power mechanism to drive the first driven gear and the second driven gear to synchronously rotate. In the sliding door drive device, due to the fact that the driven gears for driving the oscillating bars are in gear transmission with the driving gear, the driving gear can be driven by the driven gears for reverse transmission under the action that external force is artificially exerted on the driven gears. When the sliding door drive device cannot be started normally, the sliding door can be manually pushed downwards to the inner side of an air conditioning device, and therefore a lower panel is demounted down, and the air conditioning device is maintained.

Owner:GREE ELECTRIC APPLIANCES INC

Square rotary ultrasonic motor oscillator

InactiveCN101630925BSimple structureFlexible designPiezoelectric/electrostriction/magnetostriction machinesUltrasonic motorCeramic

The invention discloses a square rotary ultrasonic motor oscillator, which relates to an ultrasonic motor oscillator and aims at solving the problem that mechanical output capacity of the prior ultrasonic motor stator is limited. The square rotary ultrasonic motor oscillator consists of four front end covers, eight pairs of piezoelectric ceramics, four flanges, four pretightening studs, an insulating sleeve and an electrode plate, wherein each front end cover comprises two amplitude rods and a drive foot, the drive foot is a cylinder, two amplitude rods are orthogonally arranged, the drive foot is connected with the small end surfaces of the two amplitude rods, and the amplitude rods and the drive foot are an integral component; the pretightening studs pass through a flange through a square hole at the centre of the flange and are fixedly connected with big end surfaces of the two adjacent amplitude rods through threads at the two ends, and a pair of piezoelectric ceramics is sleeved on the stud between the amplitude rods. Body central lines of four drive feet form four square angle points through crossing axial lines of the four pretightening studs, therefore, the invention can be applied to the manufacture field of the ultrasonic motor.

Owner:HARBIN INST OF TECH

Three-degree-of-freedom spherical stator ultrasonic motor stator base and its excitation method

ActiveCN108377107BRealize reverse driveCompact structurePiezoelectric/electrostriction/magnetostriction machinesPhase differenceThree degrees of freedom

The invention relates to a three-degree-of-freedom spherical stator base body of an ultrasonic motor and an excitation method of the stator base body and belongs to the piezoelectric ultrasonic motortechnical field. The present invention aims to solve the problems of few driving feet, insufficient driving capability, complicated structure, large size and difficulty in achieving miniaturization ofan existing multi-degree-of-freedom rotation type ultrasonic motor. A pair of x-axis electrode sub-region, a pair of y-axis electrode sub-region and a pair of z-axis electrode sub-region are symmetrically distributed along the x-axis direction, y-axis direction, and z-axis direction of the surface of a piezoelectric ceramic spherical shell respectively; a blank area among all the electrode sub-regions is a non-electrode area; the polarization directions of each pair of electrode sub-regions are the same; the electrode sub-regions are polarized along the radial thickness of the spherical shell; eight driving feet are uniformly arranged on the non-electrode area; spatial distance difference between the eight driving feet and all the electrode sub-regions is 45 degrees; and a spatial phase angle between the axis of each driving foot and an xoy plane is 45 degrees. The three-degree-of-freedom spherical stator base body is used for making a multi-degree-of-freedom ultrasonic motor.

Owner:HARBIN INST OF TECH

Reversible lock body

InactiveCN102392560BRealize reverse driveAchieve lockingBuilding locksLinear motionElectrical and Electronics engineering

The invention relates to a reversible lock body comprising a lock body shell which is internally equipped with a containing cavity, and an inclined tongue and a square tongue which stretch out from one side of the lock body shell, wherein an unlocking shifting block capable of being driven by a key is arranged in the containing cavity; a rotary shifting block for driving the inclined tongue is arranged by means of being connected with the unlocking shifting block; a driving deflector rod is further arranged by means of being connected with the unlocking shifting block; a transmission bar which does a linear movement with the swinging of the driving deflector rod is arranged by means of being connected with the driving deflector rod; and one end of the transmission bar is connected with a first locking bar, and the other end of the transmission bar is connected with a second locking bar through a reversing gear assembly capable of changing the transmission direction of the transmission bar. According to the reversible lock body, no extra reserving structure is added, and simultaneously, reverse driving of the first locking bar and the second locking bar is realized so that a door lock is locked in a vertical direction. Therefore, the cost is saved, and the reversible lock body is more convenient and fast to install and maintain and is a mechanical lock body with compact structure and good practicability.

Owner:CMECH (GUANGZHOU) INDUSTRIAL LTD

Cable stripping device

InactiveCN112821294ARealize automatic clampingEasy to holdApparatus for removing/armouring cablesElectrical and Electronics engineeringMechanical engineering

Owner:HENAN SIDAO ELECTRIC POWER TECH +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com