Cable stripping device

A cable and wire-clamping trough technology, which is used in cable installation devices, cable installation, and equipment for dismantling/armored cables, etc., can solve the problems of difficult operation, low peeling precision, and easy to accidentally damage the wire core.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

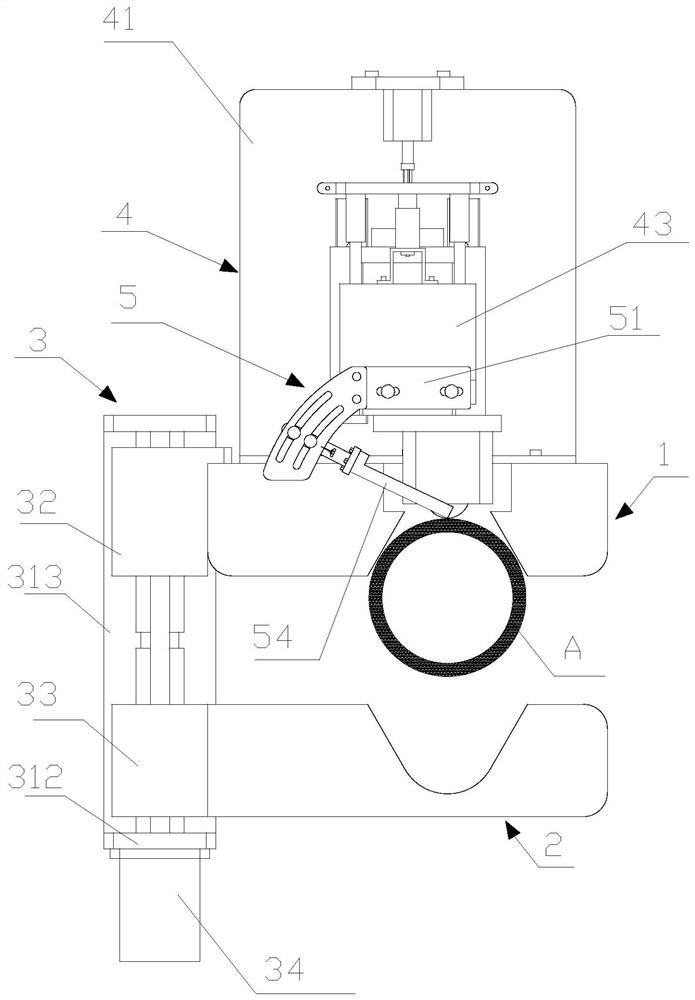

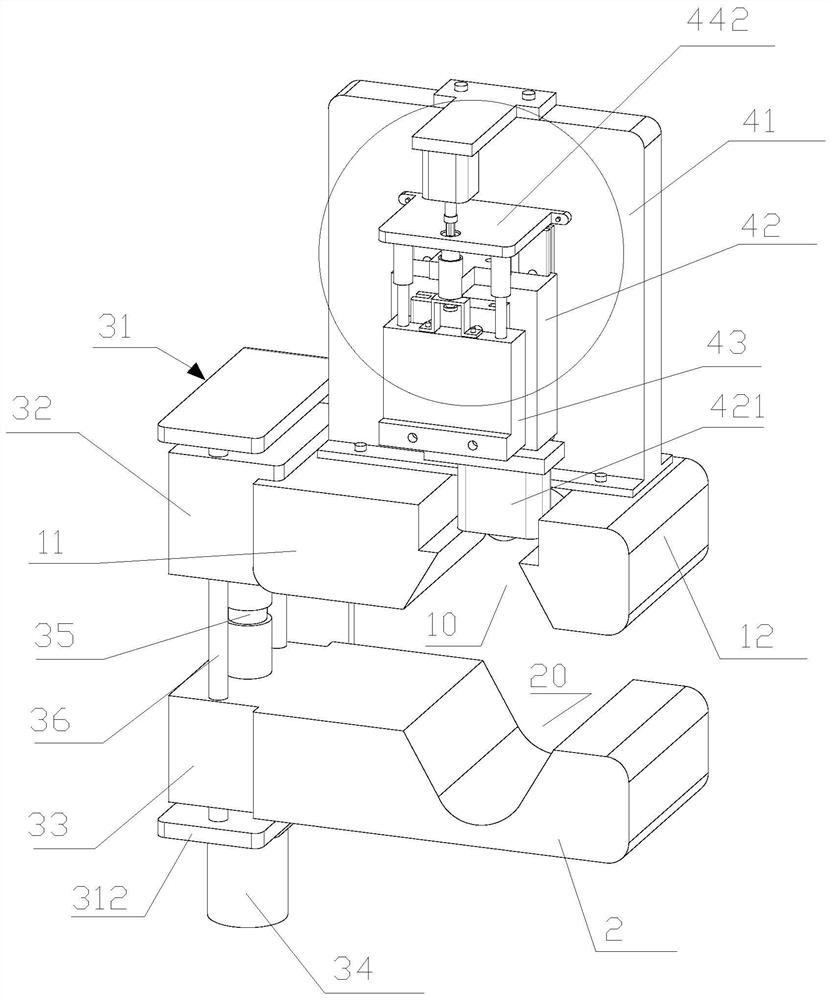

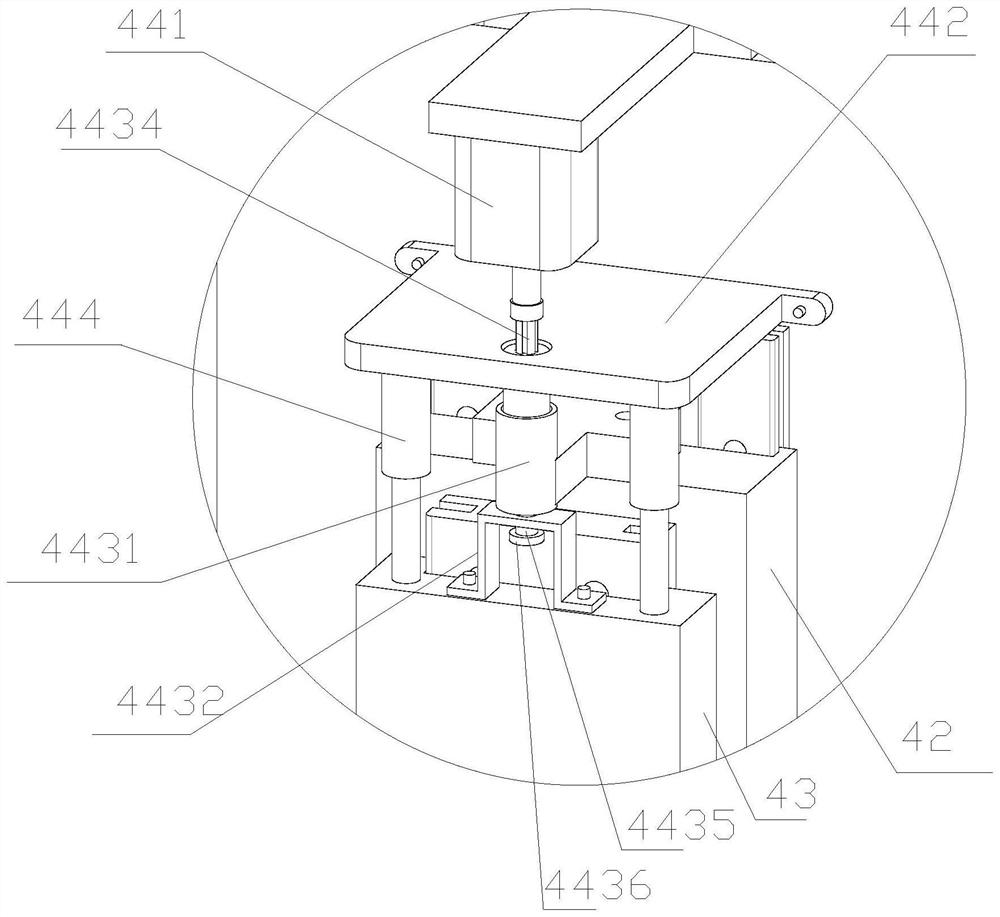

[0043]A cable peeling apparatus proposed in this embodiment includes: a top holding portion 1, a lower holding portion 2, a drive unit 3, a tool support portion 4, and a tool 5.

[0044]Both the upper gripping portion 1 and the lower clamping portion 2 are provided on the drive portion and the drive unit is used to drive at least one movement in the grip portion 1 and the lower holding portion 2 to regulate the holding portion 1 and The relative distance between the lower clamping portion 2 is to clamp the cable A.

[0045]The tool 5 is provided on the tool support portion 4, and the tool support portion 4 is used to drive the tool 5 slide to complete the knife, and the tool 5 sliding direction and the cable A above the upper grip portion 1 and the lower clamping portion 2. The center line coincides.

[0046]When the device operates, the cable A is passed from the upper clamping portion 1 and the lower clamping portion 2, and then the distance between the gripping portion 1 and the lower hol...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com