Adaptation of full-automatic diamond grinding and polishing machine and clamp adapting unit thereof

A transfer unit, fully automatic technology, applied to grinding/polishing equipment, machine tools suitable for grinding the edge of workpieces, grinding machines, etc., can solve the problems of cumbersome operation, long time-consuming, slow processing speed, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

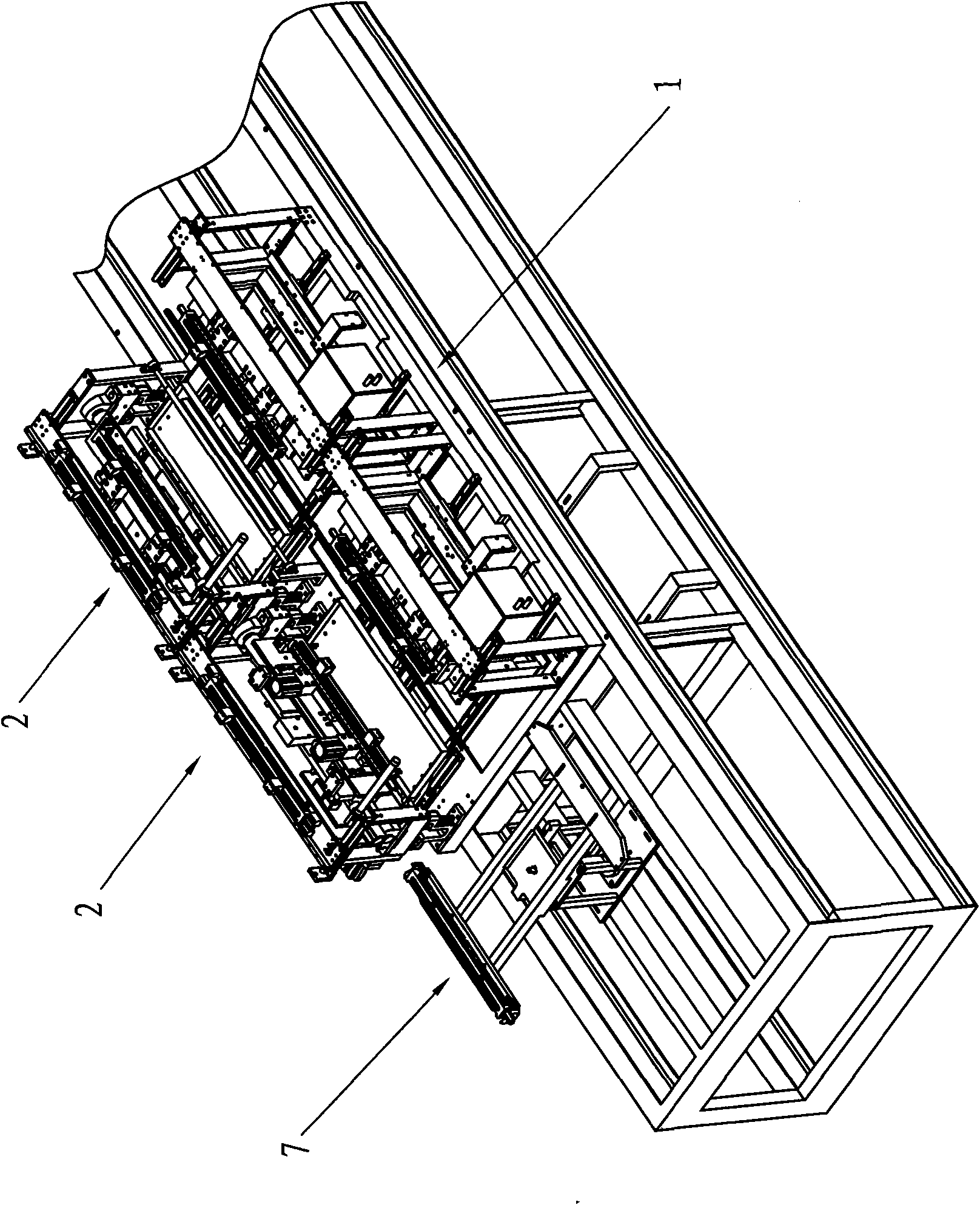

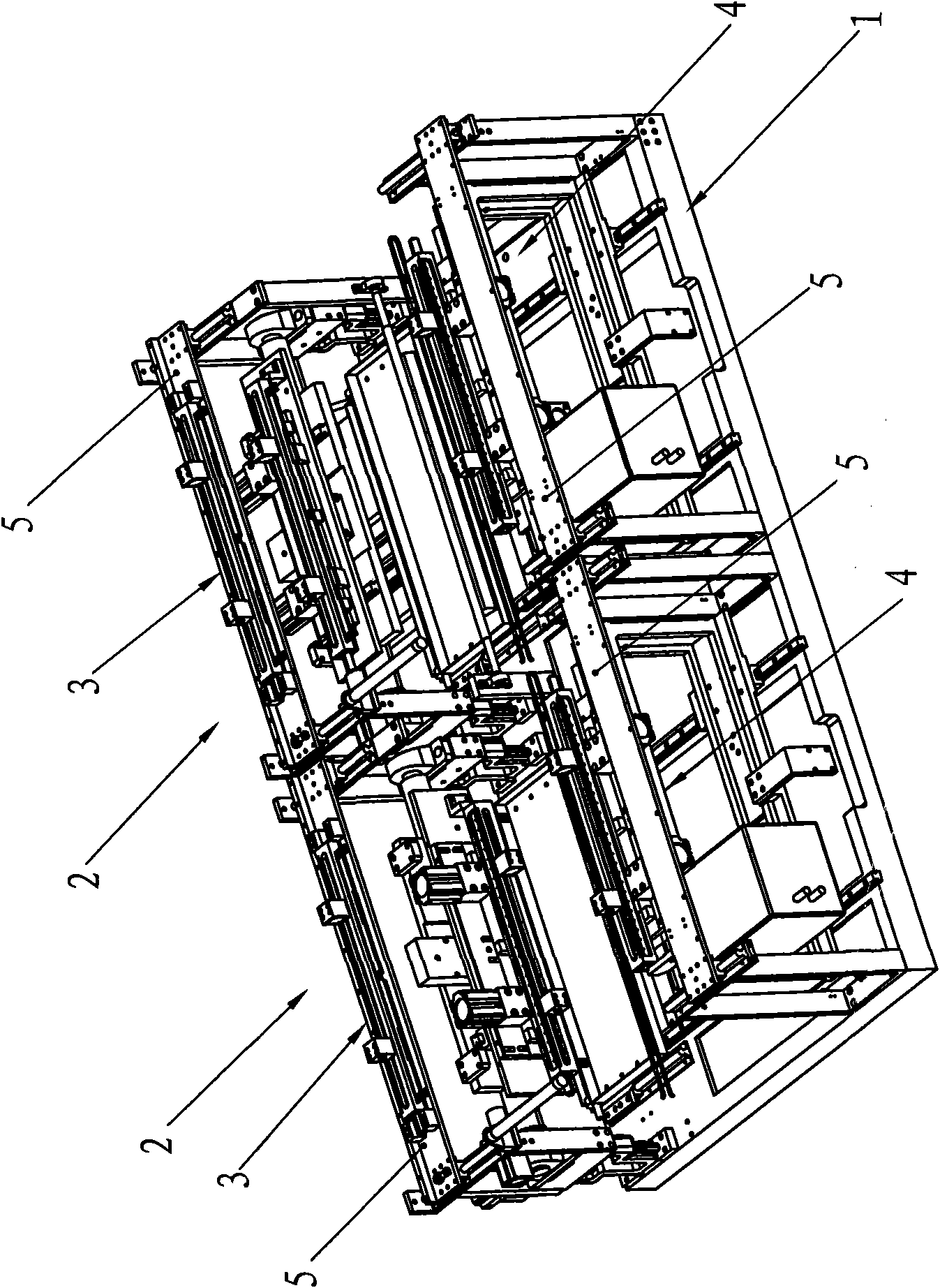

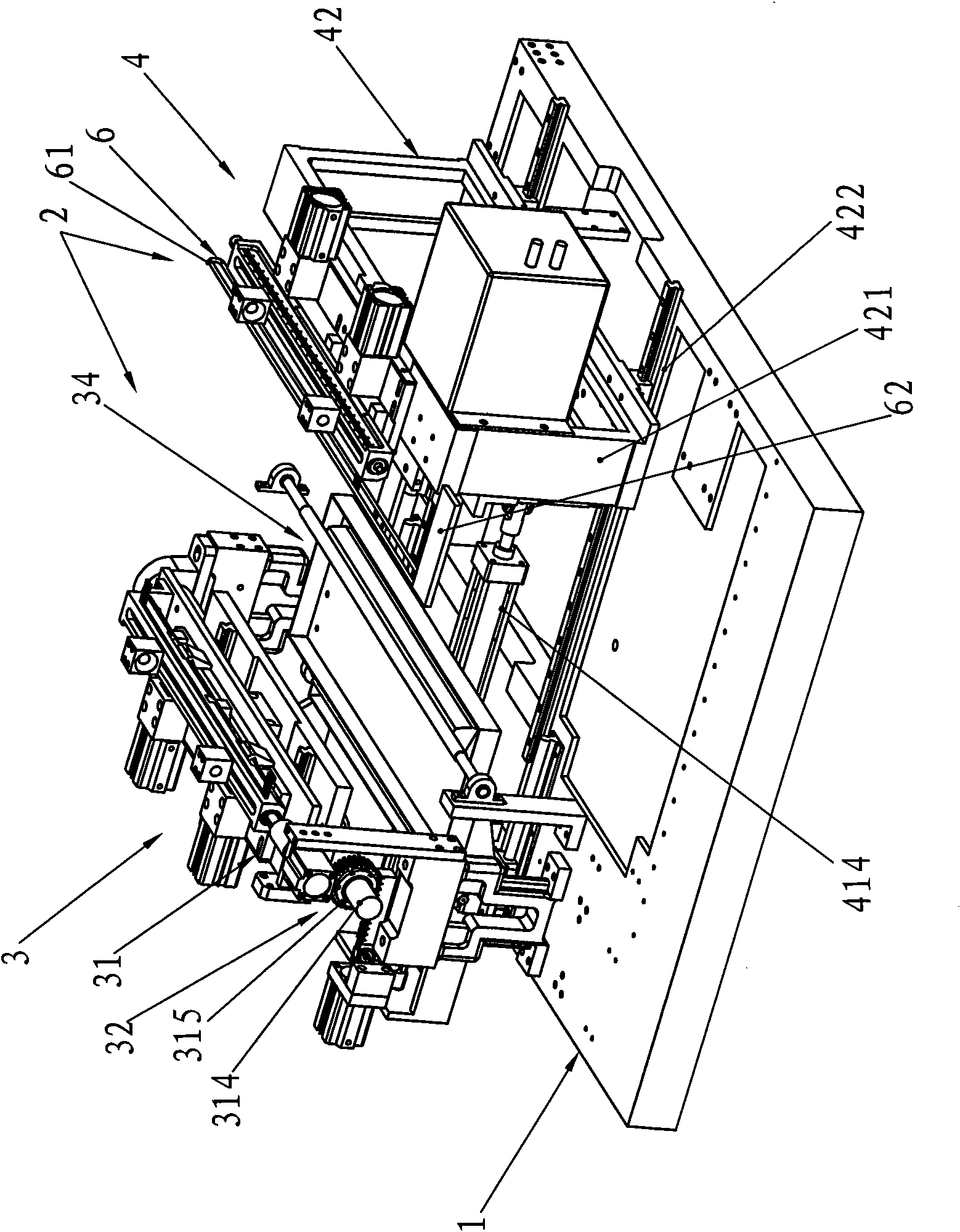

[0038] Such as Figure 1-Figure 7The transfer of a fully automatic diamond grinding and polishing machine and its fixture transfer unit shown include a bracket 1 and two groups of adjacent transfer devices 2 arranged on the bracket 1, and the two groups of transfer devices 2 One side of the clamp conversion device 7 is set, and each group of transfer devices 2 includes a feeding powder unit 3 located on one side of the bracket and a material receiving unit 3 located on the other side of the bracket and opposite to the feeding powder unit 3. Unit 4, each feeding powder unit 3 and the top of the receiving unit 4 are respectively provided with a baffle plate 5 that is slidingly matched with the support 1, and each feeding powder unit 3 includes a clamp fixing mechanism 31, which drives The clamp fixing mechanism 31 rotates the rotating mechanism 32, the waste material brushing mechanism 33 and the powder feeding mechanism 34. The clamp fixing mechanism 31 of the feeding and powde...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com