Composite flexural vibration sandwich type double-foot linear ultrasonic motor vibrator

A linear ultrasonic motor, sandwich-type technology, applied in the direction of generator/motor, piezoelectric effect/electrostrictive or magnetostrictive motor, electrical components, etc., can solve the problems of inconsistent vibration characteristics and affecting the output thrust of the motor, etc. Achieve the effect of flexible design, simple structure and improved mechanical output characteristics

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

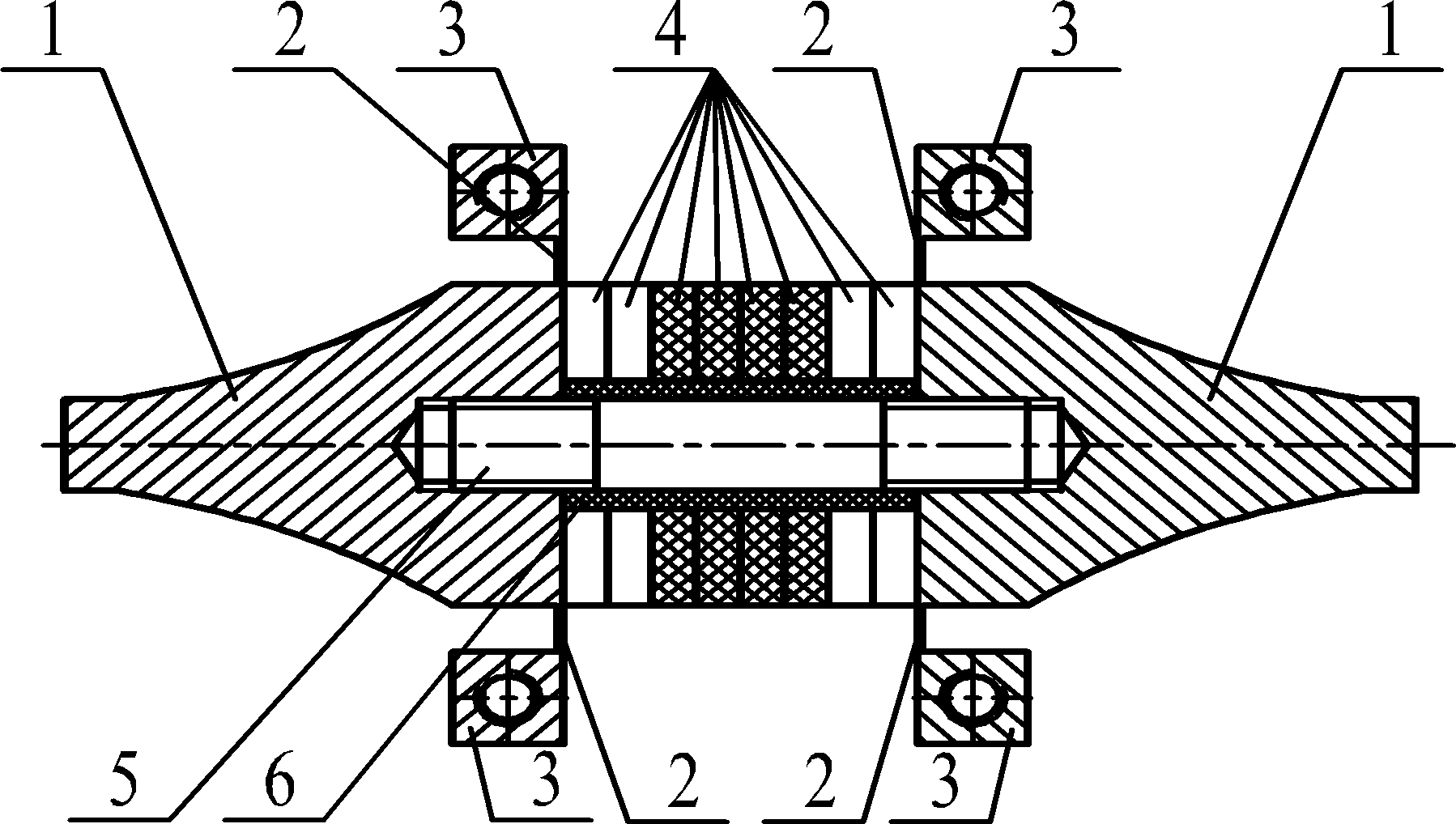

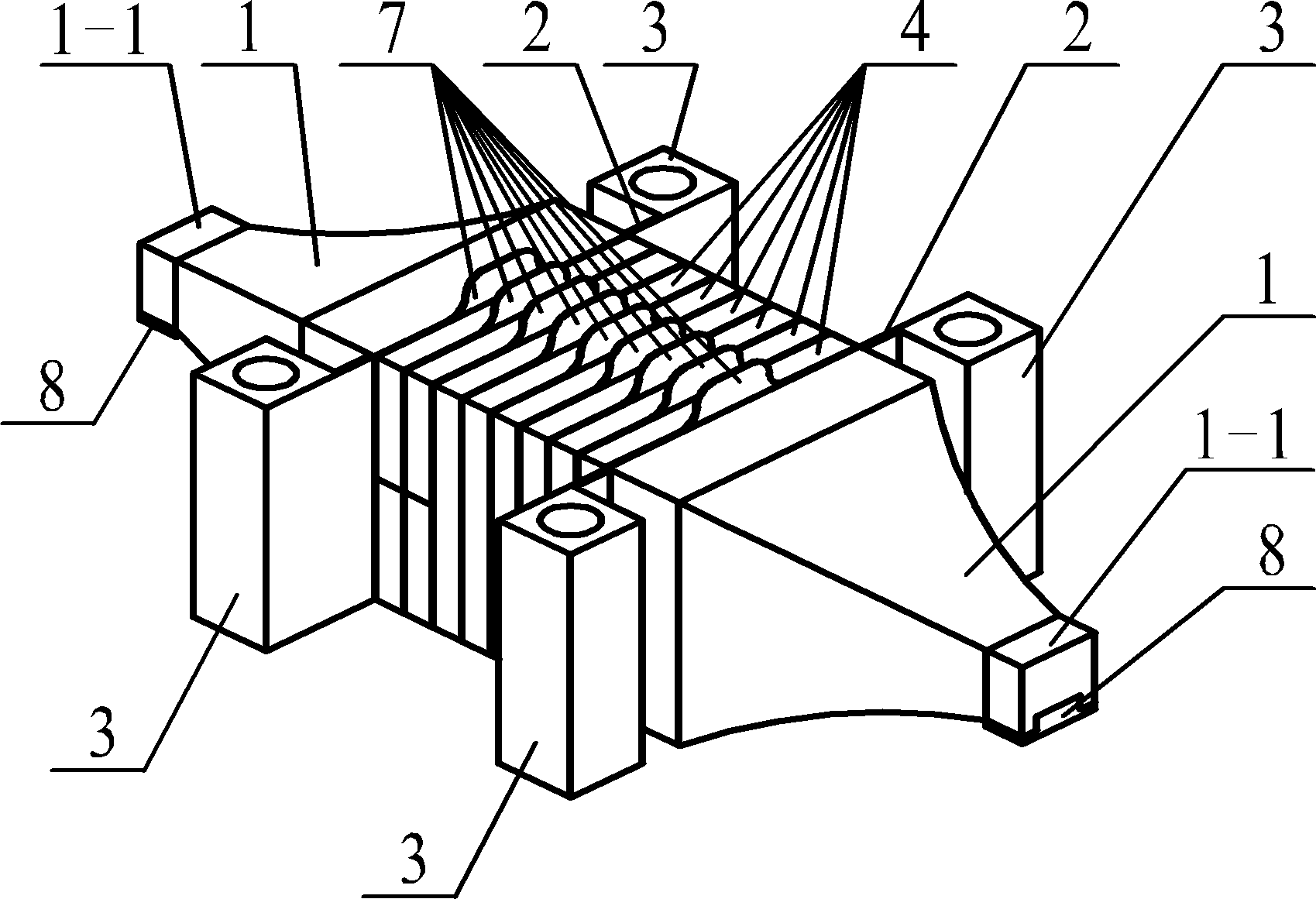

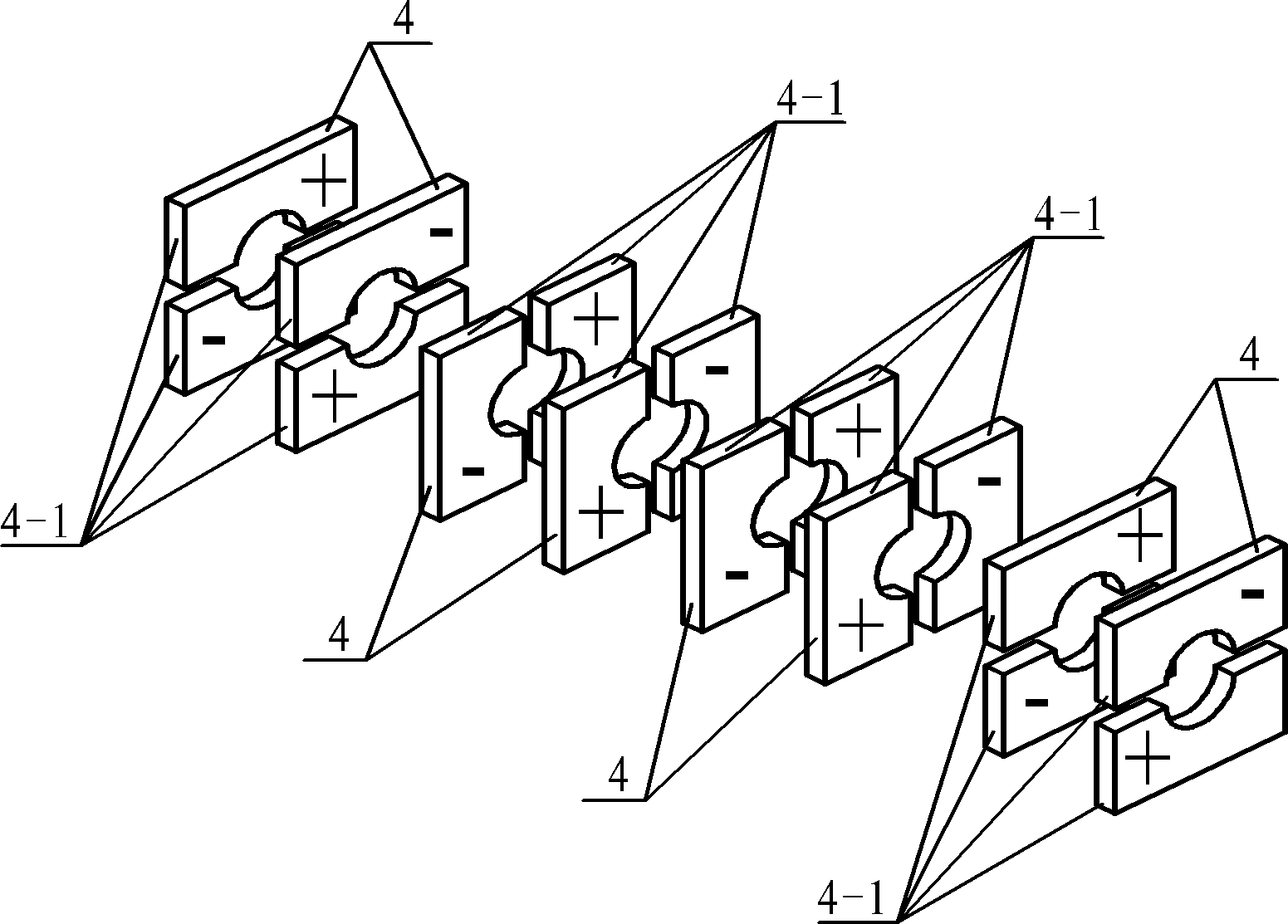

[0025] Specific implementation mode one: the following combination figure 1 and figure 2 Describe this embodiment, the composite bending vibration sandwich type biped linear ultrasonic motor vibrator in this embodiment, it includes two driving feet 1-1, two end caps 1, four thin-walled beams 2, four mounting seats 3, eight Sheet bending vibration piezoelectric ceramic sheet 4, stud 5, insulating sleeve 6 and nine electrode sheets 7,

[0026] Eight pieces of bending vibration piezoelectric ceramic sheets 4 are set on the stud 5,

[0027] The end cap 1 is a block with a square or circular cross-section and tapering. There is a blind hole with an internal thread in the center of the large end surface of the end cap 1. The two end caps 1 are respectively screwed on the stud 5. At both ends, press eight bending-vibration piezoelectric ceramic sheets 4 tightly,

[0028] A piece of electrode sheet 7 is respectively arranged between the adjacent bending vibration piezoelectric cer...

specific Embodiment approach 2

[0034] Specific implementation mode two: the following combination figure 2 Describe this embodiment, this embodiment is a further description of Embodiment 1, this embodiment also includes two friction plates 8,

[0035] The output coupling side of each driving foot 1 - 1 is provided with a rectangular groove, and a friction plate 8 is arranged in the rectangular groove.

specific Embodiment approach 3

[0036] Embodiment 3: This embodiment is a further description of Embodiment 1 or 2. The cross-section of the bending vibration piezoelectric ceramic sheet 4 in this embodiment is square or circular.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com