Cable stripping device with adjustable cutting angle, and cable stripping method thereof

A technology for cutting angles and cables, which is applied to lines/collector parts, equipment for dismantling/armored cables, electrical components, etc. It can solve problems such as difficult to ensure the stripping angle requirements, difficult to operate, and easy to accidentally damage the wire core, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

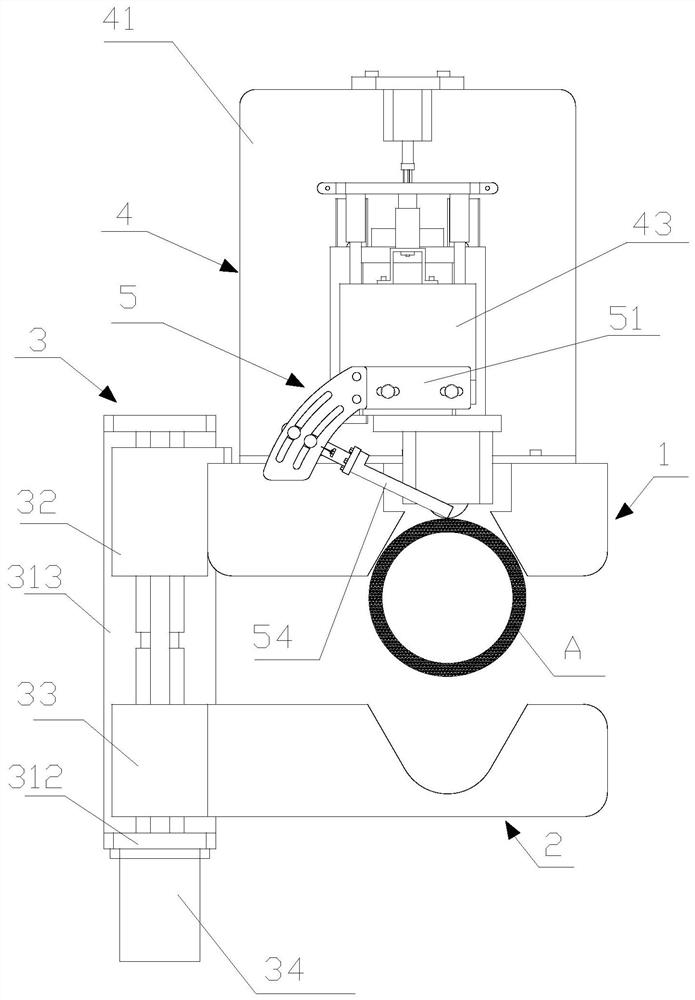

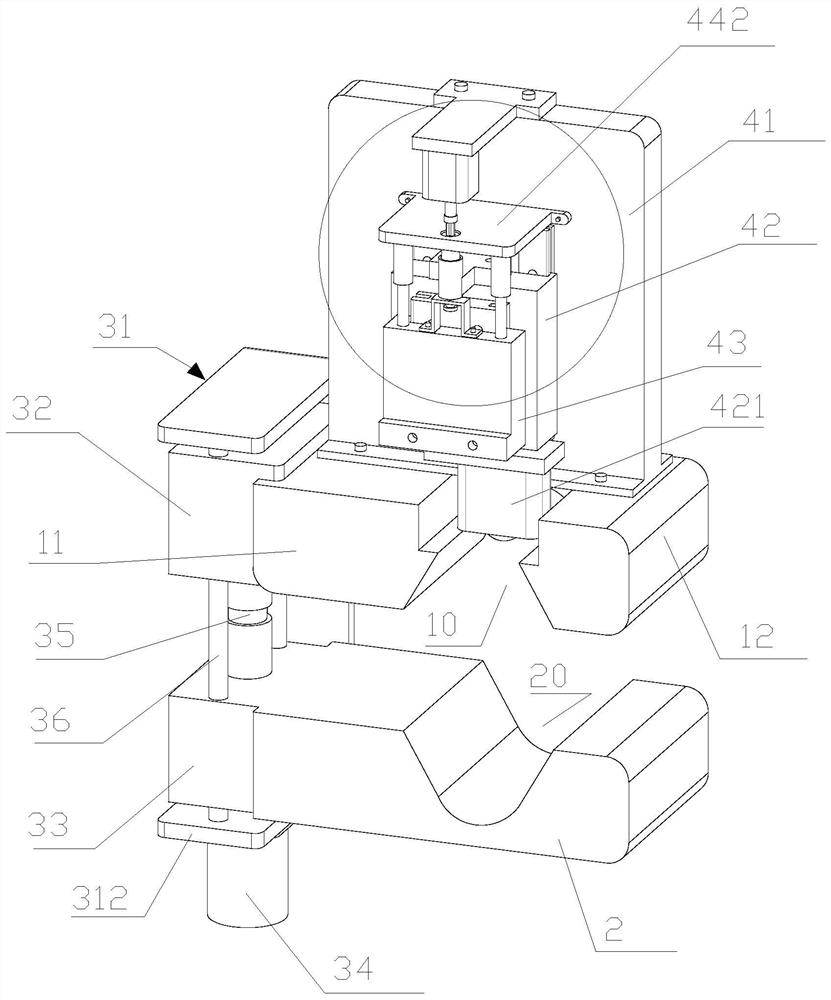

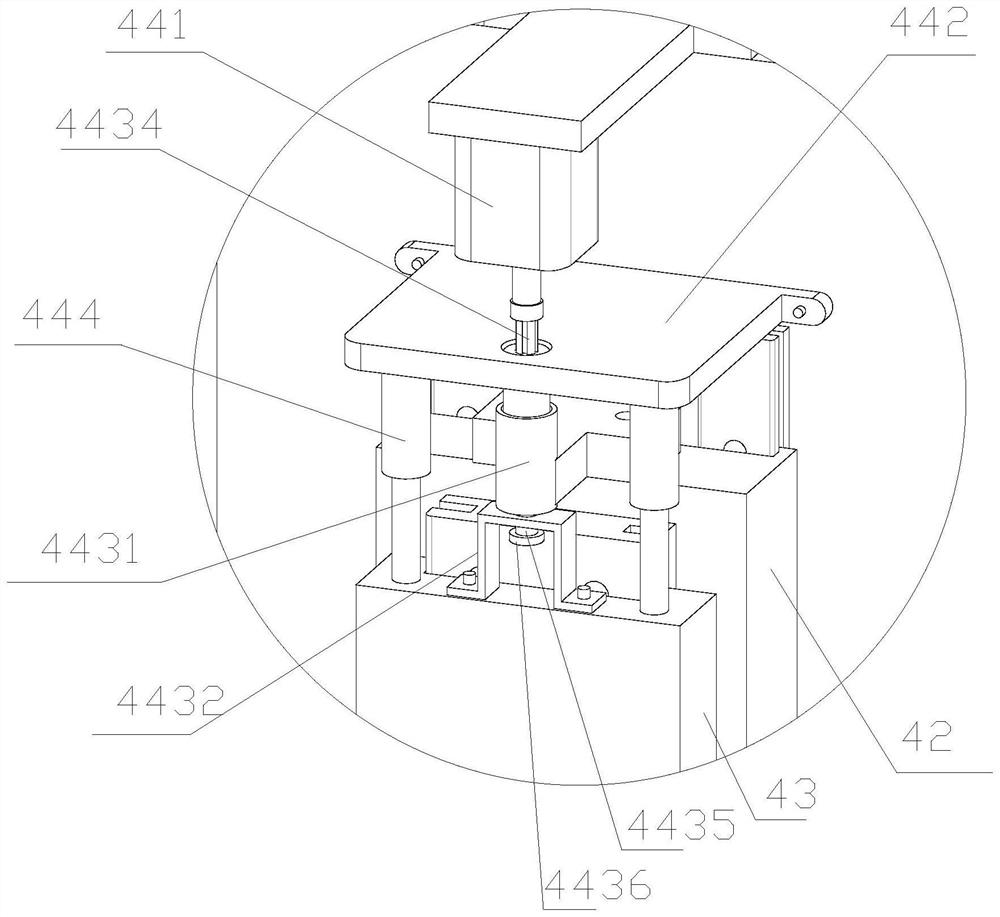

[0055] A cable stripping device proposed in this embodiment includes: an upper clamping part 1 , a lower clamping part 2 , a driving part 3 , a cutter supporting part 4 and a cutter 5 .

[0056] The upper clamping part 1 and the lower clamping part 2 are arranged on the driving part and are opposite to each other. The driving part is used to drive at least one of the upper clamping part 1 and the lower clamping part 2 to move to adjust the upper clamping part 1 and the lower clamping part 2. The relative distance between the lower clamping parts 2 is for clamping the cable A.

[0057] The tool 5 is arranged on the tool supporting part 4, and the tool supporting part 4 is used to drive the tool 5 to slide to complete the tool setting, and the sliding direction of the tool 5 is consistent with the cable A clamped by the upper clamping part 1 and the lower clamping part 2 centerlines coincide.

[0058] When the device works, the cable A is passed between the upper clamping part ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com