Vibrator of beam type linear ultrasonic motor using bending vibration modes

A linear ultrasonic motor, modal technology, applied in the direction of generator/motor, piezoelectric effect/electrostrictive or magnetostrictive motor, electrical components, etc., can solve the problem of low electromechanical coupling efficiency and mechanical output capacity constraints of ultrasonic motor , low tensile strength and other problems, to achieve the effect of improving mechanical output capacity, simple structure, and improved motor performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

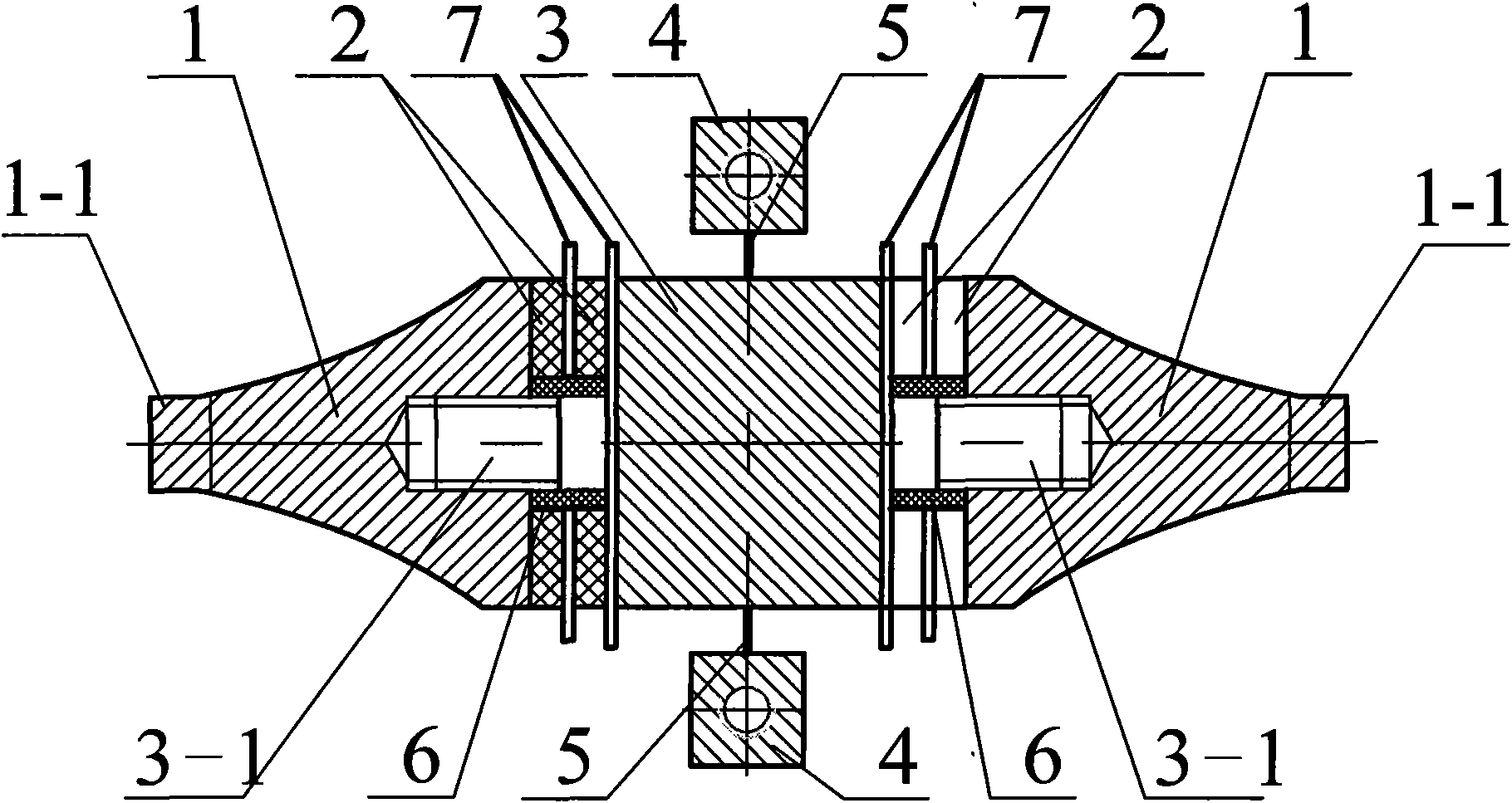

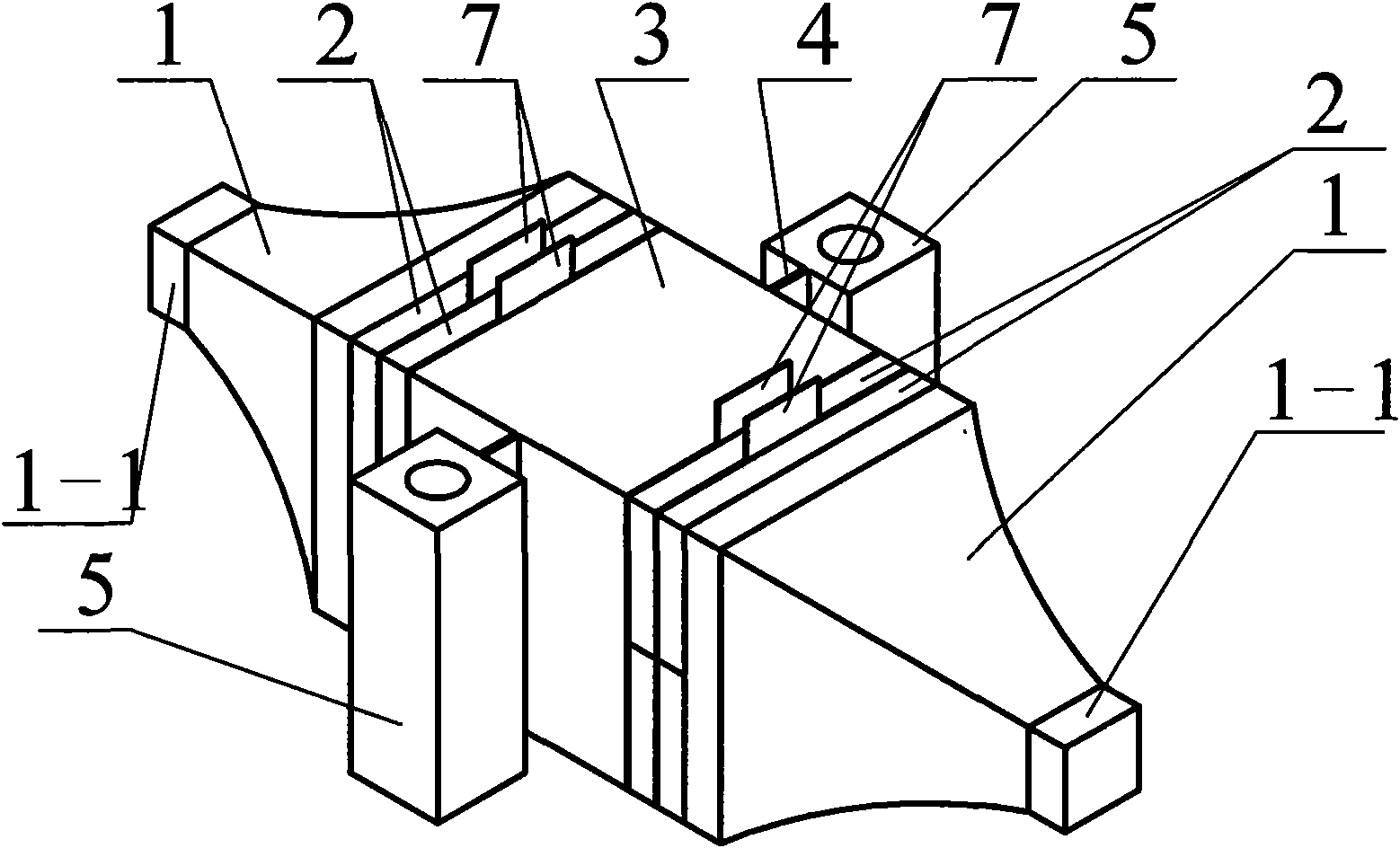

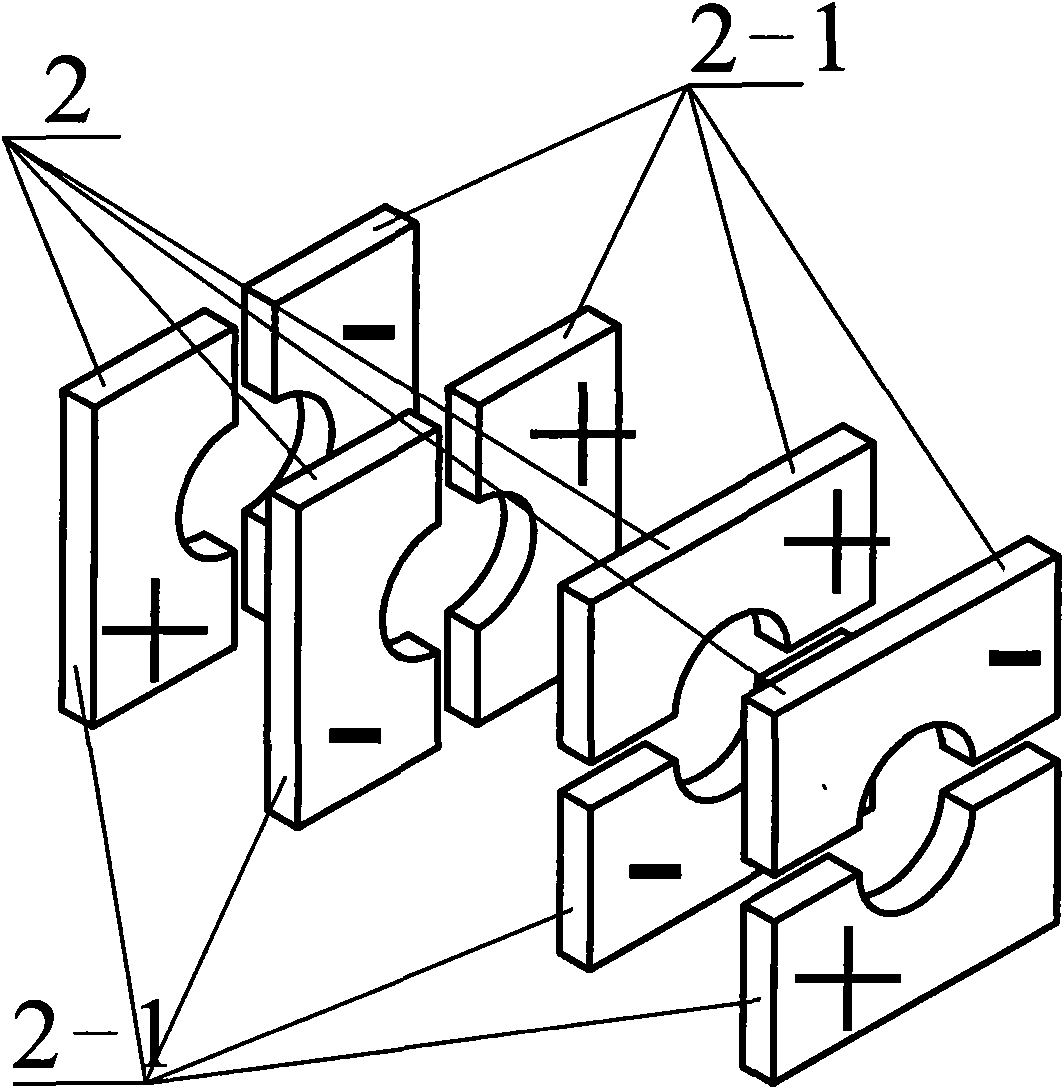

[0008] Specific implementation mode one: the following combination Figure 1 to Figure 3 This embodiment will be specifically described. This embodiment consists of two driving feet 1-1, two end covers 1, two insulating sleeves 6, two pairs of piezoelectric ceramic sheets 2 whose polarization direction is the thickness direction, a flange plate 3, four electrode sheets 7, Composed of two thin-walled beams 5 and two mounting seats 4, a stud 3-1 protrudes from the two end faces of the flange 3 along its axis, and each stud 3-1 is covered with a pair of piezoelectric ceramic sheets 2 and an insulating sleeve 6 is arranged between the stud 3-1 and the piezoelectric ceramic sheet 2, and an end cap 1 is screwed on the overhanging end of each stud 3-1 so that the piezoelectric ceramic sheet 2 is pressed Immediately between the flange 3 and the end cover 1, the end cover 1 is a quadrangular prism with a square cross-section and tapering from its head end to the end, and each end cove...

specific Embodiment approach 2

[0011] Embodiment 2: The difference between this embodiment and the beam-type linear ultrasonic motor vibrator with flexural vibration mode described in Embodiment 1 is that the cross-section of the piezoelectric ceramic sheet 2 is square or circular.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com