Cylindrical traveling-wave ultrasonic motor vibrator pretightened by spring blocks

An ultrasonic motor, cylindrical technology, applied in piezoelectric effect/electrostrictive or magnetostrictive motors, generators/motors, electrical components, etc., can solve the problem of low electromechanical coupling efficiency and difficulty in improving mechanical output capacity problem, to achieve the effect of high electromechanical coupling efficiency, improved mechanical output characteristics, and stable performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

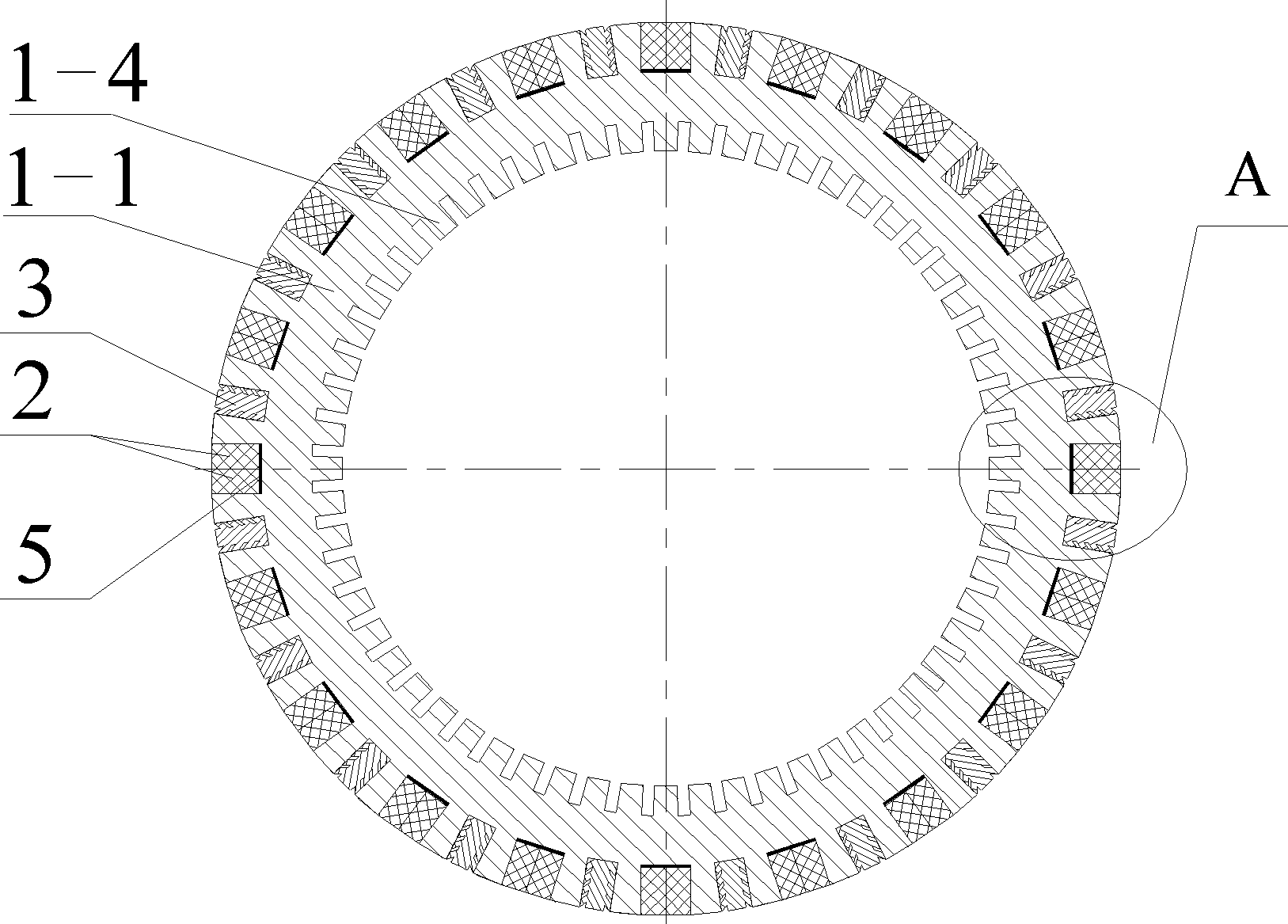

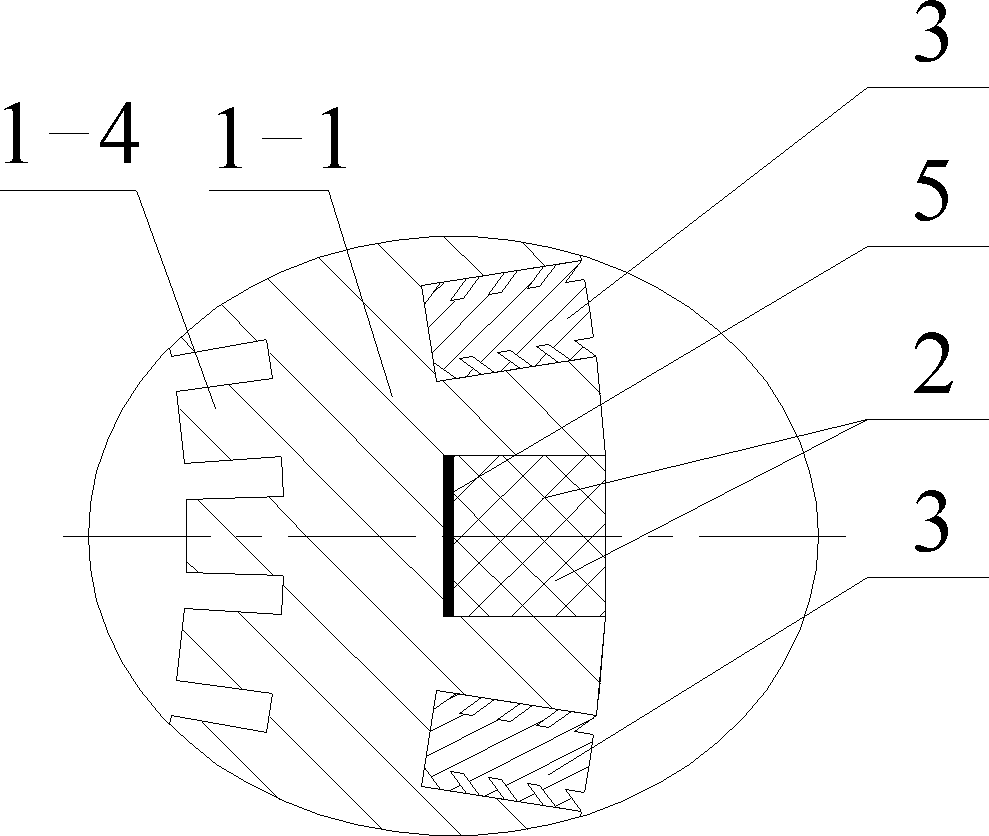

[0019] Specific embodiment one: the following combination Figure 1 to Figure 6 Illustrating this embodiment, the cylindrical traveling wave ultrasonic motor vibrator using spring block preloading described in this embodiment includes a metal base 1, 4n piezoelectric ceramic sheets, 2, 4n spring blocks 3, 4n electrode sheets 4 and 4n insulating spacers 5, n is a natural number greater than or equal to three;

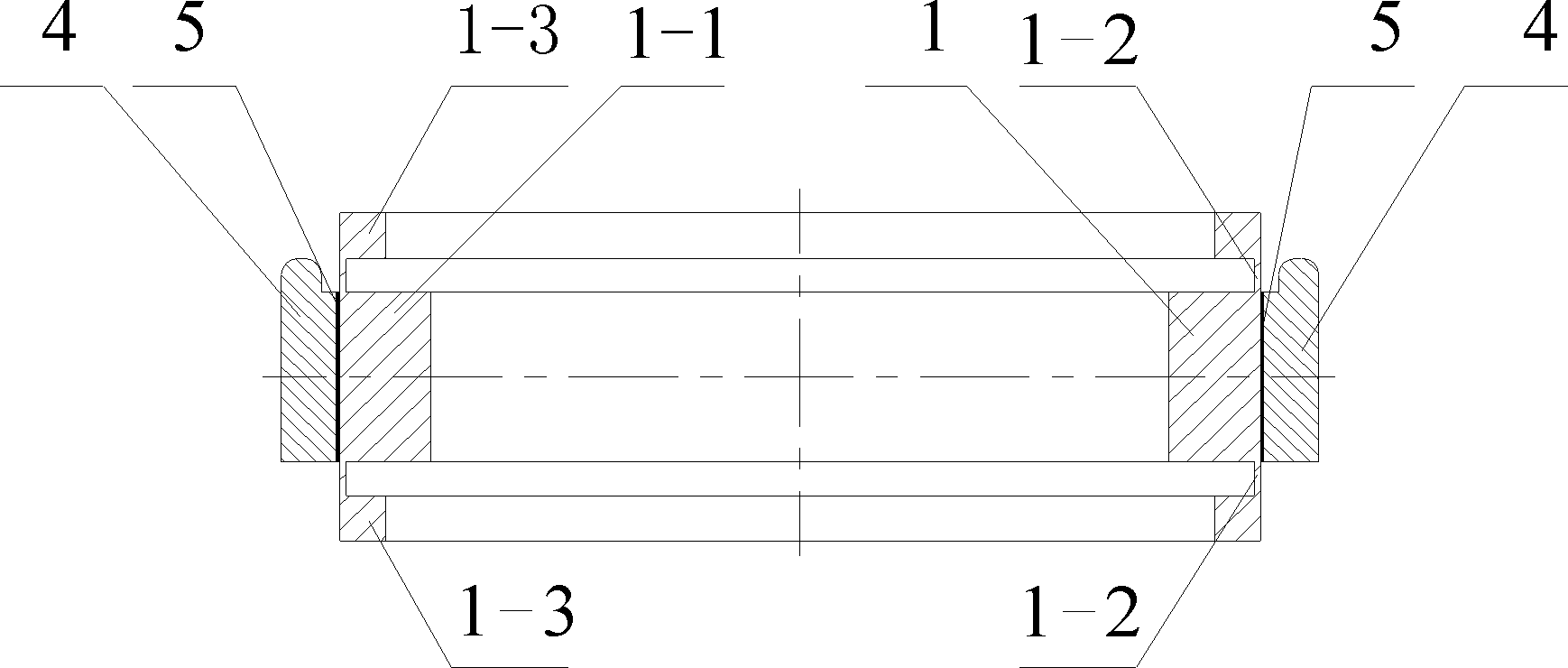

[0020] The metal base 1 is composed of a cylinder 1-1, two thin-walled rings 1-2 and two flanges 1-3. The axial ends of the cylinder 1-1 are respectively provided with a thin-walled ring 1-2 and a flange 1-2. 3. The thin-walled ring 1-2 is located between the cylinder 1-1 and the flange 1-3, and the central axes of the cylinder 1-1, the thin-walled ring 1-2 and the flange 1-3 coincide,

[0021] Continuous comb-shaped driving teeth 1-4 are uniformly processed along the circumferential direction on the inner surface of the cylinder 1-1, and 8n through grooves with rectang...

specific Embodiment approach 2

[0029] Specific embodiment two: the following combination figure 1 Describing this embodiment, this embodiment is a further description of Embodiment 1. The cylinder 1-1, the two thin-walled rings 1-2 and the two flanges 1-3 are integrated into one piece.

specific Embodiment approach 3

[0030] Embodiment 3: This embodiment is a further description of Embodiment 1 or Embodiment 2. The piezoelectric ceramic sheet pair 2 is polarized along the thickness direction to form two piezoelectric ceramic sheets of the same piezoelectric ceramic sheet pair 2 The polarization directions of the adjacent piezoelectric ceramic sheets are opposite to each other.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com