Reversible lock body

A lock body and reversing gear technology, applied in the field of mechanical locks, can solve the problems of increasing the overall cost and inconvenient use, and achieve the effects of cost saving, convenient installation and maintenance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

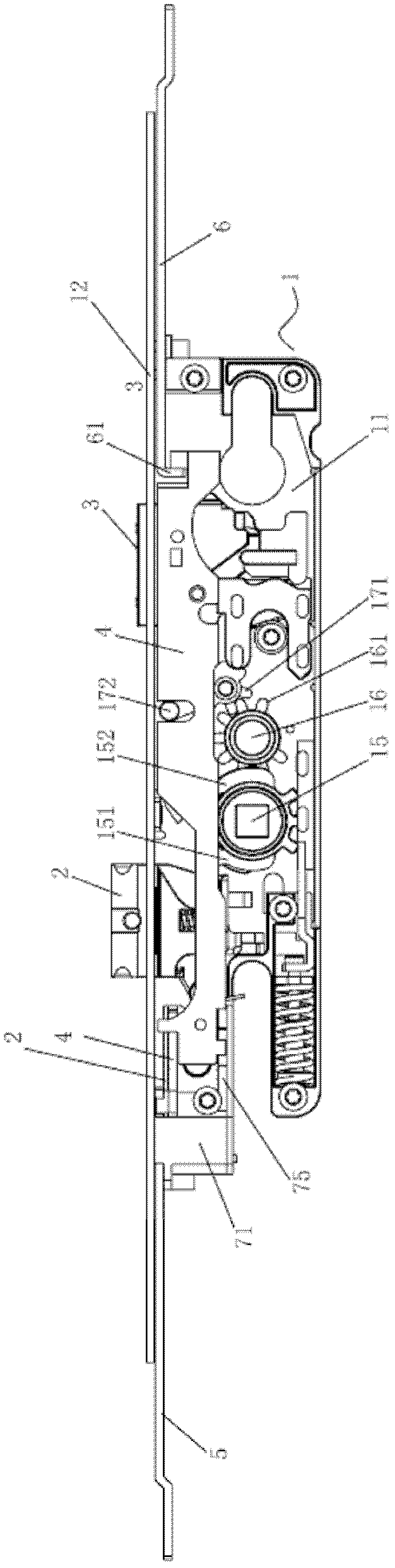

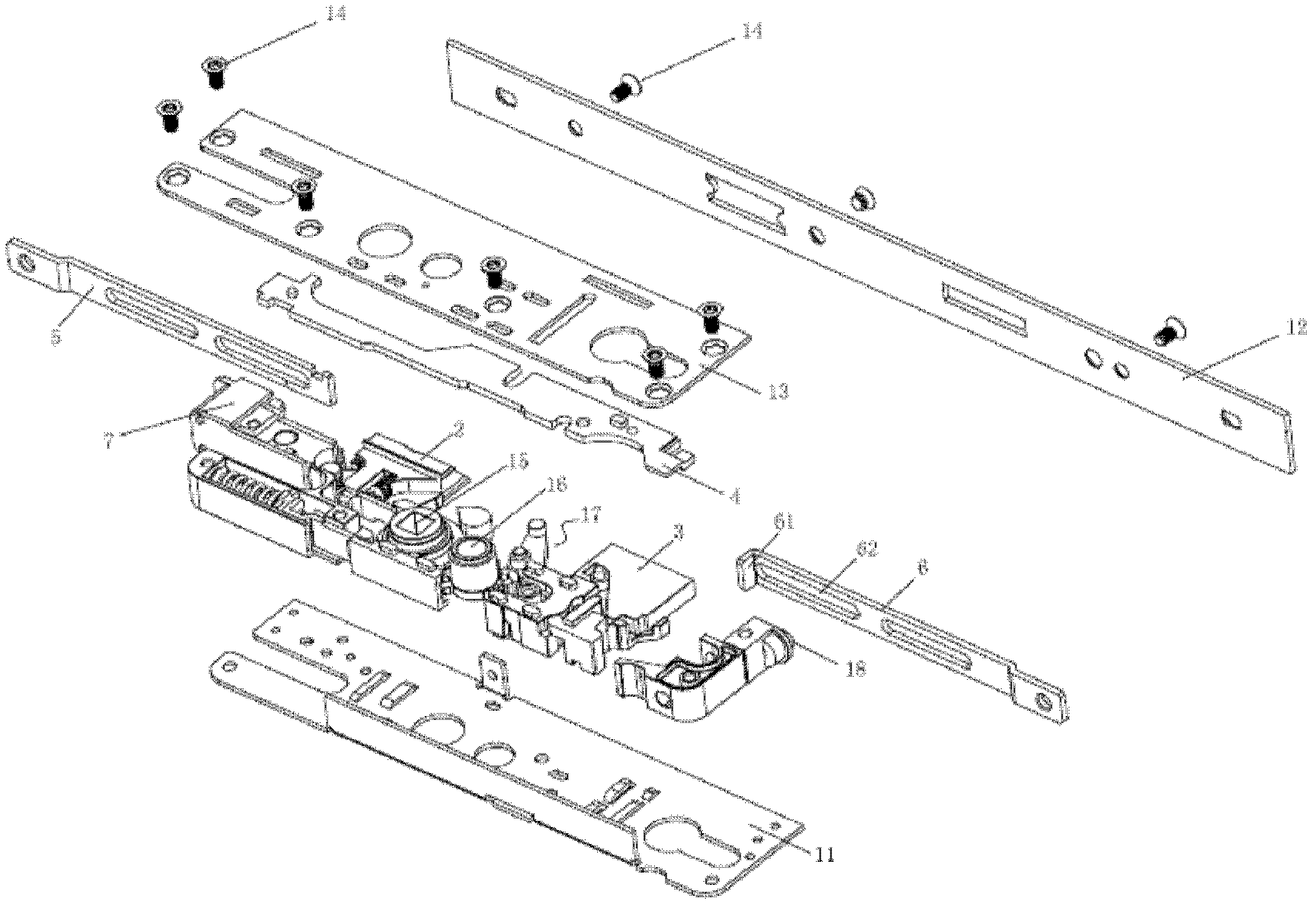

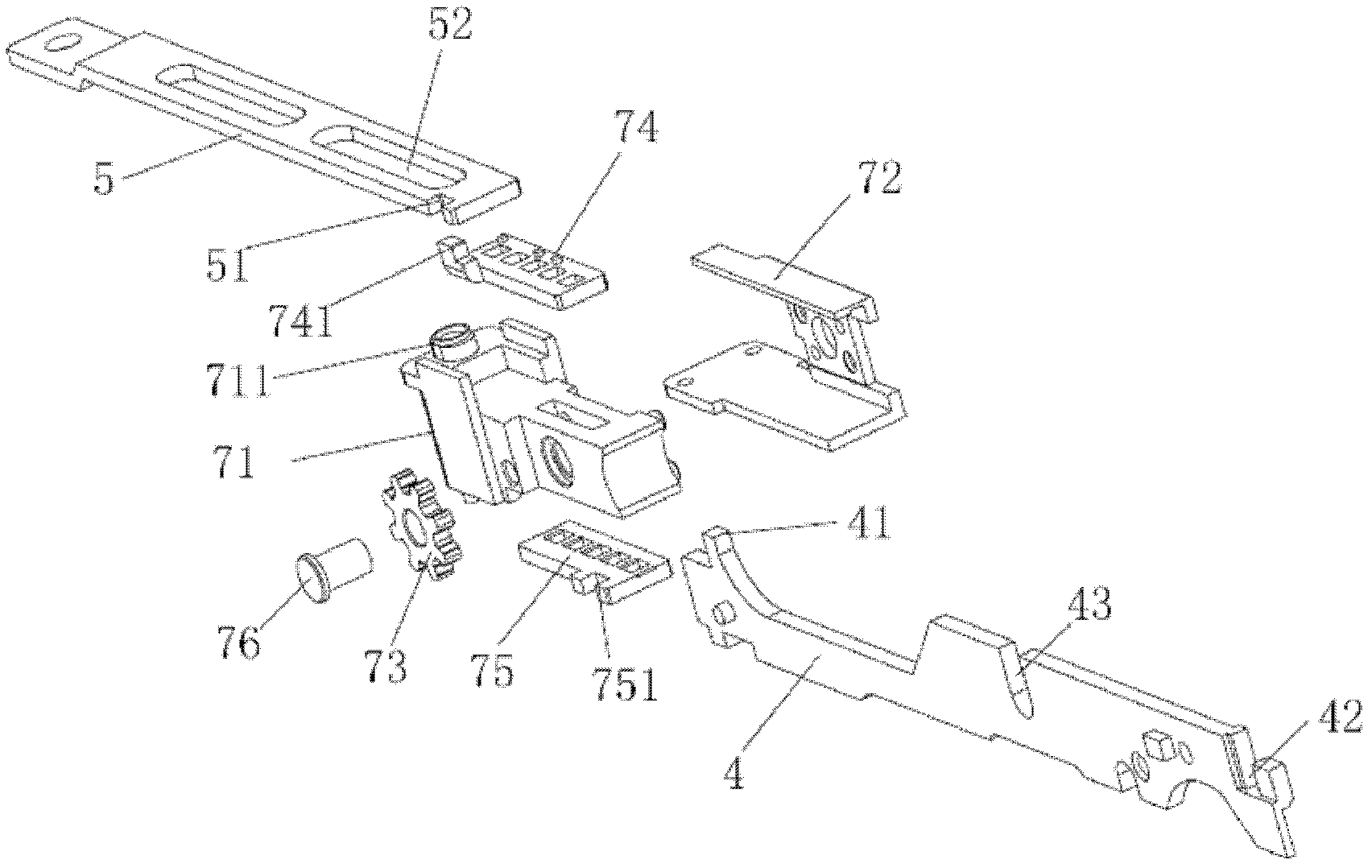

[0020] Below in conjunction with accompanying drawing and specific implementation, the present invention will be further described:

[0021] see Figure 1 to Figure 4 , the reversing lock body of the present invention includes a lock body shell 1 with a built-in cavity, the lock body shell includes a bottom plate 11 and a cover plate 13, wherein the cover plate 13 is consolidated with the bottom plate 11 by screws 14, and the lock body shell 1 is in A panel 12 is arranged close to the end side of the door frame, and the oblique tongue 2 and the square tongue 3 are arranged on the telescopic panel 12. An unlocking dial 16 that can be driven by a key is arranged in the above-mentioned cavity, and a rotating dial is connected with the unlocking dial 16. 15. The rotating block 15 cooperates with the sector gear 151 of the unlocking block 16 through the second interference block 152, and drives the oblique tongue 2 through the first interference block 151, and is connected with the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com