Meat product sauce-brushing device based on food processing and using method thereof

A technology for food processing and meat products, which is applied in the field of meat product sauce brushing device based on food processing, can solve the problems of low operation efficiency, inability to brush sauce, and difficulty in ensuring the uniformity of meat product sauce, so as to achieve sustainable, The effect of improving the degree of uniformity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

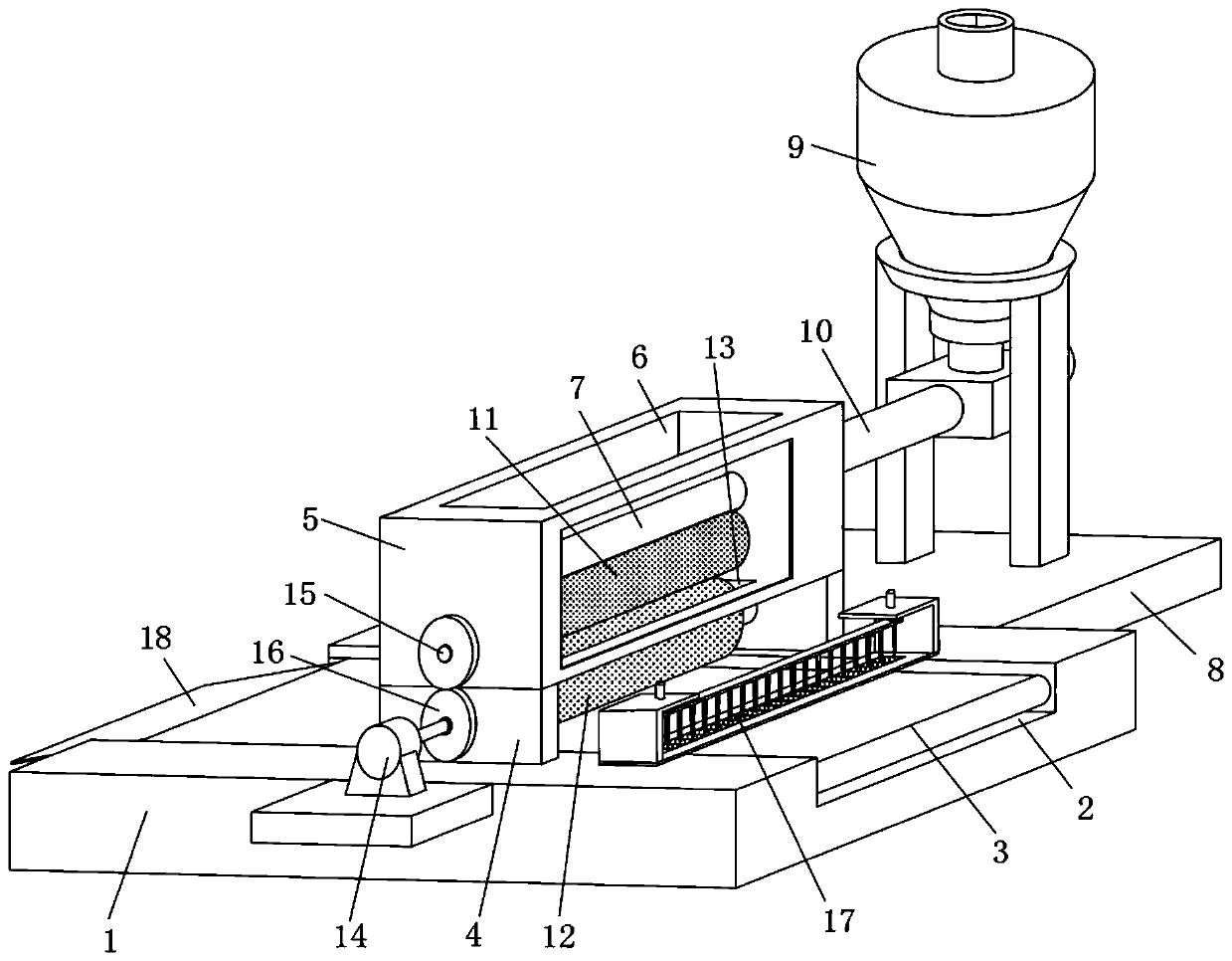

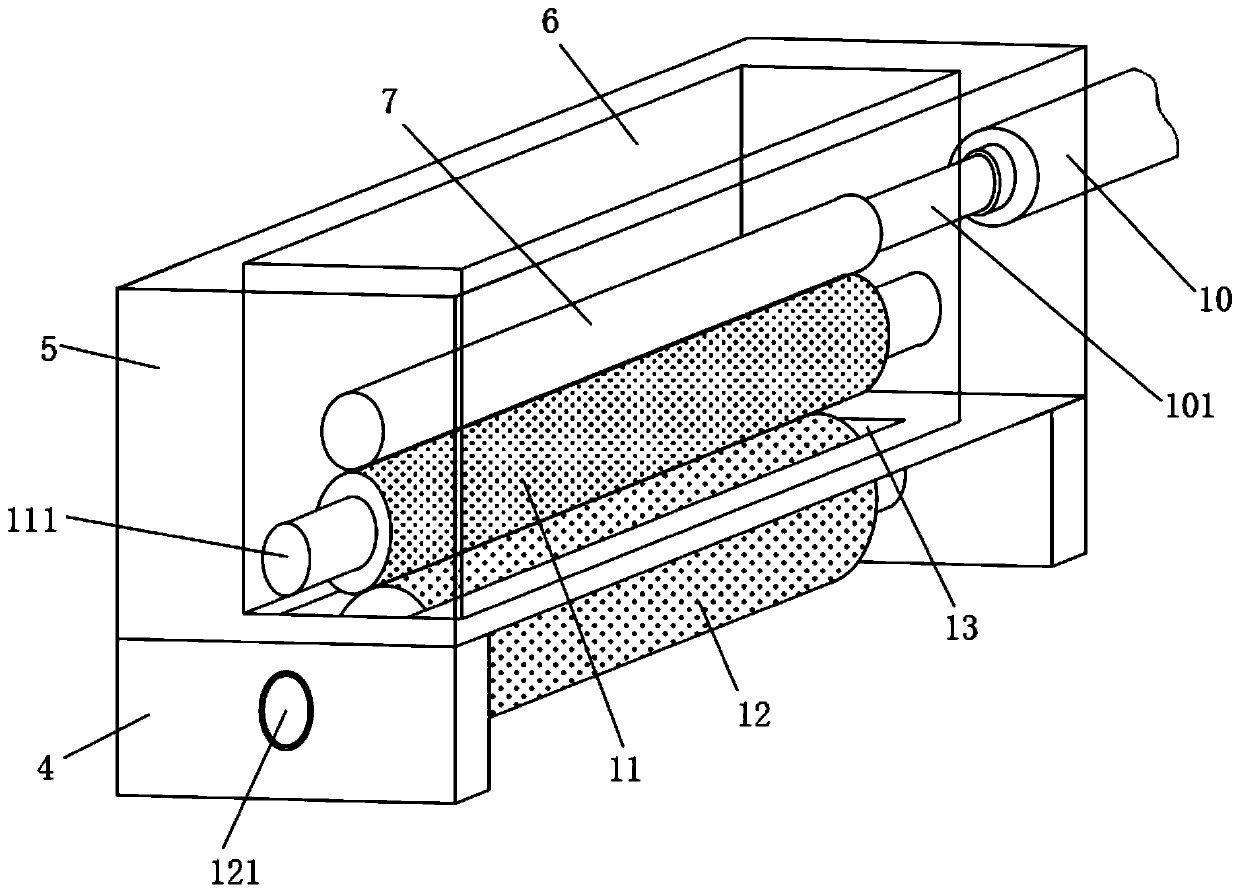

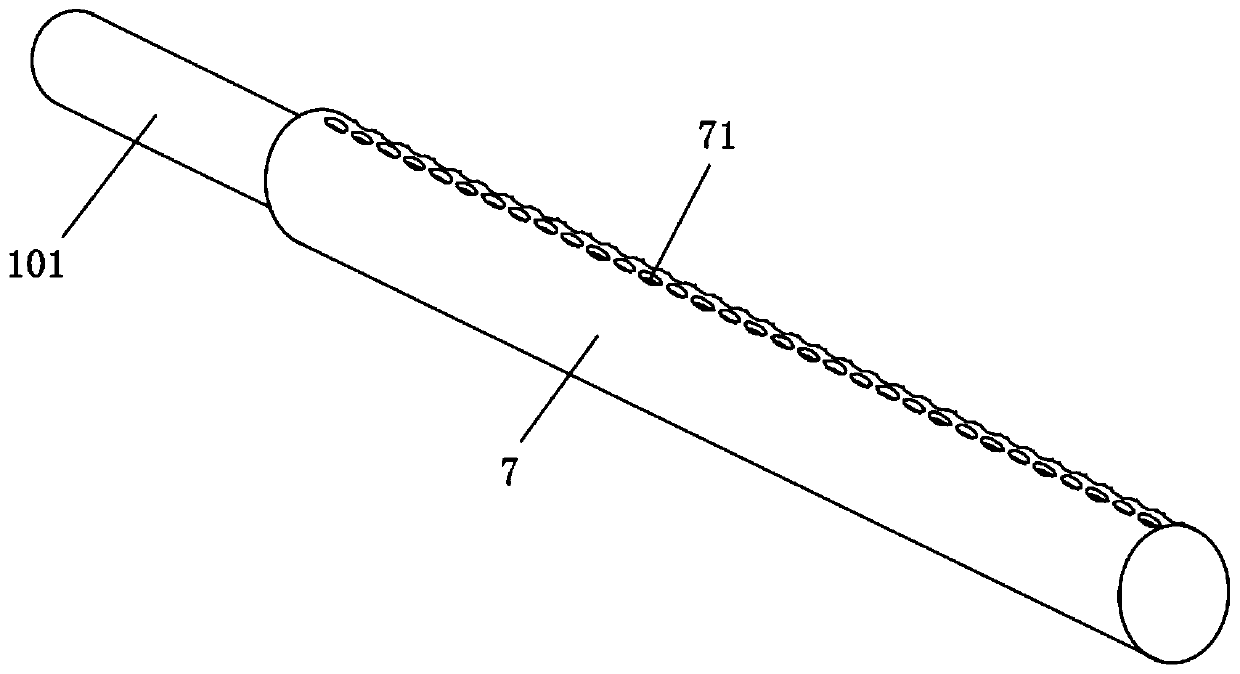

[0044] see Figure 1-3 , a sauce brushing device for meat products based on food processing, comprising a conveyor table 1, a sauce brush box 5 fixedly installed on the upper end of the conveyor table 1, and a sauce tank 9 fixedly connected to the upper end side of the conveyor table 1, the conveyor table 1 The upper end is provided with a transmission cavity 2, and a conveyor belt 3 is installed in the transmission cavity 2. The conveyor belt 3 is used to transmit the meat products to be brushed with sauce. On both sides of the upper end, an operation cavity 6 is arranged inside the brush sauce box 5, and a feed pipe 7 communicating with the sauce tank 9 is fixedly installed on the side wall of the operation cavity 6 near the upper end, and the sauce material in the sauce tank 9 is introduced Follow-up brushing sauce operation is carried out in the feeding pipe 7.

[0045] One side of the upper end of the transfer table 1 is fixedly connected with a carrier plate 8 supportin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com