Fixing fixture for synchronous cutting of multiple rectangular steel pipes

A technology for synchronous cutting and rectangular steel pipes, applied in the direction of clamping, positioning devices, clamping devices, etc., can solve problems such as deformation and bending of rectangular steel pipes, increase labor intensity of workers, and deformation of rectangular steel pipes, so as to reduce the range of horizontal movement and avoid Cantilever beam cutting, the effect of reducing the chance of deformation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] The embodiments of the present invention will be described in detail below with reference to the accompanying drawings, but the present invention can be implemented in many different ways as defined and covered by the claims.

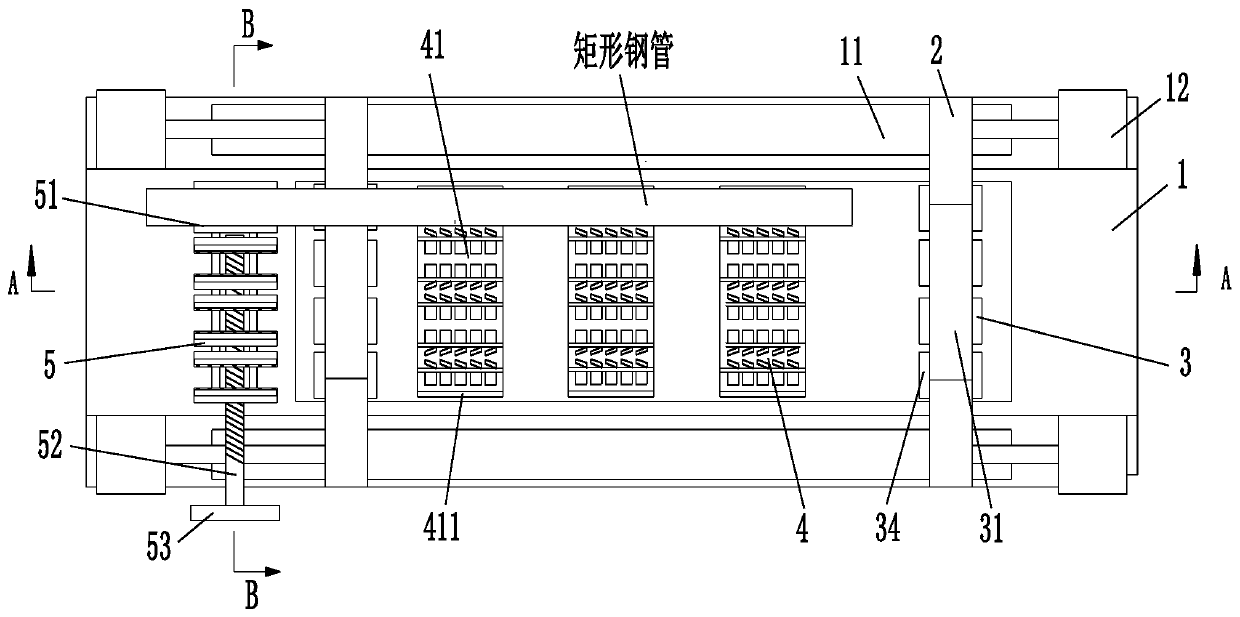

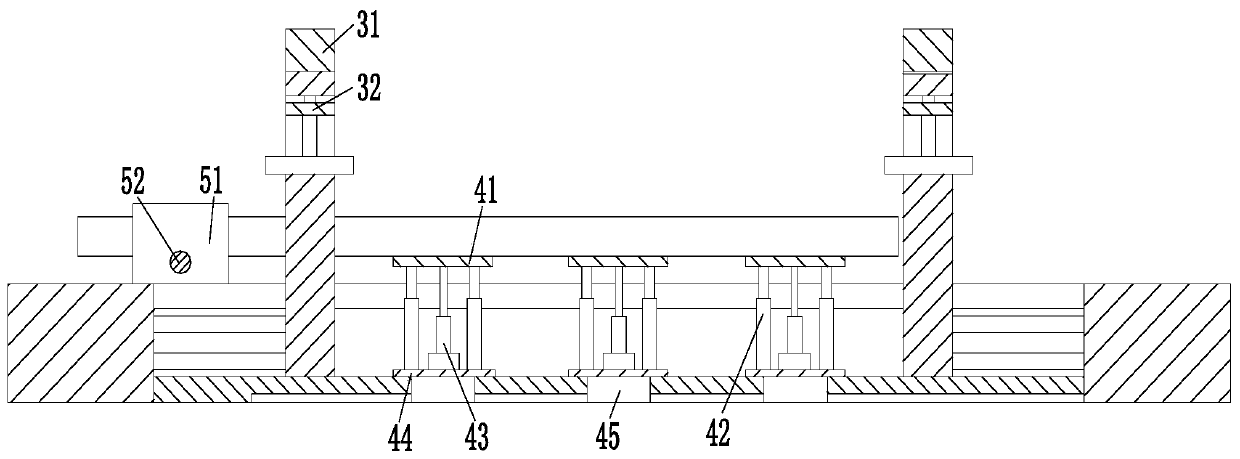

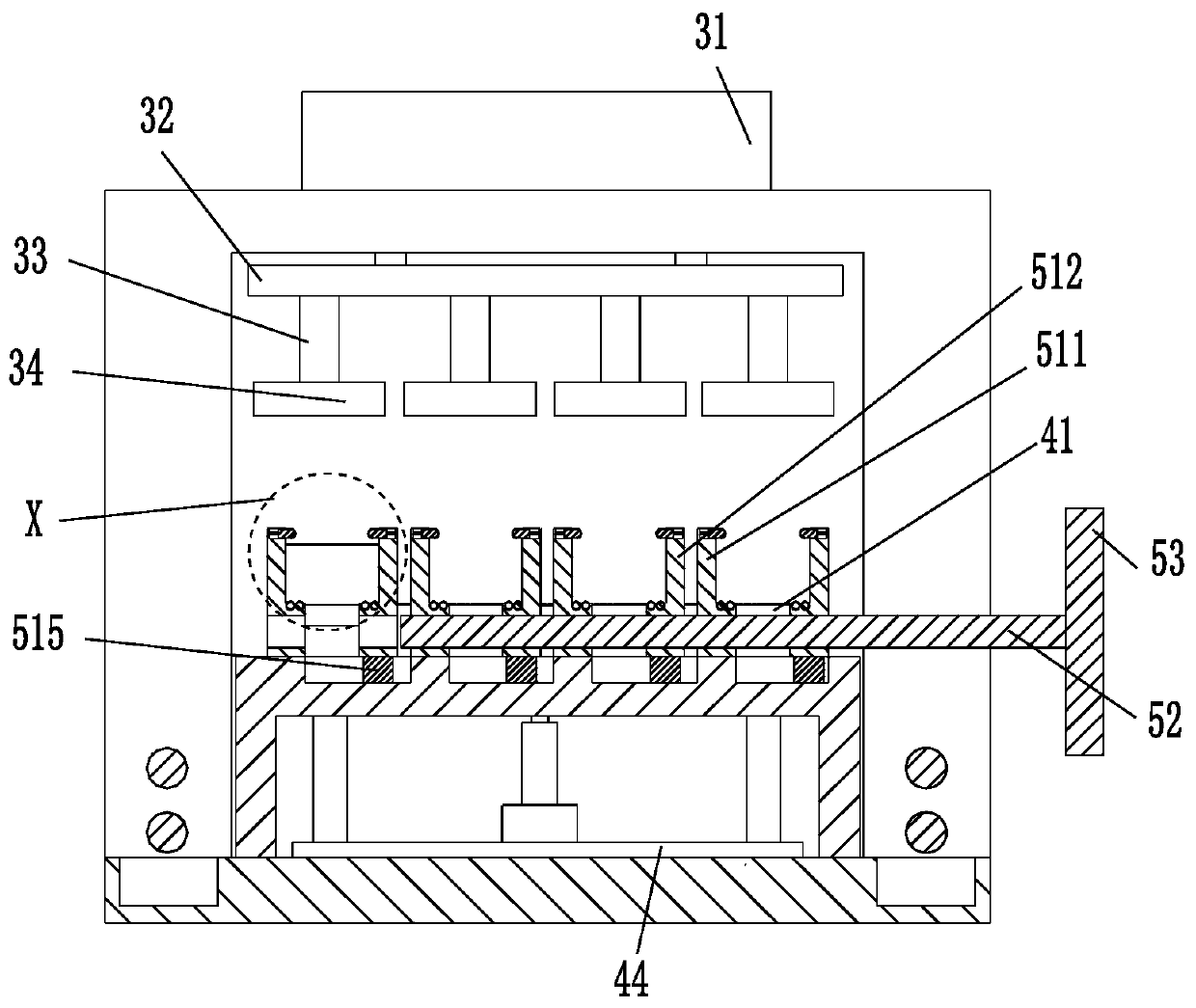

[0030] Such as Figure 1 to Figure 4 As shown, a fixed fixture for synchronous cutting of a plurality of rectangular steel pipes includes a workbench 1, a gantry frame 2, a pressing device 3, a supporting device 4 and a clamping device 5, and the left and right sides of the workbench 1 pass through The gantry 2 is symmetrically arranged in sliding mode, and the gantry 2 is provided with a pressing device 3 by sliding. The middle part of the workbench 1 is provided with a rectangular slot, and the supporting device 4 is arranged in the rectangular slot from left to right. A clamping device 5 is provided on the left side of the upper end surface of the workbench 1 , and the clamping device 5 is located on the left side of the gantry 2 on the left s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com