A manufacturing process for heat-resistant tinfoil rolls

A manufacturing process and tin foil technology, which is applied in the field of temperature-resistant tin foil paper roll production and manufacturing process, can solve the problems of easy occurrence of looseness, affect reprocessing, and low degree of adhesion, so as to reduce the phenomenon of wrinkles or overlapping layers and improve the degree of adhesion. , the effect of improving integrity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

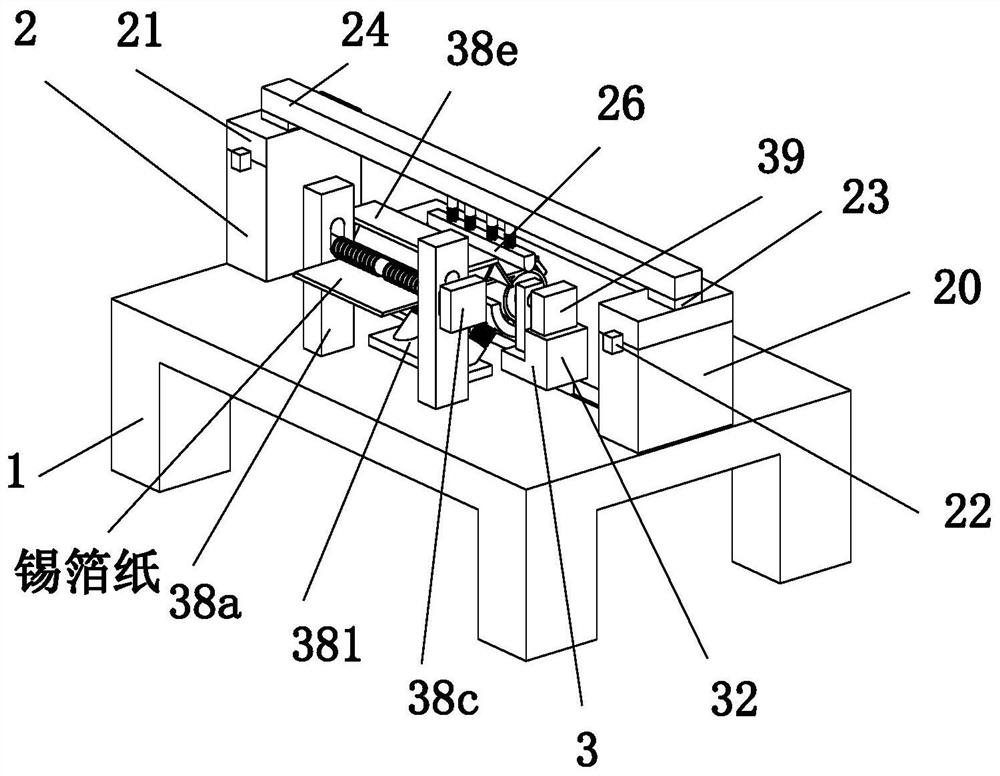

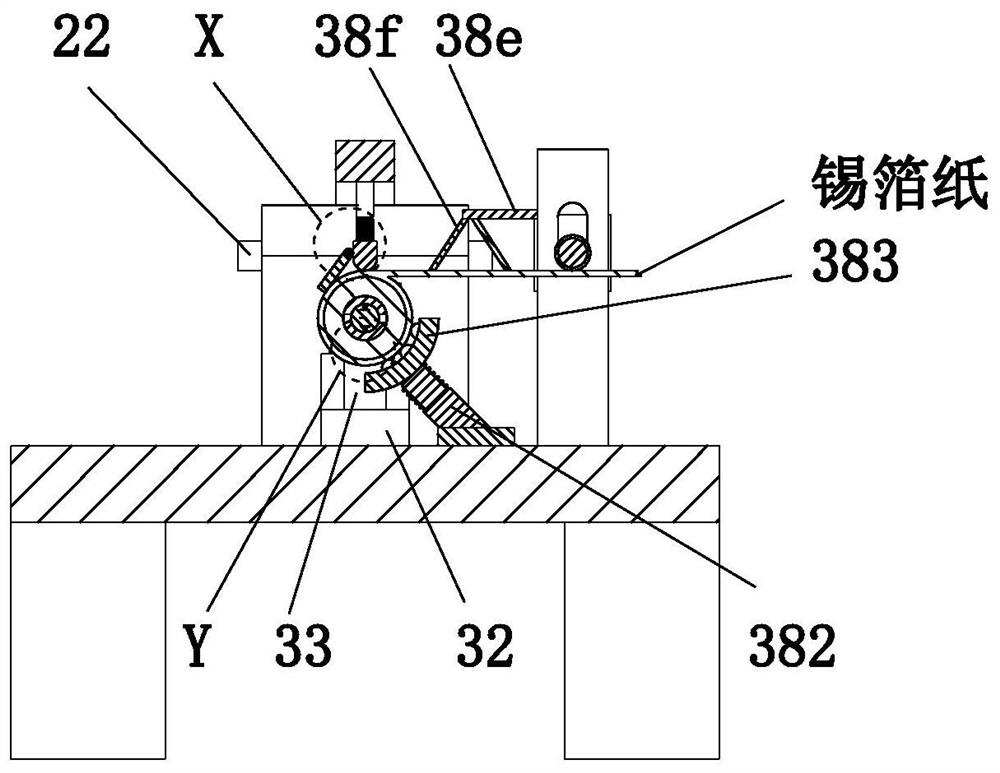

[0040] The embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings, but the present invention can be implemented in many different ways that are predetermined and covered by the claims.

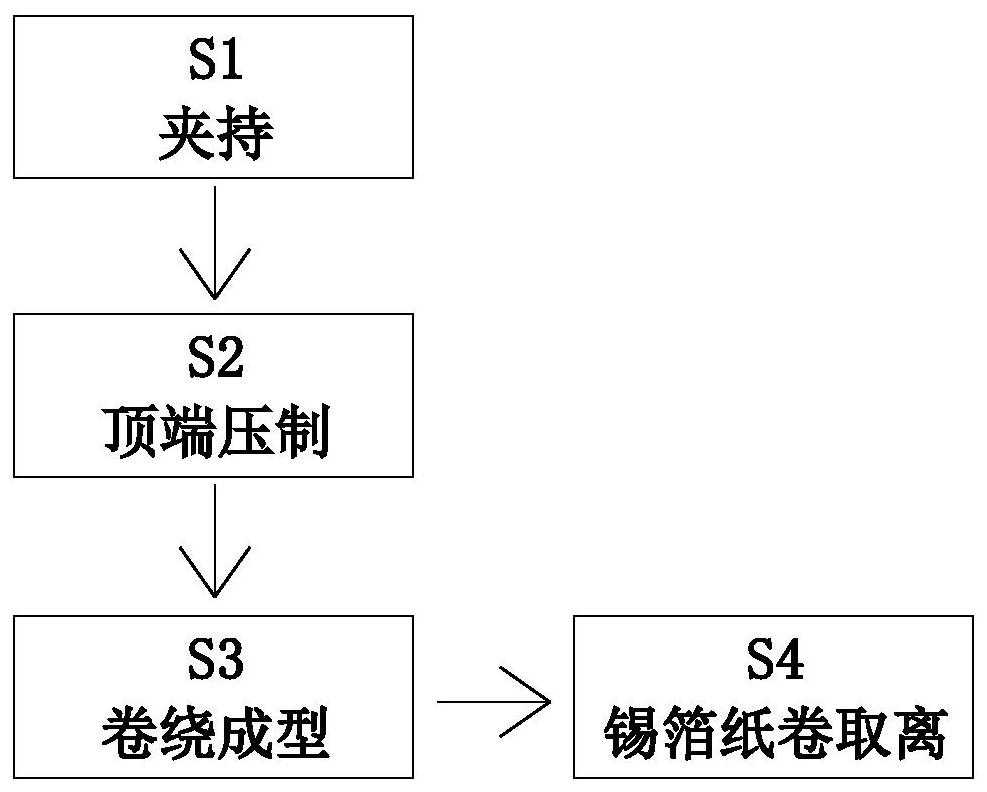

[0041] Such as Figure 1 to Figure 12 As shown, a heat-resistant tin foil roll manufacturing process uses a heat-resistant tin foil roll manufacturing device, which includes a workbench 1, a pressing mechanism 2 and a clamping mechanism 3 , the specific manufacturing process is as follows when using the above-mentioned heat-resistant tin foil roll production and manufacturing device to manufacture heat-resistant tin foil rolls:

[0042] S1. Clamping: Manually insert the winding core 38 on the long shaft 37, and at the same time drive the step seat 32 to move to the left through the No. 1 electric slider 30, and the No. 1 vertical plate 33 drives the short shaft 35 to follow the step seat 32 Synchronously move until the short rotati...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com