Ultra supercritical boiler super-heat and re-heater heating surface life evaluation method

An ultra-supercritical boiler and life evaluation technology, applied in the direction of applying stable tension/pressure to test the strength of materials, can solve problems such as inability to describe complex behavior, large consumption, and fracture

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example

[0094] The present invention takes the three-stage superheater T92 tube with cracks on the heating surface of a 1000MW ultra-supercritical unit as the research object. The crack is located on the radial outer wall of the pipe, the initial crack length is 0.1 mm, and it is considered to reach failure when it penetrates the pipe wall.

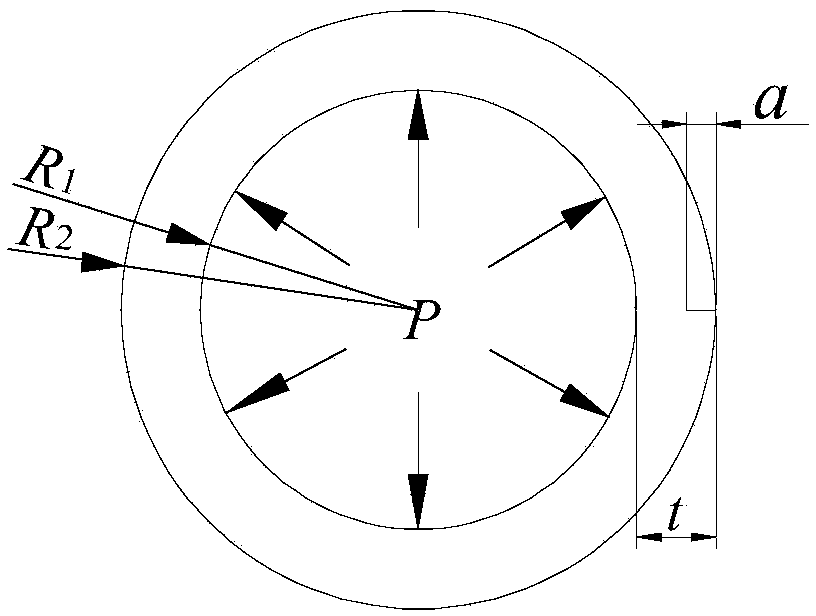

[0095] The size of the heating surface tube along the length of the tube is much larger than its diameter. In the calculation process, the end effect of the tube is ignored, and no strain is considered in the axial direction, so the problem can be simplified as a plane strain problem. figure 2 A pipe model with radial cracks.

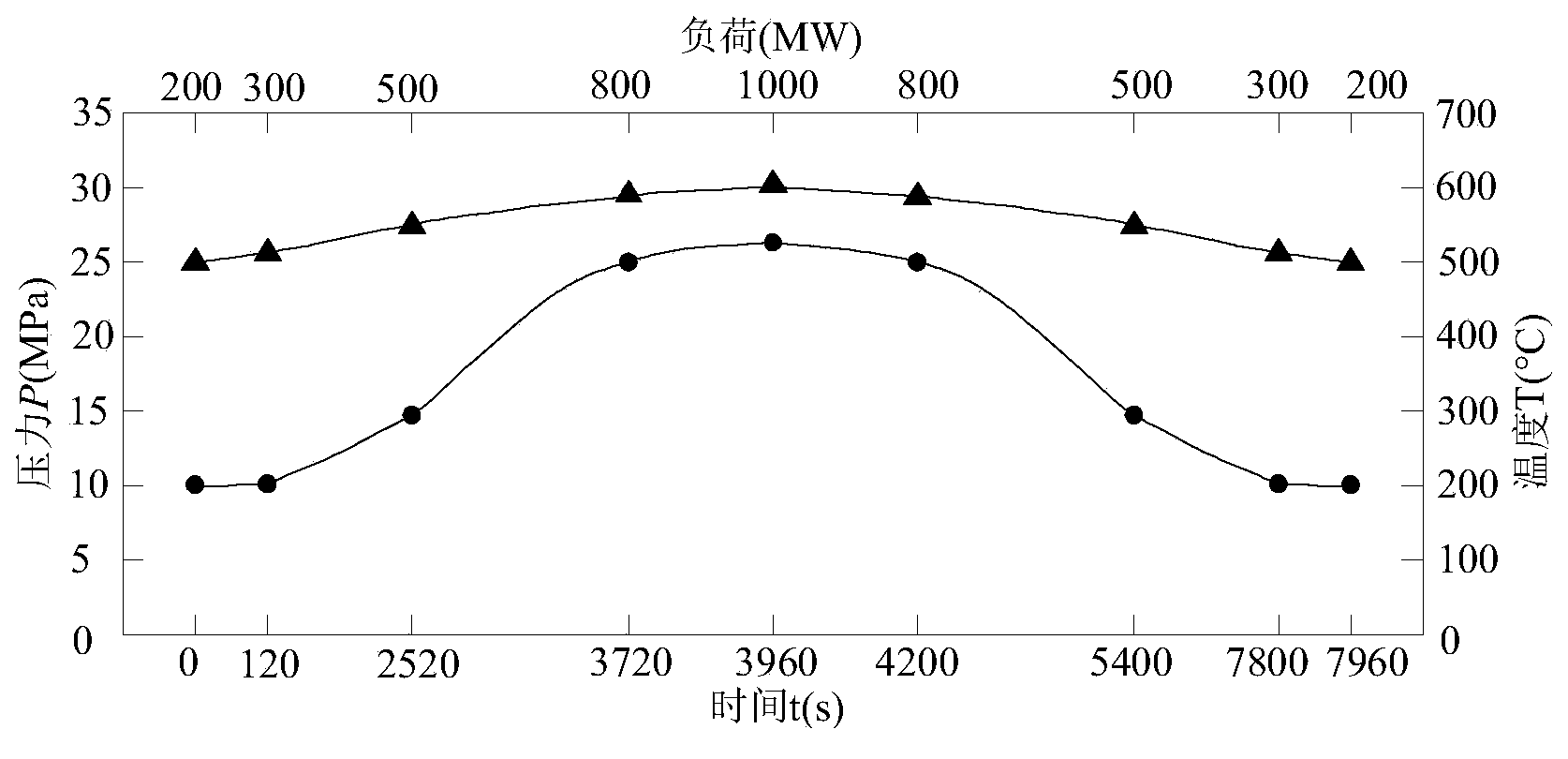

[0096] During variable load operation, such as image 3 As shown, the dotted curve represents the change of internal pressure with time; the triangle curve represents the change of temperature with time. When the load operates in the range of 200MW~1000MW, the pressure fluctuation range is 10~26.25MPa, and the temperatu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com