Automatic mold opening device of disc-type sole machine

A shoe sole machine and disc-type technology, which is applied in the field of automatic mold opening devices for disc-type shoe sole machines, can solve problems such as heavy workload, easy burns, and low work efficiency, and achieve time-consuming and labor-intensive solutions, prevent burns, and improve work efficiency Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

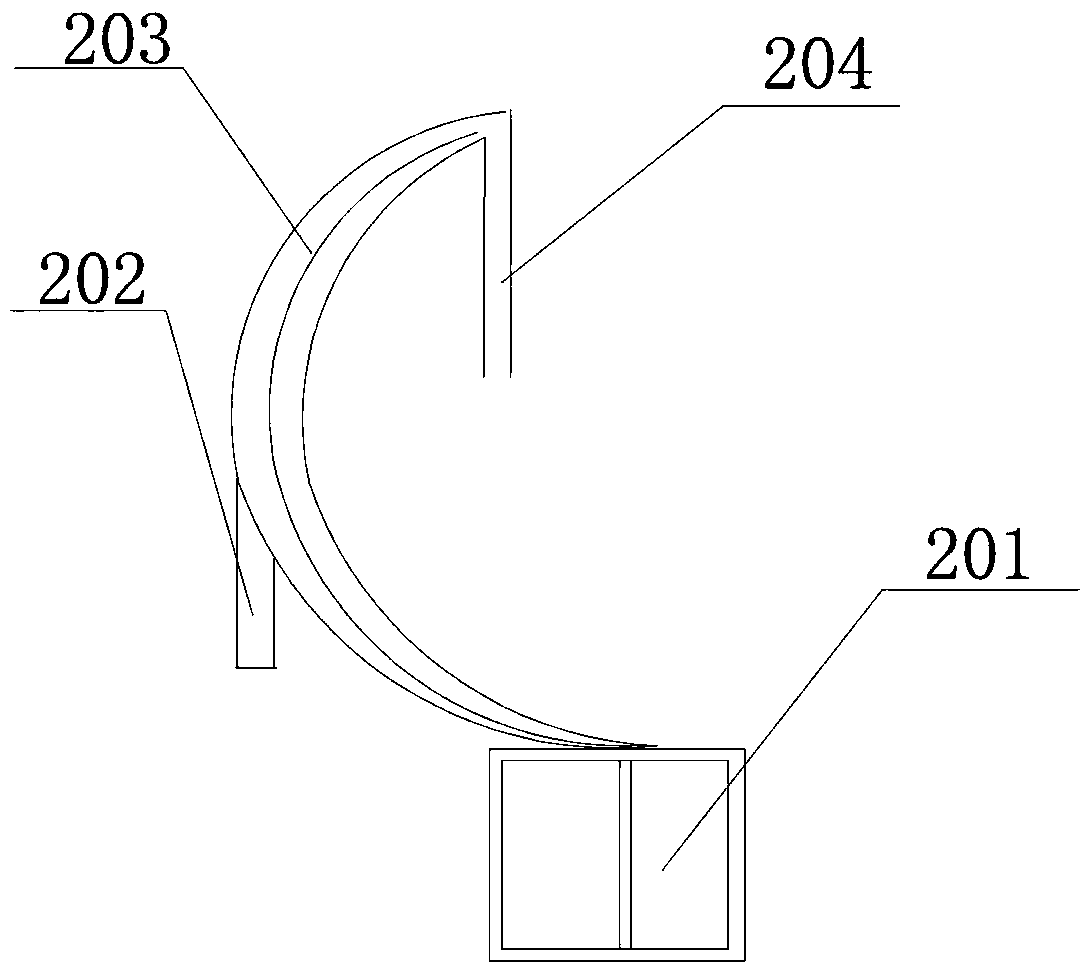

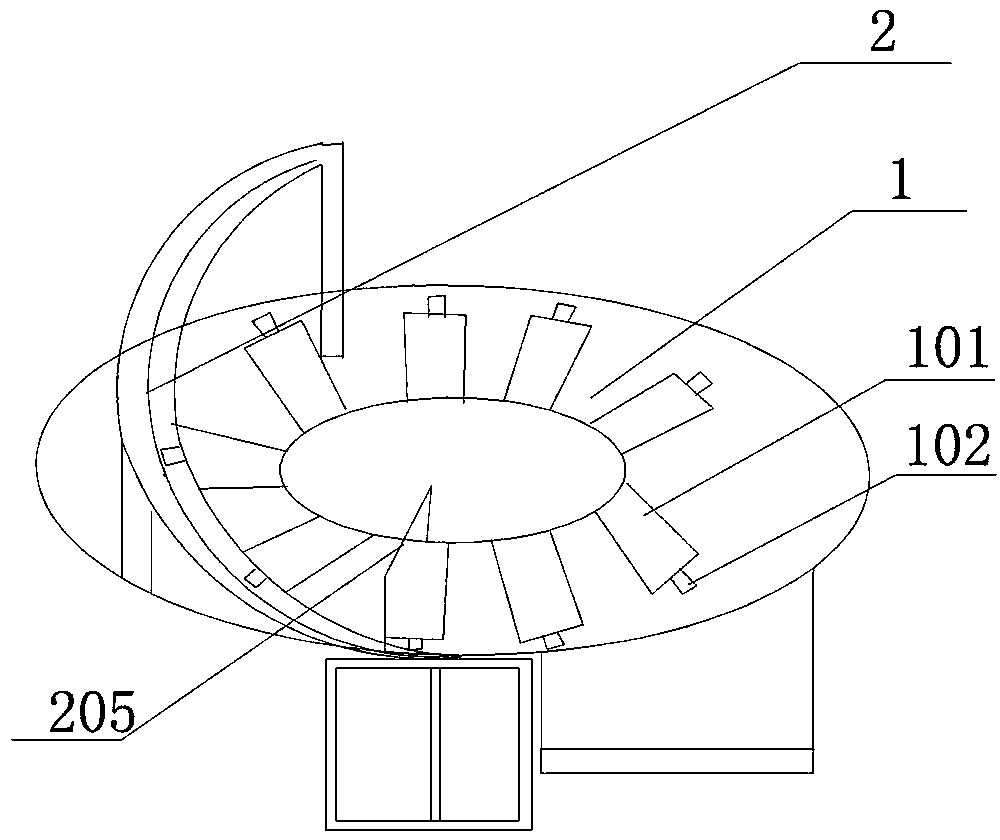

[0011] As shown in the figure, a disc-type shoe sole machine automatic mold opening device 2 is installed on the disc-type shoe sole machine 1; Composition: upper support 204 is positioned at the disc inner side of disc type shoe sole machine 1, and its height is higher than the height when mold 101 is fully opened, and middle bracket 202 is positioned at the disc outer side of disc type shoe sole machine 1, and its height is mold 101 completely Half of the height when opened; the upper end of the front support 201 is connected with the disc outside of the disc type sole machine 1, and the lower end is located on the ground; the arc track 203 is erected on the upper support 204, the middle support 202 and the front support 201, and the arc track The position of the lowest end of 203 is located on the rotation track where the mold 101 opens the handle 102 when the disc sole machine 1 rotates.

[0012] The front bracket 201 is square, rectangular or trapezoidal.

[0013] A posi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com