Patents

Literature

144results about How to "Apply pressure evenly" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

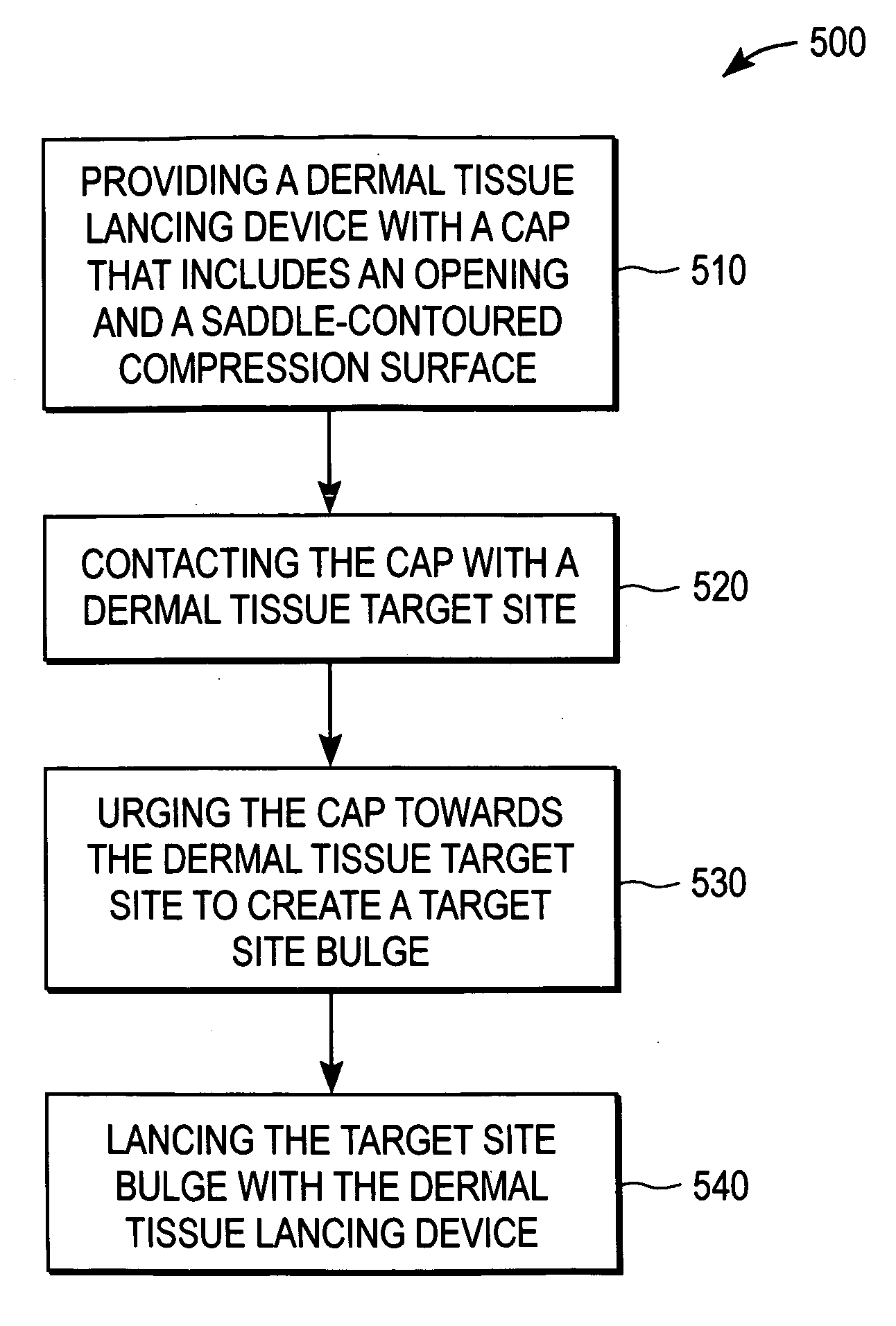

Method for lancing a dermal tissue target site

InactiveUS20050234489A1Apply pressure evenlyReliably obtainedSensorsBlood sampling devicesPunctures skinSkin tissue

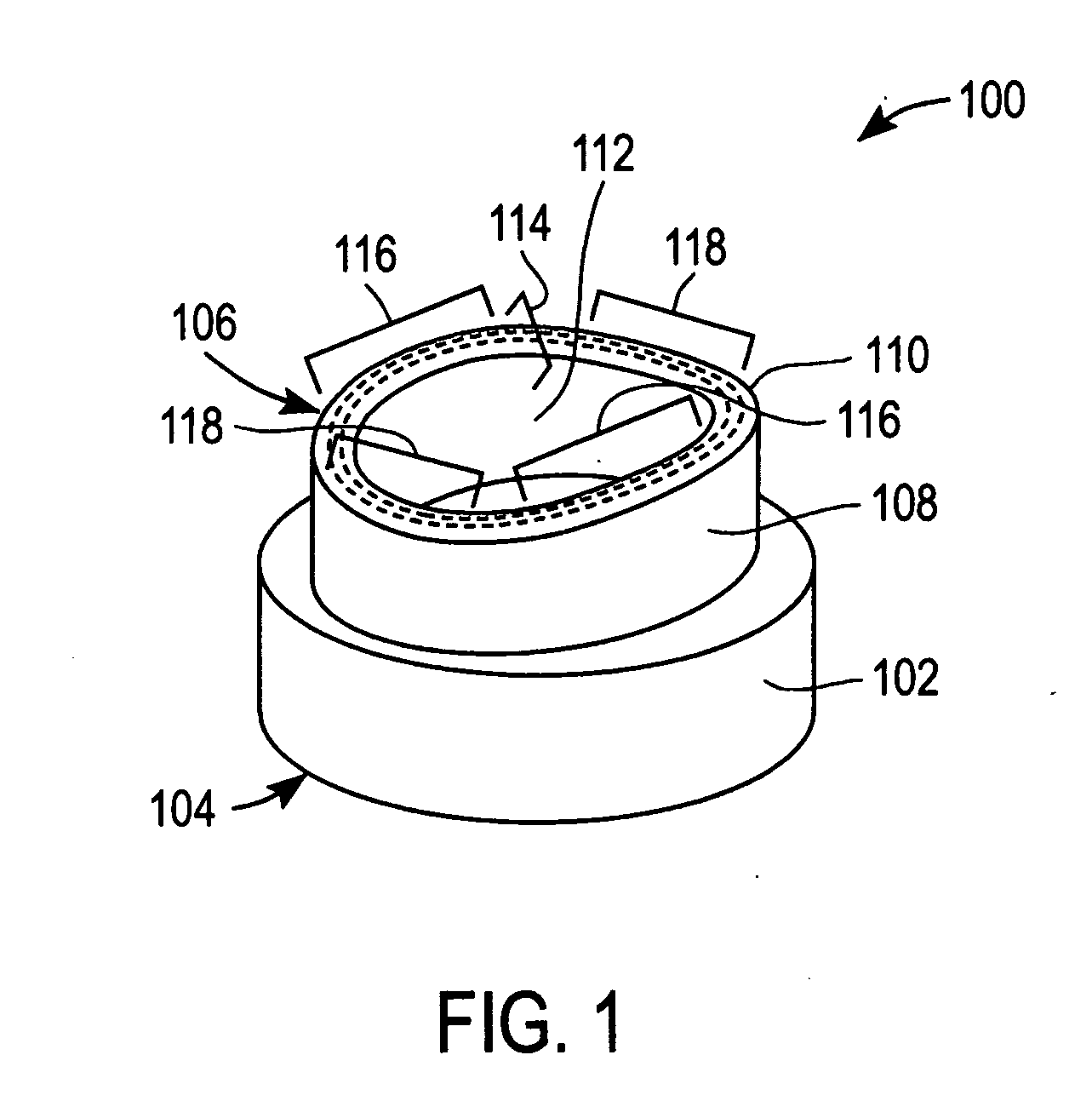

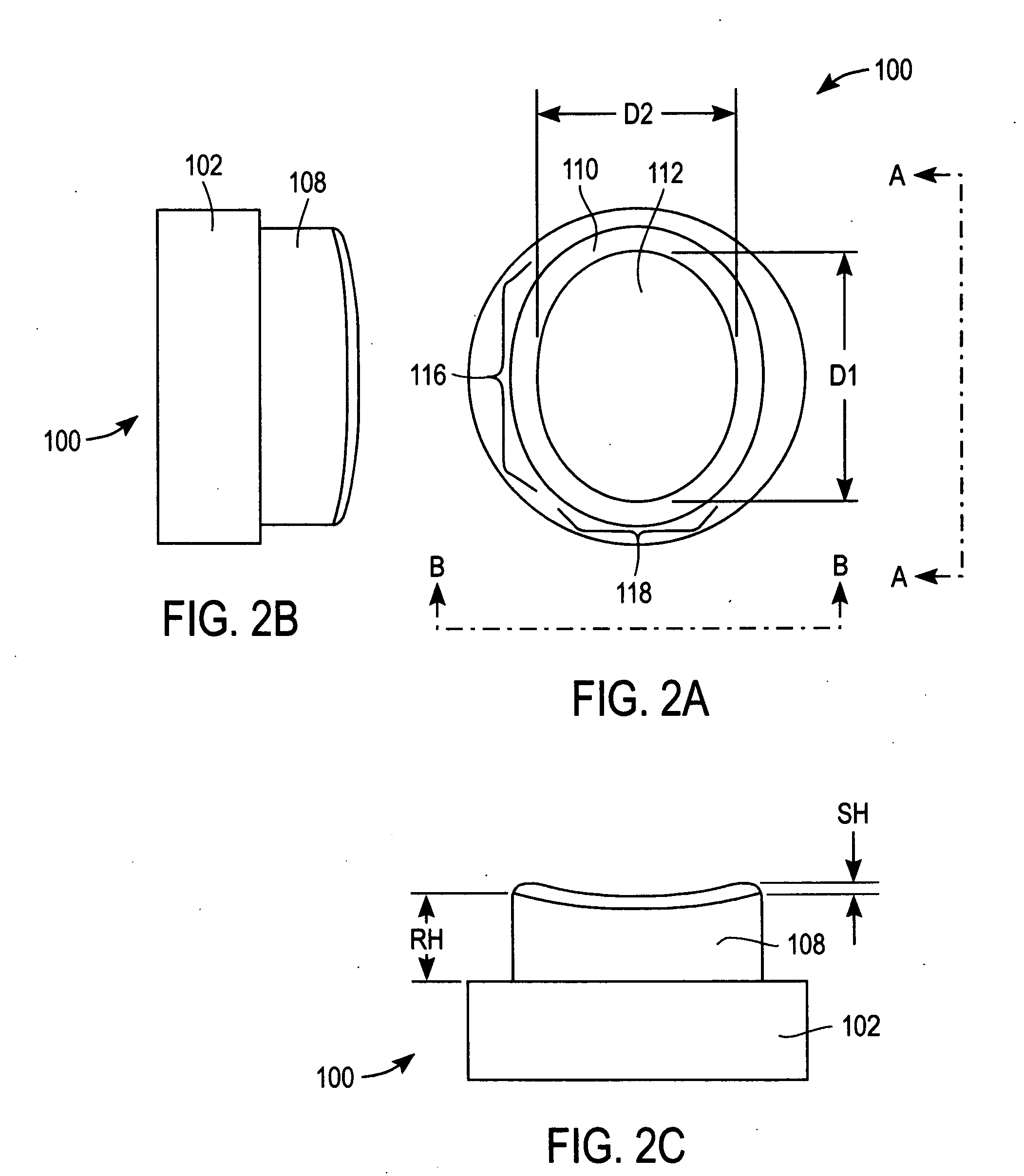

A method for lancing a dermal tissue target site includes providing a dermal tissue lancing device with a housing, a lancet that is moveable with respect to the housing, and a cap. The cap has an opening therethrough for a portion of a lancet to pass through and a continuous saddle-contoured compression surface. The continuous saddle-contoured compression surface is configured for engaging a dermal tissue target site such that, when the cap contacts and is urged towards the dermal tissue target site, the continuous saddle-contoured compression surface applies substantially uniform pressure against the dermal tissue target site. The method also includes contacting the cap with the dermal tissue target site such that the continuous saddle-contoured compression surface completely engages the target site, urging the cap towards the dermal tissue such that the continuous saddle-contoured compression surface applies essentially uniform pressure against the dermal tissue, thereby creating a target site bulge, and lancing the target site bulge.

Owner:LIFESCAN INC

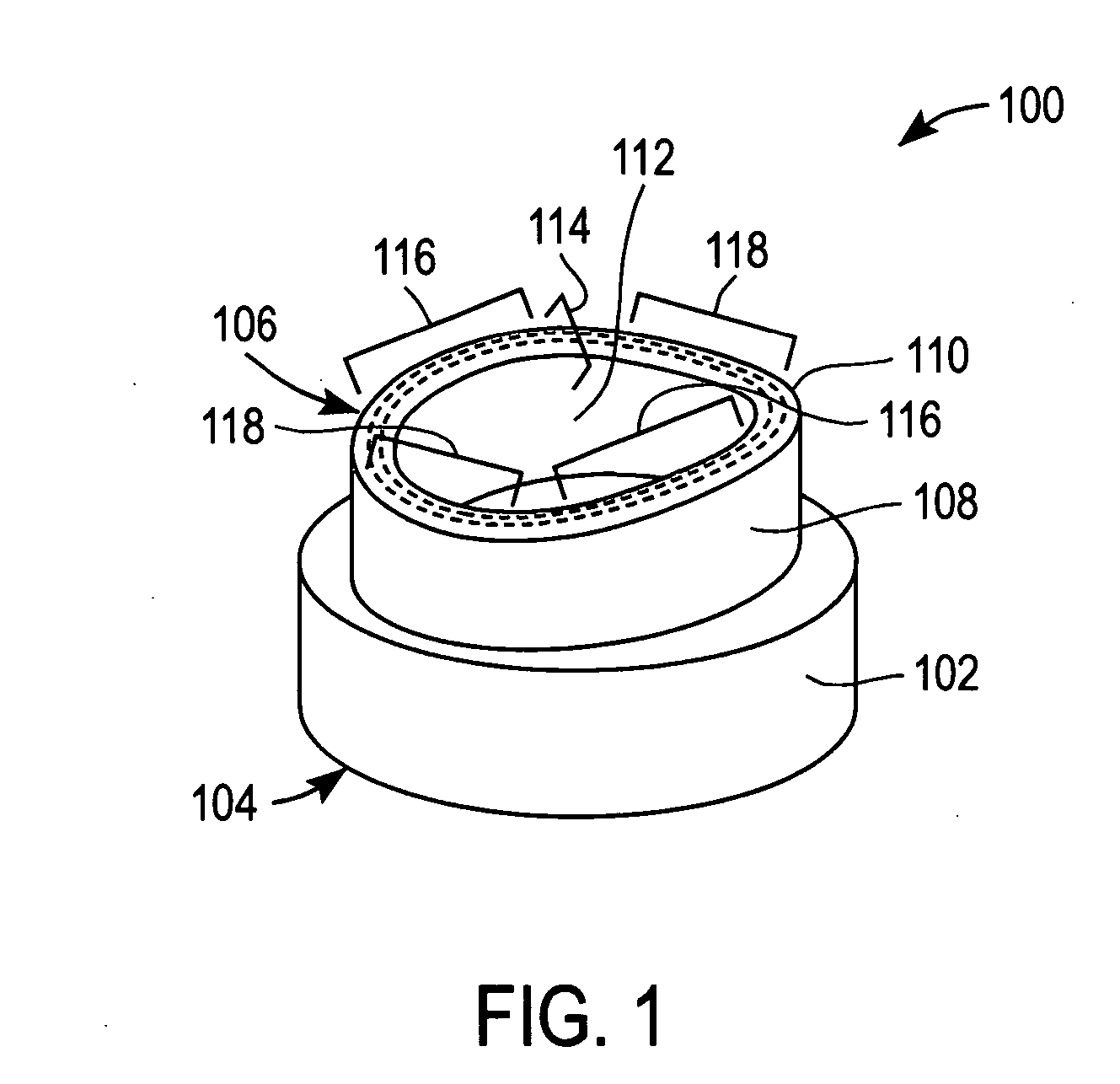

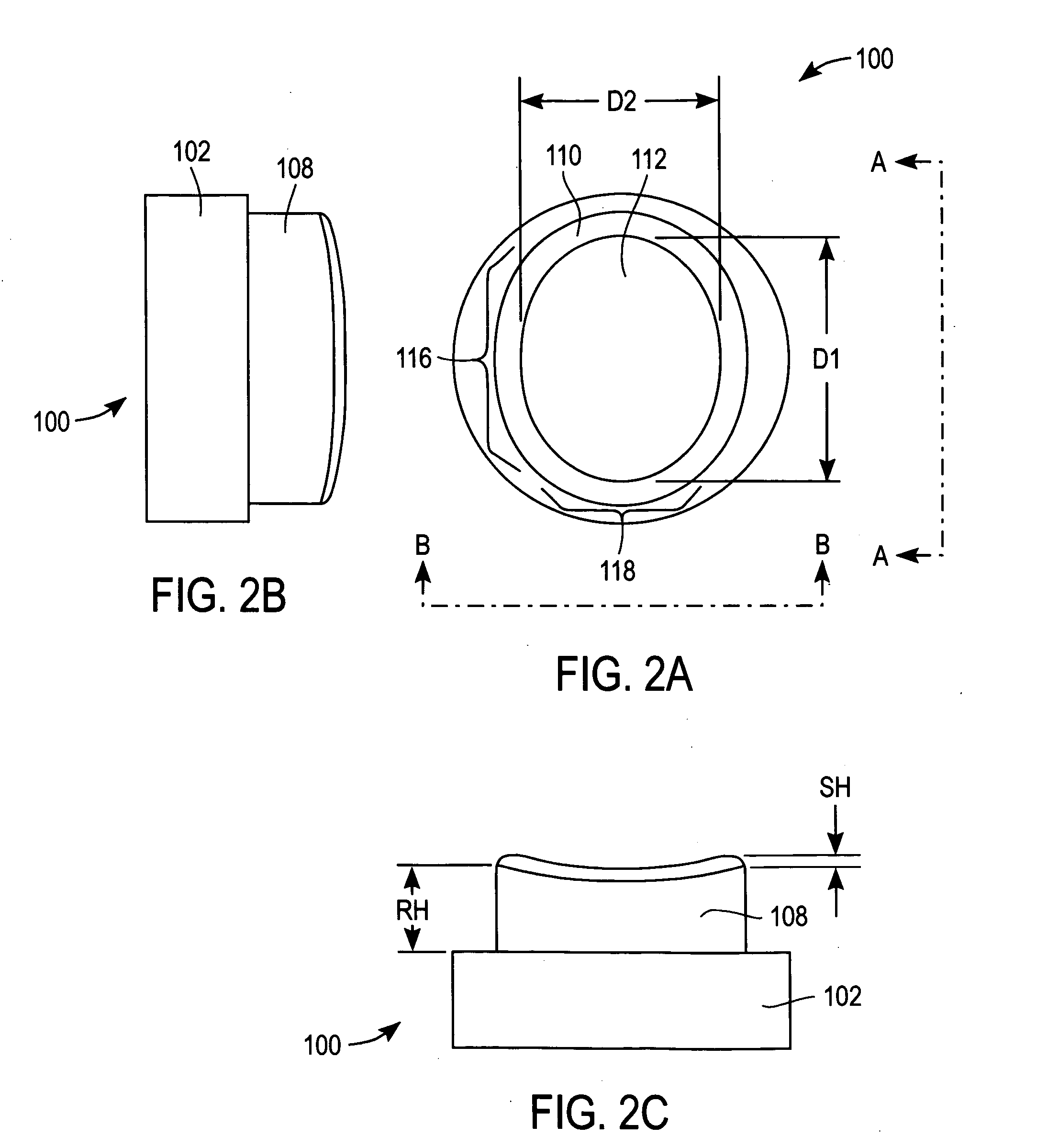

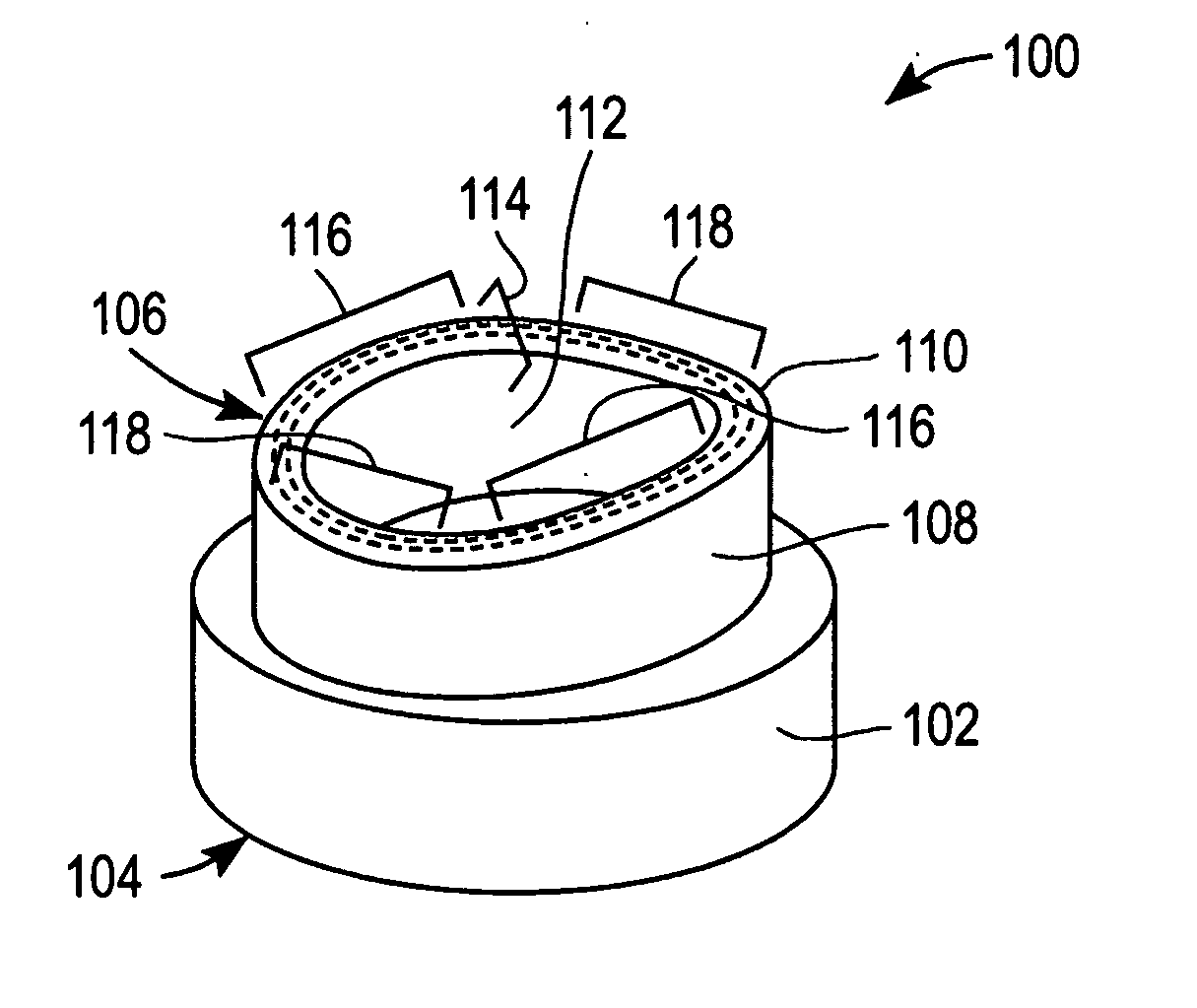

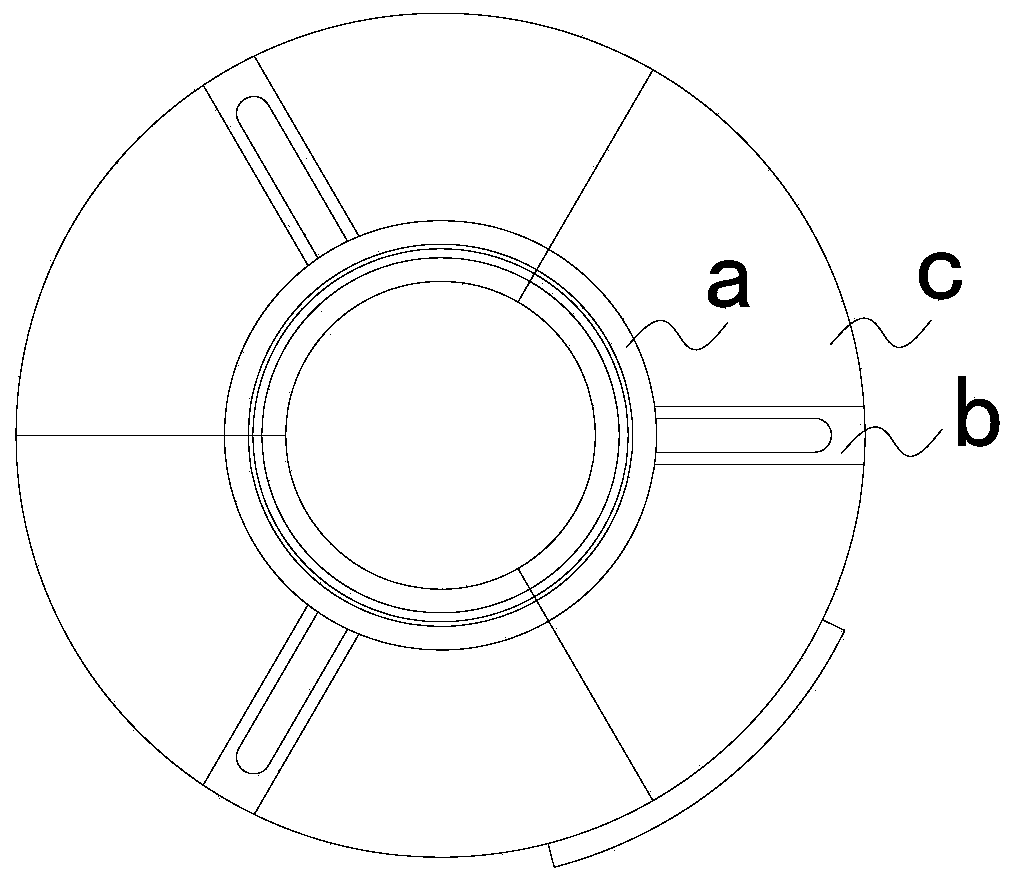

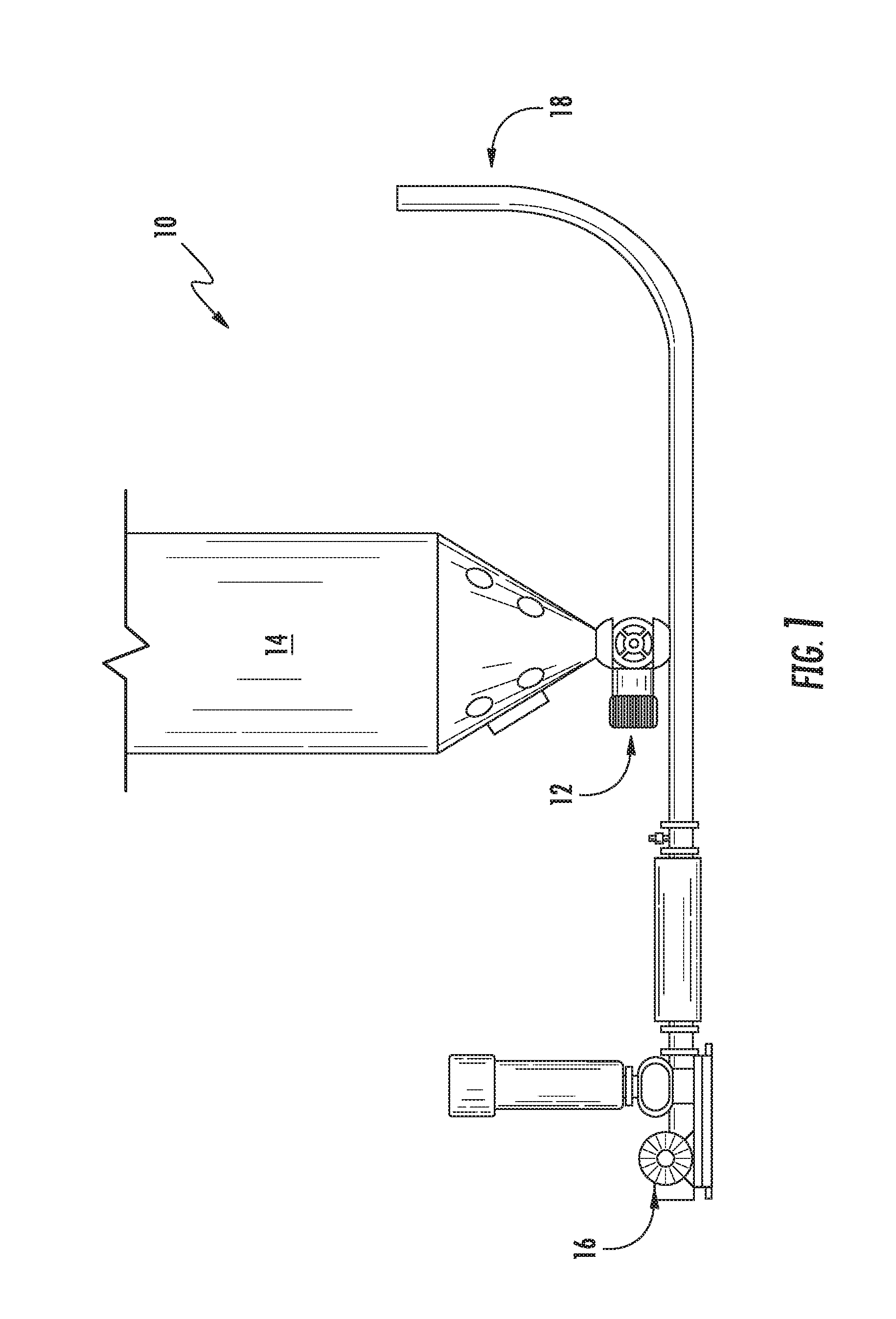

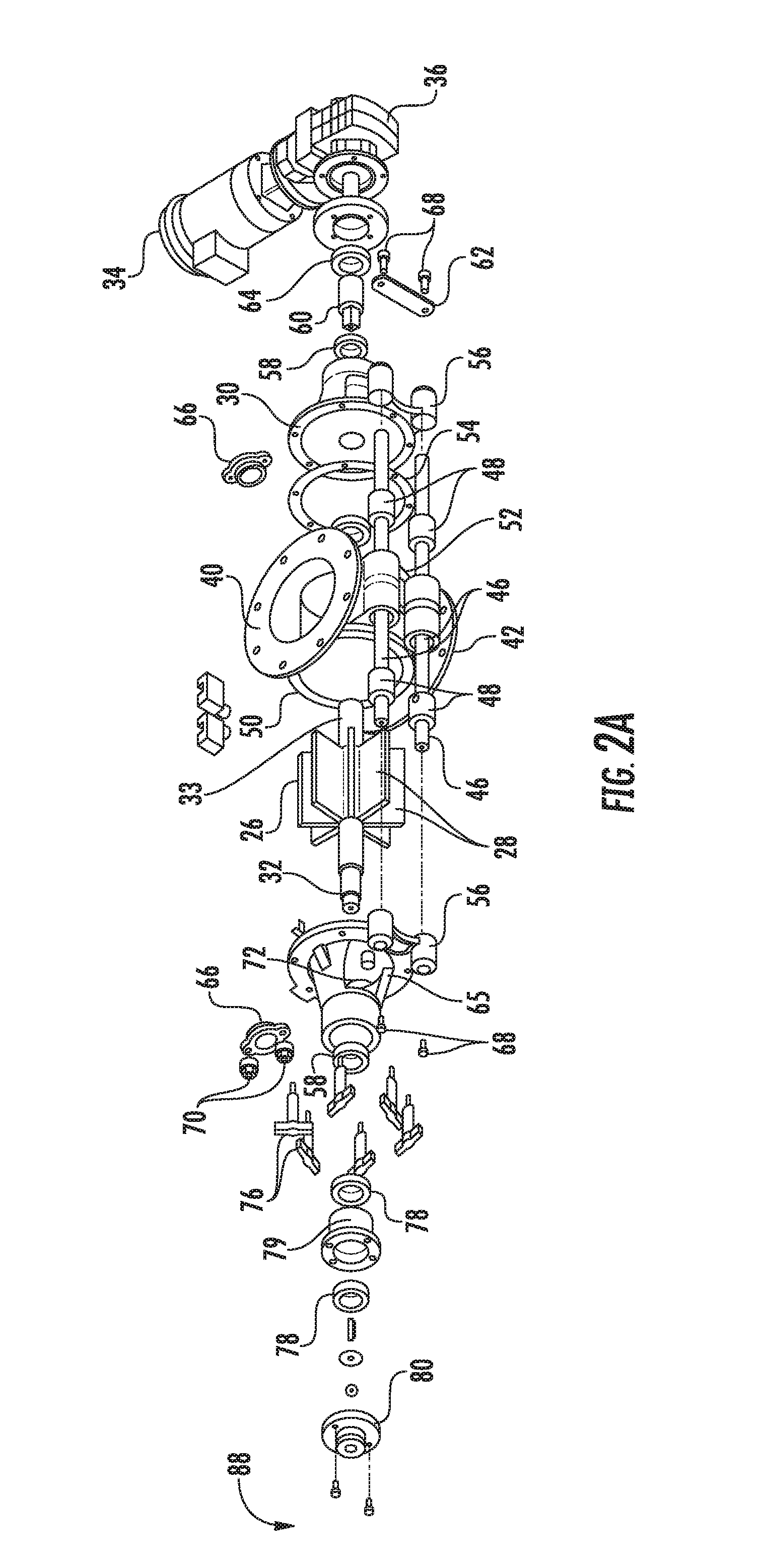

Saddle-contoured cap for a dermal tissue lancing device

InactiveUS20050234488A1Uniform applicationComfortable to useSensorsBlood sampling devicesDermisMedicine

A cap for a dermal tissue lancing device that has a housing and a lancet moveable with respect to the housing includes a body with an opening therethrough for at least a portion of the lancet to pass through. The body of the cap has a proximal end configured for engagement with the housing and a distal end. Moreover, the distal end has a projection and a rim with a continuous saddle-contoured compression surface for engaging a dermal tissue target site. When the cap contacts and is urged towards the dermal tissue target site, the continuous saddle-contoured compression surface applies substantially uniform pressure against the dermal tissue target site.

Owner:LIFESCAN INC

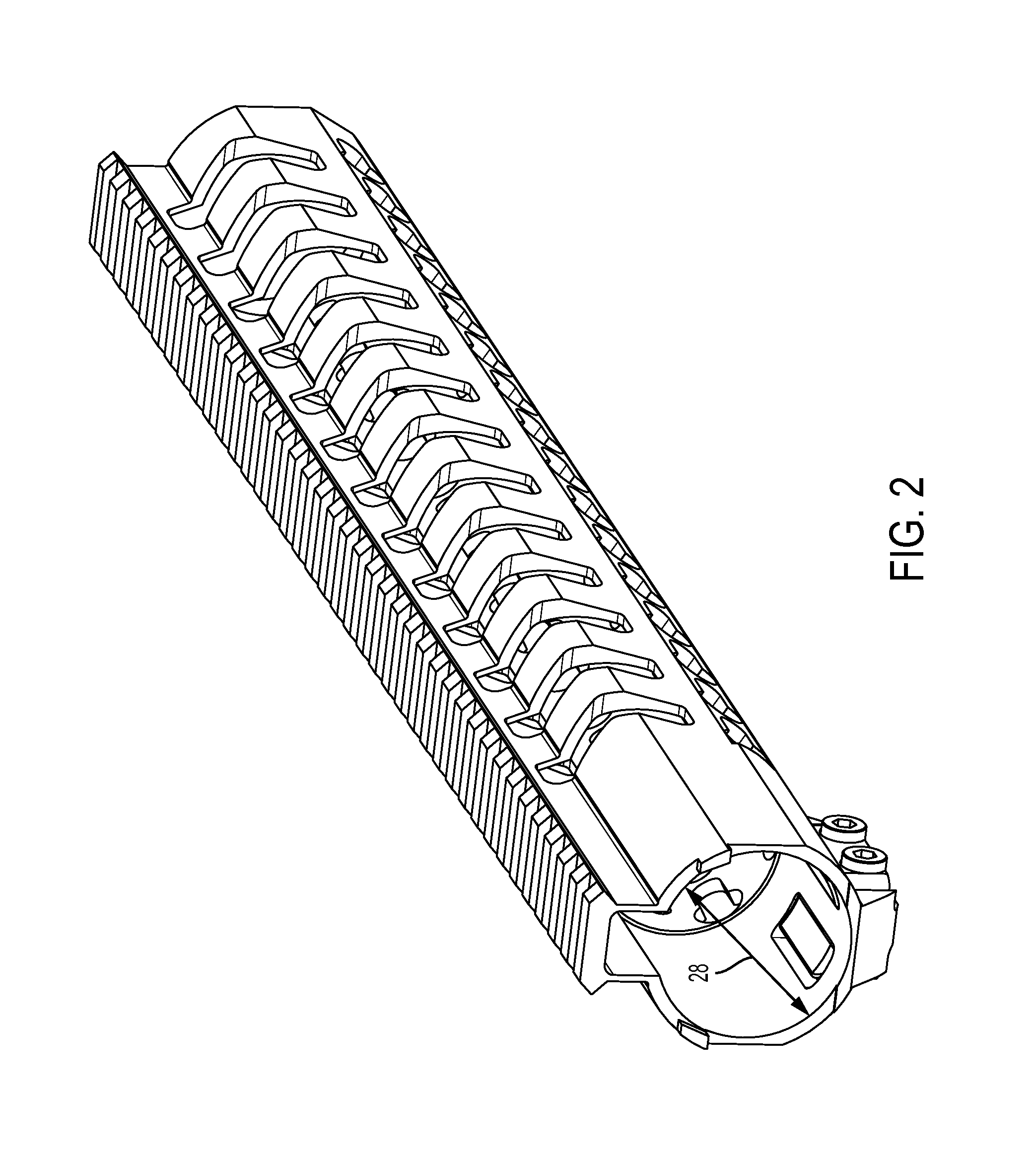

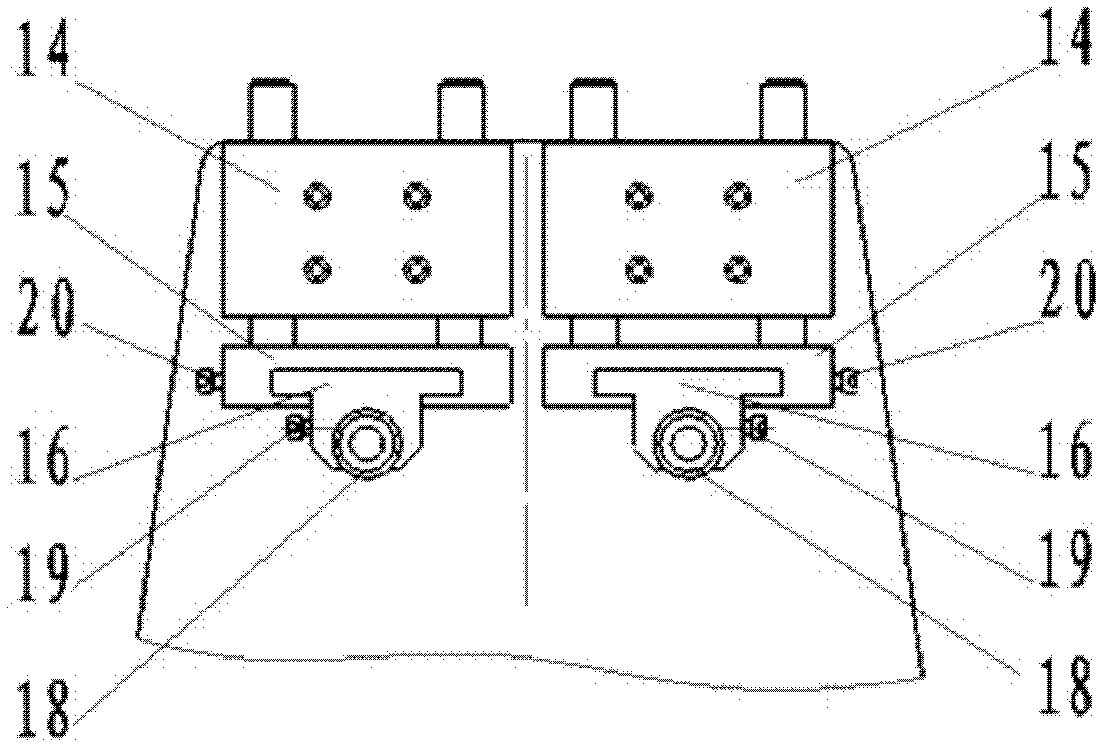

Free floating rail for a firearm

InactiveUS9389043B1Maximize and make effective frictional engagementEasy to installButtsEngineeringMechanical engineering

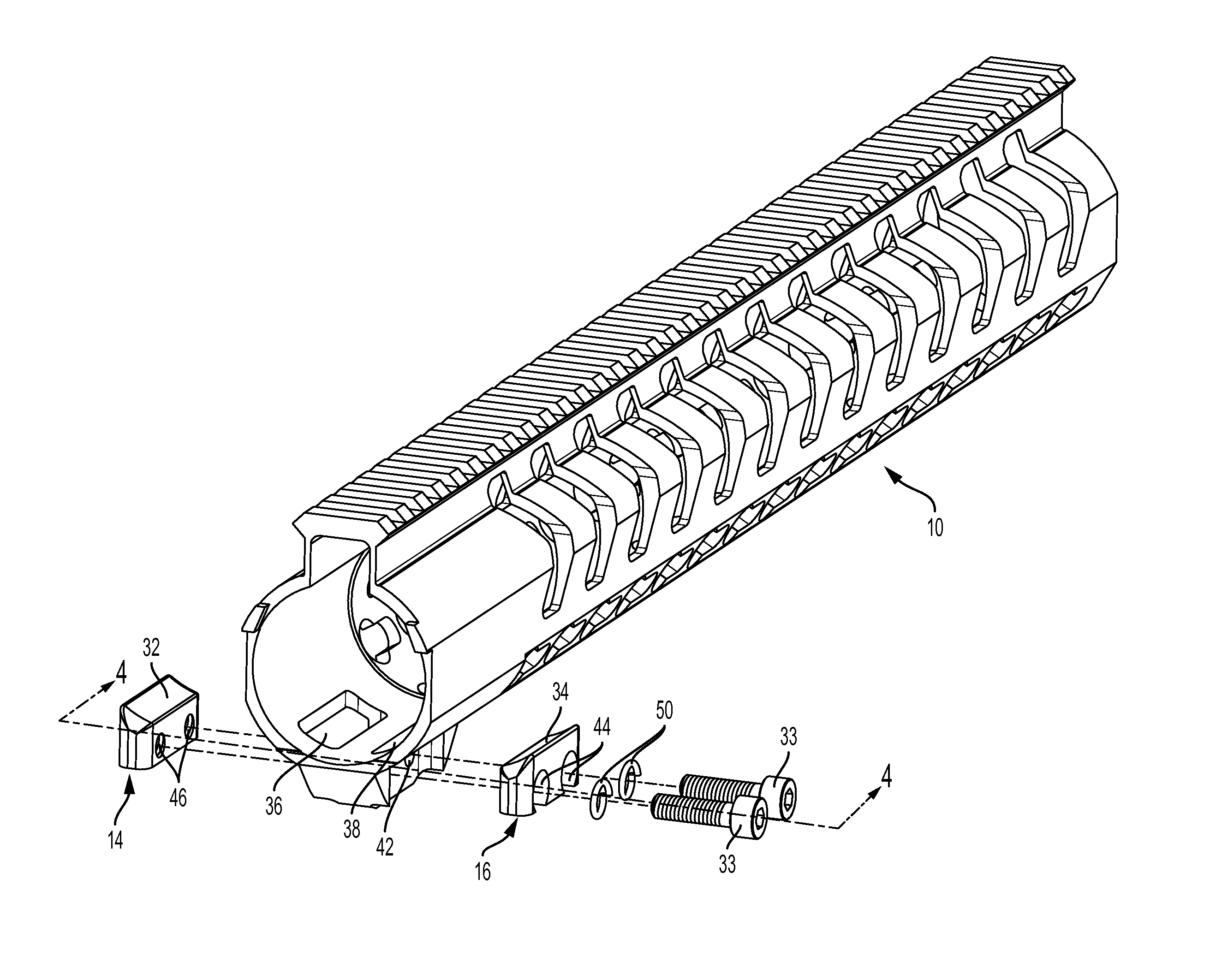

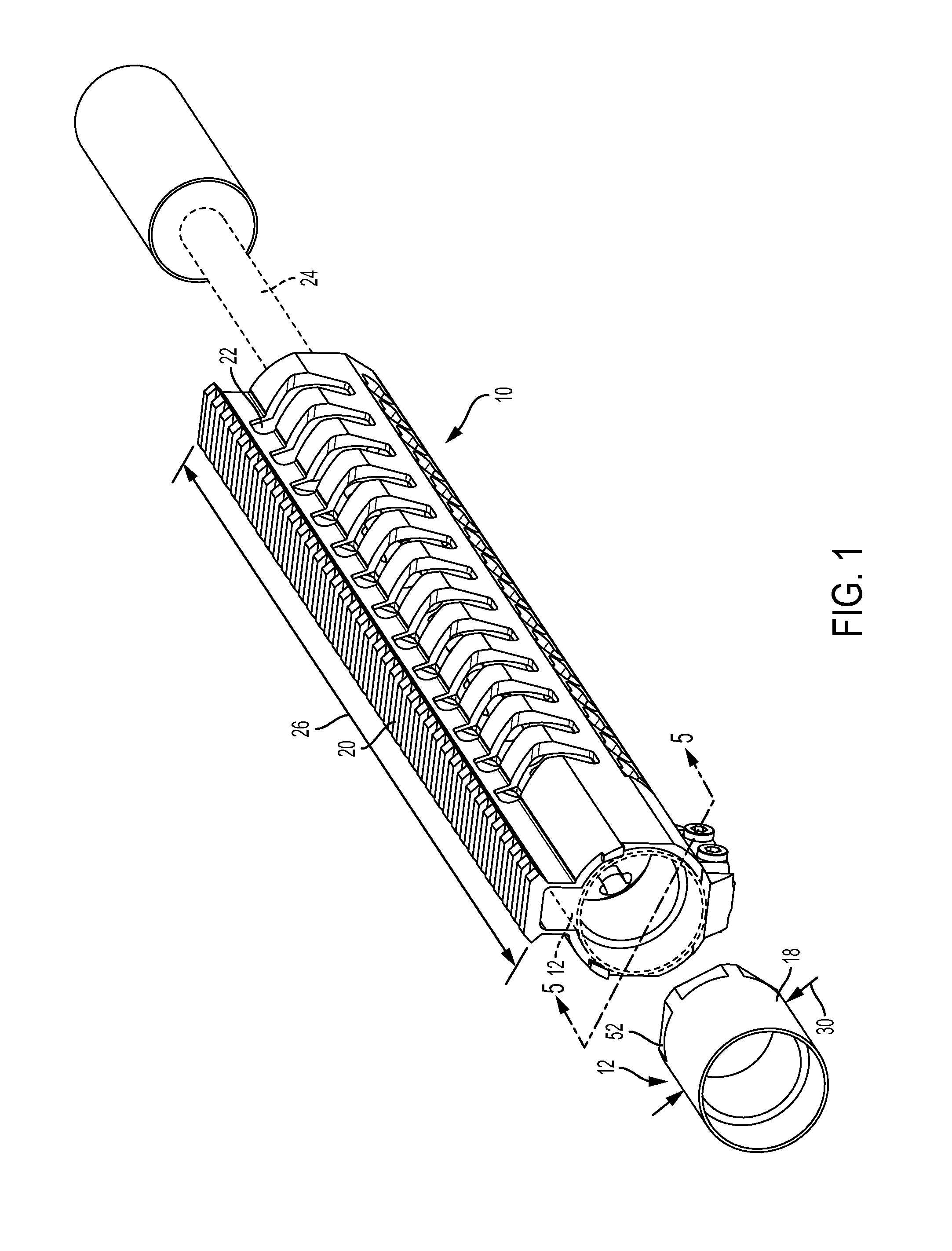

A rail is mounted solely to a barrel nut so that the rail is free-floating and does not affect movement of the barrel when the firearm is fired. The rail may have first and second wedges that are drawn together and frictionally engage a smooth exterior surface of the barrel nut in order to frictionally engage the wedges and the barrel nut. The first and second wedges have contact surfaces defined by a radius which is equal to a radius of the exterior surface of the barrel nut. By forming the contact surfaces of the first and second wedges to have a radius equal to the radius of the barrel nut, the maximum area of the contact surfaces contact or engage the exterior surface of the barrel nut to maximize frictional engagement between the barrel nut and the wedges.

Owner:ZHANG HONGJUN

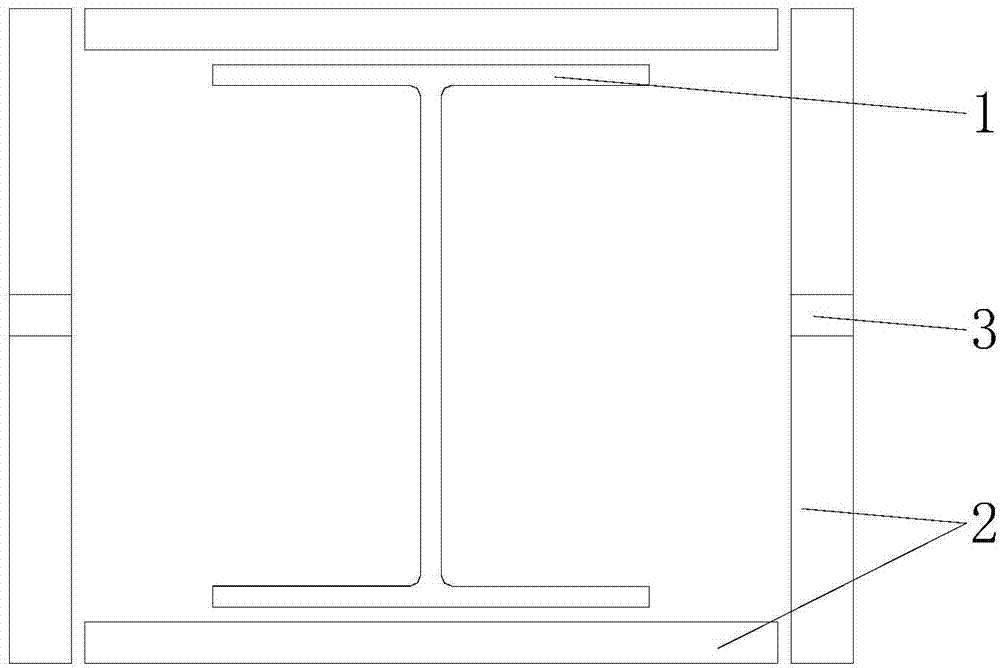

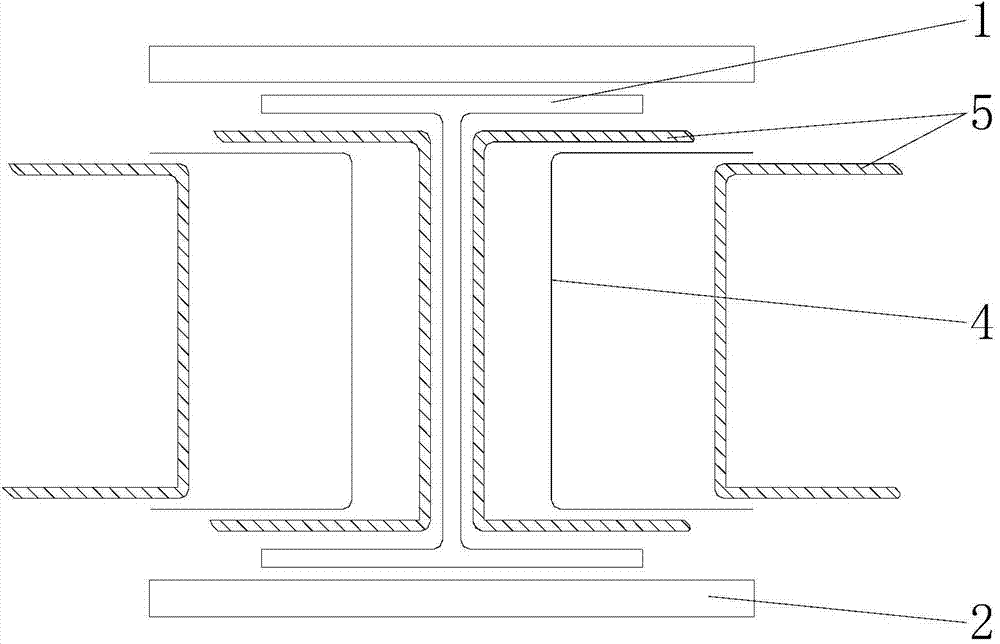

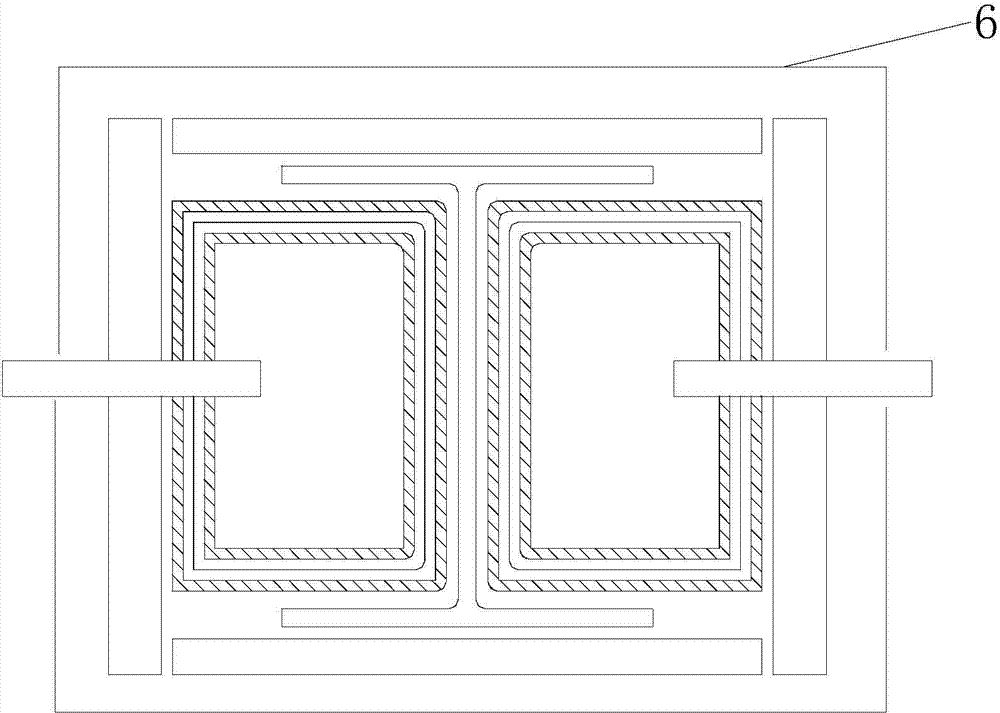

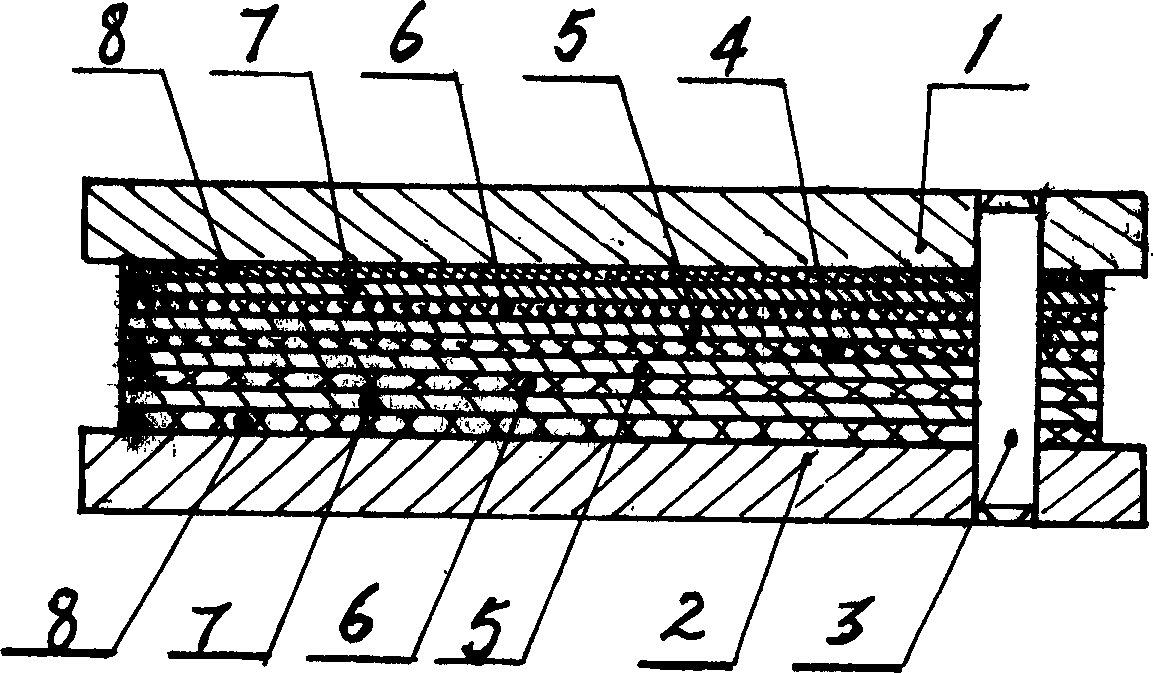

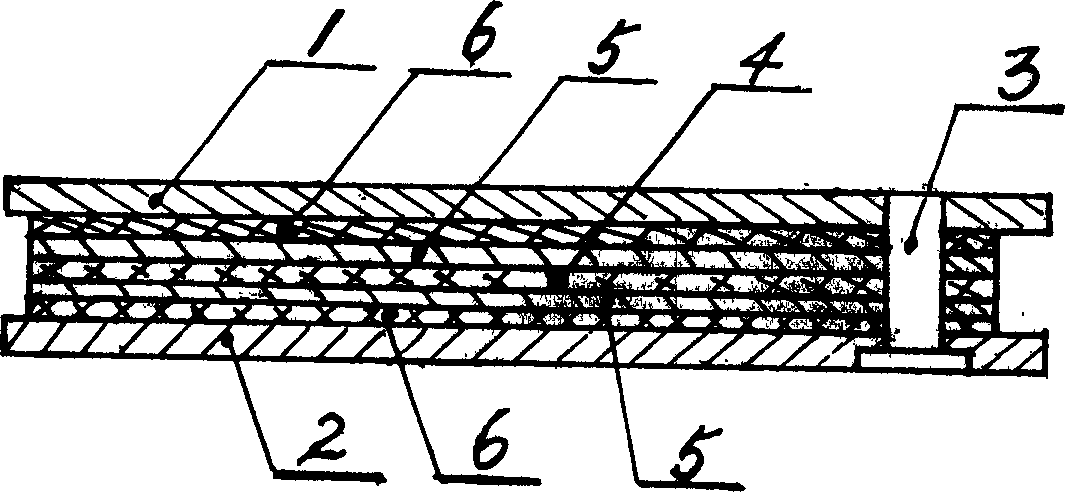

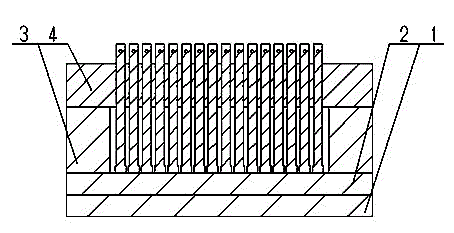

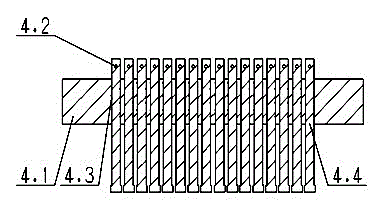

Molding method for composite material structural member with I-shaped section

The invention discloses a molding method for a composite material structural member with an I-shaped section. The composite material structural member is molded by taking a metal fake member and a molding mould to mould a glass fiber enhanced silicone rubber airbag and taking the airbag as a core mould to be combined with the molding mould. The molding method has the advantages that with the adoption of a silicone rubber airbag molded structural member, firstly, the wall of the airbag is thin, the heat transferring performance is good, the temperature gradient of the structural member and the edge is small, and the inner quality of the molded structural member is guaranteed; secondly, silicone rubber on the surface of the airbag is elastic so as to have the effect of a pressure equalizing cushion; the surface quality of a molded part is good; thirdly, the silicone rubber airbag is combined with a box-shaped structure of the airbag; meanwhile, the two ends of the I-shaped structural member are connected by the silicone rubber, the structural rigidity of the airbag is great and the molding position and the size precision of a web are guaranteed; fourthly, the airbag can be used repeatedly and can be manufactured conveniently again so that the production cost is reduced effectively; the whole molding method can uniformly apply a pressure to the web and an edge strip of the structural member and the pressure is equal to a tank pressure.

Owner:航天海鹰(镇江)特种材料有限公司

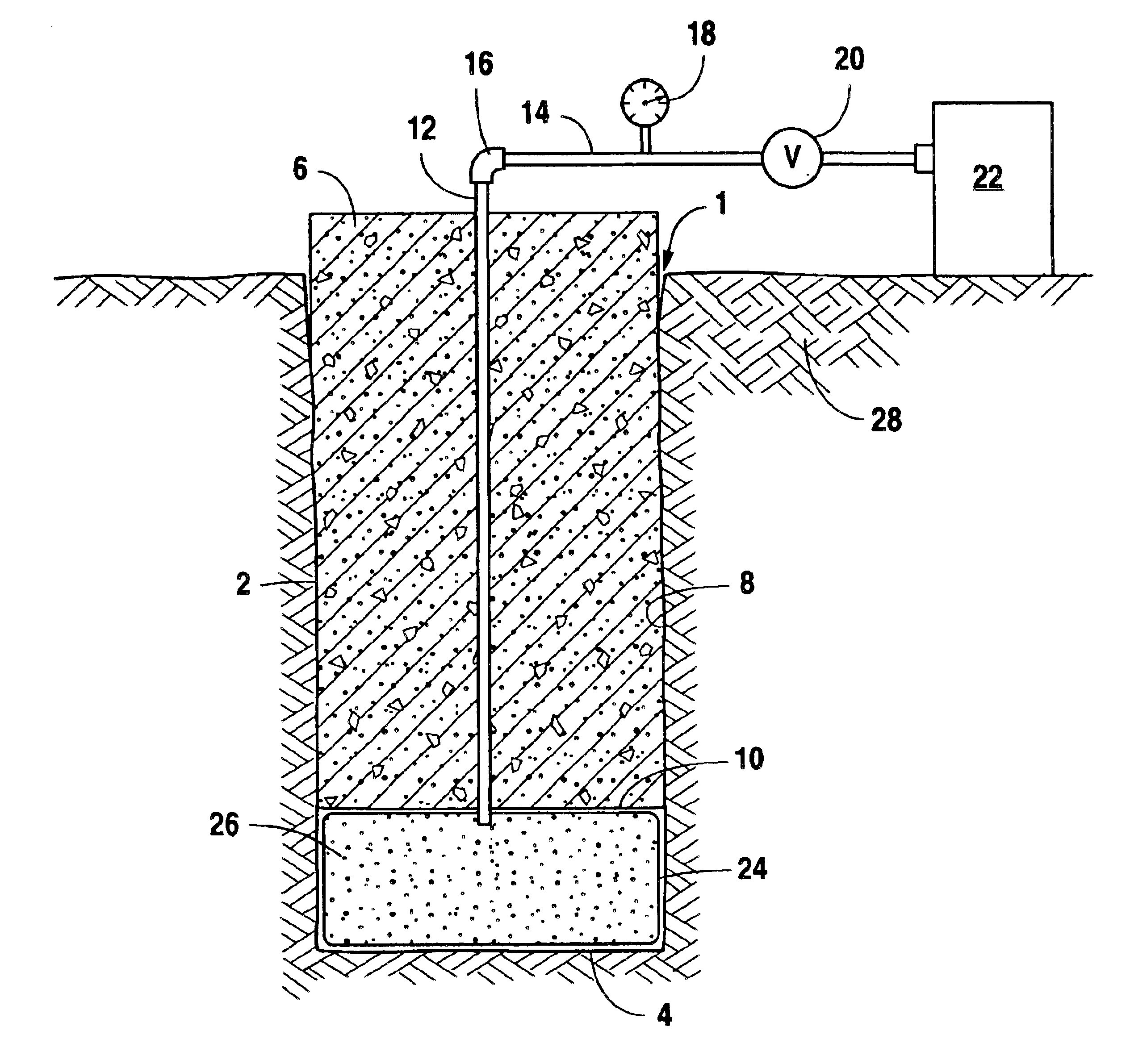

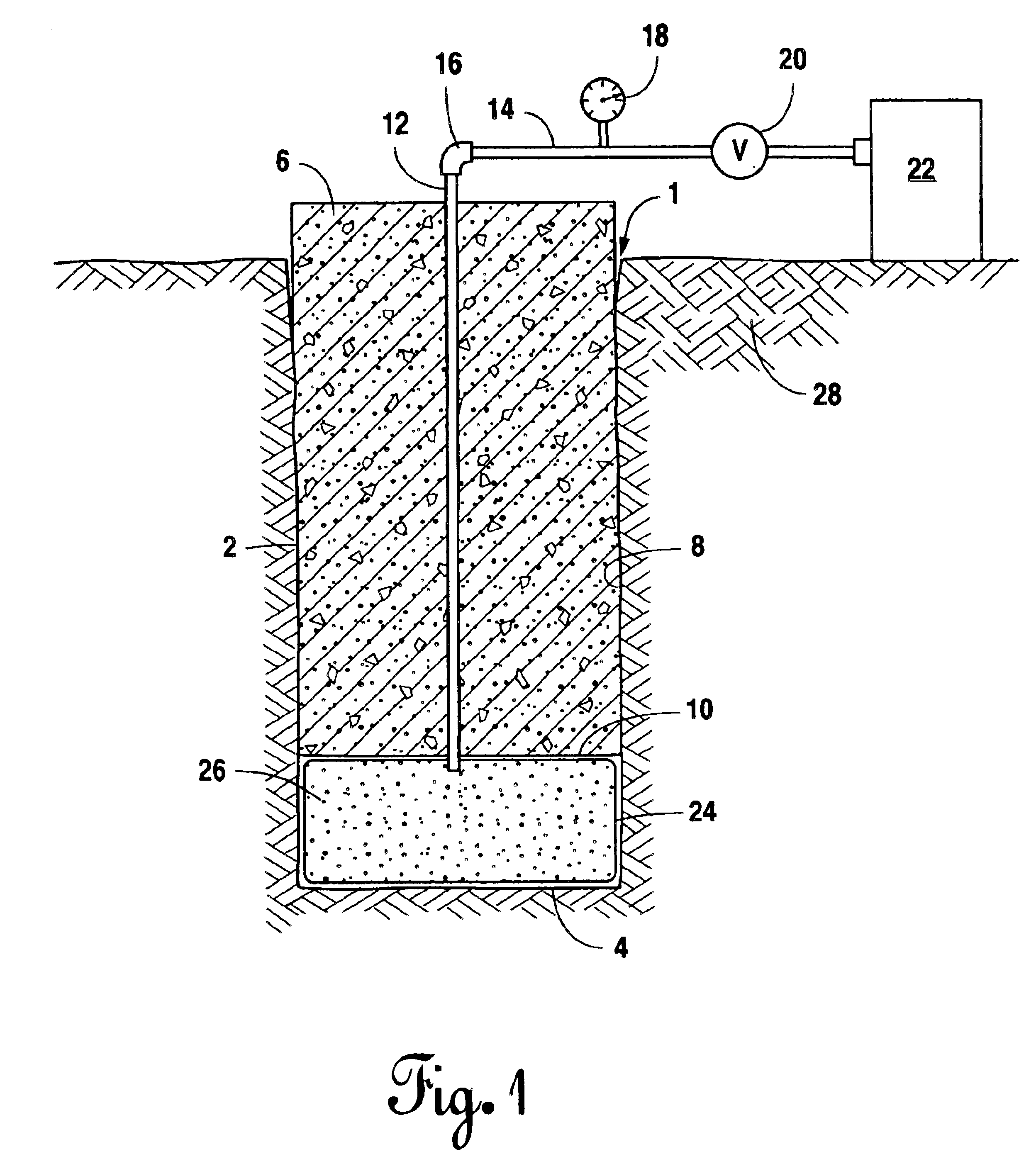

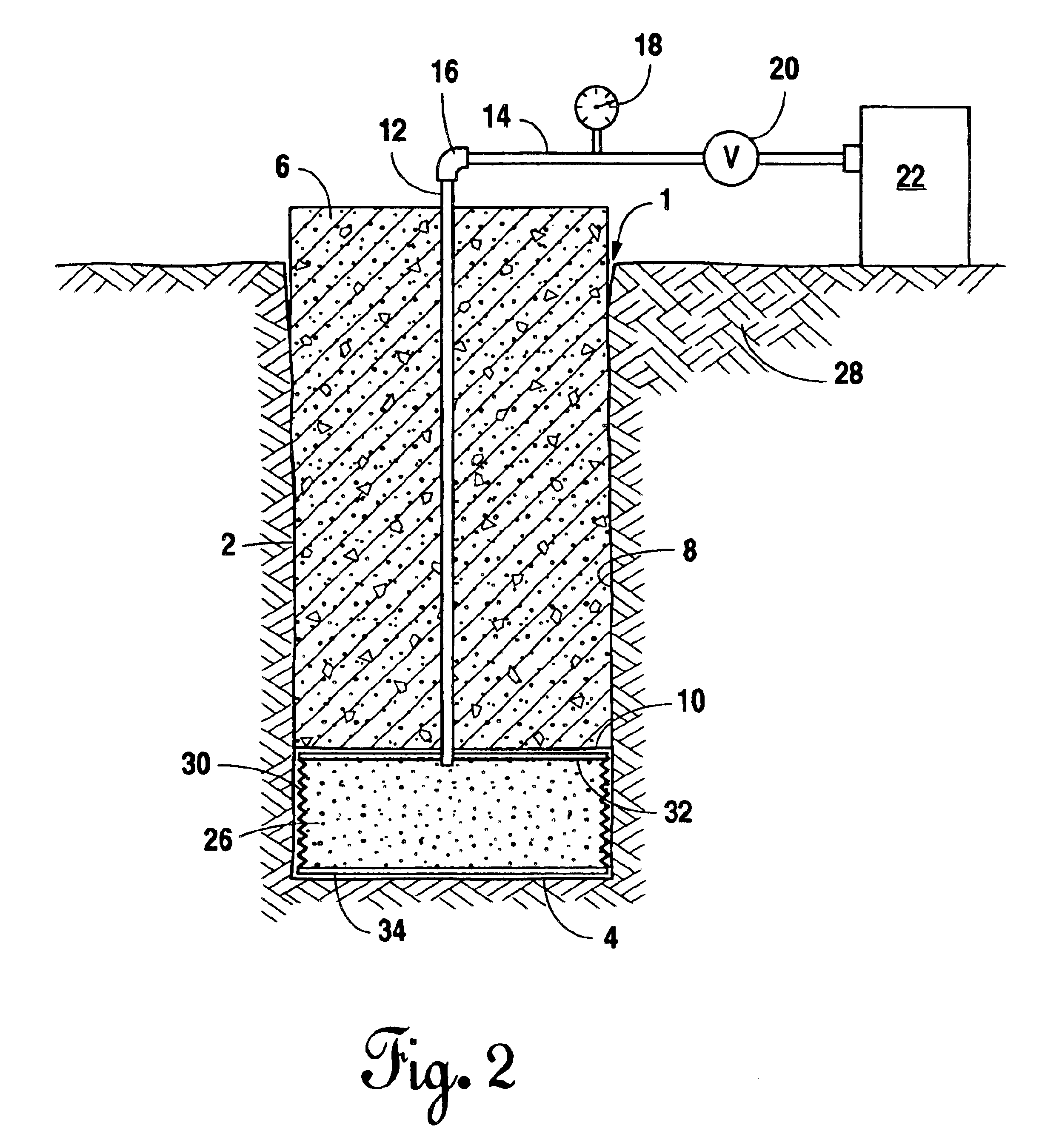

Post-stressed pile

InactiveUS6869255B1Improve carrying capacityApply pressure evenlyFoundation testingBulkheads/pilesEngineeringGuide tube

A structural pile assembly includes a driven pile and pressurized grout contained beneath the pile so as to exert an upward force on the pile. An enclosure, such as a bladder or bellows, is filled with grout from a reservoir via a conduit which preferably extends axially along the length of the pile and is left in place after the grout hardens. A pressure gauge measures the pressure of the grout within the enclosure, permitting the direct measurement of end bearing and side bearing capacities of the resulting pile assembly. The load bearing capacity of the pile is enhanced by the pressurized grout, and is preferably at least twice the end bearing capacity of an unpressurized pile.

Owner:SYNCHRO PATENTS

Cable fixing device

Owner:GREE ELECTRIC APPLIANCES INC

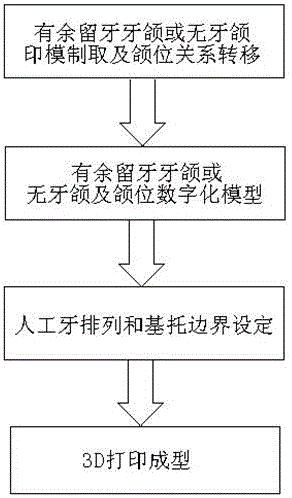

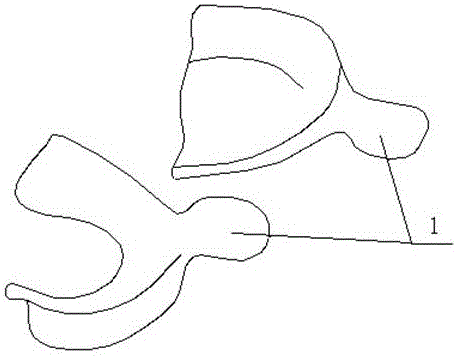

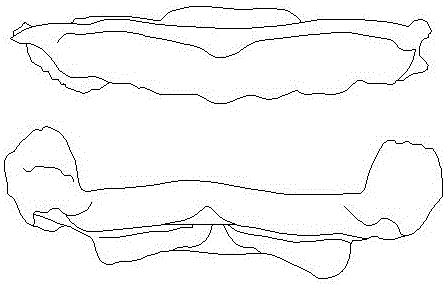

Method for producing immediate complete or half denture based on 3D printing technique

ActiveCN106037967AComfortable to wearSimple preparation steps3D printingDental prostheticsDenture baseBite registration

The invention discloses a method for producing an immediate complete or half denture based on a 3D printing technique. The method comprises the steps of preparing an impression with a remaining tooth jaw or a tooth-free jaw, transferring a jaw position relation, acquiring digital models of the remaining tooth jaw or the tooth-free jaw and the jaw position relation, setting the arrangement and the denture border of artificial teeth of the immediate complete or half denture corresponding to the form of the remaining tooth jaw or the tooth-free jaw and the jaw position relation, invoking data in a preset database, designing the artificial teeth and polishing surfaces of the artificial teeth, regulating the occlusion of the teeth to enable alveolar ridge supporting tissues to bear proper pressure distribution, and manufacturing a three-dimensional model of the immediate complete or half denture by virtue of a photo-healing three-dimensional printing technique in the 3D printing technique. The method has the advantages that the production steps are simple, the production time is short, the precision is high, the denture can be conformably worn by a patient, and meanwhile, the production cost is lowered.

Owner:AFFILIATED STOMATOLOGICAL HOSPITAL OF NANJING MEDICAL UNIV

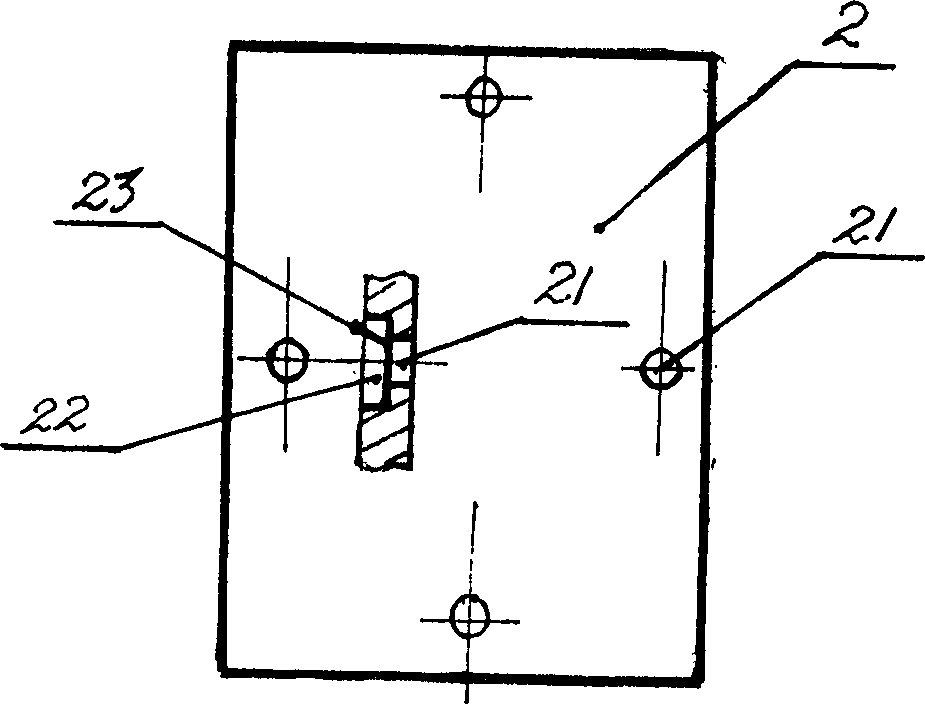

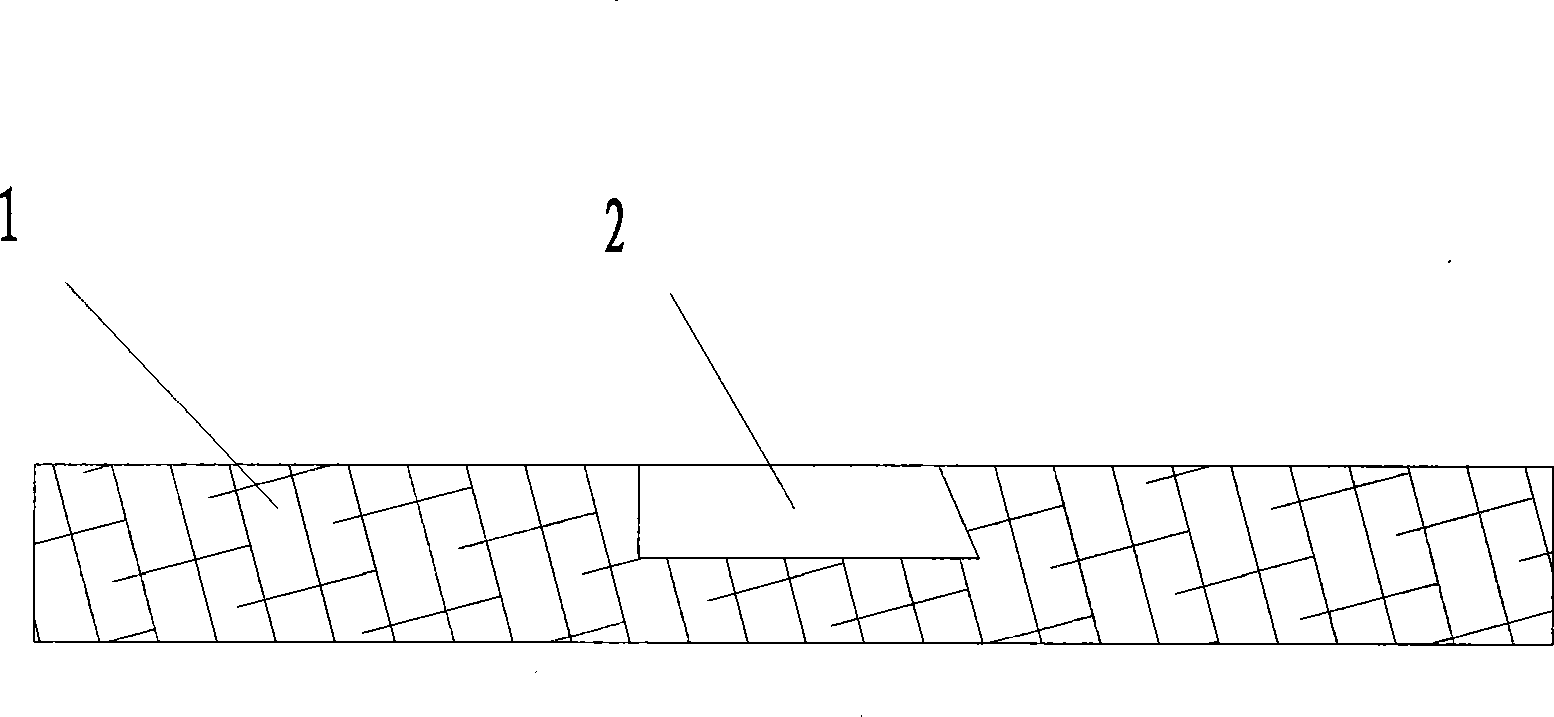

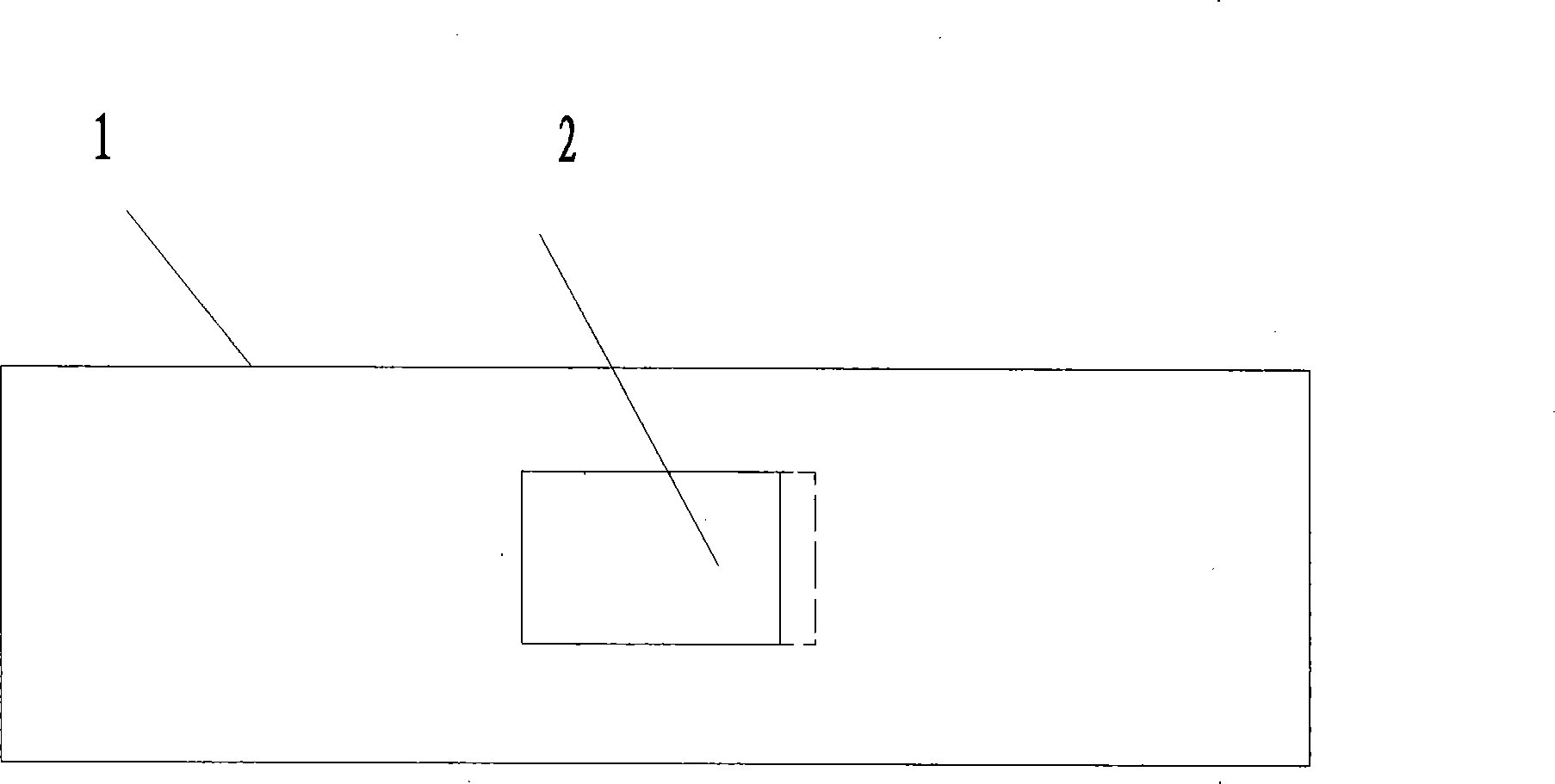

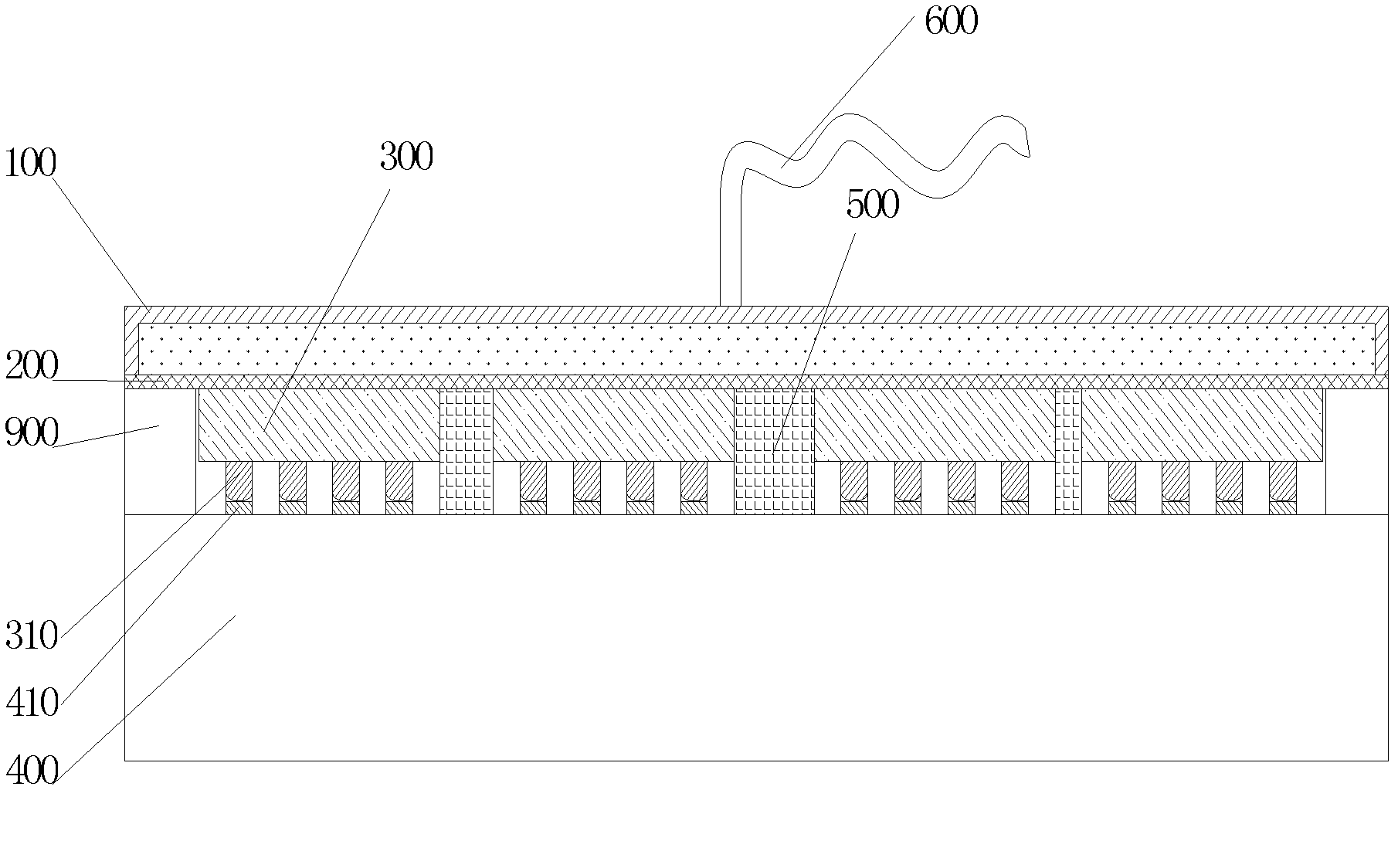

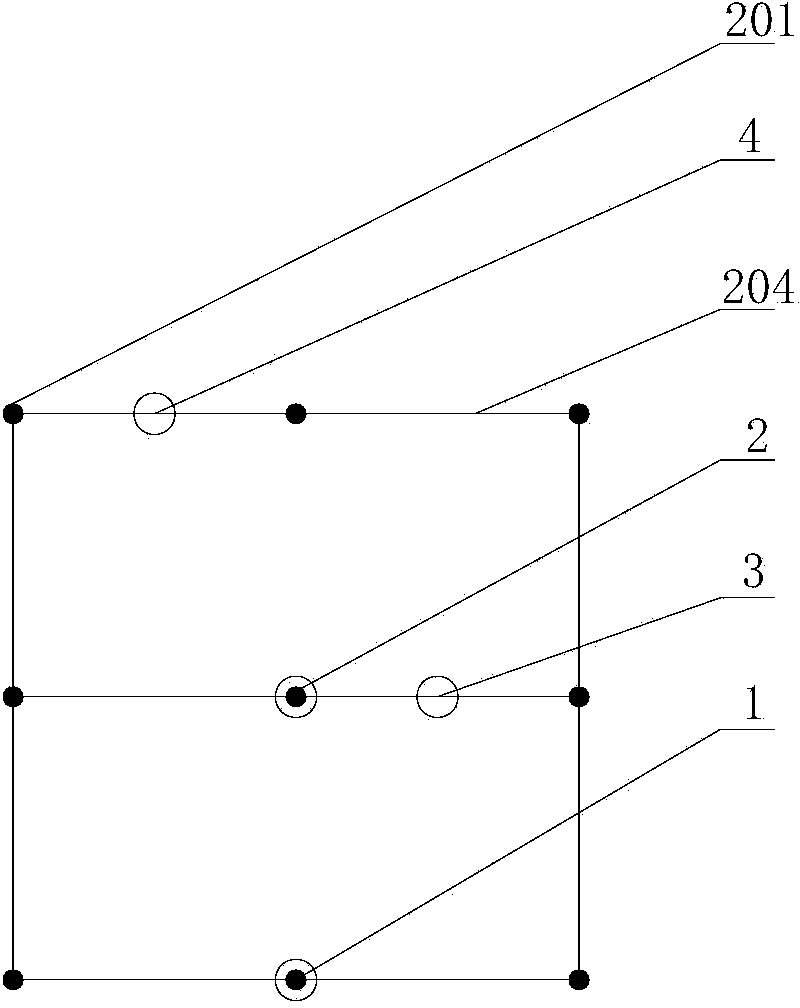

Laminated mould of multi-layer circuit board

InactiveCN1780535AEliminate defects prone to micro-dislocationsPrecise positioningPrinted circuit assemblingMultilayer circuit manufactureDigital controlMaterials science

The invention is made by means of following steps: takes high grade mirror surface stainless steel as material of lower mold plate and upper mold plate; the counter bore perpendicular to axial line of location hole is located at the bottom surface of location hole in the lower mold plate; the step locating pin is composed of the locating column and the foundation; the locating column is perpendicular to the foundation, and the upper mold plate and the lower mold plate are jointed through the step locating pin. Because the location holes in the lower mold plate and the up mold plate coincides with designing basis for each layer of circuit in multi layer circuit board, and is processed by using digital control equipment, the laminating mold has not only precise location, but also low weight, and can process 8 piece multi layer circuit board at on time by hot-pressed.

Owner:李小元

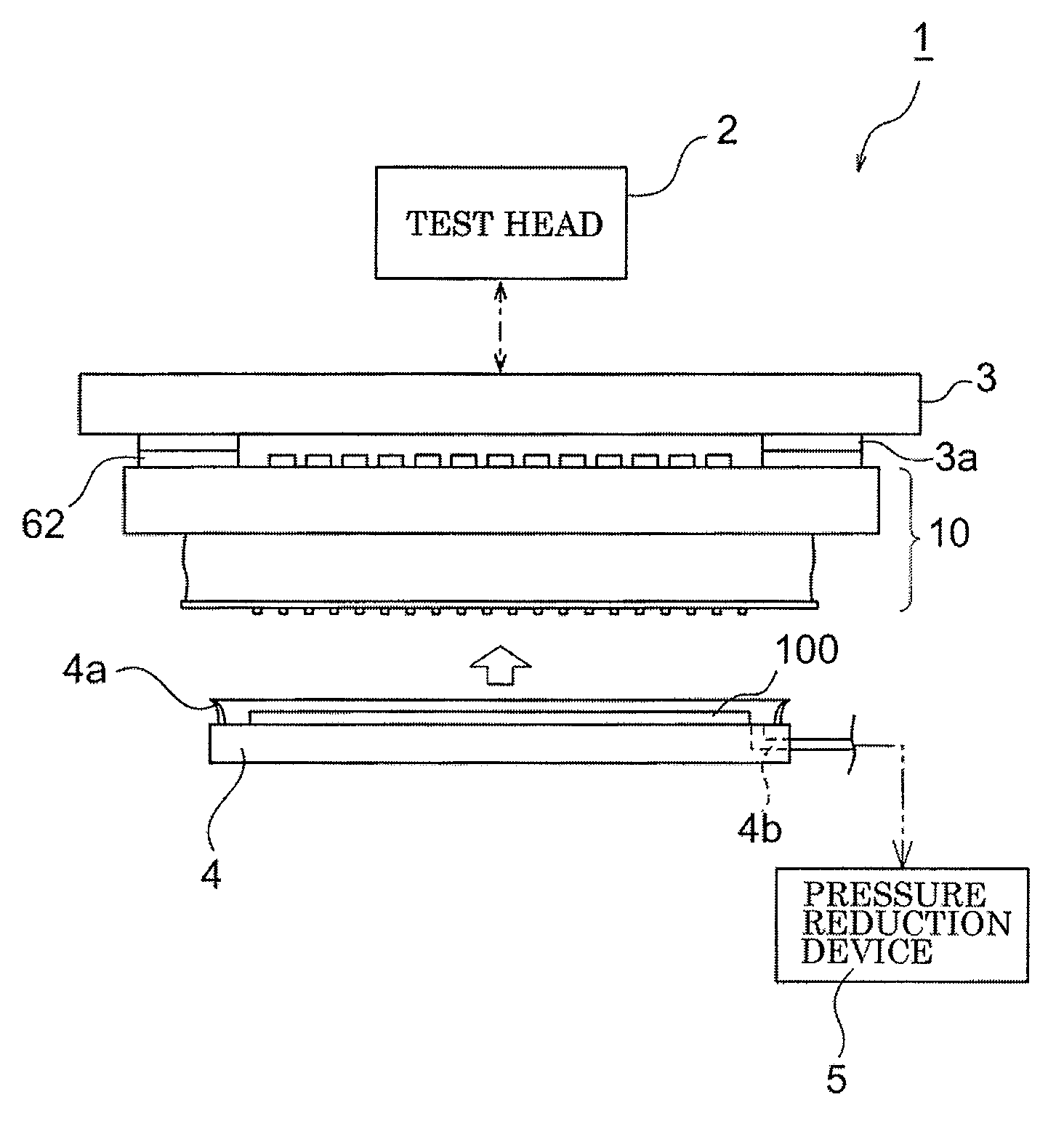

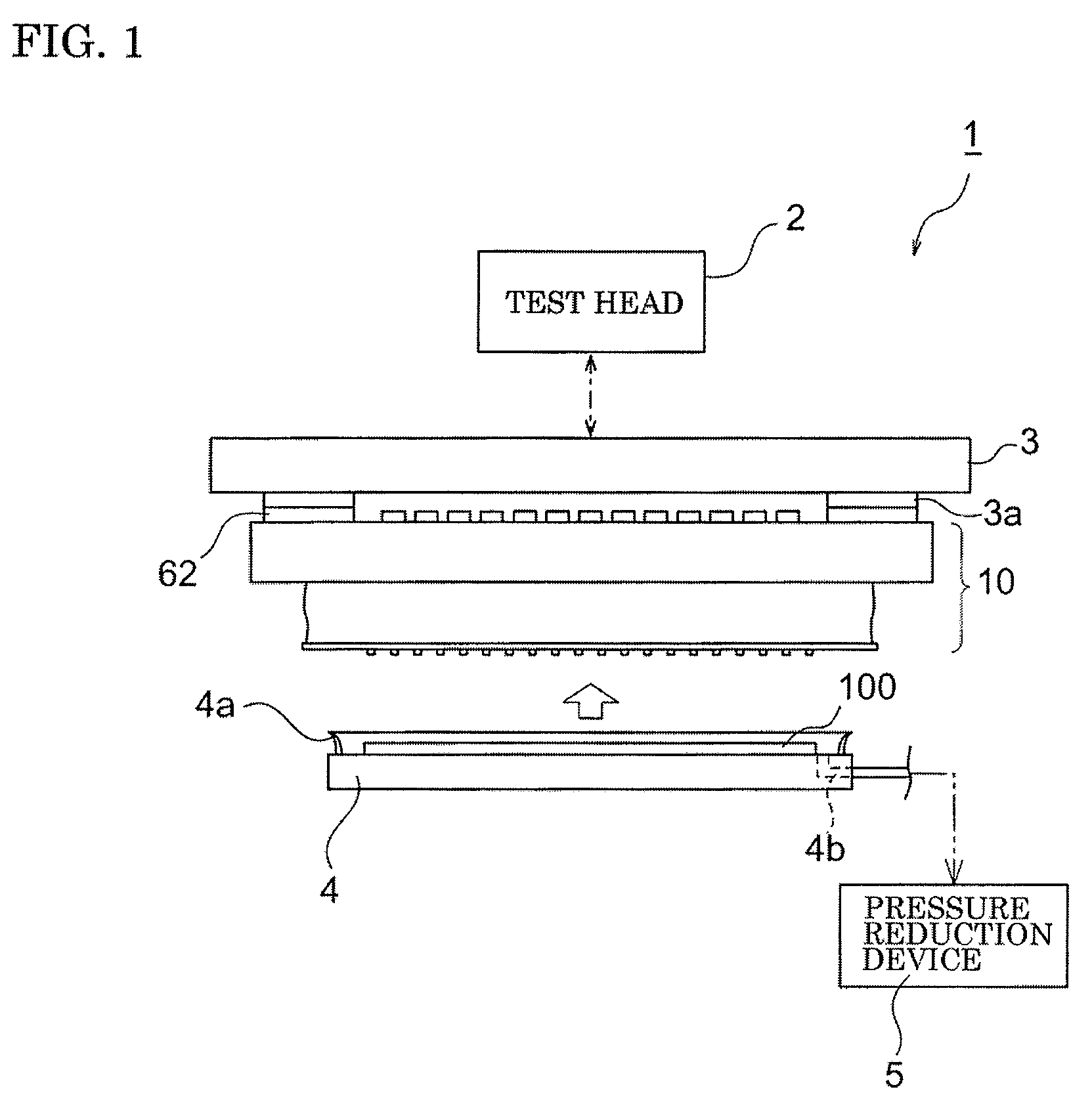

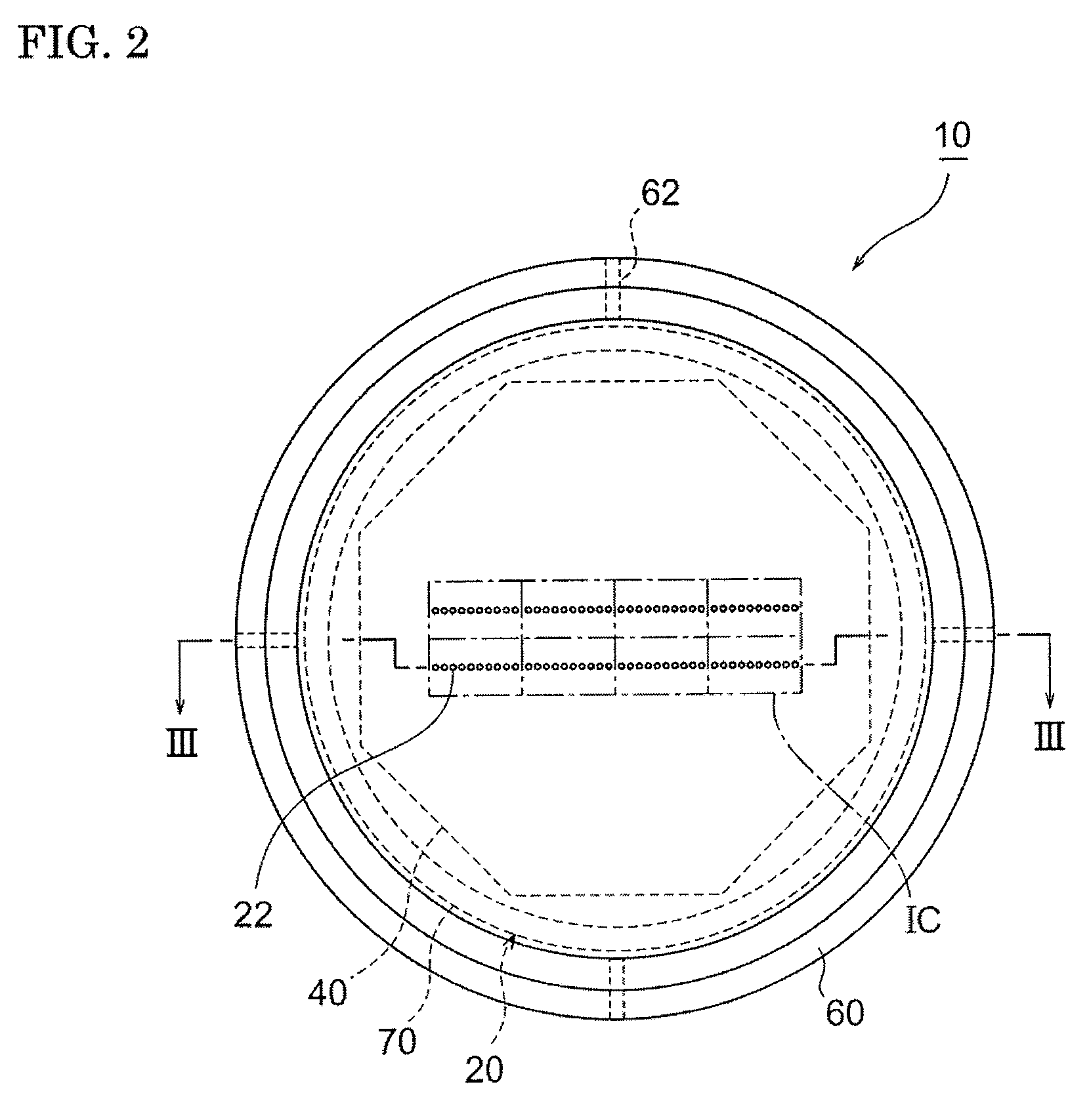

Probe, electronic device test apparatus, and method of producing the same

InactiveUS20110121847A1Apply pressure evenlyOccurrence of poor electrical contact can be suppressedElectrical measurement instrument detailsManufacture of electrical instrumentsElectricityTest set

A probe comprises: a membrane having a bump which contacts an input / output terminal of an IC device built into a semiconductor wafer under test; a pitch conversion board having a bottom surface on which a first terminal is provided and a top surface on which a second terminal connected to the first terminal is provided; a circuit board which is electrically connected to a test head and has a third terminal; a first anisotropic conductive rubber member having a first conductor part which electrically connects the bump of the membrane and the first terminal of the pitch conversion board; and a second anisotropic conductive rubber member having a second conductor part which electrically connects the second terminal of the pitch conversion board and the third terminal of the circuit board, and the second conductor parts are provided on the whole of the second anisotropic conductive rubber member.

Owner:ADVANTEST CORP +1

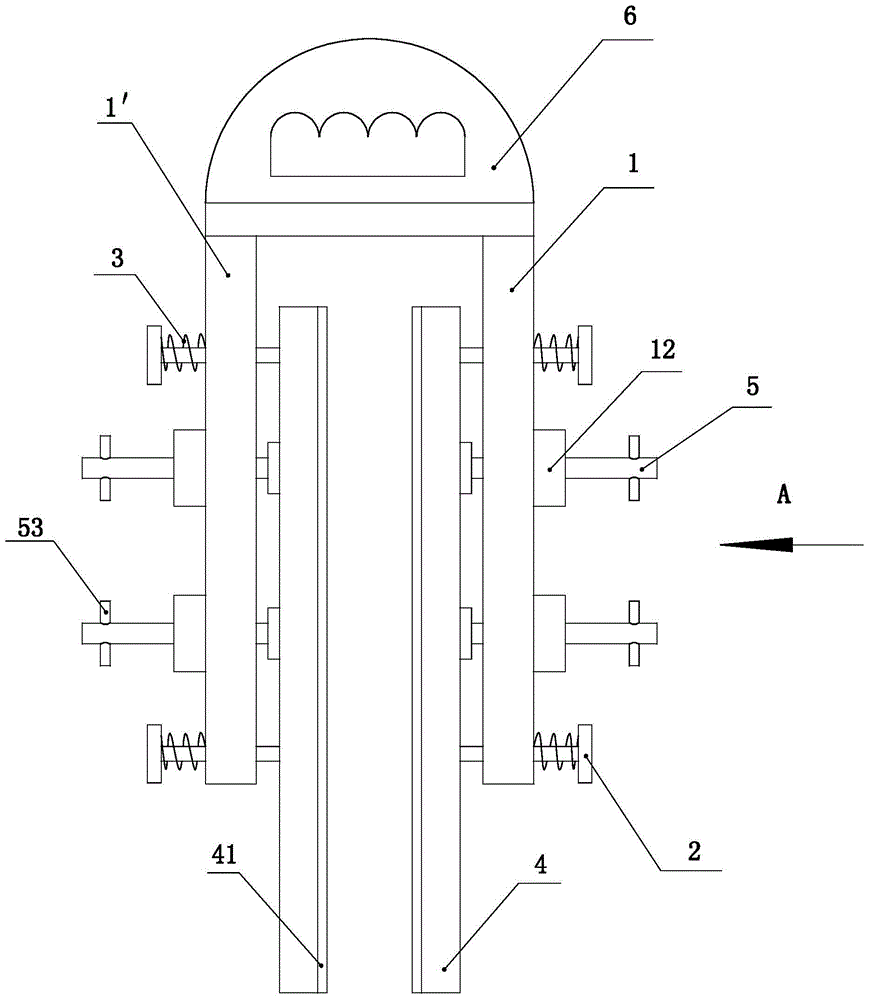

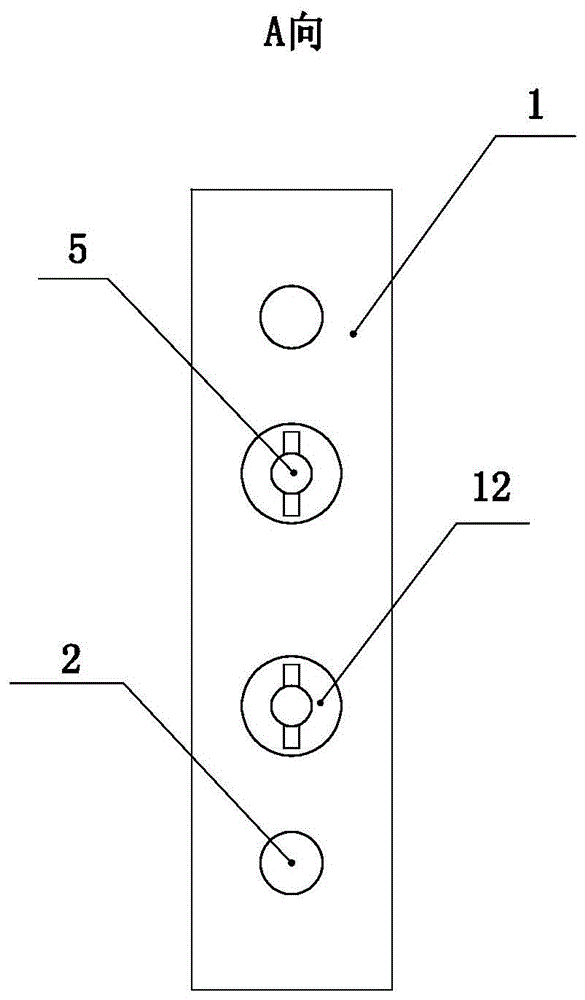

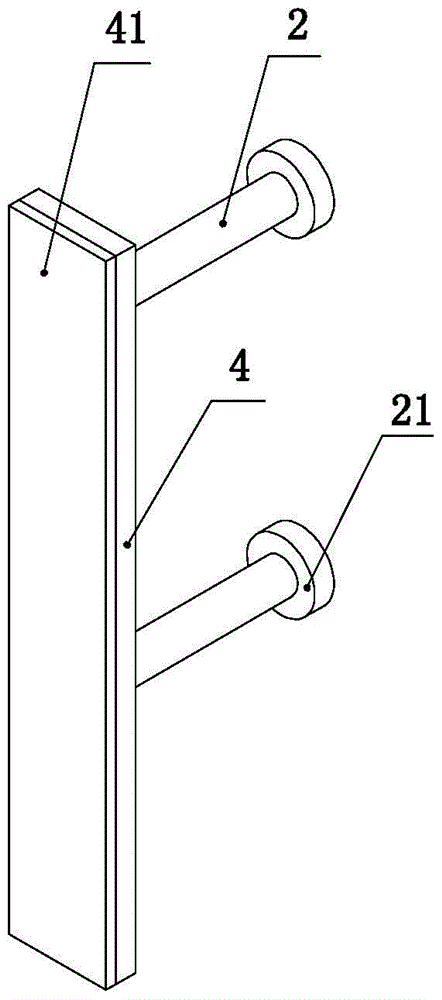

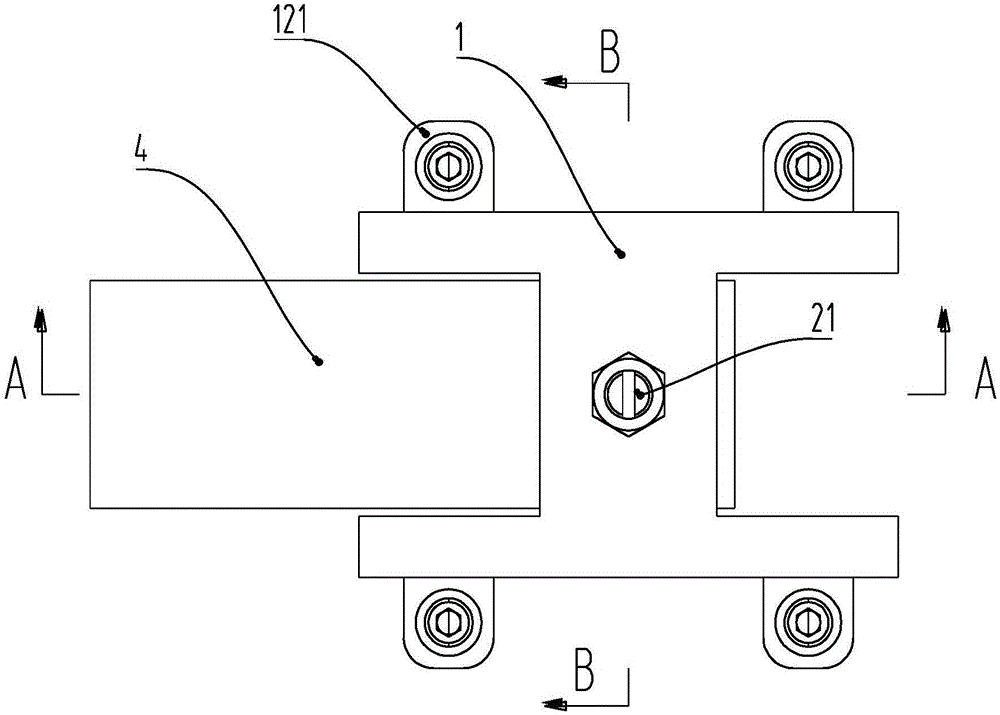

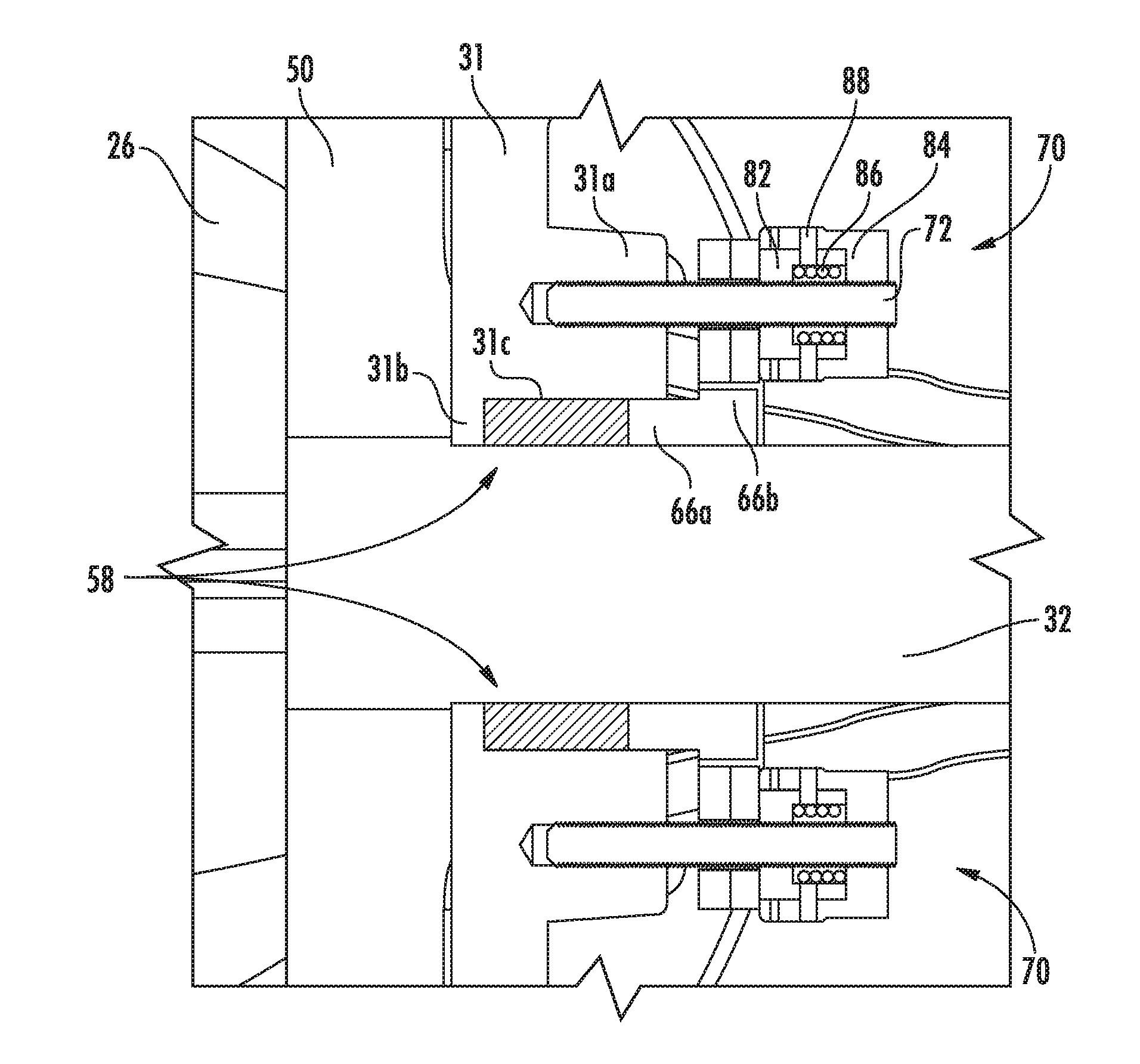

Welding device and method for superconducting lines

ActiveCN102941387AAchieve weldingApply pressure evenlyLine/current collector detailsHeating appliancesTemperature controlEngineering

The invention relates a welding device and method for superconducting lines. The welding device comprises a heating unit, a welding bedplate, heat insulation blocks and a pressing unit with a support body, wherein the welding bedplate is fastened on the heating unit; the heating unit is provided with a heater and a temperature adjustor; the pressing unit is mounted on the welding bedplate and further comprises pressing pieces and the heat insulation blocks; and the pressing pieces are mounted on the support body and used for pressing a welding head, and the heat insulation blocks are arranged between the welding bedplate and the support body. The welding device and method for the superconducting lines provided by the invention have the advantages of having a large temperature-controlled range, being high in precision, being capable of meeting the temperature control requirement on the welding of the superconducting lines, and further being capable of improving welding quality and alleviating welding dispersiveness through reducing the thickness of a welding layer, enlarging welding area, lowering welding resistance and reducing artificial operation factors.

Owner:中国船舶重工集团公司第七一二研究所

Applique wood floor technique

InactiveCN101244578APlay a finishing touchApply pressure evenlyWood mortising machinesWood slotting machinesSpecial designChinese traditional

The invention discloses an intarsia wood floor craft, which comprise the following: firstly wood floor is selected to remove sugar, parasitic egg, glue, and grease, and then dried for standby use; the above processed wood floor is provided with an inlaid bottom slot, the depth of the inlaid bottom slot is 1.5-2.5mm, the inlaid bottom slot is ground to be clean, and then filled with pigskin collagen or environment-friendly universal glue for bonding, and then inlaid with decoration, and the decoration is compacted by tool, and then extruded by sand bag until air bubbles are discharged completely, finally grinding, polishing and painting processes are performed. The new floor with Chinese traditional feature fills in the blank of floor industry, and novel special design is to obtain the favorite of consumer.

Owner:河北百年巧匠文化传播股份有限公司

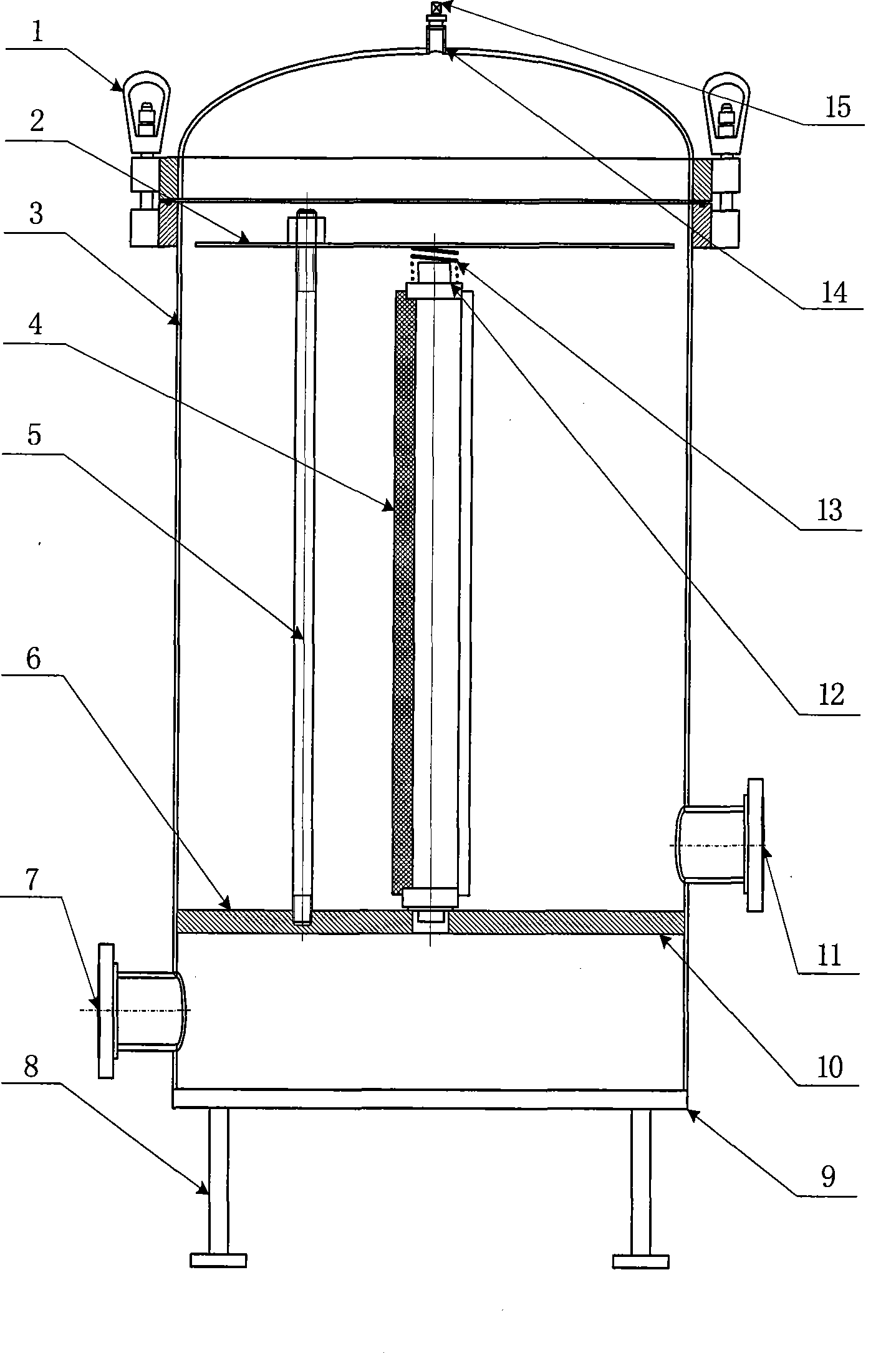

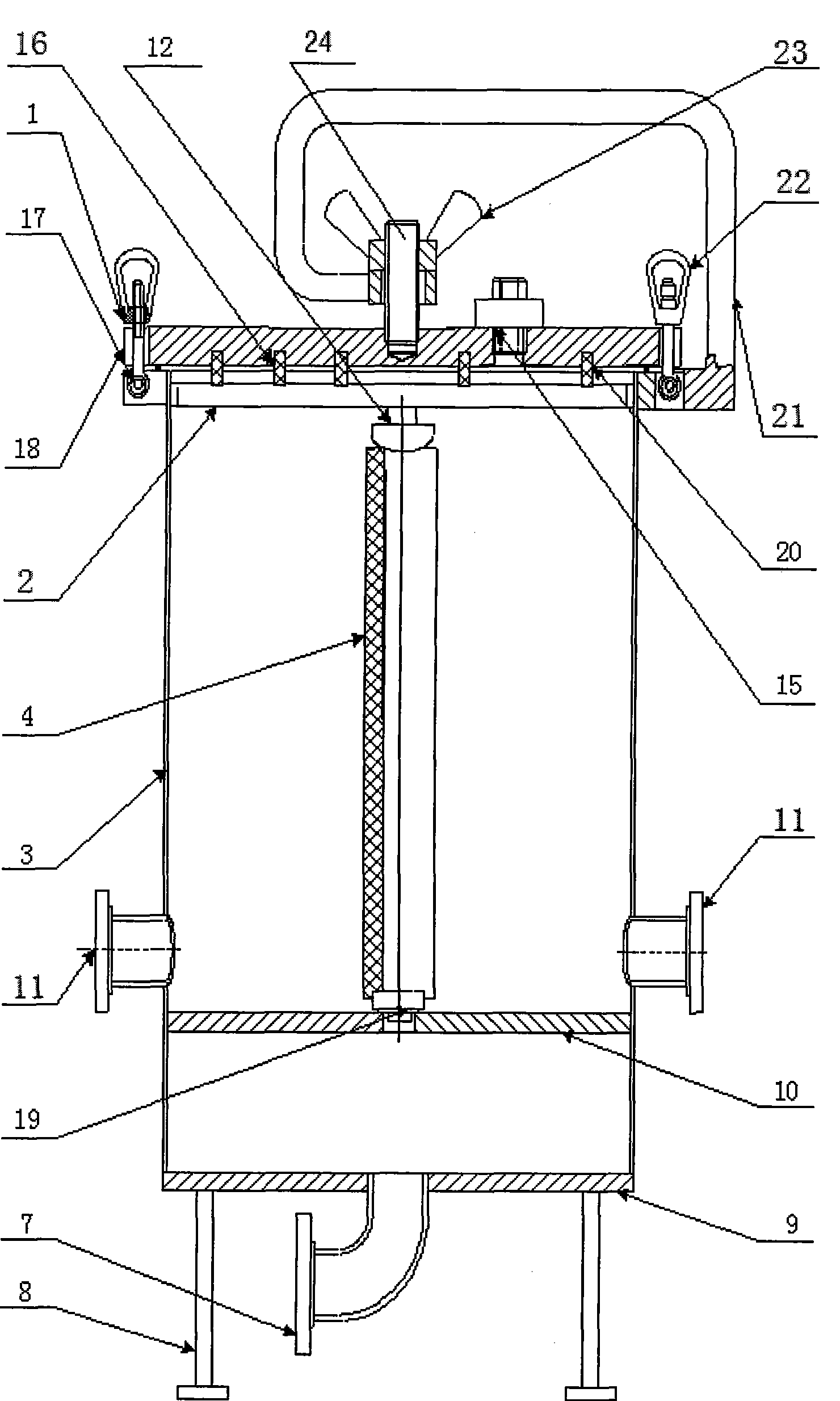

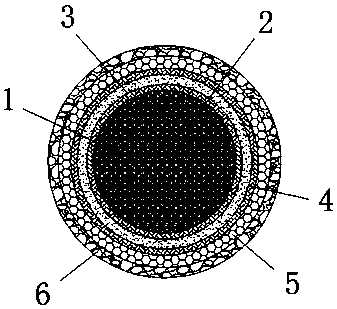

Filter

InactiveCN101455919ASolution to short lifeHydraulic balanceStationary filtering element filtersEngineeringCore plug

The invention discloses a filter, which comprises a drain plate, wherein the drain plate divides a filter cylinder into two parts of which the upper part is high and the lower part is low; the middle part of the upper part cylinder is provided with a column type filter core, the bottom end of the column type filter core is connected with the drain plate, and the top end of the column type filter core is connected with a press plate by a filter core plug; and the bottom surface of the lower part cylinder is connected with support legs by a support plate. The filter is characterized in that both sides of the lower part of the upper part cylinder are provided with a water inlet respectively, and a water outlet is arranged below the support plate of the lower part cylinder; and the edge of the upper part of the upper part cylinder is provided with a convex edge connected with an upper cover plate with vent holes through a hanging rod mechanism, and the upper cover plate is connected with the edge of the upper part of the upper part cylinder and tightly pressed against the press plate. The filter has the advantages of long service life of the filter core, high working efficiency of the filter and convenient replacement of the filter core in maintenance.

Owner:咸阳市高新天然气集中供热有限公司

Steel cable grip

ActiveCN105782344AUniform force on the surfaceFix damageRopes and cables for vehicles/pulleyTextile cablesEngineeringWire rope

Owner:STATE GRID SHANDONG ELECTRIC POWER +1

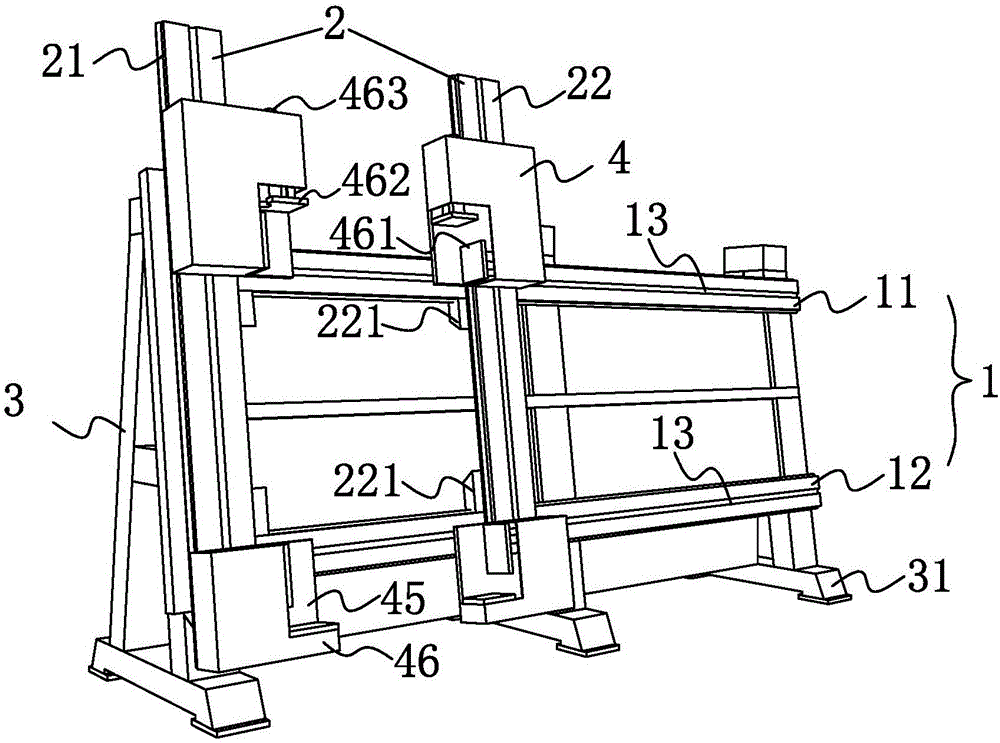

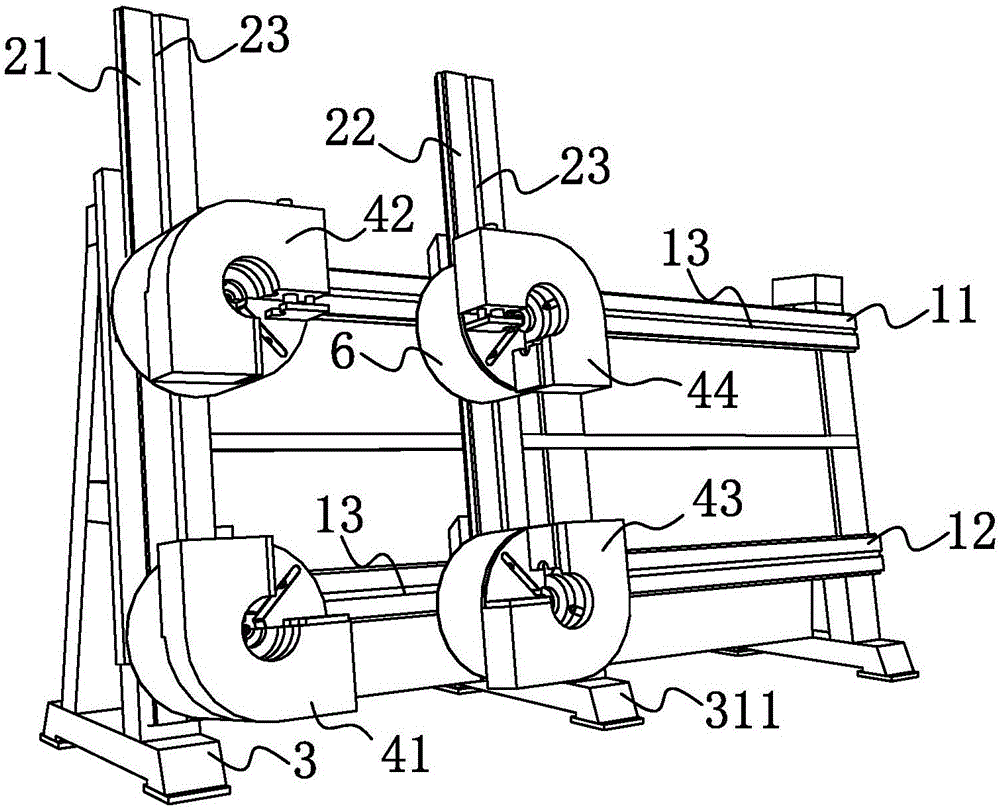

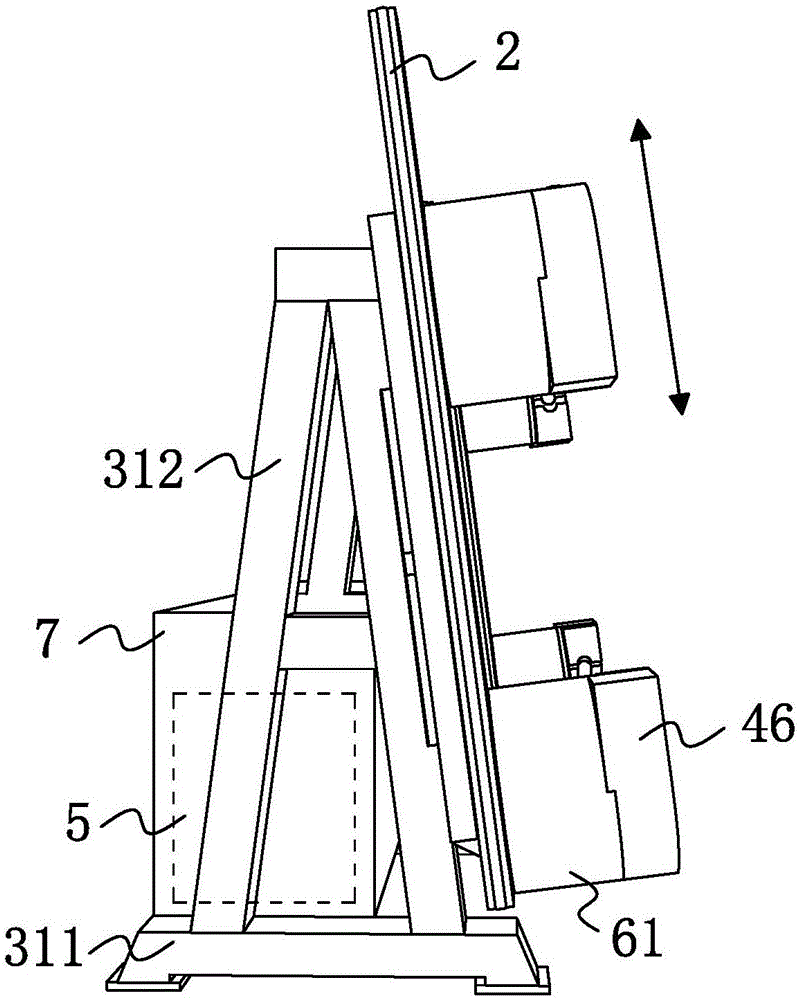

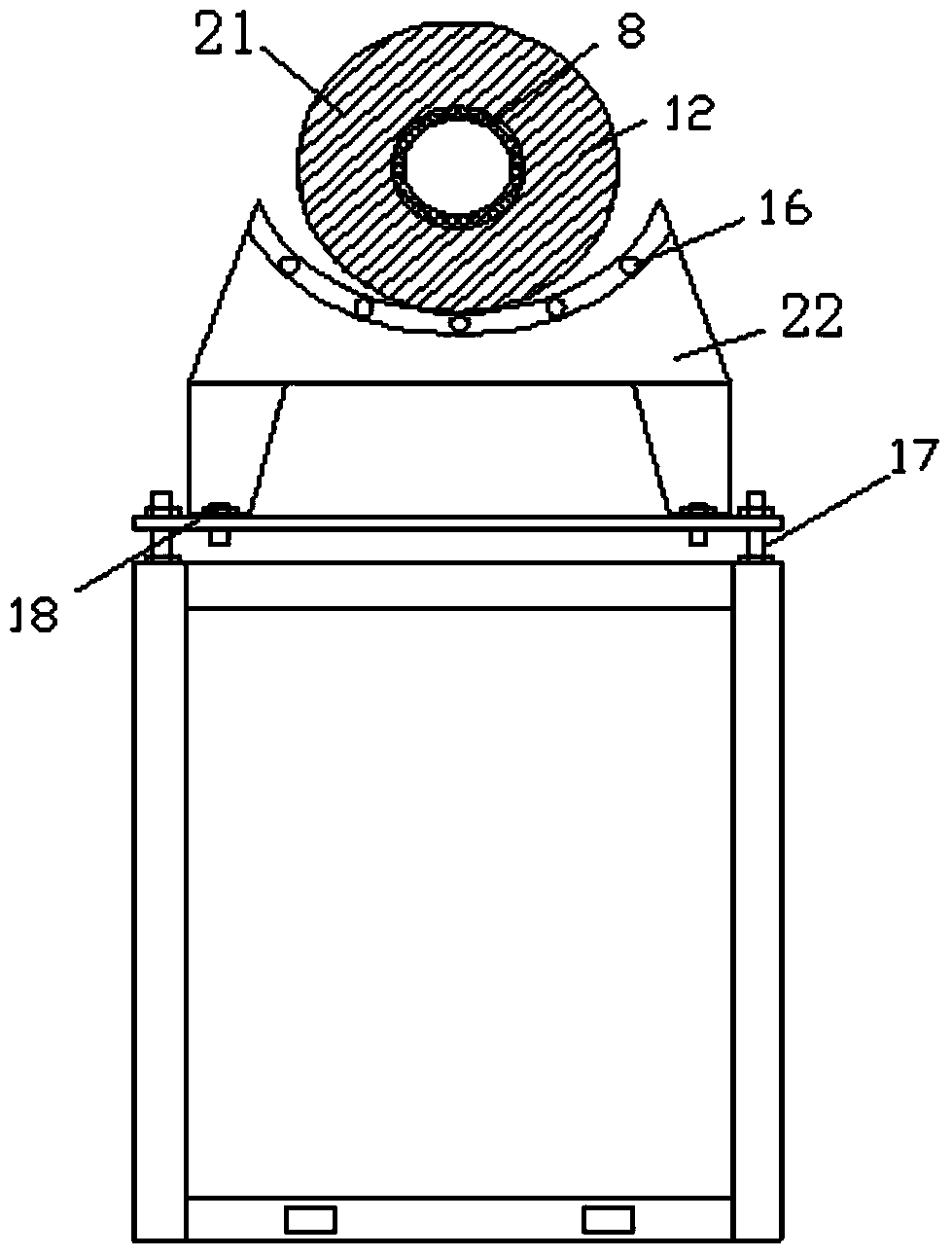

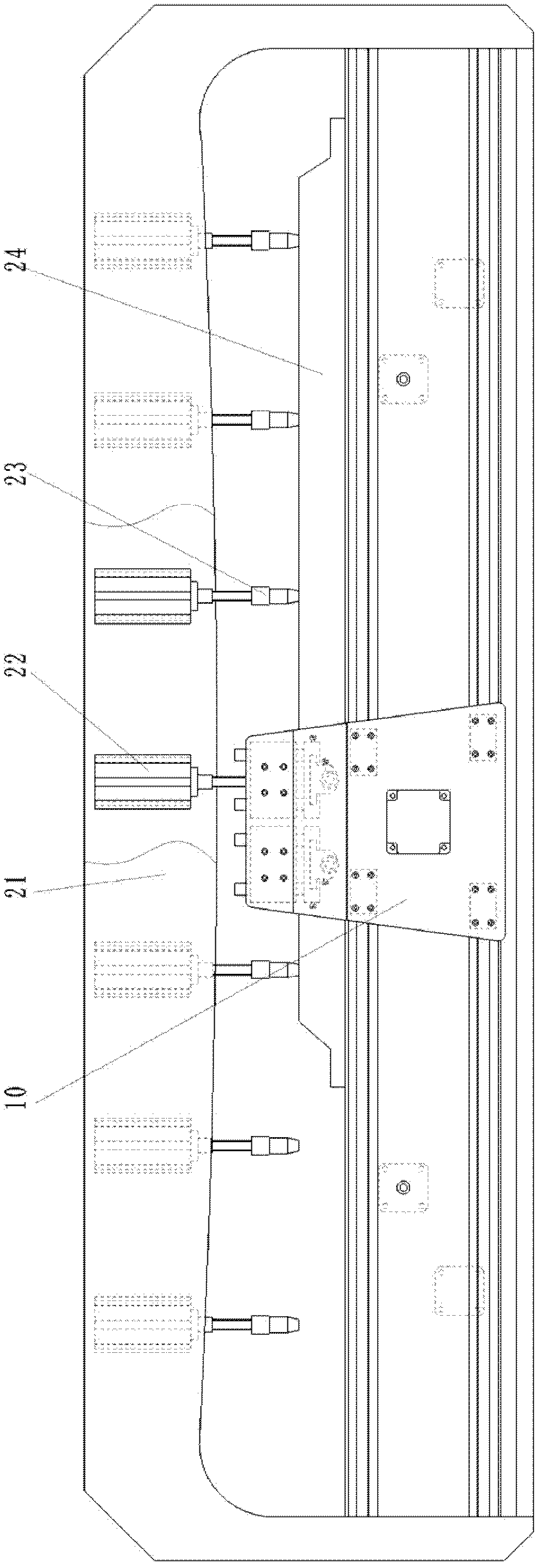

Hydraulic frame assembly equipment used for door and window profile assembly

The invention provides hydraulic frame assembly equipment used for door and window profile assembly and relates to the field of machines. By adoption of the hydraulic frame assembly equipment, the problems that existing door and window profiles are low in corner bonding strength and precision, poor in airtightness, unattractive and not durable are solved. The hydraulic frame assembly equipment is provided with a set of transverse parallel rods and a set of longitudinal parallel rods perpendicular to the set of transverse parallel rods. The longitudinal parallel rods are divided into the fixed rod and a movable rod. The fixed rod is located at one ends of the transverse parallel rods and fixed to the positions, corresponding to the transverse parallel rods, of the fixed rod. The movable rod is provided with a plurality of transmission slide blocks which are connected with a hydraulic transmission slide rail. The movable rod moves close to or away from the fixed rod under the interaction of the transmission slide blocks and the hydraulic transmission slide rail. By adoption of the hydraulic transmission frame assembly equipment, the problems of low strength and precision and large error which are prone to existing in door and window profile assembly are solved.

Owner:NORTHEAST FORESTRY UNIVERSITY

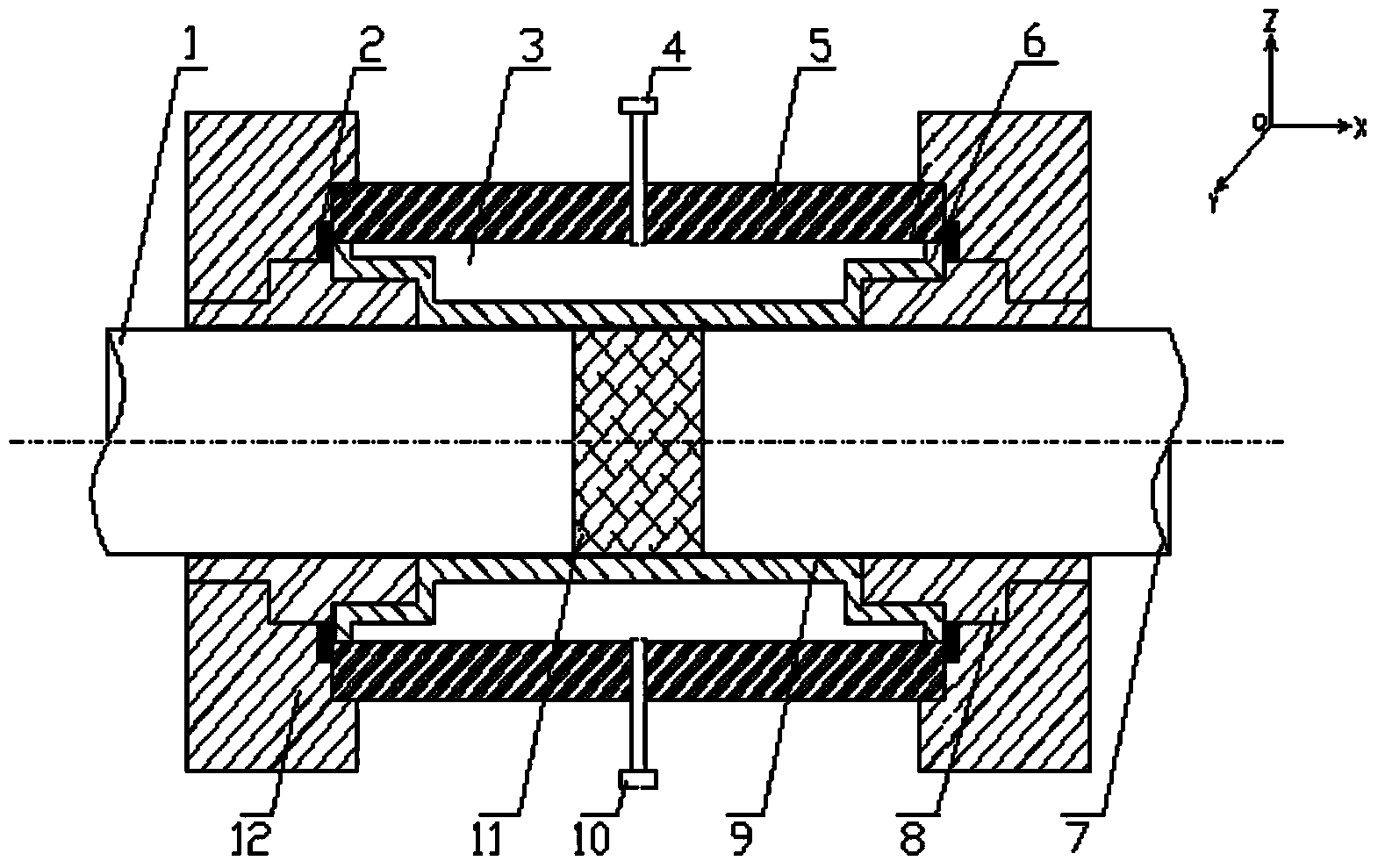

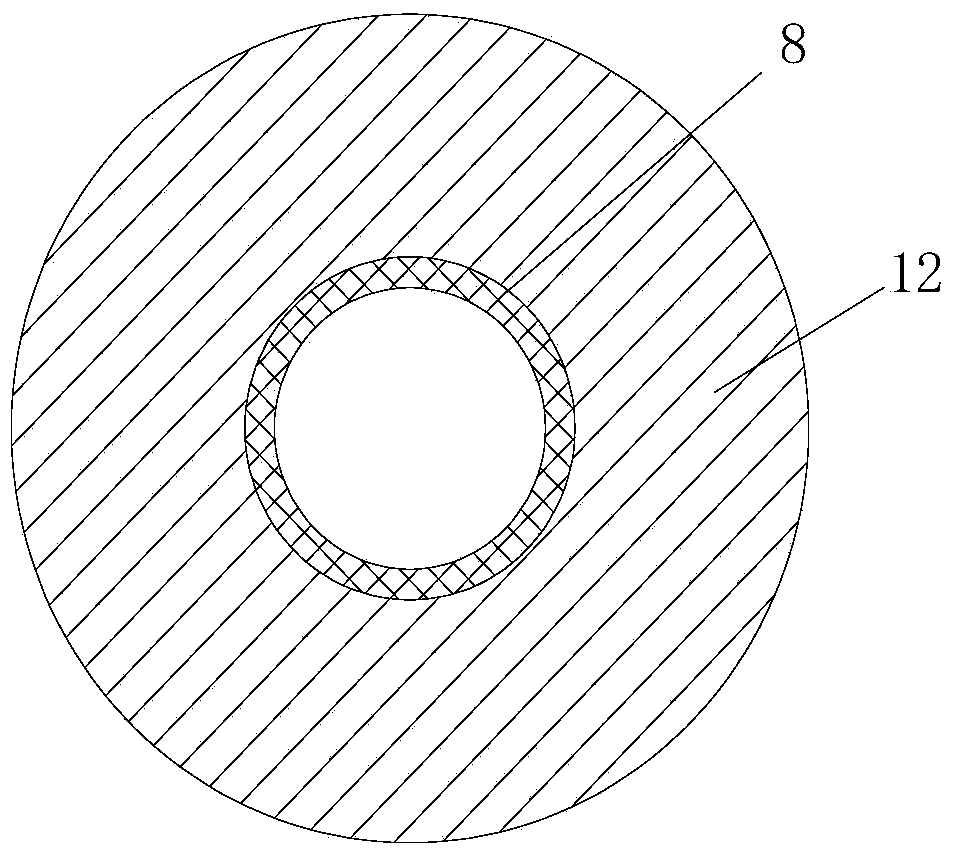

Circumferential pressurizing device for large-diameter Hopkinson pressure bar

InactiveCN103616279AEasy to adjustMeet pressurizationMaterial strength using tensile/compressive forcesEngineeringCylinder block

The invention discloses a circumferential pressurizing device for a large-diameter Hopkinson pressure bar. The circumferential pressurizing device is characterized in that a moving platform is arranged on the upper surface of a bracket and can move along the Z direction and the Y direction. A pressurizing cylinder body is arranged on the upper surface of the moving platform and can move along the X direction. One end of each of two inner bushings is arranged in each inner hole in the two ends of an oil-separating rubber sleeve; the other ends of the two inner bushings are respectively arranged in inner holes of two outer sleeves. The two inner bushings, an oil cylinder and the oil-separated rubber sleeve are fixed tightly by one pair of outer sleeves. A hydraulic oil chamber is formed between the inner surface of the oil cylinder and the outer surface of the oil-separated rubber sleeve. The circumference of the oil cylinder is provided with an oil inlet / pressure meter interface and an exhaust hole. The circumferential pressurizing device disclosed by the invention can be widely applied in indoor static-dynamic combined loading test of the Hopkinson pressure bar made of rock and concrete materials in the fields of civil air-defense engineering, geotechnical engineering and underground engineering and the like, and has the characteristics that the pressure application is accurate and uniform, the stability is high, the positioning of a test piece is accurate, the success ratio of the test is high and the service life is long and the like.

Owner:AIR FORCE UNIV PLA

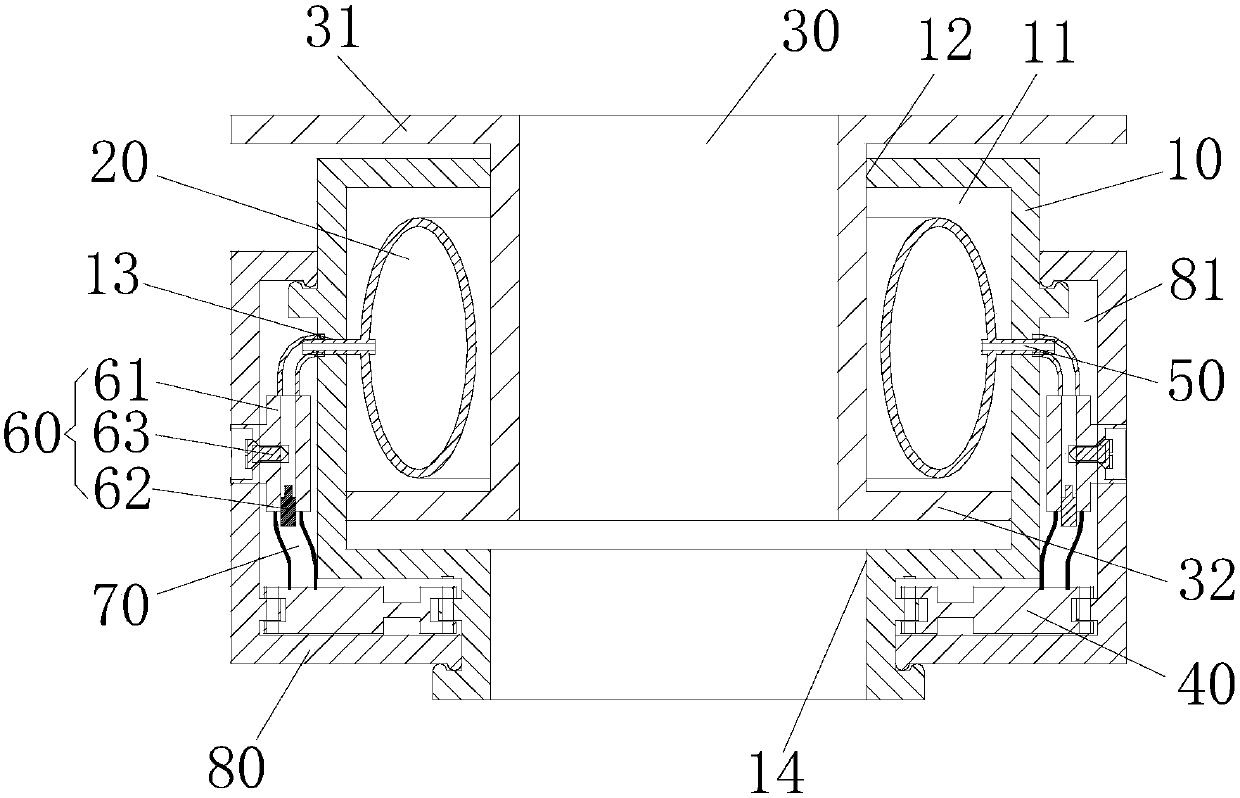

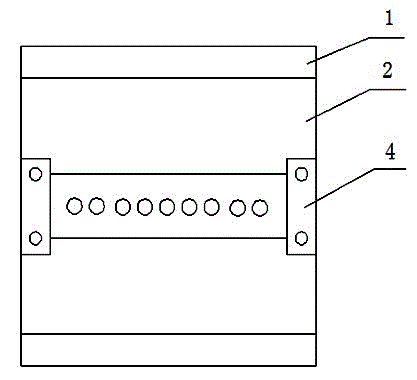

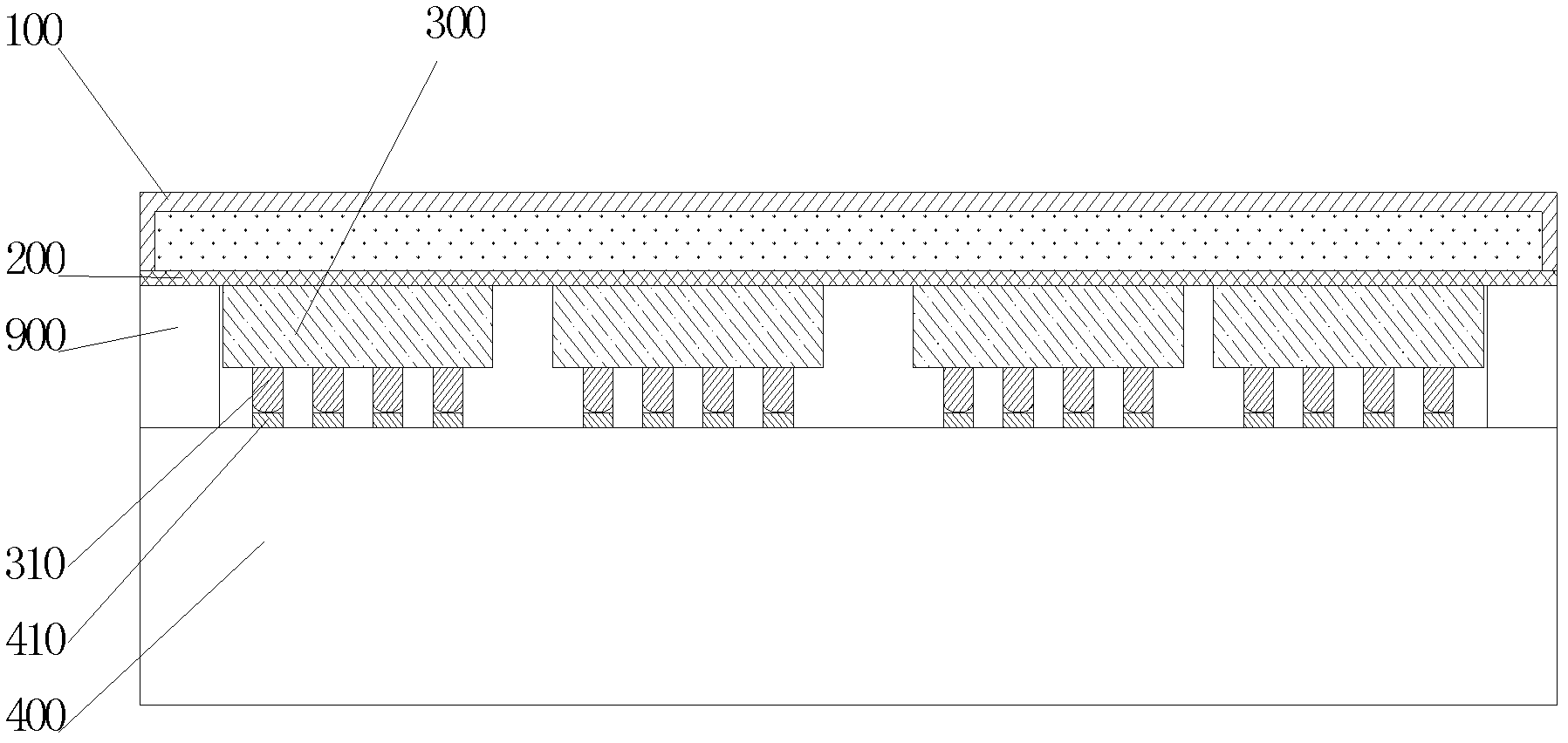

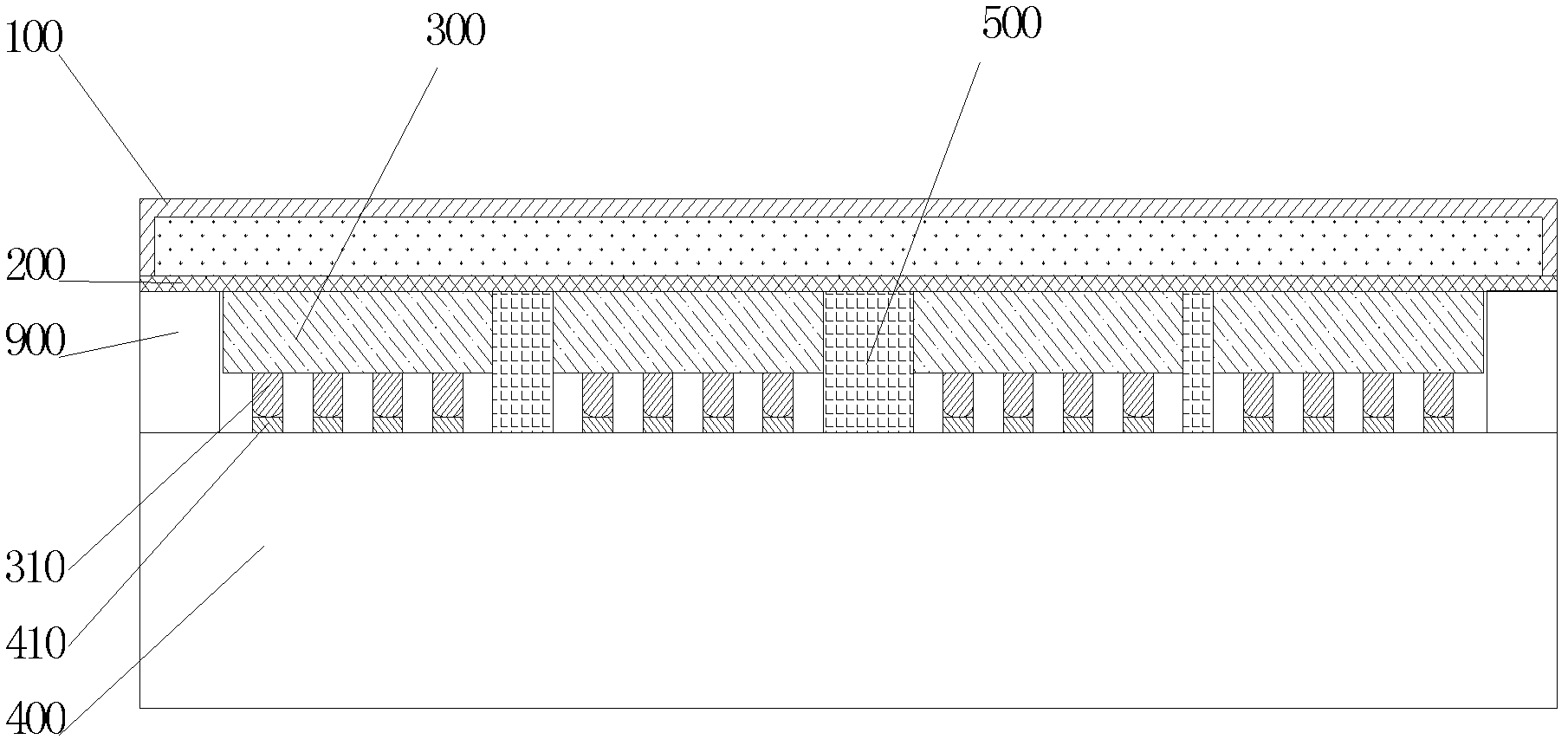

Bonder

ActiveCN103137508AApply pressure evenlyUniform pressureSemiconductor/solid-state device manufacturingEngineering

Owner:NAT CENT FOR ADVANCED PACKAGING

A jig for removing air bubbles in glass crevices

A fixture for removing air bubbles in glass cracks, relating to the technical field of glass manufacturing, solves the problem of uneven application of force when the existing fixture clamps the edge of the glass, and solves the time-consuming and laborious problem of manually clamping multiple fixtures on the edge of the glass. The present invention provides a fixture for removing air bubbles in glass gaps. The substrate is the main body. The two substrates are fixedly connected by a handle. Two parallel splints are arranged between the two substrates. There is a ejector rod between the base plate and the corresponding splint, the ejector rod is screwed to the base plate, and the movement of the splint is realized by the movement of the ejector rod, so that the two splints are close to each other and clamp the edge position of the glass, and the splint has a certain length , avoiding the time-consuming and labor-intensive problems caused by using multiple fixtures. At the same time, the splint applies pressure evenly to the glass, avoiding damage to the glass caused by uneven force application.

Owner:SHANDONG WENSHENG GLASS

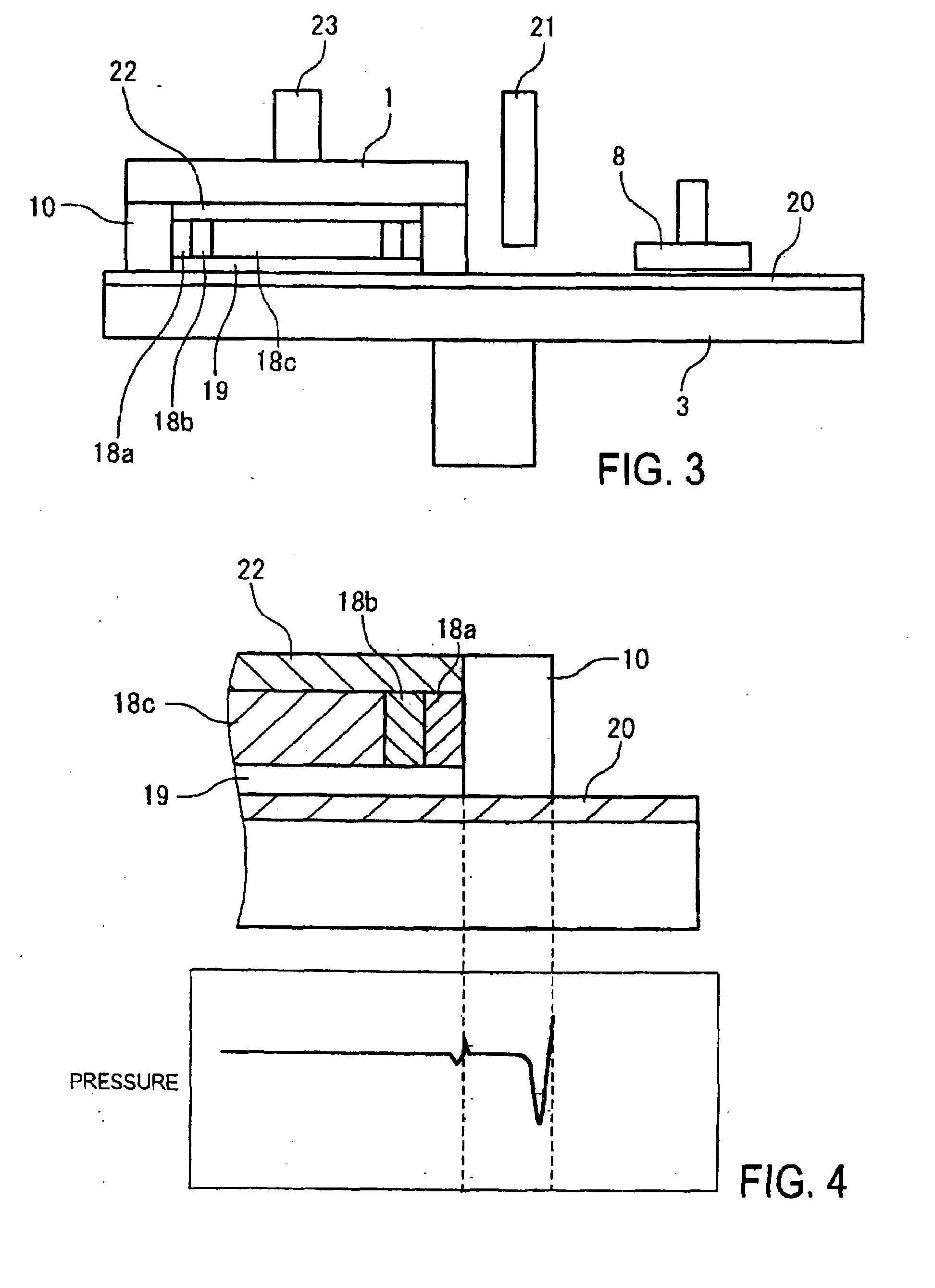

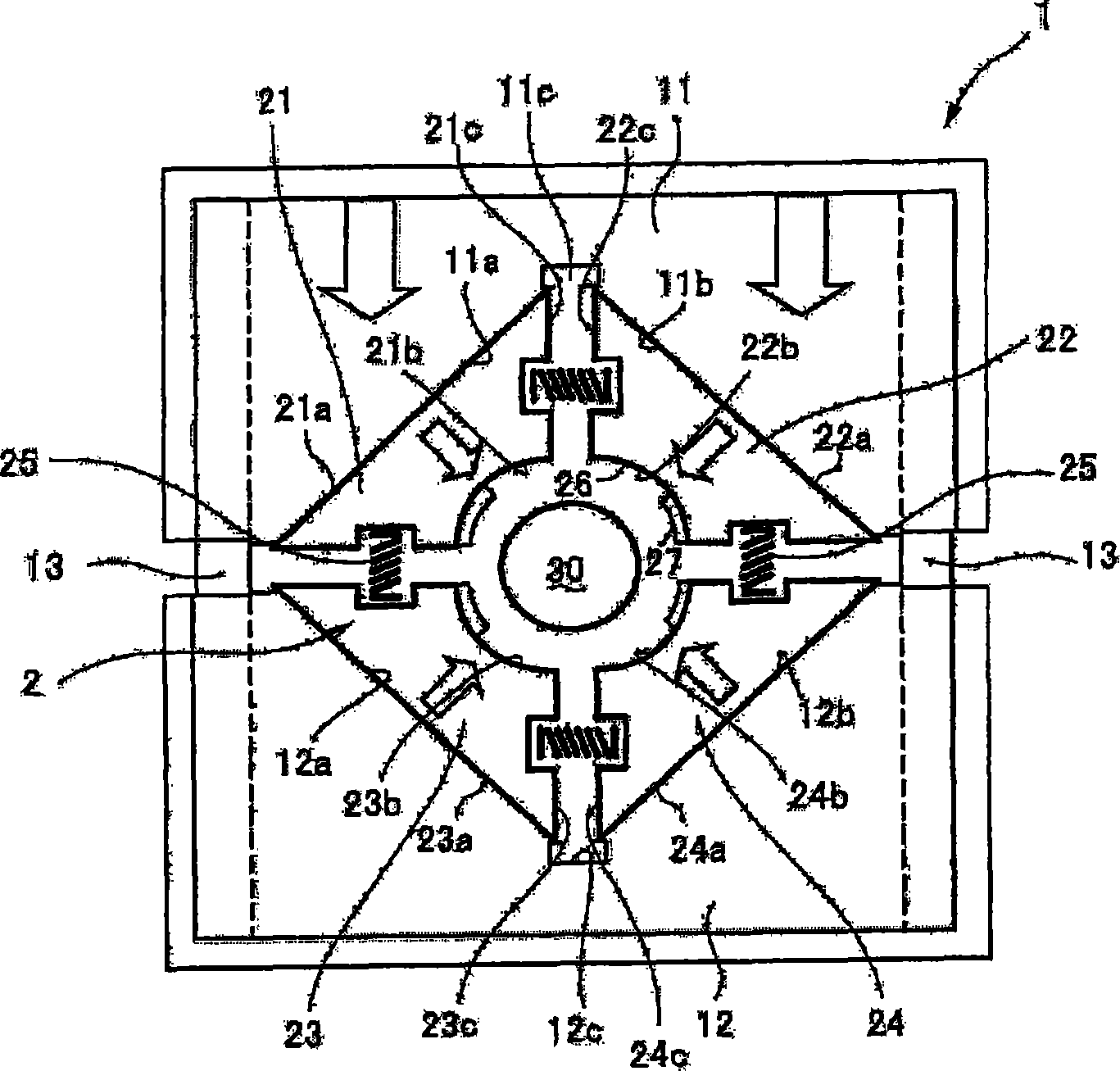

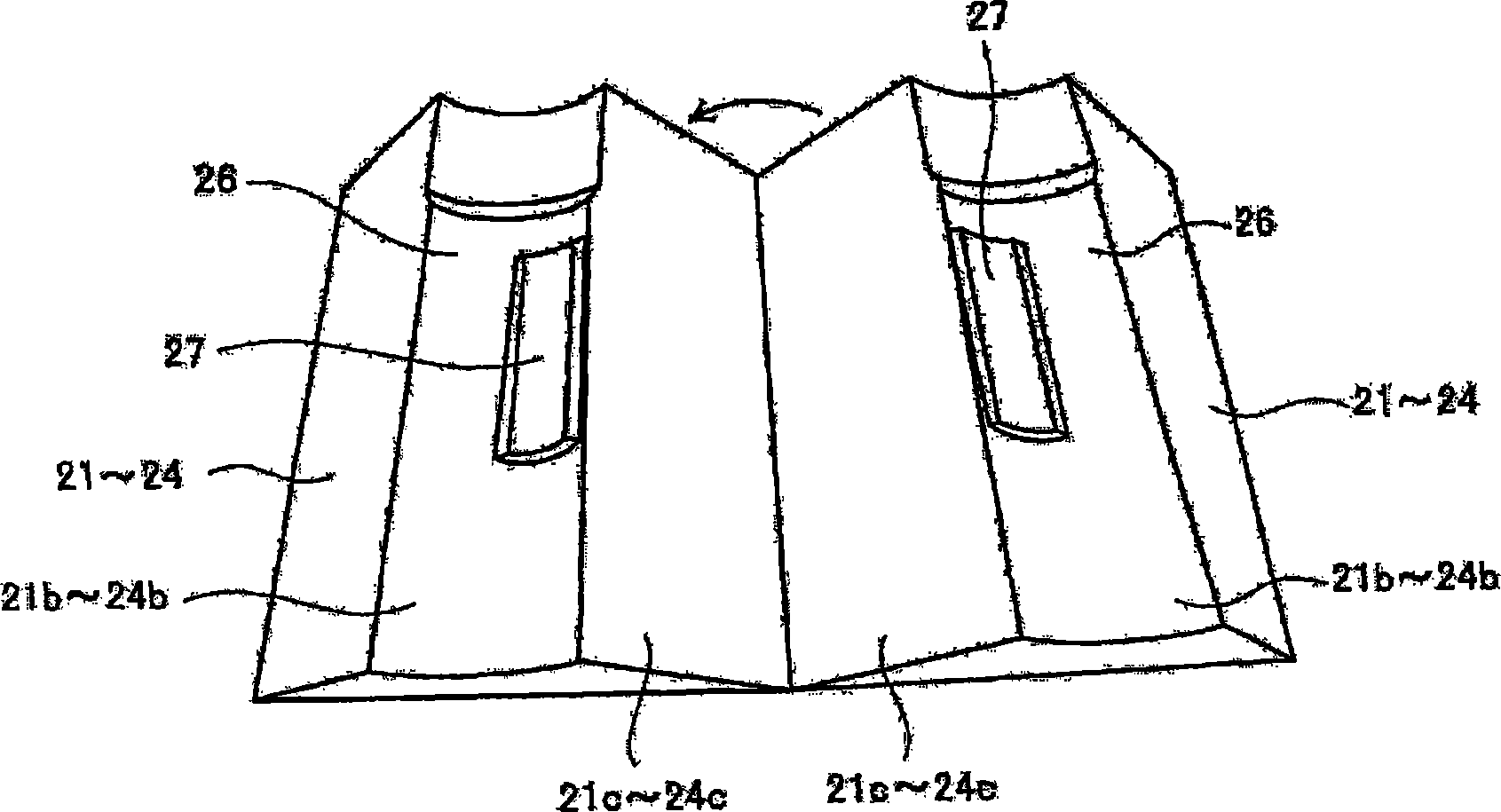

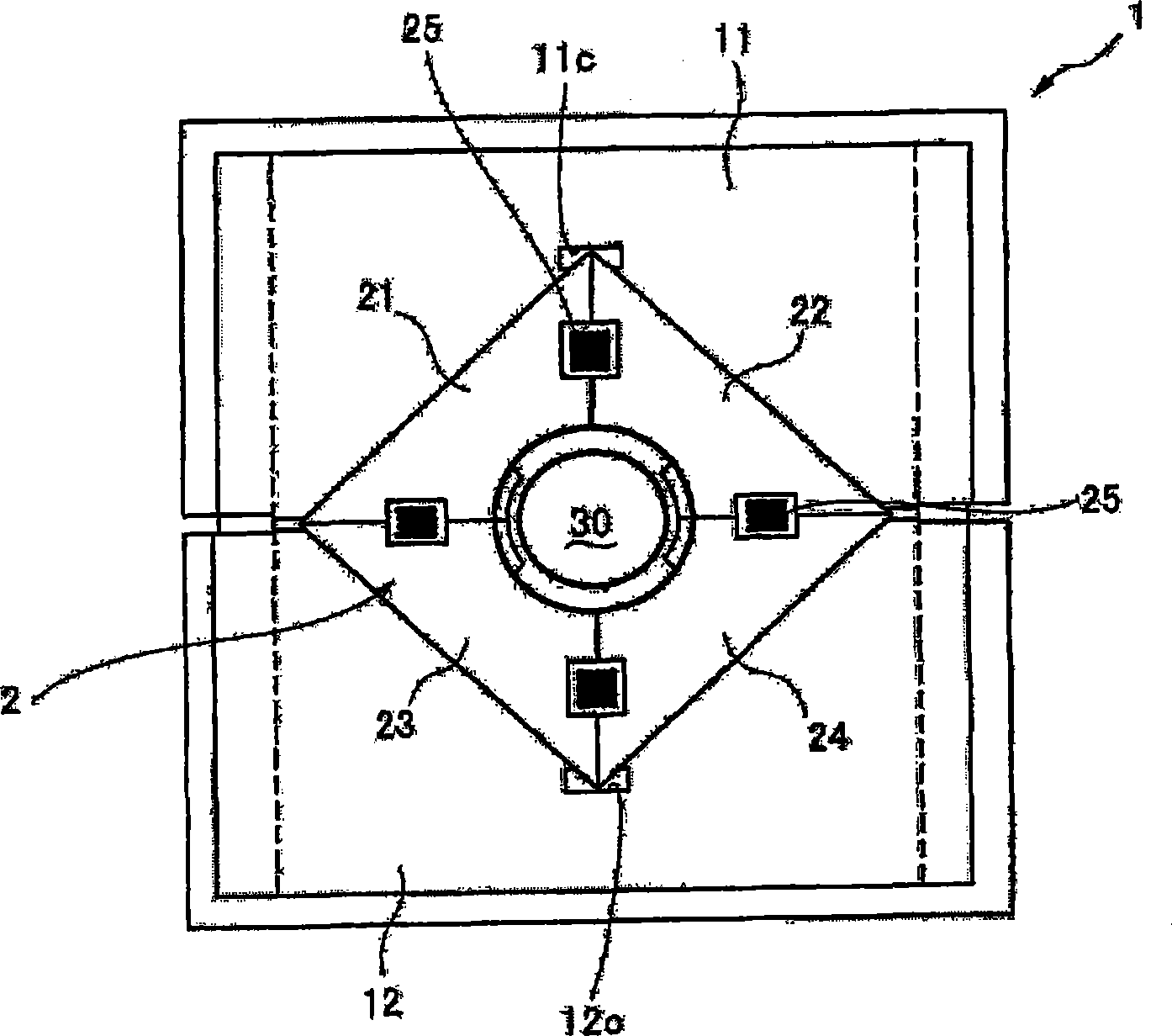

Apparatus for forming pipe material and the method

InactiveCN100542708CUniform forming pressureReduce the number of processesShaping toolsForging/hammering/pressing machinesEngineeringPipe

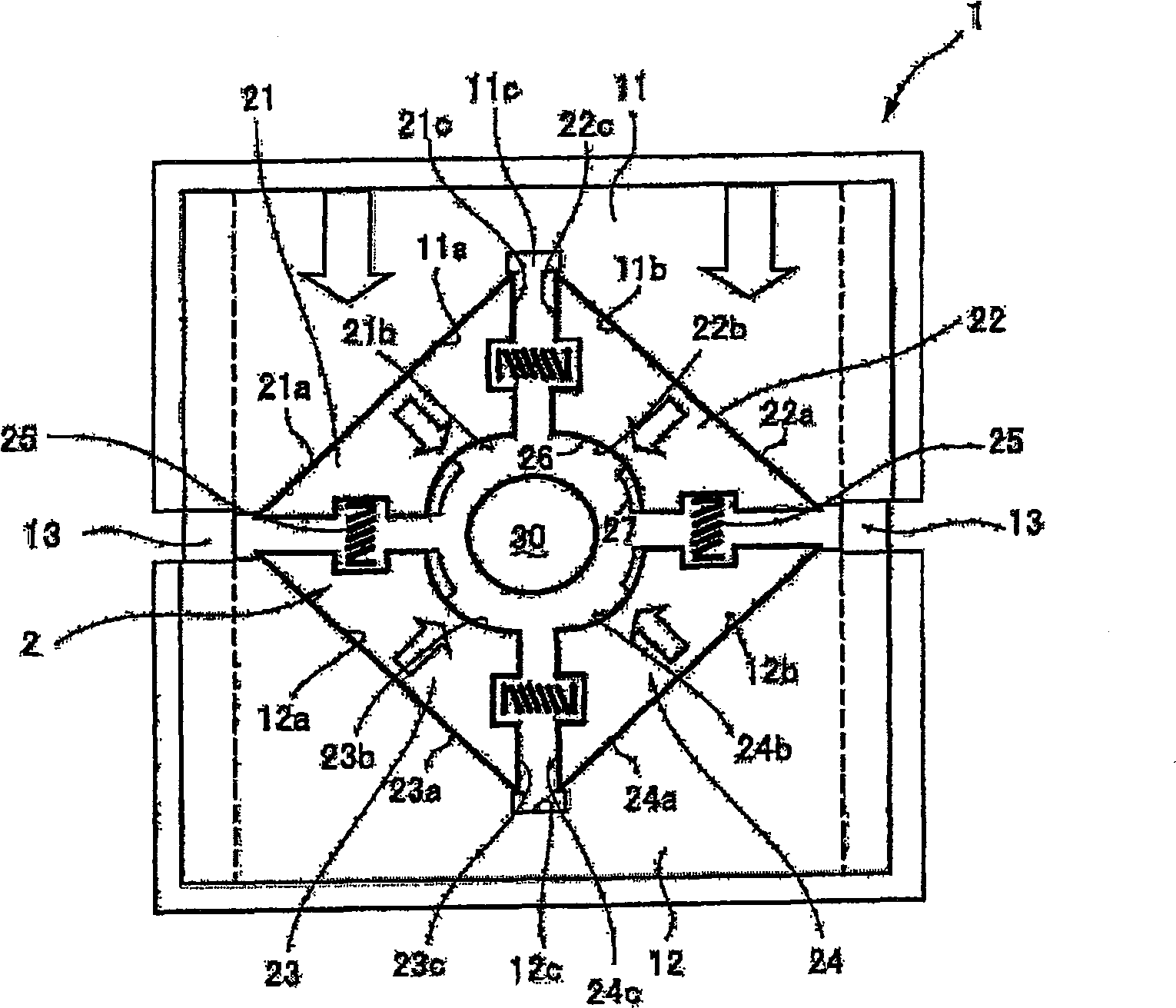

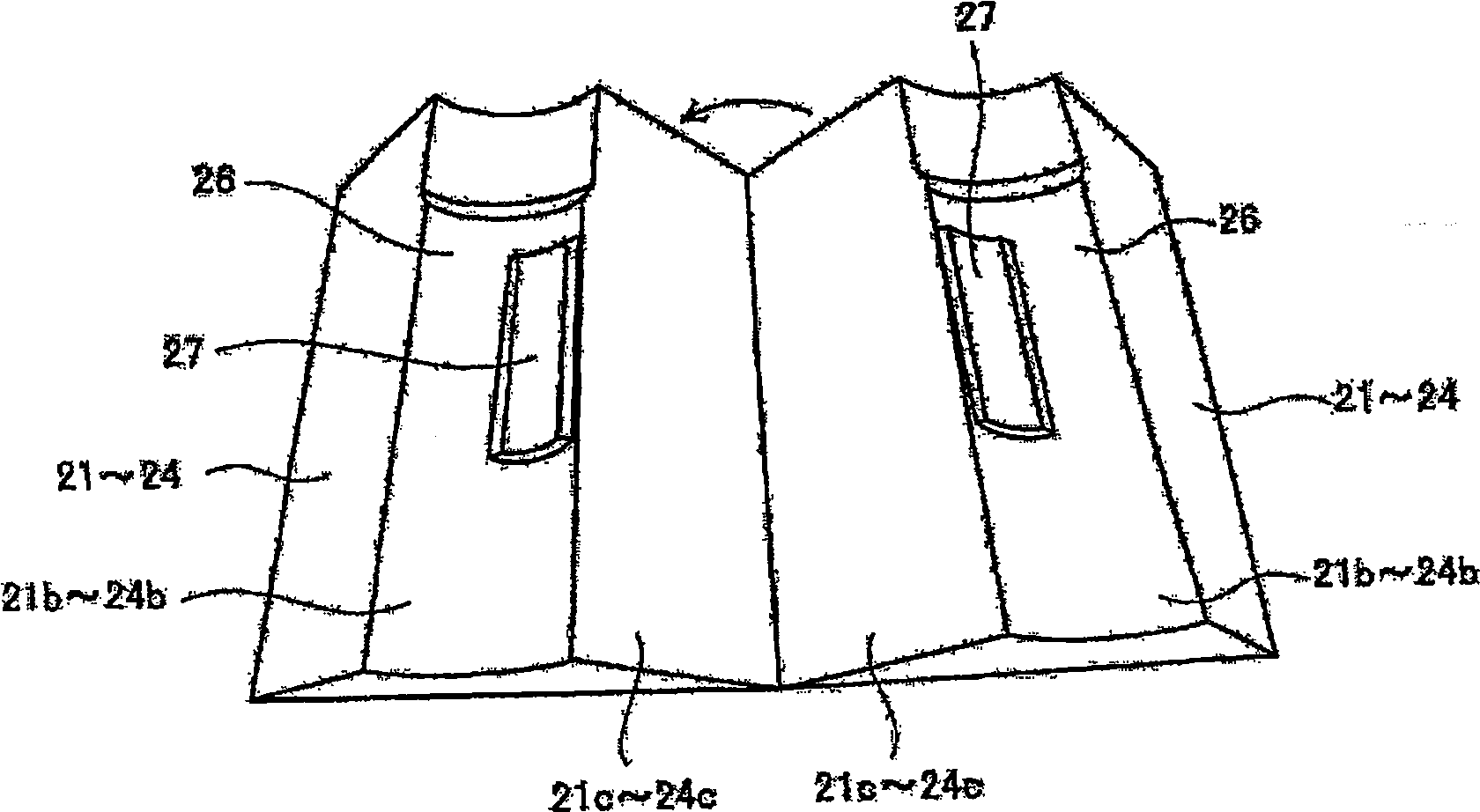

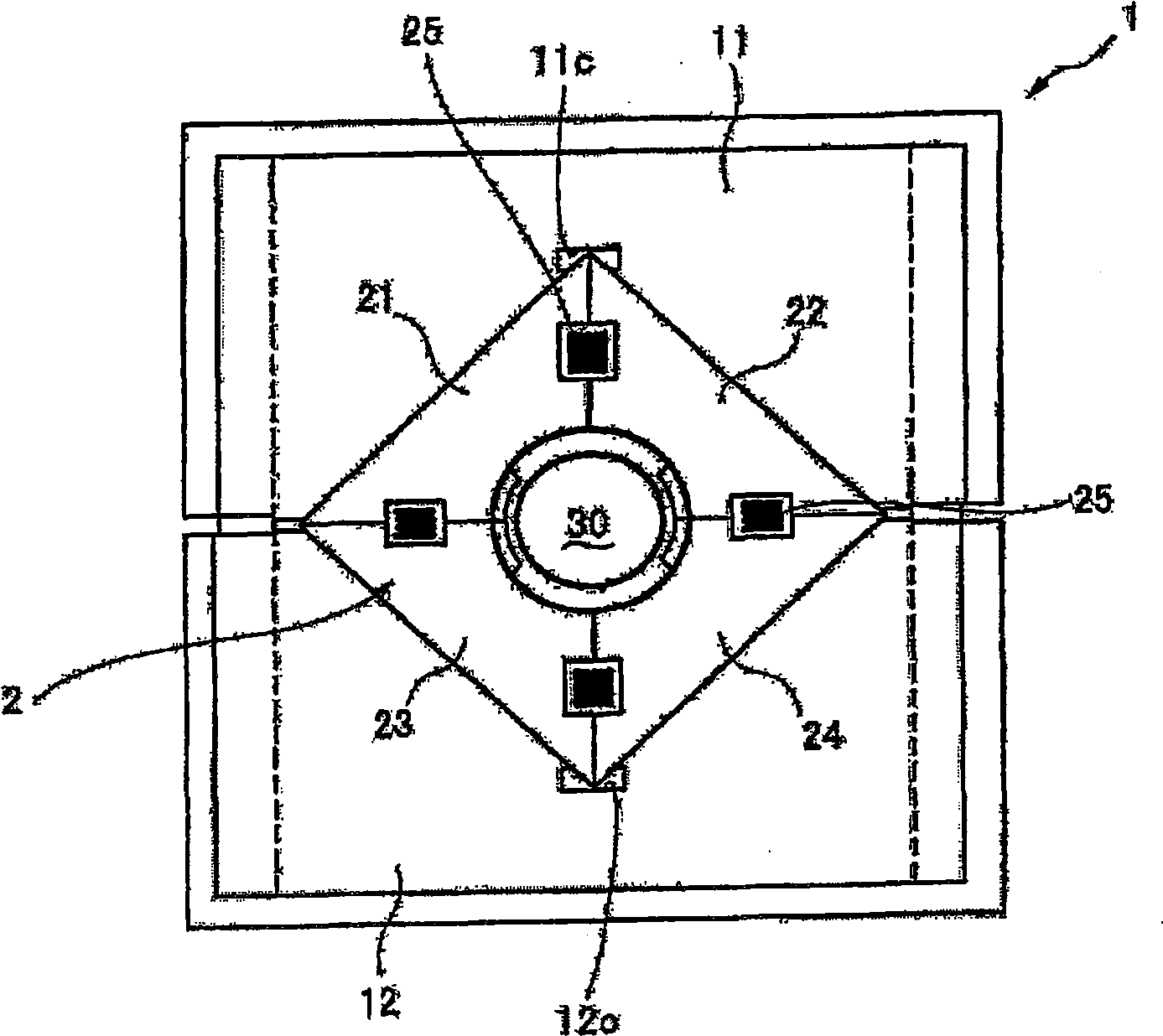

[PROBLEMS] To provide a molding device that a plurality of split dies can be equally clamped with a single drive source. [MEANS FOR SOLVING PROBLEMS] In subjecting a tube material to drawing and caulking, a tube material is first externally inserted into a cored bar (30). In this case, upper and lower split dies (11, 12) constituting an external die (1) are in a mold opened state. From this state, an upper split die (11) constituting an external die (1) is moved downwardly. This allows four split dies (21, 22, 23, 24) constituting an inner die (2) to evenly move toward the center, and an exhaust pipe is subjected to drawing and caulking simultaneously by molding faces (26, 27) formed on the inner face of the four split dies.

Owner:HONDA MOTOR CO LTD

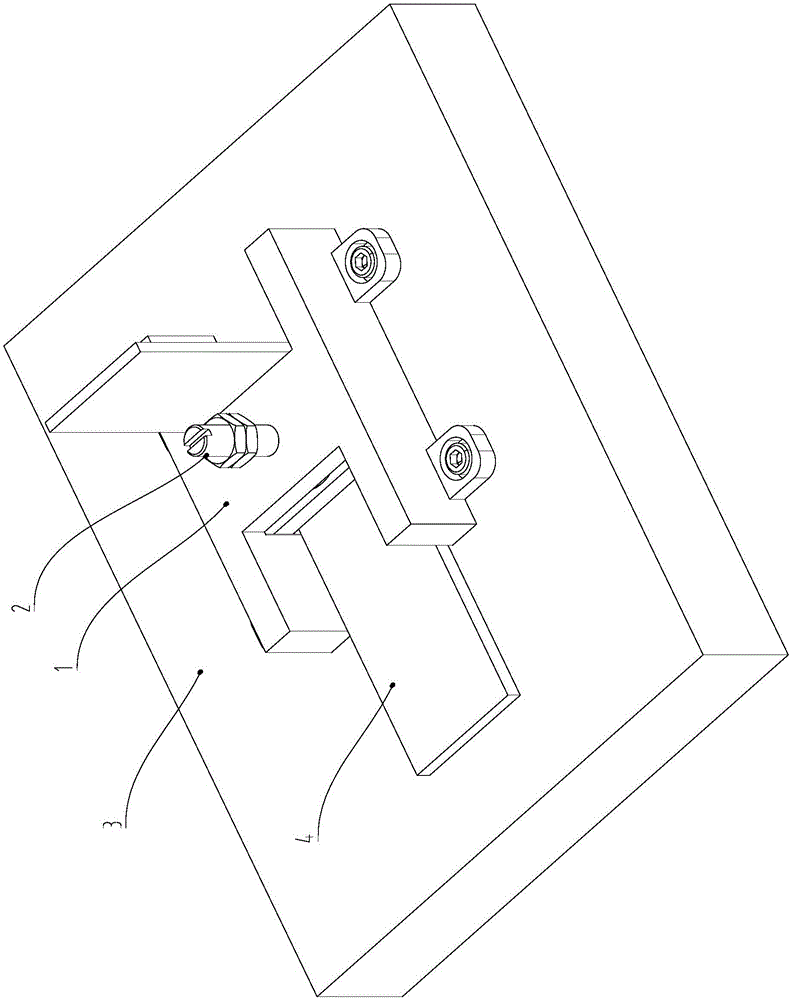

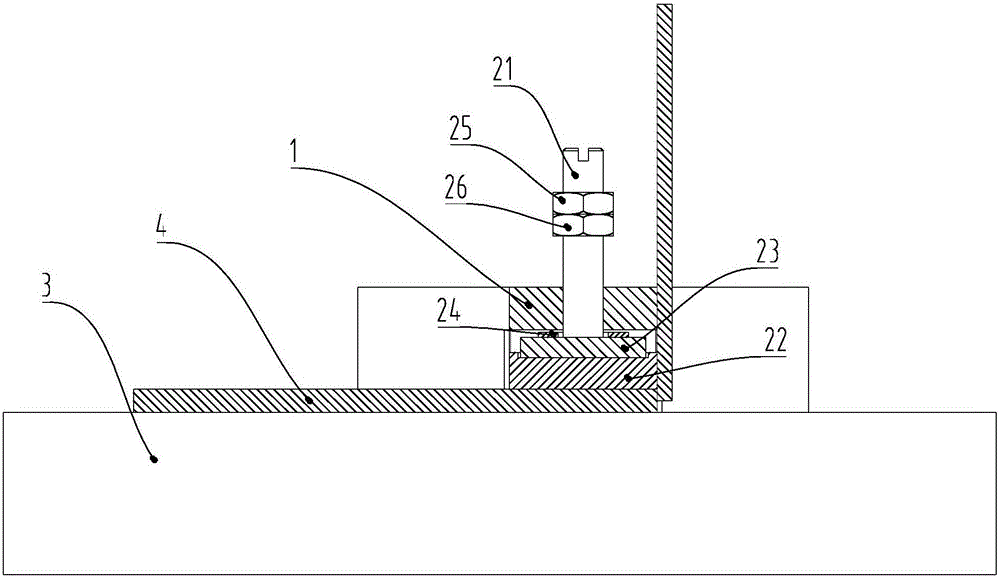

Device for power battery module side plate tensile test

ActiveCN106092737AImprove accuracyGuaranteed to move normallyMaterial strength using tensile/compressive forcesPower batteryEngineering

The invention provides a device for a power battery module side plate tensile test. The device comprises a base and a compression assembly. The base is fixed to a test table and provided with a threaded hole. The compression assembly comprises a vertically-arranged screw rod and a pressing plate horizontally installed at the lower end of the screw rod. The upper end of the screw rod penetrates out of the threaded hole, and the screw rod is in threaded connection with the threaded hole. The pressing plate is located between the base and the test table. The pressing plate can rotate along with the screw rod in the threaded hole so as to move up and down. The device is fixed to the test table and can accurately fix and press a power battery module, and accuracy of the tensile test can be greatly improved.

Owner:BEIJING PRIDE NEW ENERGY BATTERY

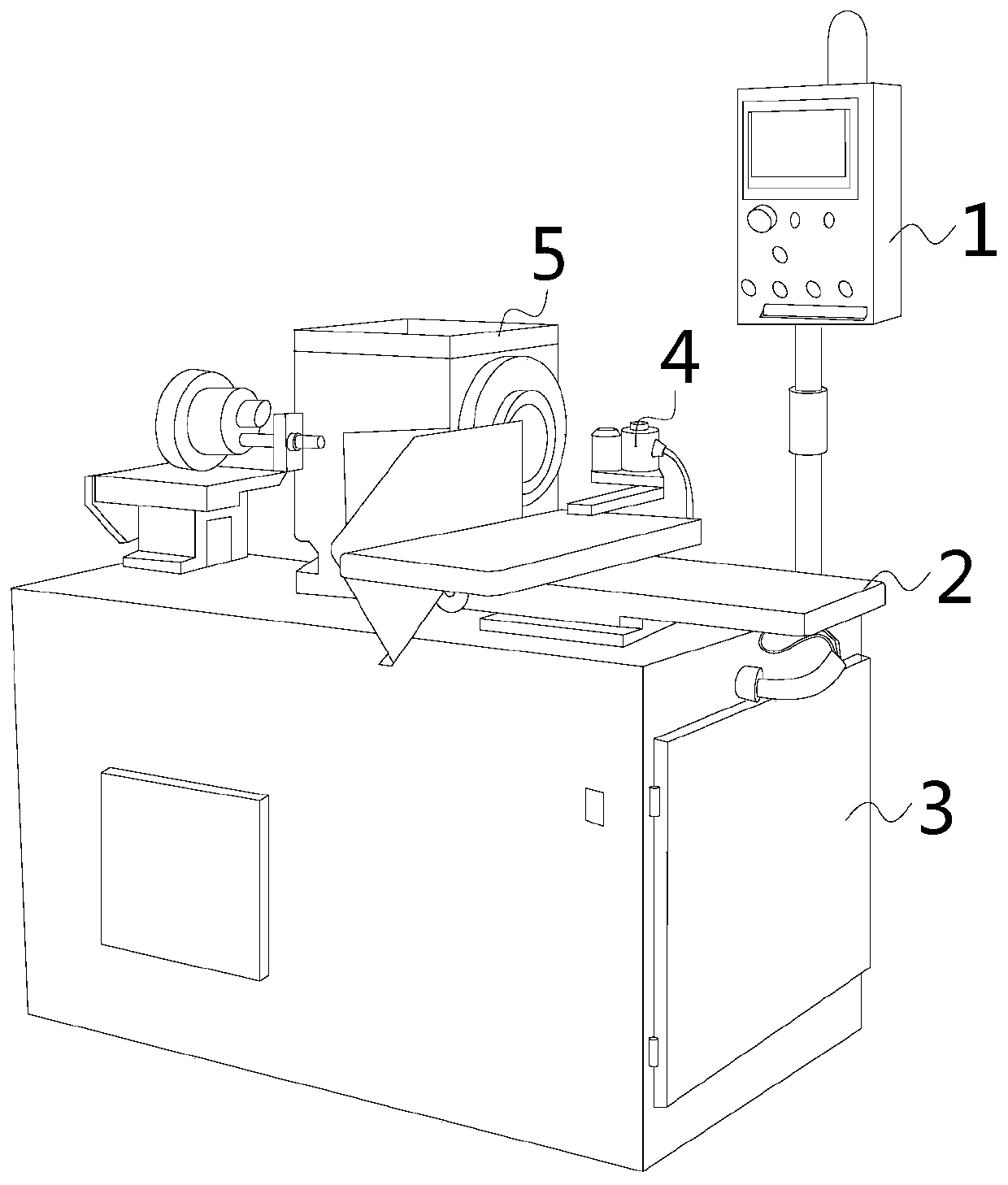

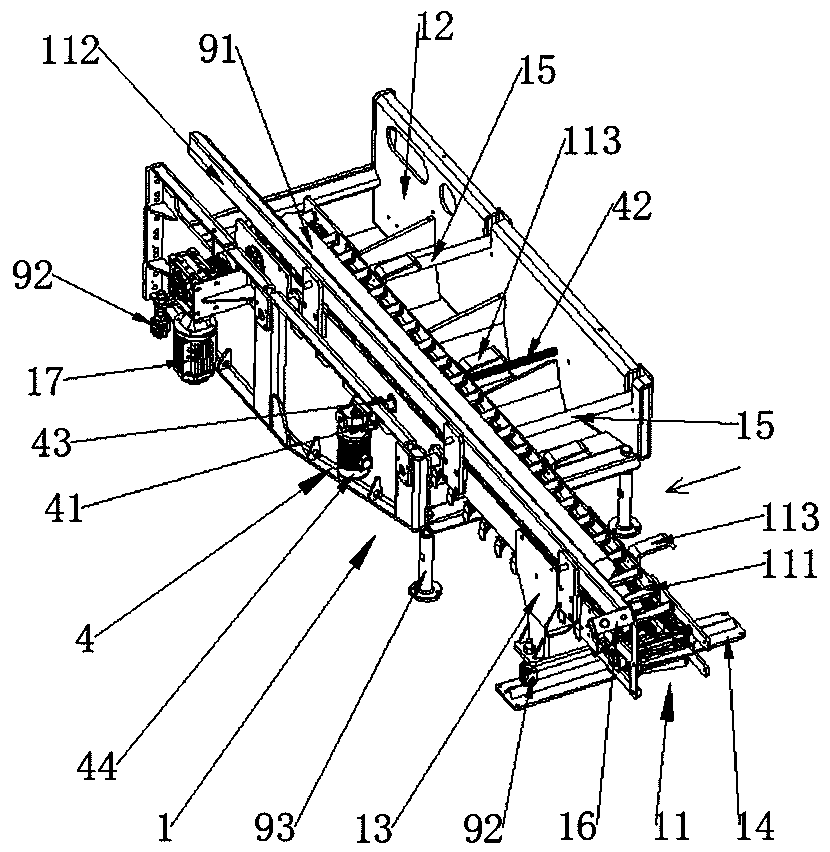

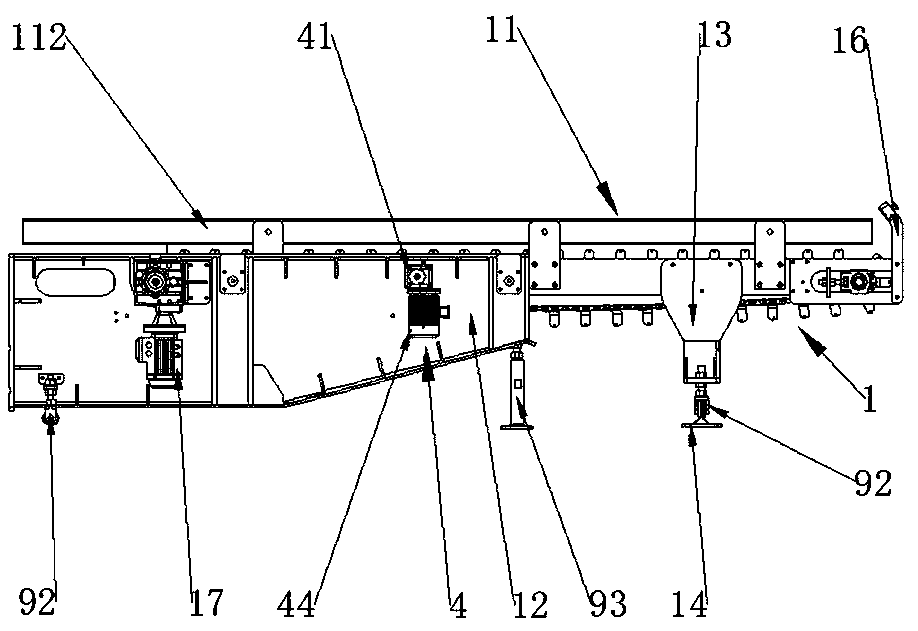

Bearing ring automatic machining equipment

ActiveCN110270695AControl opening and closingEasy to control and adjust the tightness of the clampingAutomatic/semiautomatic turning machinesChucksEngineeringMachining

The invention discloses bearing ring automatic machining equipment. The equipment structurally comprises a controller, an operating console, a body, a tool, a soft claw disc mounting base and a soft claw disc. The operating console is arranged at one end of the top end surface of the body, and the soft claw disc mounting base is mounted at the other end of the top end surface of the body. The soft claw disc is movably mounted on the soft claw disc mounting base. The controller and the tool are mounted on the portion, located at one side of the operating console, of the body in parallel. The tool is located between the soft claw disc mounting base and the controller. The soft claw disc is composed of a claw, a sliding base, a claw body and a motor. The motor is located under the claw body. According to the bearing ring automatic machining equipment, through cooperation of the claw, the claw body, the motor and the like, on the one hand, a circular truncated cone is made to rise and fall continuously by means of forward and reverse rotating of the motor, meanwhile, the contact area is further increased through uniform three-point force application and an L-type structure and a piston of the claw, the clamping stability and the adjusting convenience are improved, and it is guaranteed that no single plane inner diameter / outer diameter variation deviation occurs when an extra-large thin-wall bearing is machined.

Owner:临清市毅轩轴承有限公司

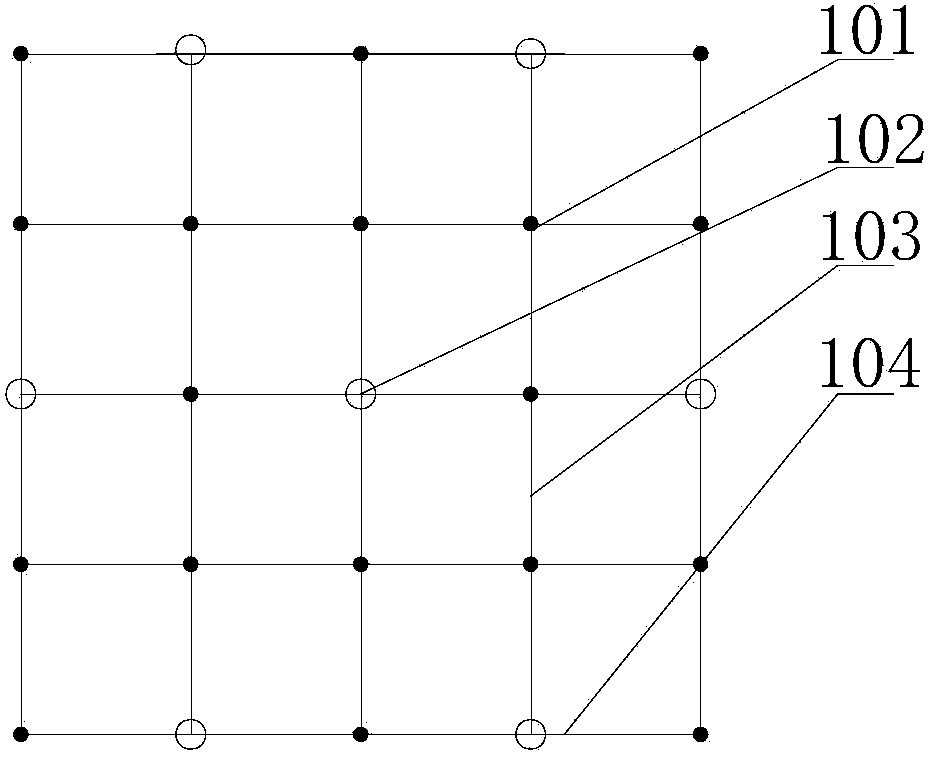

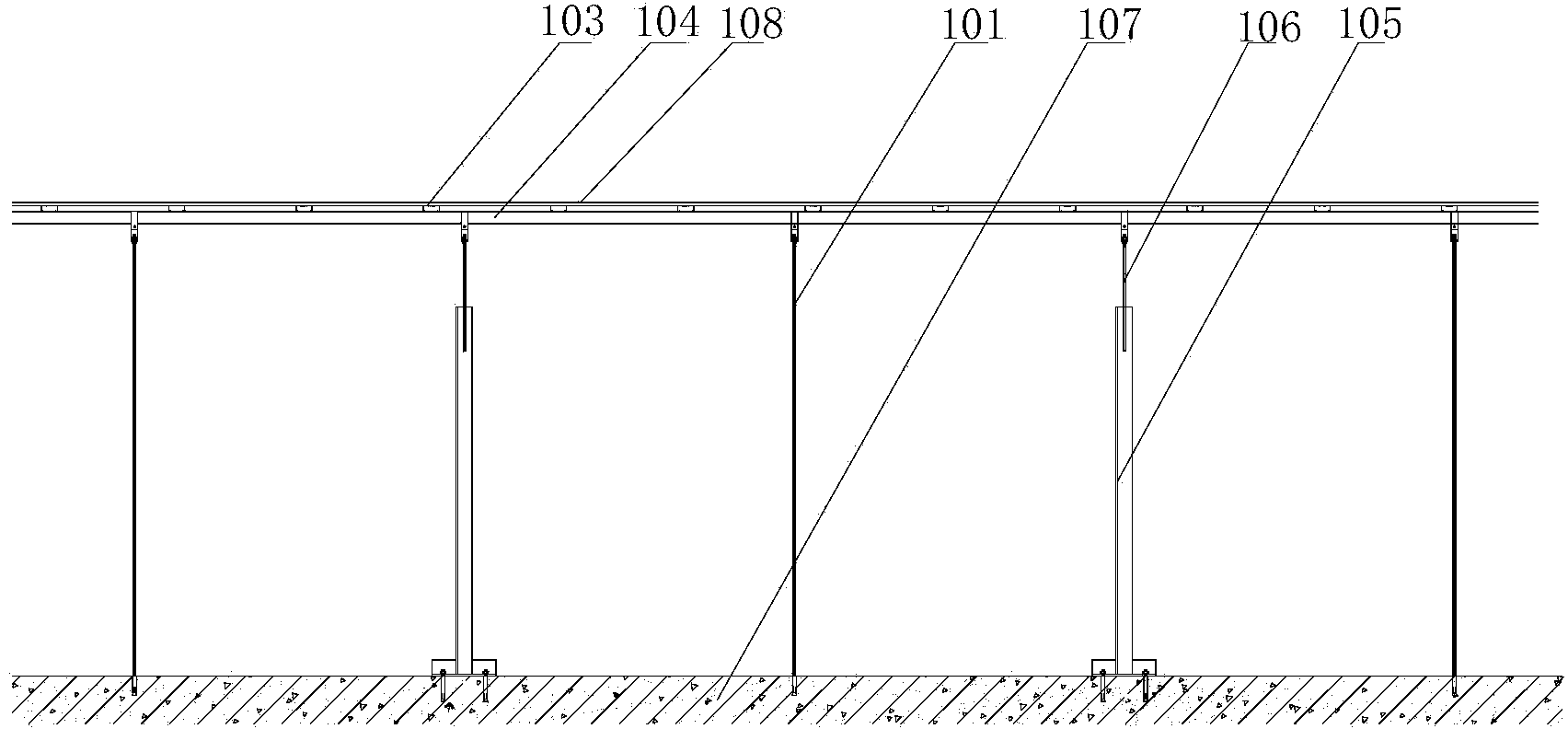

Test method for measuring ultimate bearing capacity of ceiling support system

ActiveCN104330276AEasy to fixApply pressure evenlyStructural/machines measurementSupporting systemKeel

The invention relates to ultimate bearing capacity measuring method in the building field, in particular to a test method for measuring ultimate bearing capacity of a ceiling support system. The method comprises fixing the ceiling support structural system on the building floor in an inverted mode, fixing a face plate on the top surfaces of main keels and auxiliary keels, arranging a special loading apparatus, fixing the loading apparatus with the ceiling support structural system and the face plate firmly, and applying downward pressure to the loading apparatus through a ceiling support structural system inversion method to simulate upward negative wind pressure generated by the wind load to the ceiling in the prior decorative ceiling structures. By the aid of the method, the problem that the support limit bearing capacity of the ceiling support structural system cannot be measured accurately in the prior decorative ceiling project is solved.

Owner:QINGDAO JIANAN CONSTR GROUP

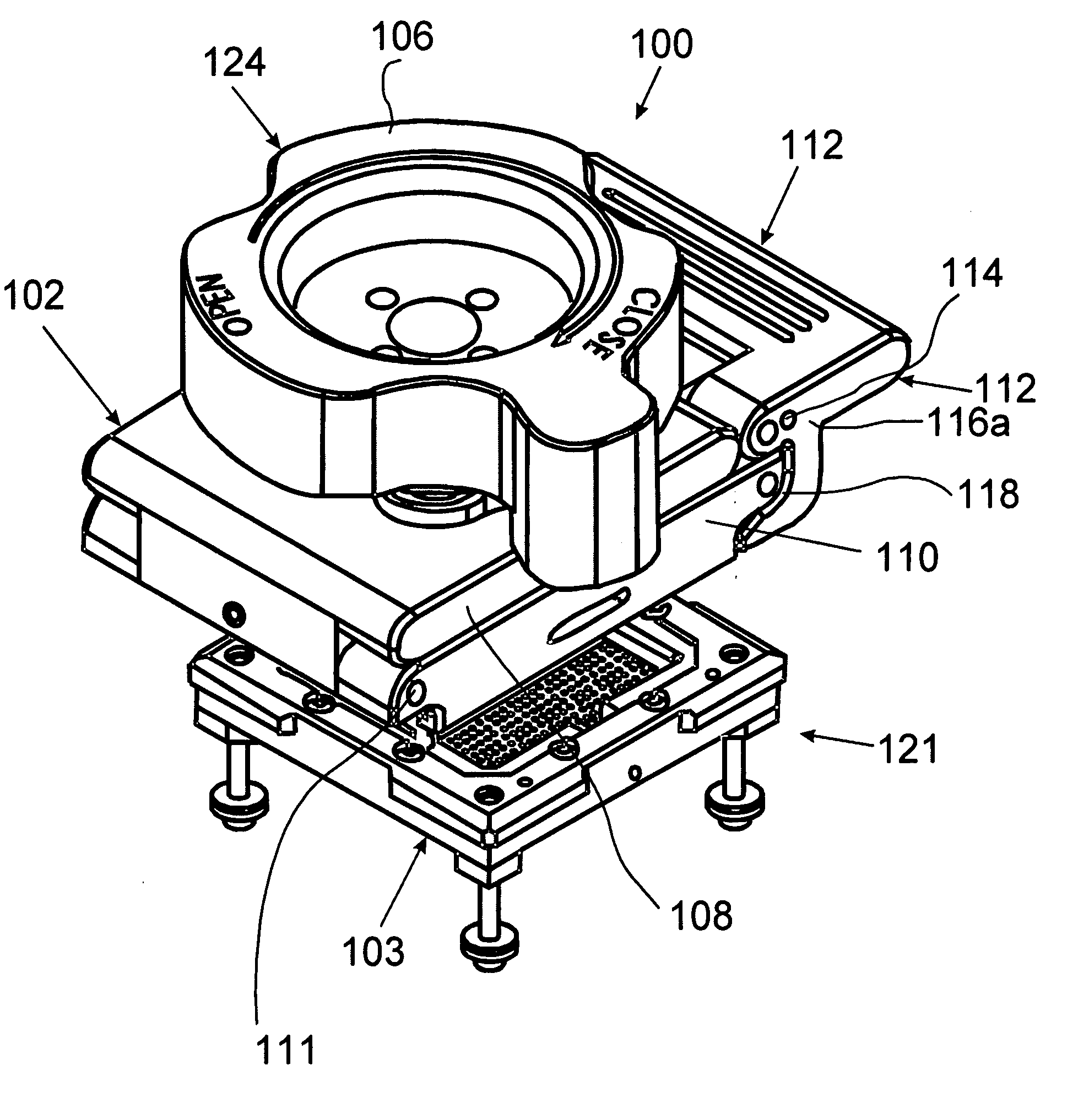

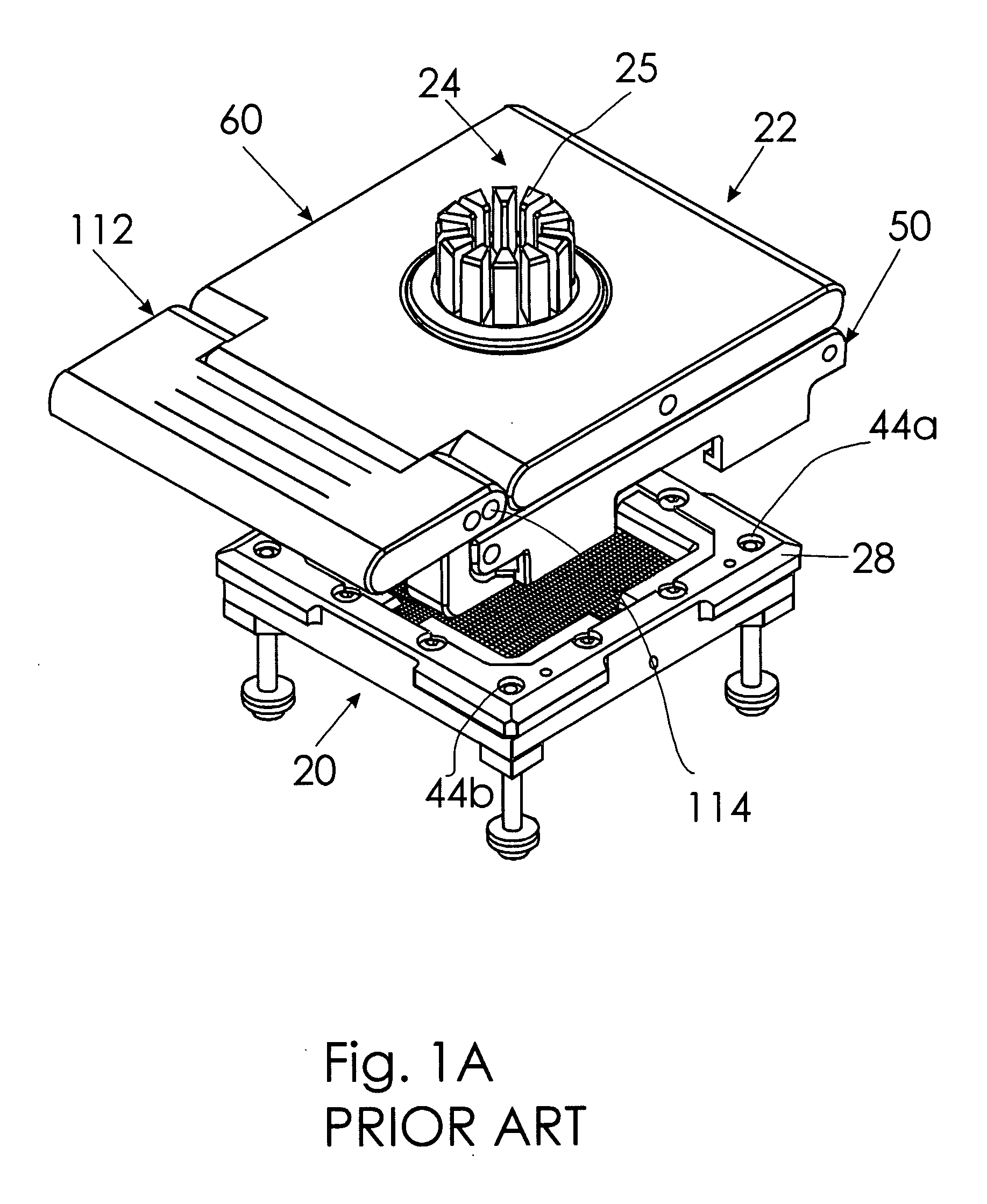

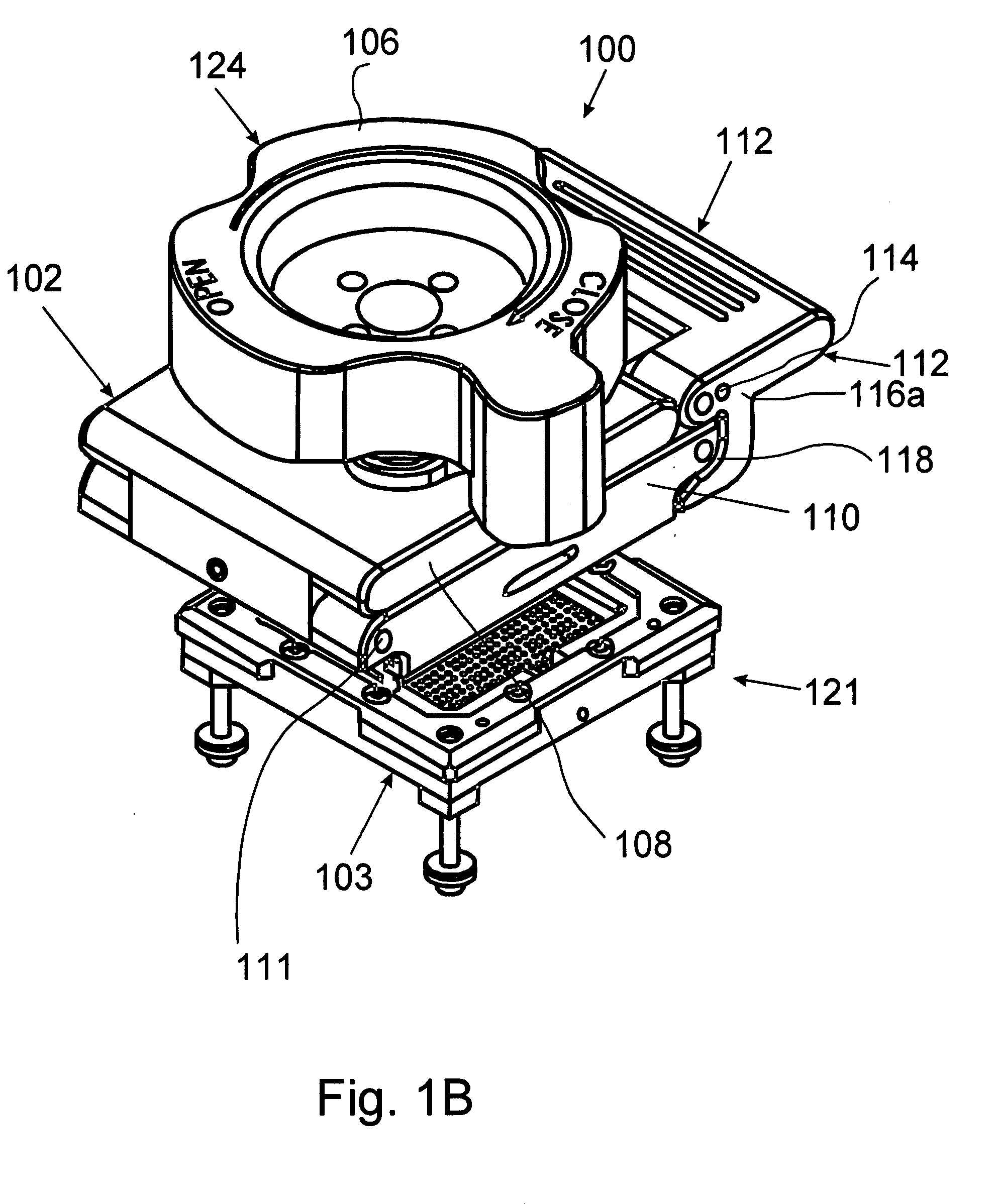

Object-clamping lid subassembly of a test socket for testing electrical characteristics of an object

InactiveUS20080265918A1Easy constructionEasy to assembleElectrical measurement instrument detailsElectrical testingEngineeringTest object

The test-socket lid subassembly of the invention consists of a lid for locking the object in the socket unit and a pusher with a handle for clamping the object in the locked position. The pusher is separated from the lid and is inserted into the lid for pressing on the object to fix the latter in the socket only after the lid is locked in place. The pusher is made in the form of a threaded ring, which has an outer thread for engagement with the inner thread in the central opening of the lid member for movement in the direction perpendicular to the contact surface of the object. This provides uniform distribution of pressure on the test object that is locked in the socket subassembly.

Owner:PROTOS ELECTRONICS

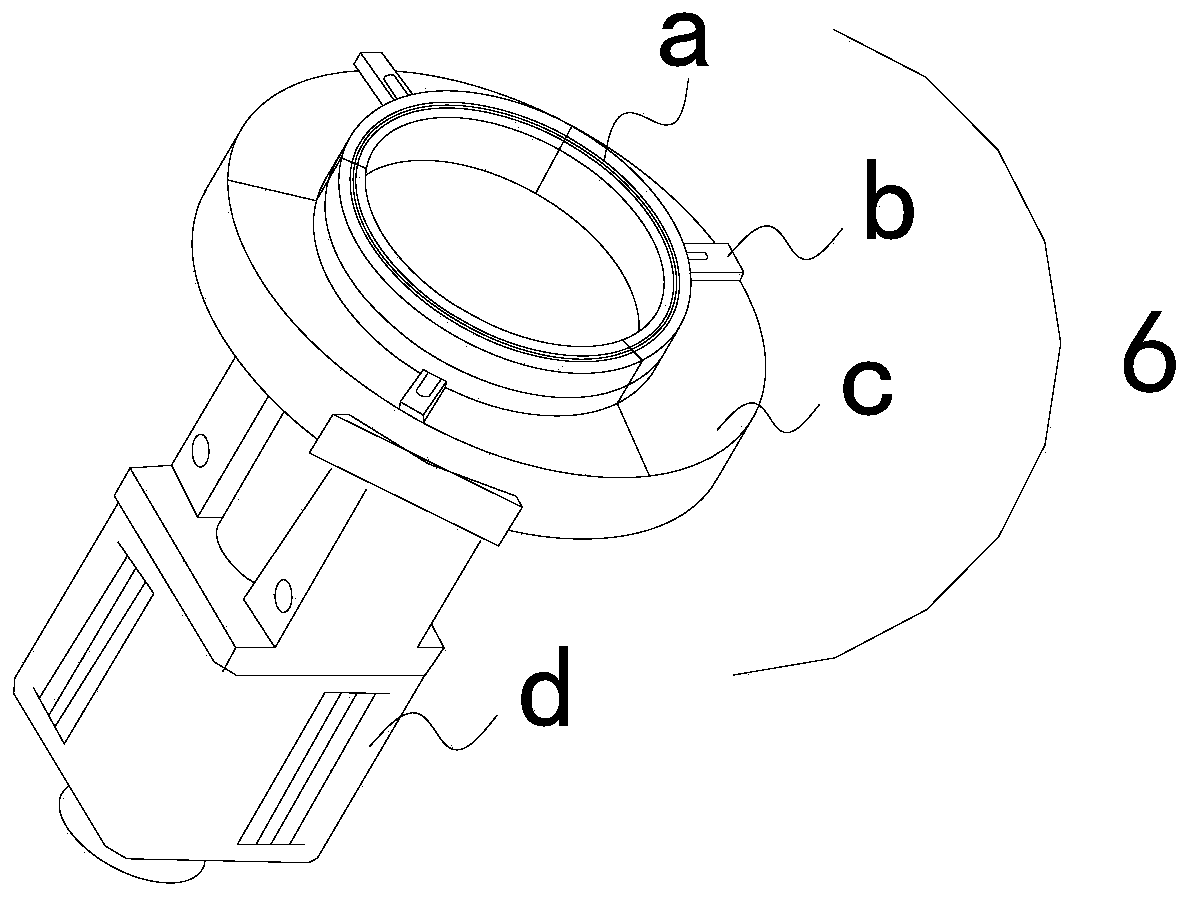

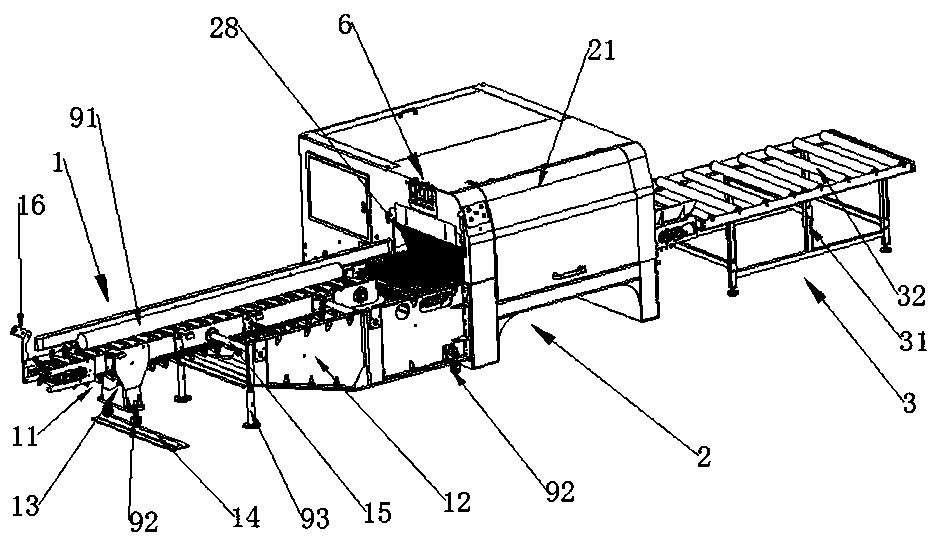

Intelligent log cutting and sawing machine

PendingCN110340986AHigh yieldReduce sorting processFeeding devicesCircular sawsElectric machinerySprocket

The invention relates to an intelligent log cutting and sawing machine comprising a feeding and sorting device, a cutting machine and a discharging device; the feeding and sorting device comprises a feeding conveyor chain, a base arranged below the rear part of the feeding conveyor chain, and a feeding motor and a pitch adjustment mechanism which are fixed to the base; an output shaft of the feeding motor is in transmission connection with a driving sprocket of the feeding conveyor chain; after a plurality of support rods penetrate through brackets on the both sides of the feeding conveyor chain, the two ends of each support rod are fixed to the base separately; the cutting machine comprises a machine tool, and a controller, a feeding device and a cutting mechanism which are fixed to the machine tool; the base is fixed to the machine tool; the cutting mechanism comprises a plurality of saw blade groups in different diameters and used for cutting logs; the pitch adjustment mechanism isdriven by the controller to operate for adjusting the position of the feeding conveyor chain on the base, so that a channel sawed by the cutting machine is selected according to the diameter data of the logs; the outturn rate of the logs is maximized, and the sorting and stacking procedures for different log diameters are reduced; and the production efficiency and social efficiency are improved greatly.

Owner:FUJIAN DELI ELECTRICAL & MECHANICAL CO LTD

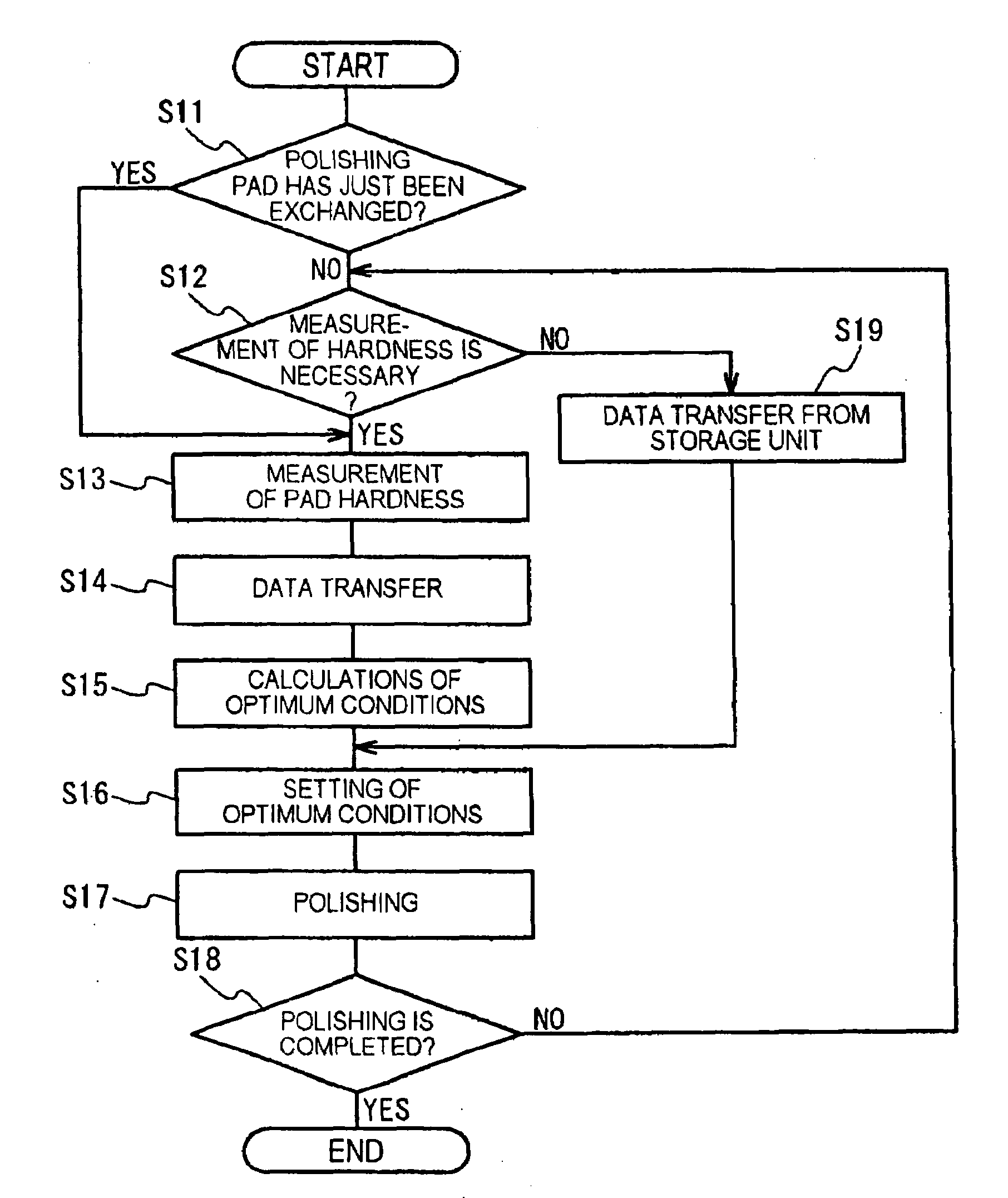

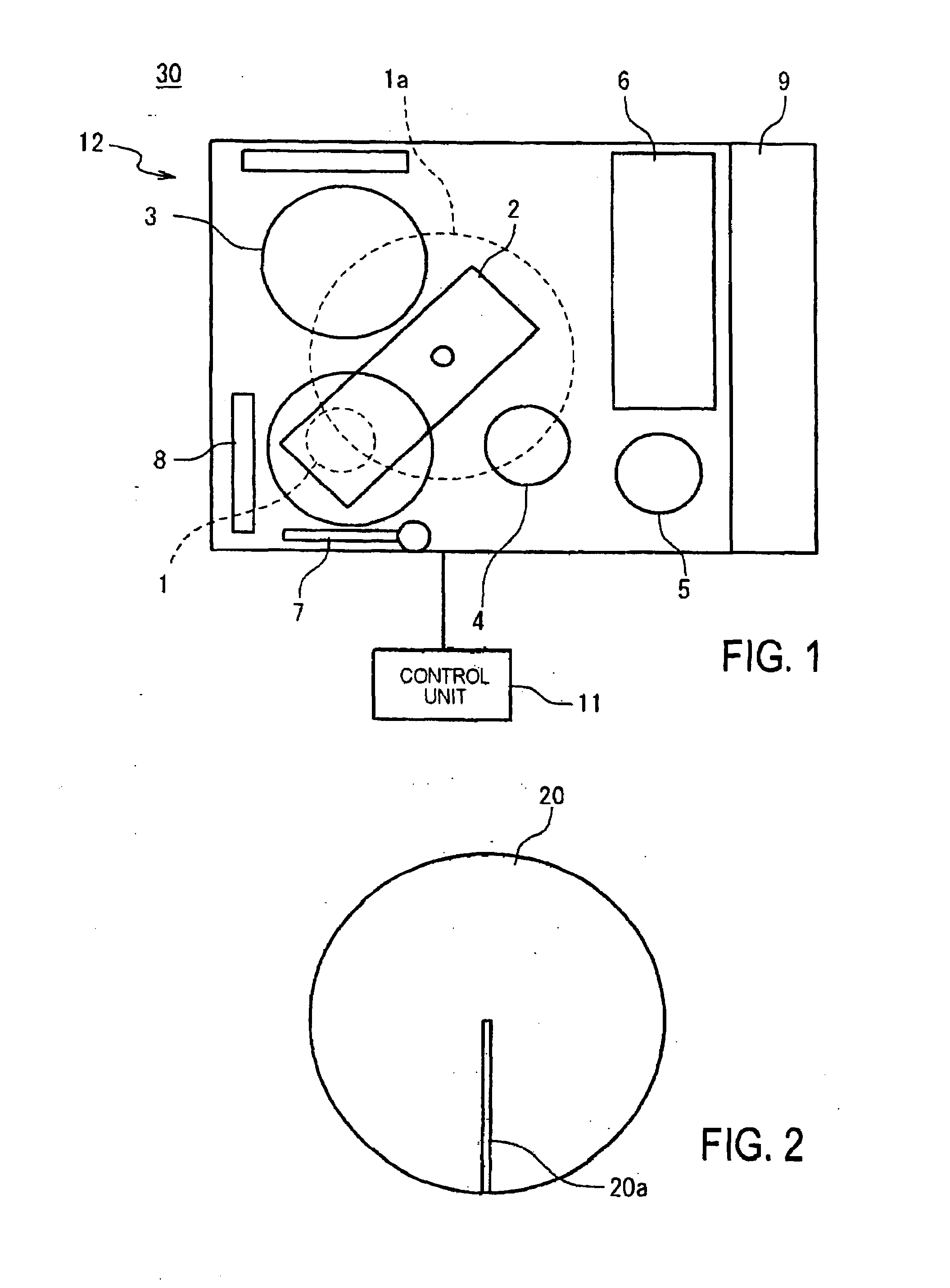

Method of and apparatus for semiconductor device

InactiveUS20070281485A1Uniform polishing of surfacePolished evenlySemiconductor/solid-state device manufacturingLapping machinesHardnessEngineering

A semiconductor device fabrication method by which a semiconductor wafer is polished by pressing the semiconductor wafer against a polishing pad includes: an optimum condition calculation step for finding polishing conditions based on the hardness of the polishing pad; and a step of polishing the semiconductor wafer according to the polishing conditions that have been found.

Owner:ELPIDA MEMORY INC

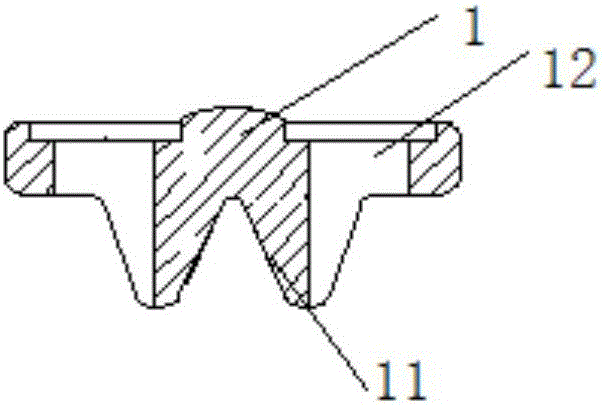

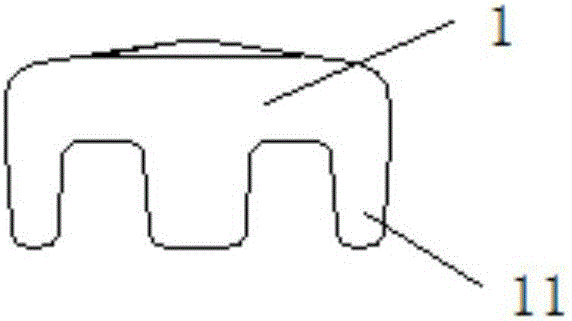

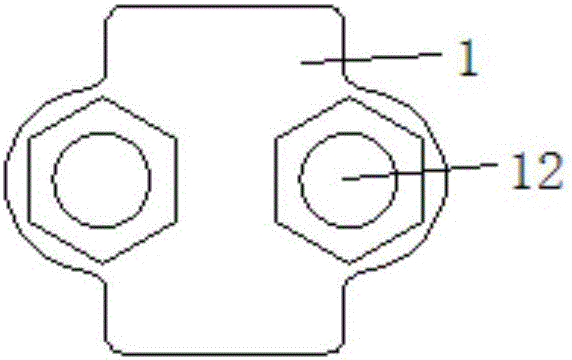

Apparatus for forming pipe material

InactiveCN101247903AUniform forming pressurePrecision MachinabilityShaping toolsForging/hammering/pressing machinesEngineeringMechanical engineering

The invention provides a molding device that a plurality of split dies can be equally clamped with a single drive source. In subjecting a tube material to drawing and caulking, a tube material is first externally inserted into a cored bar (30). In this case, upper and lower split dies (11, 12) constituting an external die (1) are in a mold opened state. From this state, an upper split die (11) constituting an external die (1) is moved downwardly. This allows four split dies (21, 22, 23, 24) constituting an inner die (2) to evenly move toward the center, and an exhaust pipe is subjected to drawing and caulking simultaneously by molding faces (26, 27) formed on the inner face of the four split dies.

Owner:HONDA MOTOR CO LTD

Forming method of carbon fiber pipe type piece

The invention discloses a forming method of a carbon fiber pipe type piece. The forming of the carbon fiber pipe type piece comprises the following steps that S1, a heat-shrinkable plastic pipe layeris pre-treated, the inner surface and the outer surface of the heat-shrinkable plastic pipe layer are coated with a second isolation layer, and the surface of a mold is coated with a first isolation layer; S2, the carbon fiber material is immersed in a solution in advance, and then paving of the pre-immersed material is carried out; and S3, the pre-sucking process is carried out, under the condition of certain temperature and pressure, a certain amount of resin is sucked from carbon fiber material layer laminated blocks, so that the resin content of the carbon fiber material layer is controlled. According to the forming method, the heat-shrinkable plastic pipe layer is automatically shrunk under the high-temperature condition, meanwhile, the resin of the carbon fiber material layer is softened under the condition of high temperature, the carbon fiber material layer can be uniformly pressed by the shrinkage of the heat-shrinkable plastic pipe layer, so that the resin is flat, the effectof enabling the surface of the workpiece to be smooth is achieved, and the method is suitable for being widely popularized and used.

Owner:滁州市润琦碳纤维制品有限公司

Rotary Valve Seal Pressure and Indicator System

InactiveUS20170002955A1Adjustable pressureEasy to adjustSpindle sealingsEngine sealsParticulatesRotary valve

A rotary valve is configured to control flow of particulate matter from a storage source into a conduit under pneumatic pressure. The valve comprises a cylindrical housing, opposing end plates partially enclosing said cylindrical housing, and a vaned rotor having opposing shafts protruding through annular seals provided in said end plates. At least one spring-loaded cartridge is adapted to exert a pre-determined pressure against said annular seals.

Owner:PRATER INDS

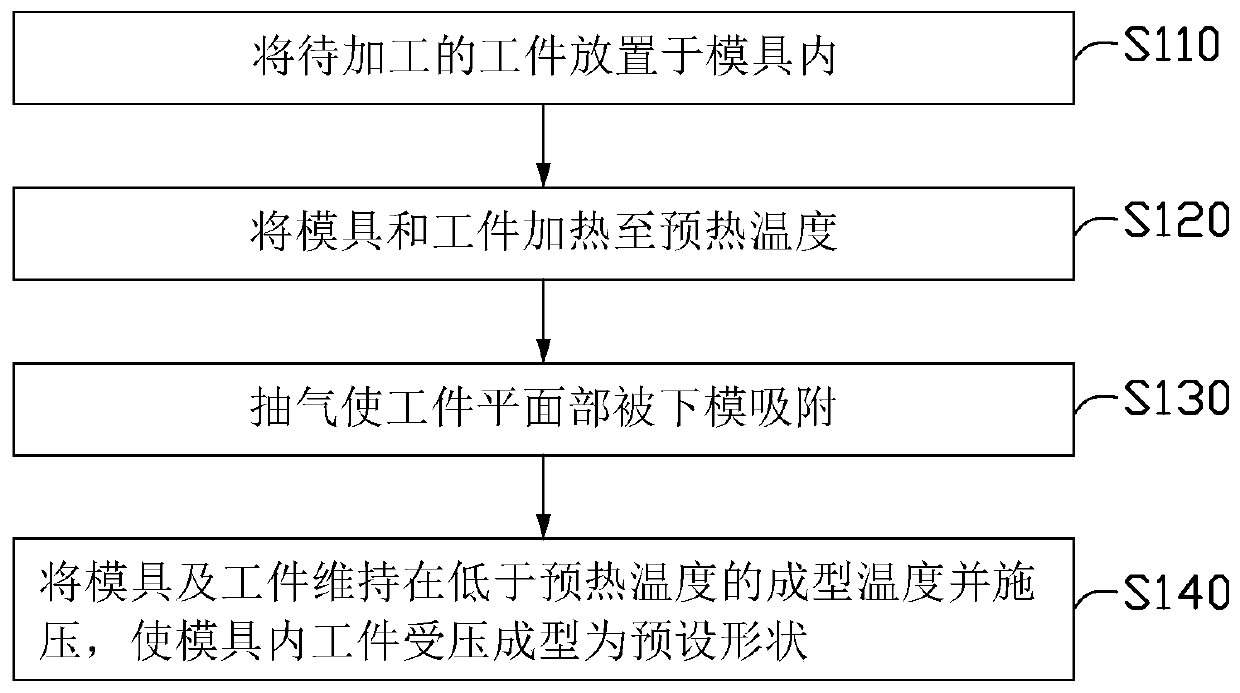

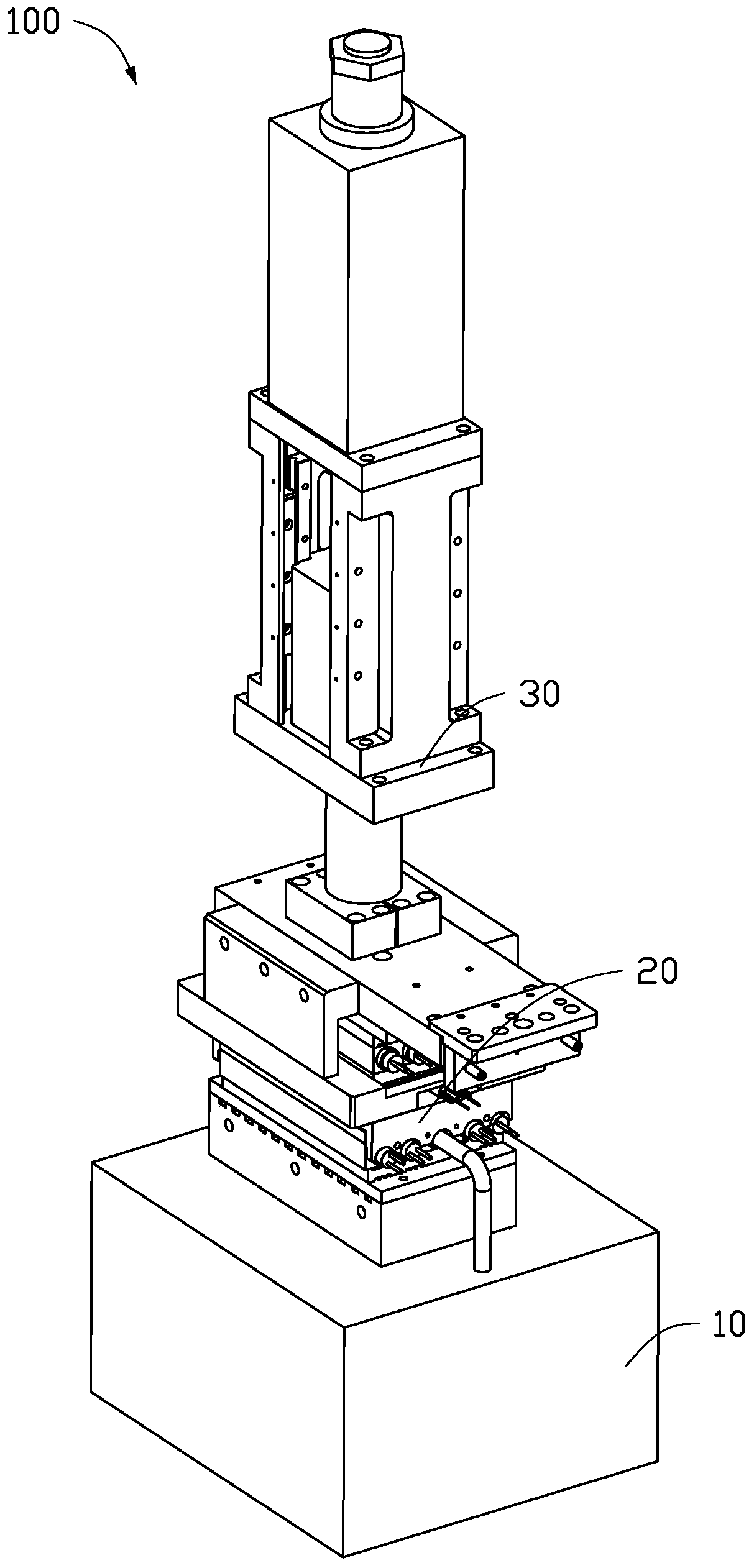

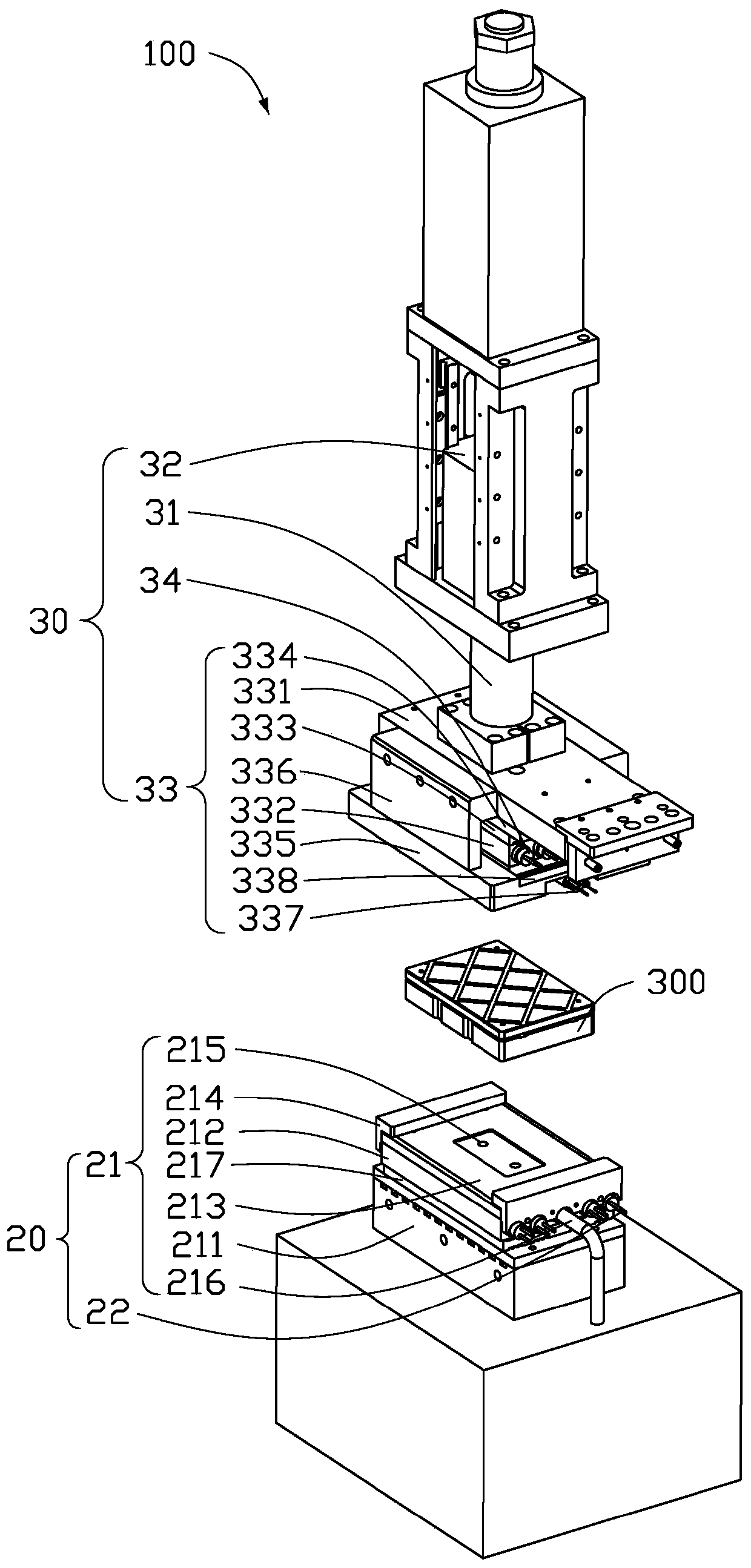

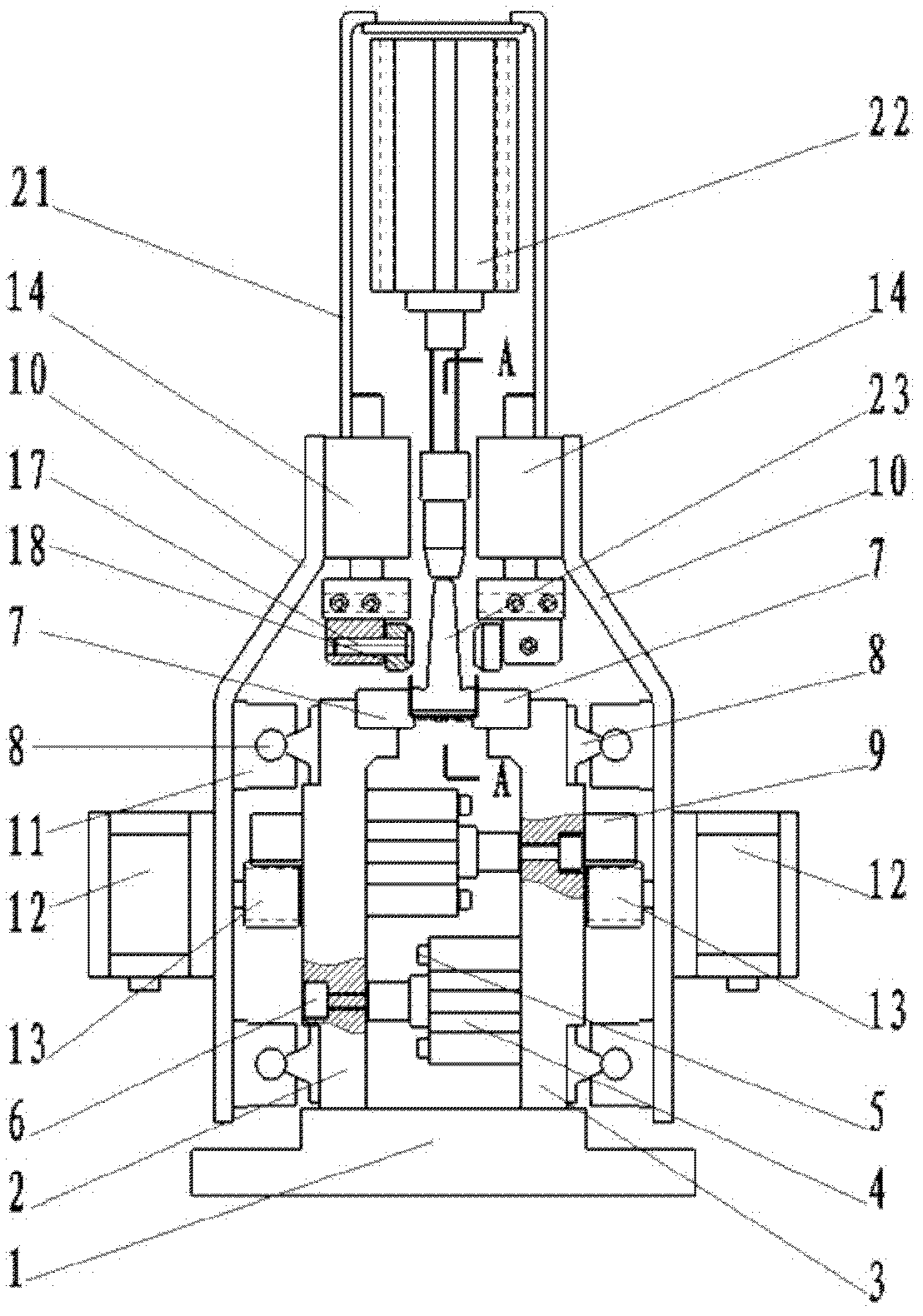

Hot press molding method

InactiveCN111099813AApply pressure evenlyAvoid uneven forceGlass reforming apparatusMachining processMechanical engineering

A hot press molding method comprises the following steps: a workpiece to be machined is placed on a lower die of a mold, the workpiece comprises a workpiece plane part and a workpiece to-be-bent part,and the workpiece plane part makes direct contact with the surface of the lower die; the mold and the workpiece are heated to a preheating temperature; air is exhausted to enable the workpiece planepart to be adsorbed by the lower die; and the mold and the workpiece are kept at a forming temperature lower than the preheating temperature, pressure is applied, and the workpiece in the mold is pressed to be formed into a preset shape. According to the method provided by the invention, heat absorption and hot pressing in sequence can be realized, the workpiece plane part is adsorbed by the lowerdie, it is guaranteed that the large-area workpiece does not deform, the effect that the workpiece to-be-bent part is mainly stressed and bent can be achieved only by applying small pressure to the upper die, and various problems such as press-fit die marks, dark lines, pocking marks and X-shaped lines which are prone to occurring in a traditional machining process can be greatly reduced. Meanwhile, a heating mode and a forming process are improved, so that the energy consumption of equipment can be effectively reduced while the processing efficiency is greatly improved.

Owner:FUTAIHUA PRECISION ELECTRONICS ZHENGZHOU

Flat-clothing machine tool

The invention discloses a flat clothing machine tool. The flat clothing machine tool comprises a side clamping device, a jacking device, a cladding and pressing sliding platform device and a cladding and pressing movement device; a base plate is fixedly provided with a fixed supporting beam; a movable supporting beam is parallel to the fixed supporting beam and can move relative to the fixed supporting beam; and a jaw is formed above two beams respectively and is used for clamping a workpiece. A push-pull air cylinder is arranged between the fixed supporting beam and the movable supporting beam; a plurality of jacking air cylinders are arranged in an upper cavity of a door-shaped frame; a stepping motor is fixedly arranged outside a cladding and pressing sliding platform surface, and a gear is driven by the stepping motor to move on a rack; a double-rod air cylinder is fixedly arranged inside the upper end of the cladding and pressing sliding platform surface; and a molding rolling shaft and a molding roller are connected and arranged through a T-shaped groove and a T-shaped sliding block. The machine tool has the advantages that: side clamping force is uniform; the machine tool has high stability and structural rigidity, can realize accurate positioning and fixed-length cladding and pressing, applies pressure uniformly, has a small number of parts, and few faults, and is highin efficiency, low in cost, and fully-automatic; and the structure is easy to adjust, and actions are accurate.

Owner:无锡立达纺织机械器材有限公司

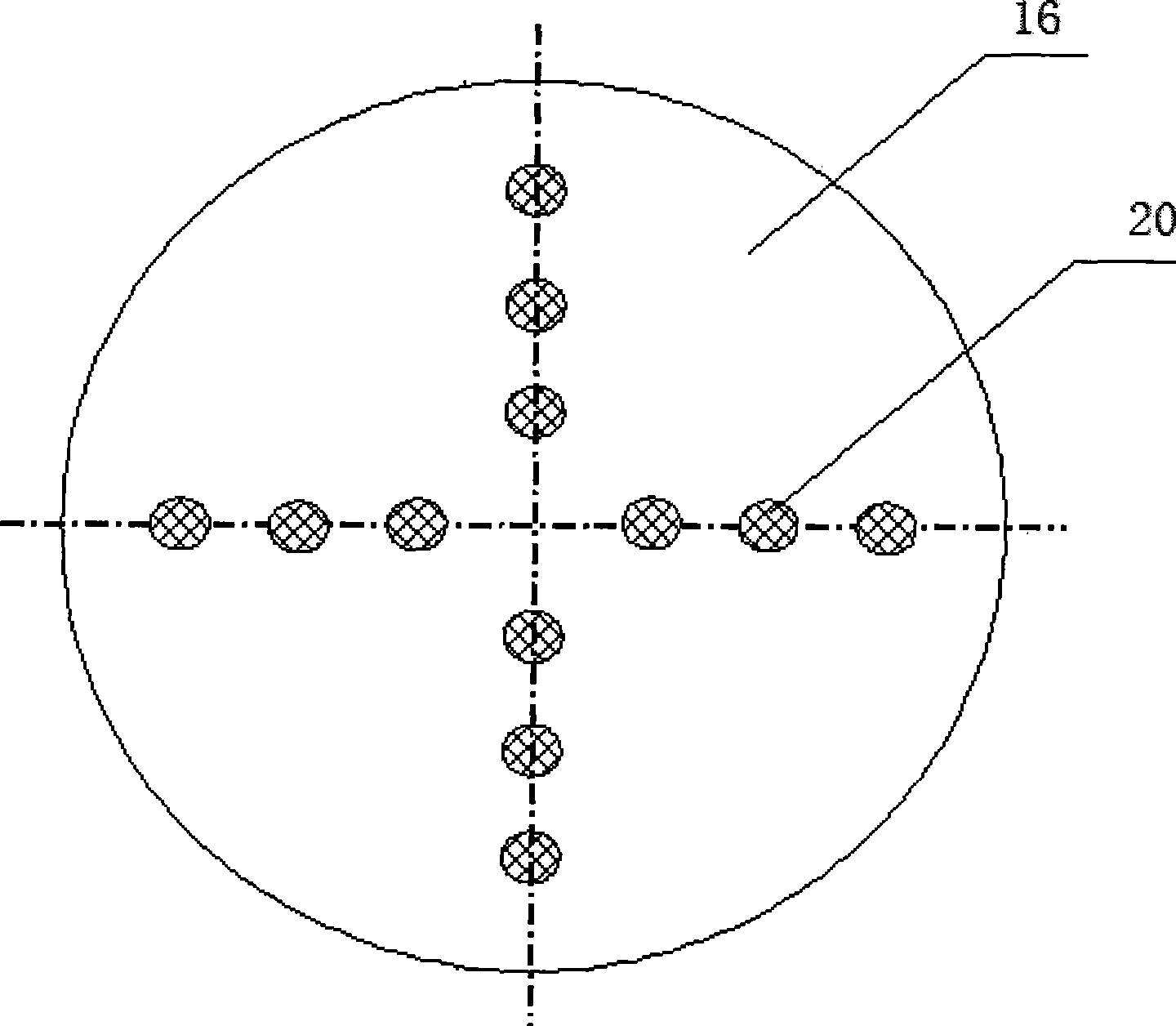

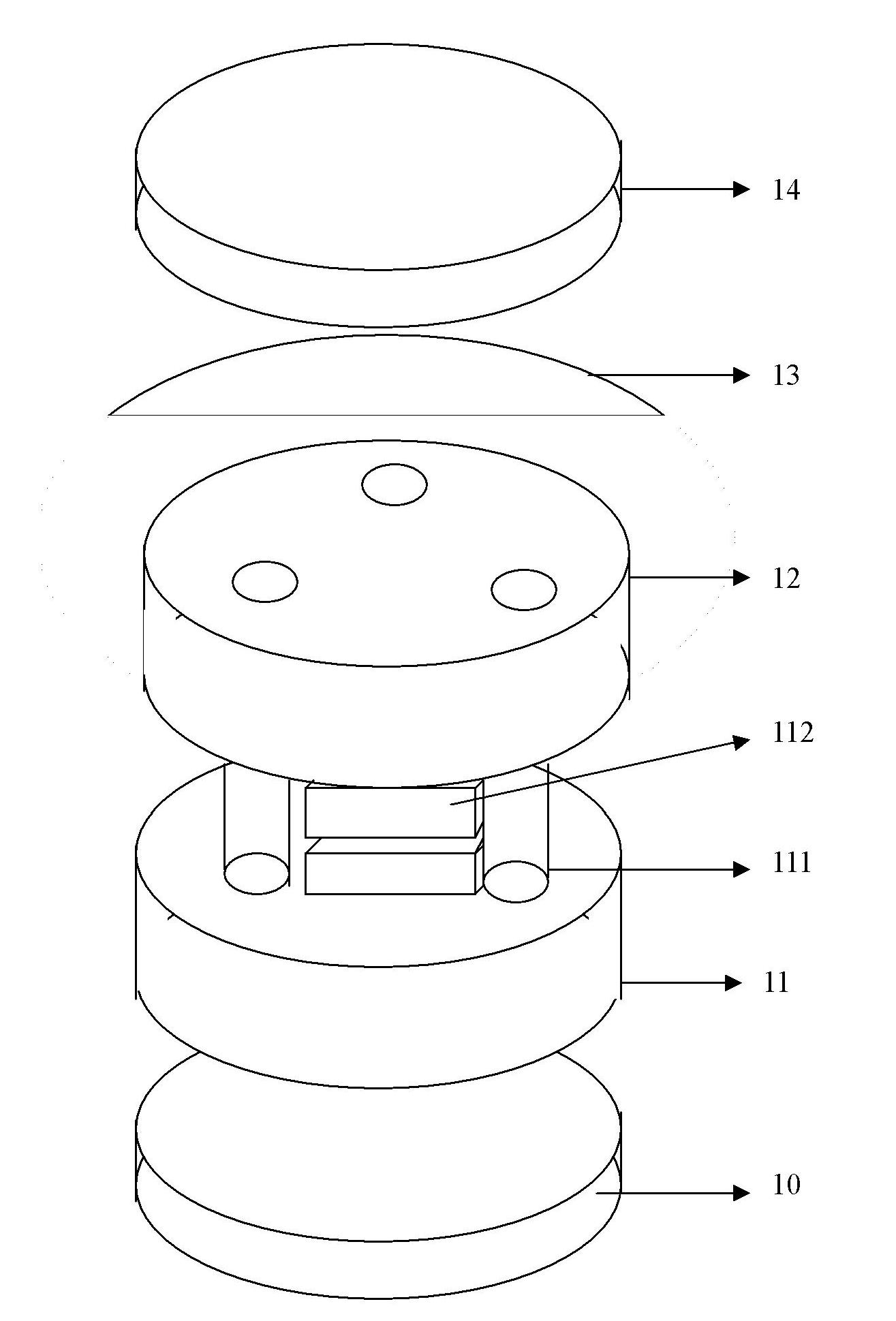

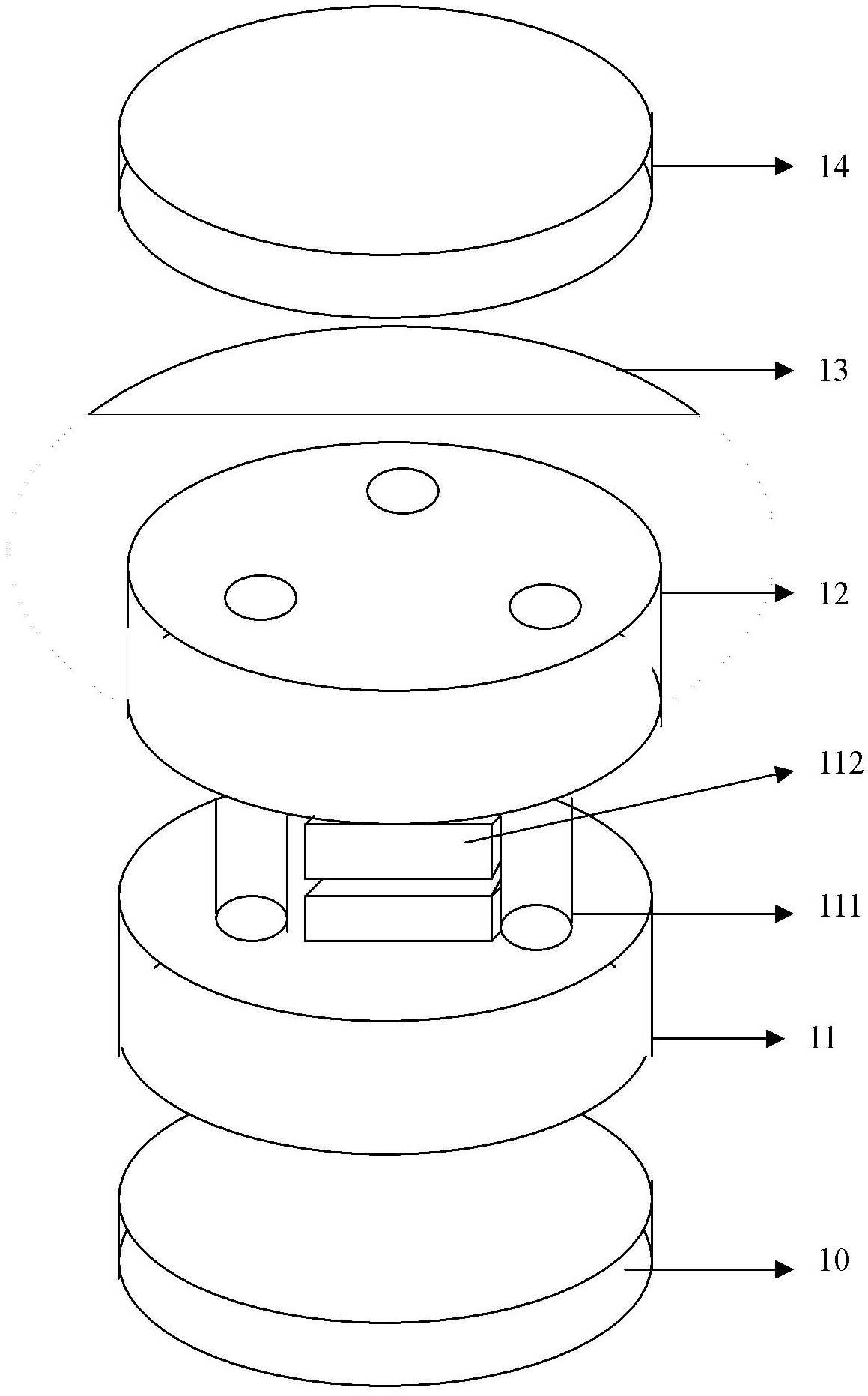

Uniform axial force applying device for graphical heterogeneous bonding of silicon-based III-V epitaxial material

InactiveCN102646620ARealize automatic levelingApply pressure evenlySemiconductor/solid-state device manufacturingAxial pressureEngineering

The invention discloses a uniform axial force applying device for graphical heterogeneous bonding of a silicon-based III-V epitaxial material. The uniform axial force applying device comprises a lower force applying cover plate, a lower bearing support, an upper force applying support, a planoconvex lens and an upper force applying cover plate, wherein the lower force applying cover plate is wafer-shaped; the lower bearing support is wafer-shaped and is positioned on the lower force applying cover plate, and a plurality of round holes are uniformly distributed on the upper surface of the lower bearing support; the upper force applying support is wafer-shaped and is positioned on the lower force bearing support, and a plurality of round holes are uniformly distributed on the upper surface of the upper force applying support; and the lower bearing support and the upper force applying support are connected by a plurality of directional cylinders in an inserting manner; two protective accompanying pieces are also arranged between the lower bearing support and the upper force applying support and are superimposed from top to bottom; the planoconvex lens is positioned on the upper force applying support; and the upper force applying cover plate is wafer-shaped, and is positioned on the planoconvex lens. The uniform axial force applying device has the characteristics that the whole axial pressure applying method does not adopt a direct pressurizing mode, but a leveling part, the force bearing parts and the protective parts are added, so that the uniform pressure applying is realized; and a target chip can bear larger pressure without fragmentation, so that the firmer bonding is realized.

Owner:INST OF SEMICONDUCTORS - CHINESE ACAD OF SCI

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com